Abstract

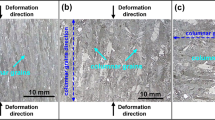

Isothermal hot compression tests on the as-cast high-Cr ultra-super-critical rotor steel with columnar grains were carried out in the temperature range from 1223 to 1523 K and at strain rates from 0.001 to 1 s−1. The compression direction was parallel to the longitudinal direction of columnar grains. The constitutive equation based on Arrhenius model was presented, and the processing maps based on the dynamic material model were developed, correlating with microstructure observation. The main softening mechanism was dynamic recovery at 1223 K under strain rates from 0.1 to 1 s−1, whereas it was dynamic recrystallization under other deformation conditions. The constitutive equation modified by strain compensation reasonably predicted the flow stresses. The processing maps and microstructure evolution mechanism schematic indicated that the optimum hot working parameters lay in the zone defined by the temperature range from 1423 to 1473 K and the strain rate range from 0.001 to 1 s−1.

Similar content being viewed by others

References

A. H. V. Pavan, K. S. N. Vikrant, R. Ravibharath, K. Singh, Mater. Sci. Eng. A 642 (2015) 32–41.

F. Sun, Y. F. Gu, J. B. Yan, Z. H. Zhong, M. Yuyama, Mater. Lett. 159 (2015) 241–244.

M. I. Isik, A. Kostka, V. A. Yardley, K. G. Pradeep, M. J. Duarte, P. P. Choi, D. Raabe, G. Eggeler, Acta Mater. 90 (2015) 94–104.

M. C. Flemings, Metall. Trans. 5 (1974) 2121–2134.

M. Klimenkov, E. Materna-Morris, A. Möslang, J. Nucl. Mater. 462 (2015) 280–288.

D. H. Meng, F. G. Lu, H. C. Cui, Y. M. Ding, X. H. Tang, X. Huo, J. Mater. Res. 30 (2015) 197–205.

N. Tsuji, K. Tsuzaki, T. Maki, ISIJ Int. 33 (1993) 783–792.

Y. C. Lin, M. S. Chen, H. B. Li, D. X. Wen, J. L. Zhang, M. He, Mater. Des. 77 (2015) 41–49.

M. E. Wahabi, L. Gavard, F. Montheillet, J. M. Cabrera, J. M. Prado, Acta Mater. 53 (2005) 4605–4612.

L. M. Dougherty, I. M. Robertson, J. S. Vetrano, Acta Mater. 51 (2003) 4367–4378.

Y. Qin, Mater. Sci. Eng. A 357 (2003) 1–6.

F. Chen, Z. S. Cui, S. J. Chen, Mater. Sci. Eng. A 528 (2011) 5073–5080.

W. H. Zhang, S. H. Sun, D. L. Zhao, R. Z. Wang, Z. H. Wang, W. T. Fu, Mater. Des. 32 (2011) 4173–4179.

Y. Zhang, Z. Chai, A. A. Volinsky, R. H. Tian, H. L. Sun, P. Liu, Y. Liu, Mater. Sci. Eng. A 662 (2016) 320–329.

Y. C. Lin, L. T. Li, Y. C. Xia, Y. Q. Zhang, J. Alloy. Compd. 550 (2013) 438–445.

S. K. Rajput, G. P. Chaudhari, S. K. Nath, J. Mater. Process. Technol. 237 (2016) 113–125.

A. Momeni, K. Dehghani, Mater. Sci. Eng. A 528 (2011) 1448–1454.

A. Momeni, K. Dehghani, Mater. Sci. Eng. A 527 (2010) 5467–5473.

K. M. Perkins, M. R. Bache, Int. J. Fatigue 27 (2005) 715–726.

V. Lepingle, G. Louis, D. Allue, B. Lefebvre, B. Vandenberghe, Corros. Sci. 50 (2008) 1011–1019.

Z. H. Wang, W. T. Fu, B. Z. Wang, W. H. Zhang, Z. Q. Lv, P. Jiang, Mater. Charact. 61 (2010) 25–30.

B. Z. Wang, W. T. Fu, Z. Q. Lv, P. Jiang, W. H. Zhang, Y. J. Tian, Mater. Sci. Eng. A 487 (2008) 108–113.

L. Zeng, M. Q. Xu, X. R. Ma, Y. J. Huang, S. G. Zhang, Q. D. Hu, J. G. Li, ISIJ Int. 54 (2014) 2302–2308.

F. Chen, Z. S. Cui, D. S. Sui, B. Fu, Mater. Sci. Eng. A 540 (2012) 46–54.

Y. C. Lin, Y. C. Xia, X. M. Chen, M. S. Chen, Comp. Mater. Sci. 50 (2010) 227–233.

Y. Qin, G. Götz, W. Blum, Mater. Sci. Eng. A 341 (2003) 211–215.

S. Z. Li, Z. Eliniyaz, L. T. Zhang, F. Sun, Y. Z. Shen, A. D. Shan, Mater. Charact. 73 (2012) 144–152.

D. Ponge, G. Gottstein, Acta Mater. 46 (1998) 69–80.

D. Samantaray, S. Mandai, A. K. Bhaduri, Mater. Des. 31 (2010) 981–984.

Y. Zhang, H. L. Sun, A. A. Volinsky, R. H. Tian, Z. Chai, P. Liu, Y. Liu, Acta Metall. Sin. 29 (2016) 422–430.

Z. Ding, S. Jia, P. Zhao, M. Deng, K. Song, Mater. Sci. Eng. A 570 (2013) 87–91.

Q. C. Fan, X. Q. Jiang, Z. H. Zhou, W. Ji, H. Q. Cao, Mater. Des. 65 (2015) 193–203.

D. X. Wen, Y. C. Lin, J. Chen, J. Deng, X. M. Chen, J. L. Zhang, M. He, Mater. Sci. Eng. A 620 (2015) 319–332.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, Zy., Zhang, D., Hu, Qd. et al. Constitutive analysis and optimization on hot working parameters of as-cast high Cr ultra-super-critical rotor steel with columnar grains. J. Iron Steel Res. Int. 24, 916–924 (2017). https://doi.org/10.1016/S1006-706X(17)30134-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(17)30134-6