Abstract

In this article, I analyze how emerging-market firms upgrade their capabilities. Complementing the upgrading-through-technological capabilities view, I propose a power-repositioning argument, whereby local firms improve their power position through taking more control of the chain as part of the upgrading process. In particular, I argue that international expansion toward downstream activities enhances the power position of emerging-market supplier firms in globally integrated buyer-driven industries. This process enables local firms to break away from low-value-added positions within the value chain and exert more power within the governance structure of global value chains.

Similar content being viewed by others

Notes

Songkhla is a province in Southern Thailand well known for seafood supplies. TU’s first factory was located in Samut Sakorn, a province in Eastern Thailand with access to the Gulf of Thailand, another major location for seafood supplies.

Details on the early development of the TU group are based on the group’s 56-1 report in 1999, the company’s Website, and interview with the founder, Kraisorn Chansiri (SME Plus, 2012).

The company used the name TUF to refer to the group until 2015, when it rebranded the group’s name to Thai Union (TU).

References

Bair, J. (2005) Global capitalism and commodity chains: Looking back, going forward. Competition and Change 9(2): 153–180.

Bair, J. (2008) Analysing global economic organization: Embedded networks and global chains compared. Economy and Society 37(3): 339–364.

Bazan, L. and Navas-Alemán, L. (2004) The underground revolution in the Sinos Valley: A comparison of upgrading in global and national value chains. In: H. Schmitz (ed.) Local Enterprises in the Global Economy: Issues of Governance and Upgrading. Cheltenham: Edward Elgar, pp. 110–139.

Boston Consulting Group (2006) How 100 top Companies from Rapidly Developing Economies are Changing the World: BCG Global Challengers 2006. Boston, MA: Boston Consulting Group.

Boston Consulting Group (2011) Companies on the Move: Rising stars from Rapidly Developing Economies are Shaping Global Industries: BCG Global Challengers 2011. Boston, MA: Boston Consulting Group.

Boston Consulting Group (2013) Allies and Adversaries: BCG Global Challengers. Boston, MA: Boston Consulting Group.

Boston Consulting Group (2014) Redefining Global Competitive Dynamics: BCG Global Challengers 2014. Boston, MA: Boston Consulting Group.

Dyer, W.G. and Wilkins, A.L. (1991) Better stories, not better constructs, to generate better theory: A rejoinder to Eisenhardt. Academy of Management Review 16(3): 613–619.

Eisenhardt, K.M. (1989) Building theories from case study research. Academy of Management Review 14(4): 532–550.

Eisenhardt, K.M. and Graebner, M.E. (2007) Theory building from cases: Opportunities and challenges. Academy of Management Journal 50(1): 25–32.

Flyvbjerg, B. (2006) Five misunderstandings about case-study research. Qualitative Inquiry 12(2): 219–245.

Gentile-Lüdecke, S. and Giroud, A. (2012) Knowledge transfer from TNCs and upgrading of domestic firms: The polish automotive sector. World Development 40(4): 796–807.

Gereffi, G. (1994) The organization of buyer-driven global commodity chains: How US retailers shape overseas production networks. In: G. Gereffi and M. Korzeniewicz (eds.) Commodity Chains and Global Capitalism. London: Praeger, pp. 95–122.

Gereffi, G. (1999) International trade and industrial upgrading in the apparel commidity chain. Journal of International Economics 48(1): 37–70.

Gereffi, G., Humphrey, J., Kaplinsky, R. and Sturgeon, T. (2001) Introduction: Globalisation, value chains and development. IDS Bulletin 32(3): 1–8.

Giroud, A. (2012) Mind the gap: How linkages strengthen understanding of spillovers. European Journal of Development Research 24(1): 20–25.

Giroud, A. and Mirza, H. (2015) Refining of FDI motivations by integrating global value chains’ considerations. Multinational Business Review 23(1): 67–76.

Giuliani, E., Pietrobelli, C. and Rabellotti, R. (2005) Upgrading in global value chains: Lessons from Latin American clusters. World Development 33(4): 549–573.

Greenpeace (2015) Supply chained: Human rights abuses in the global tuna industry, http://www.greenpeace.org/international/Global/seasia/2015/png1/Supply-chained_EN.pdf, accessed 20 December 2015.

Hamilton, A., Lewis, A., McCoy, M.A., Havice, E. and Campling, L. (2011) Market and Industry Dynamics in the Global Tuna Supply Chain. Honiara, Solomon Islands: Pacific Islands Forum Fisheries Agency (FFA).

