Abstract

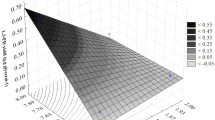

A technological scheme for producing 1,3-propanediol from raw glycerol was designed, simulated, and economically assessed. The production process was composed of three main stages, namely: glycerol purification, glycerol fermentation, and 1,3-propanediol recovery and purification. First, a typical stream of raw glycerol was purified up to 98 wt %, and then the fermentation took place in a two continuous stages process by means of a Klebsiella pneumoniae strain. For the fermentation stage, a rigorous analysis was carried out using a kinetic model considering both substrate and products inhibition. Thus, multiplicity of steady states and hysteresis loops were studied for the first fermentation stage. Also, in order to optimize both the outlet concentration of 1,3-propanediol and its productivity, three different objective functions were analyzed. As result, each objective function led to an optimal condition, such as: the highest global yield to 1,3-propanediol (0.599 mol/mol), the highest outlet concentration of 1,3-propanediol (0.512 mol/L), and the highest global productivity (1.157 × 10−2), respectively. Then, the downstream process for 1,3-propanediol recovery and purification was designed based on a reactive-extraction process and a reactive-distillation process. This downstream process was applied to each scenario analyzed on the fermentation stage. Finally, the three scenarios were economically assessed and the lowest production cost was obtained for the third scenario. Simulation process and fermentation analysis were performed using Aspen Plus and MatLab respectively, while the economic assessment was carried out using the Aspen Icarus Process Evaluator.

Similar content being viewed by others

References

Posada, J.A., Orrego, C.E., and Cardona, C.A., Biodiesel production: biotechnological approach, Int. Rev. Chem. Eng., 2009, vol. 1, p. 571.

Zheng, Y., Chen, X., and Shen, Y., Commodity chemicals derived from glycerol, an important biorefinery feedstock, Chem. Rev., 2008, vol. 108, p. 5253.

Silva, G.P., Mack, M., and Contiero, J., Glycerol: a promising and abundant carbon source for industrial microbiology, Biotechnol. Adv., 2009, vol. 27, p. 30.

Pagliaro, M. and Rossi, M., The future of Glycerol: New Usages for a Versatile Raw Material, Cambridge: RSC, 2008.

Morita, T., Konishi, M., Fukuoka, T., Imura, T., and Kitamoto, D., Microbial conversion of glycerol into glycolipid biosurfactants, mannosylerythritol lipids, by a basidiomycete yeast, Pseudozyma Antarctica JCM 10317T, J. Biosci. Bioeng., 2007, vol. 104, p. 78.

Posada, J.A., Cardona, C.A., Cetina, D.M., and Orrego, C.E., Bioglycerol as Raw Material to Obtain Added Value Products, Researching Advances for Biofuels Production, Cardona, C.A., Ed., Manizales: Universidad Nacional de Colombia, 2009, p. 103.

Posada, J.A. and Cardona, C.A., Design and analysis of fuel ethanol production from raw glycerol, Energy, 2010, vol. 35, p. 5286.

Posada, J.A., Naranjo, J.M., López, J.A., Higuita, J.C., and Cardona, C.A., Design and analysis of poly-3-hydroxybytyrate production processes from crude glycerol, Process Biochem., 2000, vol. 46, p. 310.

Saxena, R.K., Anand, P., Saran, S., and Isar, J., Microbial production of 1,3-propanediol: recent developments and emerging opportunities, Biotechnol. Adv., 2009, vol. 27, p. 895.

Ma, C., Zhang, L., Dai, J., and Xiu, Z., Relaxing the coenzyme specificity of 1,3 propanediol oxidoreductase from Klebsiella pneumonia by rational design, J. Biotechnol., 2010, vol. 146, p. 173.

Menzel, K., Zeng, A.P., and Deckwer, W.D., Enzymatic evidence for an involvement of pyruvate dehydrogenase in the anaerobic glycerol metabolism of Klebsiella pneumonia, J. Biotechnol., 1997, vol. 56, p. 135.