Humphrey, J. and Schmitz, H. (2002) How does insertion in global value chains affect upgrading in industrial clusters? Regional Studies 36(9): 1017–1027.

Humphrey, J. and Schmitz, H. (2004) Chain governance and upgrading: Taking stock. In: J. Humphrey (ed.) Local Enterprises in the Global Economy: Issues of Governance and Upgrading. Cheltenham, UK: Edward Elgar, pp. 349–381.

Ivarsson, I. and Alvstam, C.G. (2005) Technology transfer from TNCs to local suppliers in developing countries: A study of AB Volvo’s truck and bus plants in Brazil, China, India and Mexico. World Development 33(8): 1325–1344.

Ivarsson, I. and Alvstam, C.G. (2009) Learning from foreign TNCs: A study of technology upgrading by local suppliers to AB Volvo in Asia and Latin America. International Journal of Technology Management 48(1): 56–76.

Ivarsson, I. and Alvstam, C.G. (2011) Upgrading in global value-chains: A case study of technology-learning among IKEA-suppliers in China and Southeast Asia. Journal of Economic Geography 11(4): 731–752.

Jeenanunta, C., Rittippant, N., Chongphaisal, P., Thumsamisorn, A. and Visantvetchakij, T. (2013) Khowledge transfer of outward foreign direct investment by Thai multinational enterprises. Asian Journal of Technology Innovation 21(S1): 64–81.

Kaplinsky, R., Morris, M. and Readman, J. (2002) The globalization of product markets and immiserizing growth: Lessons from the South African furniture industry. World Development 30(7): 1159–1177.

Kuldilok, K.S., Dawson, P.J. and Lingard, J. (2013) The export competitiveness of the tuna industry in Thailand. British Food Journal 115(3): 328–341.

Kumaraswamy, A., Mudambi, R., Saranga, H. and Tripathy, A. (2012) Catch-up strategies in the Indian auto components industry: Domestic firms’ responses to market liberalization. Journal of International Business Studies 43(4): 368–395.

Lall, S. (1993) Promoting technology development: The role of technology transfer and indigenous effort. Third World Quarterly 14(1): 95–108.

Lall, S. (2000) The technological structure and performance of developing-country manufactured exports, 1985–1998. Oxford Development Studies 28(3): 337–369.

Lall, S. (2001) Competitiveness indices and developing countries: An economic evaluation of the global competitiveness report. World Development 29(9): 1501–1525.

Lall, S. (2004) Industrial success and failure in a globalizing world. International Journal of Technology Management and Sustainable Development 3(3): 189–213.

Mair, J., Marti, I. and Ventresca, M.J. (2012) Building inclusive markets in rural Bangladesh: How intermediaries work institutional voids. Academy of Management Journal 55(4): 819–850.

McDermott, G.A. and Corredoira, R.A. (2010) Network composition, collaborative ties and upgrading in emerging-market firms: Lessons from the Argentine autoparts sector. Journal of International Business Studies 41(2): 308–329.

Miyake, M.P., Guillotreau, P., Sun, C.H. and Ishimura, G. (2010) Recent Developments in the Tuna Industry: Stocks, Fisheries, Management, Processing, Trade and Markets. Rome, Italy: Food and Agriculture Organization of the United Nations.

Morrison, A., Pietrobelli, C. and Rabellotti, R. (2008) Global value chains and technological capabilities: A framework to study learning and innovation in developing countries. Oxford Development Studies 36(1): 39–58.

Nation (2014) TUF, Mahidol university to collaborate on research. 10 December, http://www.nationmultimedia.com/business/TUF-Mahidol-University-to-collaborate-on-research-30249471.html, accessed 3 December 2015.

Navas-Alemán, L. (2006) Opportunities and obstacles for industrial upgrading of Brazilian footwear and furniture firms: A comparison of global and national value chains. Unpublished PhD thesis. Brighton, UK: Institute of Development Studies, University of Sussex.

Navas-Alemán, L. (2011) The impact of operating in multiple value chains for upgrading: The case of the Brazilian furniture and footwear industries. World Development 39(8): 1386–1397.

Osterblom, H. et al (2015) Transnational corporations as ‘keystone actors’ in marine ecosystems. PLoS ONE 10(5): e0127533.

Pietrobelli, C. and Rabellotti, R. (2007) Upgrading to Compete: SMEs, Clusters and Value Chains in Latin America. Cambridge, MA: Harvard University Press.