Barbirato, F., Himmi, E.H., Conte, T., and Bories, A., 1,3-Propanediol production by fermentation: an interesting way to valorize glycerin from the ester and ethanol industries, Ind. Crops Prod., 1998, vol. 7, p. 281.

Zheng, P., Sun, J., van den Heuvel, J., and Zeng A.P., Discovery and investigation of a new, second triose phosphate isomerase in Klebsiella pneumonia, J. Biotechnol., 2006, vol. 125, p. 462.

Deckwer, W.D., Microbial conversion of glycerol to 1,3-propanediol, FEMS Microbiol. Rev., 1995, vol. 16, p. 143.

Menzel, K., Zeng, A.P., Biebl, H., and Deckwer, W.D., Kinetic, dynamic and pathway studies of glycerol metabolism by Klebsiella pneumonia in anaerobic continuous culture. Part I: The phenomena and characterization of oscillation and hysteresis, Biotechnol. Bioeng., 1996, vol. 52, p. 549.

Zeng, A.P., Menzel, K., and Deckwer, W.D., Kinetic, dynamic and pathway studies of glycerol metabolism by Klebsiella pneumonia in anaerobic continuous culture. Part II: Analysis of metabolic rates and pathways under oscillation and steady-state conditions, Biotechnol. Bioeng., 1996, vol. 52, p. 561.

Posada, J.A. and Cardona, C.A., Validation of glycerin refining obtained as a by-product of biodiesel production, Ing. Univ., 2010, vol. 14, p. 2.

Dasari, M.A., Kiatsimkul, P.P., Sutterlin, W.R., and Suppes, G.J., Low-pressure hydrogenolysis of glycerol to propylene glycol, Appl. Catal., A., 2005, vol. 281, p. 225.

Barbirato, F., Soucaille, P., and Bories, A., Physiologic mechanisms involved in accumulation of 3-hydroxy-propionaldehyde during fermentation of glycerol by Enterobacter agglomerans, Appl. Environ. Microbiol., 1996, vol. 62, p. 4405.

Papanikolaou, S., Ruiz-Sanchez, P., Pariset, B., Blanchard, F., and Fick, M., High production of 1,3-propanediol from industrial glycerol by a newly isolated Clostridium butyricum strain, J. Biotechnol., 2000, vol. 77, p. 191.

Gonzalez-Pajuelo, M., Meynial-Salles, I., Mendes, F., Andrade, J.C., Vasconcelos, I., and Soucaille, P., Metabolic engineering of Clostridium acetobutylicum for the industrial production of 1,3-propanediol from glycerol, Metab. Eng., 2005, vol. 7, p. 329.

Ito, T., Nakashimada, Y., Senba, K., Matsui, T., and Nishio, N., Hydrogen and ethanol production from glycerol-containing wastes discharged after biodiesel manufacturing process, J. Biosci. Bioeng., 2005, vol. 100, p. 260.

Zhao, Y.N., Chen, G., and Yao, S.J., Microbial production of 1,3-propanediol from glycerol by encapsulated Klebsiella pneumonia, Biochem. Eng. J., 2006, vol. 32, p. 93.

Cardona, C.A. and Sanchez, O.J., Energy consumption analysis of integrated flowsheets for production of fuel ethanol from lignocellulosic biomass, Energy, 2006, vol. 31, p. 2447.

Quintero, J.A., Montoya, M.I., Sanchez, O.J., Giraldo, O.H., and Cardona, C.A., Fuel ethanol production from sugarcane and corn: comparative analysis for a Colombian case, Energy, 2008, vol. 33, p. 385.

Cardona, C.A., Quintero, J.A., and Paz, I.C., Production of bioethanol from sugarcane bagasse: status and perspectives, Bioresour. Technol., 2009, vol. 101, p. 4754.

Gutierrez, L.F., Sanchez, O.J., and Cardona, C.A., Process integration possibilities for biodiesel production from palm oil using ethanol obtained from lignocellulosic residues of oil palm industry, Bioresour. Technol., 2009, vol. 100, p. 1227.

Menzel, K., Zeng, A.-P., and Deckwer, W.-D., High concentration and productivity of 1,3-propanediol from continuous fermentation of glycerol by Klebsiella pneumoniae, Enzyme Microb. Technol., 1997, vol. 20, p. 82.

Xiu, Z.L., Song, B.H., Sun, L.H., and Zeng, P., Theoretical analysis of effects of metabolic overflow and time delay on the performance and dynamic behavior of a two-stage fermentation process, Biochem. Eng. J., 2002, vol. 11, p. 101.

Xiu, Z.L., Song, B.H., Wang, Z.T., Sun, L.H., Feng, E.M., and Zeng, A.P., Optimization of dissimilation of glycerol to 1,3-propanediol by Klebsiella pneumoniae in one- and two-stage anaerobic cultures, Biochem. Eng. J., 2004, vol. 19, p. 189.

Edgar, T.F., Himmelblau, D.M., and Lasdon, L.S., Optimization of Chemical Processes, New York: McGraw-Hill, 2001, 2nd ed.

Raval, K.N., Hellwig, S., Prakash, G., Ramos-Plasencia, A., Srivastava, A., and Biichs, J., Necessity of a two-stage process for the production of azadirachtin-related limonoids in suspension cultures of Azadirachta indica, J. Biosci. Bioeng., 2003, vol. 96, p. 16.

Adkesson et al., US Patent 200510069997 A1, 2005.

Corbin, D.R. and Norton, T., US Patent 603 048, 2003.

Cardona, C.A., Posada, J.A., and Montoya, M.I., Use of glycerol from biodiesel production: conversion to added value products, Proc. 6th Eur. Congr. on Chemical Engineering, Copenhagen, 2007, p. 35.

Malinowski, J.J., Reactive extraction for downstream separation of 1,3-propanediol, Biotechnol. Prog., 2000, vol. 16, p. 76.

Liu, D., Hao, J., and Liu, H., Novel route of reactive extraction to recover 1,3-propanediol from a dilute aqueous solution, Ind. Eng. Chem. Res., 2005, vol. 44, p. 4380.

Liu, D., Hao, J., Xu, F., and Liu, H., Downstream processing of 1,3-propanediol Fermentation broth, J. Chem. Technol. Biotechnol., 2006, vol. 81, p. 102.

Samant, K. and Ng, K.M., Synthesis of extractive reaction processes, AIChE J., 1998, vol. 44, p. 1363.

Serafimov, L.A., Zharov, V.T., and Timofeyev, V.S., Rectification of multicomponent mixtures. I. Topological analysis of liquid vapor phase equilibrium diagrams, Acta Chim. Acad. Sci. Hung., 1971, vol. 69, no. 4, p. 383.

Pisarenko, Yu.A., Serafimov, L.A., and Cardona, K.A., Optimization of reactive distillation processes, Theor. Found. Chem. Eng., 1999, vol. 33, p. 455.

Serafimov, L.A., Pisarenko, Yu.A., and Kulov, N.N., Coupling chemical reaction with distillation: thermodynamic analysis and practical applications, Chem. Eng. Sci., 1999, vol. 54, p. 1383.

Pisarenko, Yu.A., Serafimov, L.A., Cardona, C.A., Efremov, D.L., and Shuwalov, A.S., Reactive distillation design: analysis of the process statics, Rev. Chem. Eng., 2001, vol. 17, no. 4, p. 253.

Giessler, S., Danilov, R.Y., Pisarenko, R.Y., Serafimov, L.A., Hasebe, S., and Hashimoto, I., Feasible separation modes for various reactive distillation systems, Ind. Eng. Chem. Res., 1999, vol. 38, p. 4060.

Posada, J.A., Cardona, C.A., and Rincó, L.E., Sustainable biodiesel production from palm using in situ produced glycerol and biomass for raw bioethanol, Proc. 32nd Symp. on Biotechnology for Fuels and Chemicals, Clearwater Beach, Fla., 2010, p. 172.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Posada, J.A., Cardona, C.A., Higuita, J.C. et al. Design and economic analysis of the technological scheme for 1,3-propanediol production from raw glycerol. Theor Found Chem Eng 47, 239–253 (2013). https://doi.org/10.1134/S0040579513030093

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579513030093