Pietrobelli, C. and Rabellotti, R. (2011) Global value chains meet innovation systems: Are there learning opportunities for developing countries? World Development 39(7): 1261–1269.

Pietrobelli, C. and Saliola, F. (2008) Power relationships along the value chain: Multinational firms, global buyers and performance of local suppliers. Cambridge Journal of Economics 32(6): 947–962.

SME PLus (2012) Cheewit lae turakij khong racha tuna lok ‘Kraisorn Chansiri’ TUF President (Life and business of tuna king ‘Kraisorn Chansiri’, TUF President). Thai (March): 45–57.

Thai Union (2014) Annual Report. Samutsakorn, Thailand: Thai Union.

The Economist (2012) Coming to a plate near you. 27 October, http://www.economist.com/news/business/21565242-led-food-industry-thailand’s-companies-are-quietly-going-global-coming-plate-near, accessed 3 December 2015.

UNCTAD (2013) World Investment Report: Global Value Chains: Investment and Trade for Development. Geneva, Switzerland: UNCTAD.

Yin, R.K. (1994) Case Study Research: Design and Methods, 2nd edn. Thousand Oaks, CA: Sage.

Yin, R.K. (2009) Case Study Research: Design and Methods, 4th edn. Los Angeles, CA: Sage Publications.

Author information

Authors and Affiliations

Corresponding author

Additional information

†The author is also guest editor for this special issue. To avoid a possible conflict of interest, this article was taken through the review process and accepted by Michael A. Witt, Editor-in-Chief of Asian Business & Management.

Appendix

Appendix

A background of Thai Union’s (TU) development and the canned-tuna industry

Upgrading process of TU group

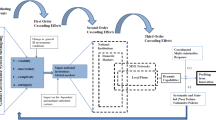

The TU group rose from a small exporter to become the world’s largest producer of shelf-stable tuna products and one of the world’s largest seafood producers in less than 50 years. The group now employs over 35 000 people in global operations spanning four continents, recording a revenue of US$3.8 billion in 2014 and aiming to reach $8 billion in 2020 (see company Website, www.thaiuniongroup.com). TU global manufacturing footprints cover nine different countries: Thailand, Vietnam, India, Papua New Guinea, the United States, France, Portugal, Ghana and the Seychelles. Its chronological development can be divided into four stages: product and process upgrading under contract manufacturing (1977–1994); domestic functional and sectoral upgrading (1994–1997); value-chain upgrading in downstream activities (1997–2010); and global scale and scope via international acquisitions (2010–present).

Product and process upgrading under contract manufacturing (1977–1994) Footnote 2

The group’s beginnings date back to 1977, when Thai Union Manufacturing was established as a small tuna-canning company. The company’s tuna exports formally took off with the establishment of Thai Union Frozen Products (TUF) in 1988 as an OEM producer.Footnote 3 Its initial products were frozen cooked tuna and canned cat food.

The first milestone took place in 1992, when the company formed a strategic partnership with Mitsubishi Corporation and Hagoromo Foods Corporation, two Japanese trading companies with dominant market share in Japan. This relationship proved to be critical in transforming TU into an internationally qualified exporter, as the Japanese companies contributed significantly to its product and process upgrading, especially in the areas of supply-chain management, raw-material sourcing and quality control (Jeenanunta et al, 2013).

The next major step came in 1994, when TU became a publicly listed company on the Stock Exchange of Thailand. Public listing allowed the company to raise capital to further its growth both domestically and internationally. By 1998, the TU group had acquired other domestic tuna canneries to solidify its position as the country’s largest seafood producer and exporter.

Functional and sectoral upgrading in domestic value chain (1994–1997)

TU’s next stage of development was characterized by attempts to move into higher-value-added stages of the value chain, particularly toward the downstream functions of building its own brands in the domestic market. In 1994, the group launched its own brand, Sealect, for canned tuna and other ready-to-eat tuna products (for example, tuna spread). In addition, the group also extended its product line to fish-based snacks and launched another brand, Fisho, for this product line.

Creating its own brands allowed TU to engage in functional upgrading through moving downstream into marketing and sales functions. Despite Sealect’s domestic orientation, having its own brand was a crucial step allowing the group to expand its activities from solely manufacturing into marketing and sales. Similarly, launching different product lines enhanced the group’s inter-sectoral upgrading, as the competence acquired from the canned-tuna industry could be extended to other product lines. This step was key, as TU continues to expand into different product lines in the seafood industry.

Global value chain upgrading in downstream activities (1997–2010)

The decade following the 1997 Asian financial crisis was crucial for TU’s development. The devaluation of the Baht in July 1997 benefited Thailand’s exporters, including TU. The group’s strong financial position enabled rapid international expansion in the years following the 1997 crisis. This period is marked by TU’s international acquisitions of canned-tuna downstream activities, particularly those that could strengthen its portfolio of brands and its marketing and distribution channels. At the same time, international acquisitions were also used to extend the group’s product lines in its major markets, particularly in the United States.

TU’s most important internationalization milestone was the 1997 joint acquisition of Chicken of the Sea – the third-largest canned-tuna brand in the United States. TU later bought out its partners and became sole owner in 2001. The group set up Chicken of the Sea Frozen Foods to extend the product line from canned tuna to frozen seafood under the same brand in 2006. Another leading brand was acquired in 2005 with the purchase of Century Trading, owner of China’s leading canned-tuna brand, Century. It was during this stage that TU began to increase its power in the canned-tuna industry through international acquisitions of downstream activities.

Global scale and scope via international acquisitions (2010–present)

With more experience from its major investment in the United States, TU set its sights on more international acquisitions. These deals signal its entry into another stage of development, in which it seeks to enhance its global scale and scope through backward integration into upstream activities such as fishing-fleet operations and control of more global brands.

Another milestone acquisition was the 2010 acquisition of the European canned-seafood giant, MW Brands, from Trilantic Capital Partners (see Hamilton et al, 2011, p. 163). This takeover significantly strengthened TU’s foothold in Europe, especially France, the United Kingdom, the Netherlands, Ireland and Italy, through acquisitions of four leading brands, namely John West, Petit Navire, Mareblu and Hyacinthe Parmentier. TU also reinforced its position as the world’s leading seafood supplier when the group acquired the French smoked-salmon producer, MerAlliance, and Norway’s leading seafood company, King Oscar, in 2014. The group’s planned acquisition of Bumble Bee Seafood, another large US seafood company, rival to TU’s Chicken of the Sea, was aborted in December 2015 when the deal triggered an antitrust investigation by the US Department of Justice.

Canned-tuna industry

The canned-tuna industry is one of the most globalized, characterized by three important trends: increasing globalization in production and consumption; increasing concentration of the industry; and intensifying power of retailers. Established since the 1860s, when tuna was a low-value substitute for salmon or sardines, the industry has since expanded globally both in production and consumption (Miyake et al, 2010).

While Europe, the United States and Japan remain the largest markets, tuna production facilities have moved from key locations near those markets to developing economies further away. Thailand, Ecuador and Iran are now among the world’s top producers, with Thailand accounting for 40 per cent of the world market (Kuldilok et al, 2013). The global integration of production facilities across many developing economies makes canned tuna one of the world’s most complex and globally integrated industries (Miyake et al, 2010).

The second characteristic of the canned-tuna industry is its concentrated nature. Its value chain can be broadly divided into four stages: fishing, trading, processing, and retail and distribution (see Hamilton et al, 2011). Most stages are now under the control of a few large multinational firms that exert strong influence in the industry. Trading is the most concentrated, with only three companies dominating all tuna trading in the world. Developing economies, especially Thailand and Ecuador, have become influential players in the production of canned tuna thanks to their abilities to achieve economies of scale, cluster synergies in food production industries and tandem development of supporting industries like packaging. Owing to the need for scale, mergers and acquisitions have been common at domestic, regional and global levels.

The concentrated nature of the industry is similarly increasing among canned-tuna buyers. The third feature of this industry is the growing dominance of multinational retailers as lead buyers. The increasing dominance of retailers and supermarkets reinforces this demand-driven characteristic of the industry even further, forcing firms in upstream sectors to pay more attention to consumer demands in key markets. As a result, tuna processors have been increasingly squeezed between the upstream end, dominated by tuna trading companies and the downstream side, in which retailers dominate the sales of private labels and brands in canned tuna.

In sum, the canned-tuna industry exemplifies a globally integrated value chain in which dominant global buyers and suppliers exert strong power over tuna canneries. Osterblom et al (2015) posit that there are 13 MNEs in the world that dominate the value chain of seafood production, from sourcing to distributing to end consumers.

Rights and permissions

About this article

Cite this article

Pananond, P. From servant to master: Power repositioning of emerging-market companies in global value chains. Asian Bus Manage 15, 292–316 (2016). https://doi.org/10.1057/abm.2016.7

Published:

Issue Date:

DOI: https://doi.org/10.1057/abm.2016.7