Abstract

This study aimed to model energy use, energy efficiency, and greenhouse gas emissions in rain-fed wheat production by using a nonparametric data envelopment analysis (DEA) method. Data were collected through face-to-face interviews with 140 wheat farmers in 4 districts of Antalya Province. The energy inputs (independent variables) were human labor, seeds, chemical fertilizers, herbicides, and diesel fuel, and the energy output was the dependent variable. The results showed that the average energy consumption and the output energy for the studied wheat production system were 21. 07GJ ha−1 and 50. 99 GJ ha−1, respectively, and the total GHG emissions were calculated to be 592.12 kg CO2eq ha−1. Chemical fertilizer has the highest share of energy consumption and total GHG emissions. Based on the results from DEA, the technical efficiency of the farmers was found to be 0.81, while pure technical and scale efficiencies were 0.65 and 0.76, respectively. The results also highlighted that there is a potential opportunity to save approximately 14% (2.93 GJ ha−1) of the total energy consumption and consequently a 17% reduction in GHG emissions by following the optimal amounts of energy consumption while keeping the wheat yield constant. Efficient use of energy and reduction in GHG emissions will lead to resource efficiency and sustainable production, which is the main aim of the green economy.

Similar content being viewed by others

1 Introduction

The agriculture and energy sectors are closely linked with each other, as agriculture is a producer and consumer of energy [1]. Although agriculture is not the largest energy-consuming sector, all agricultural operations are energy intensive. Both commercial and noncommercial energy is used in agricultural operations either directly or indirectly [2]. Increasing demand for food has diverted attention to modern agricultural methods focused on increasing yield. The demand for enhancement in agricultural yield can be met in two ways: either by increasing the use of energy sources or optimizing input energy use in agricultural systems [3]. Moreover, the aspiration of countries for self-sufficiency in food production and role in the international market has led to increased use of modern agricultural methods. Energy has become an important element of modern agriculture due to its heavy dependence on fuel and other commercial energies [3].

Increased use of energy in agriculture is credited to constant growth in population, limited cultivable land supply, and growing desires for higher living standards [3]. During 1900–2000, there was an 80–100% increase in cultivable area, and on-farm energy production increased six-fold, while energy consumption in the same period increased 85-fold [4]. In China, there was a 100-fold increase in fossil fuel energy use in fertilizer and pesticide production along with irrigation between 1955 and 1992 [5]. A study by Canakci et al. [6] stated that a large proportion (60–90%) of energy used in agricultural production is from nonrenewable sources. The increasing use of energy from nonrenewable sources has an adverse impact on the sustainability of the system and will decrease production [7].

After the green revolution, the yield per area increased with the influx of new inputs and mechanization [8]. This led to increased use of undesirable inputs mainly due to the lack of technical knowledge of the farmers. Evidence shows that excessive use of input has adversely impacted production in some cases apart from other related problems [9]. Among other inputs, increased use of energy input has created many environmental hazards. Furthermore, this has resulted in a loss of biodiversity. The use of chemical fertilizers and pesticides has caused pollution of the aquatic environment [10]. Agricultural operations using fossil fuels also contribute to the emission of different greenhouse gases, such as carbon dioxide (CO2), nitrous oxide (N2O), and methane (CH4) [11]. The overuse of chemical fertilizer is responsible for nonpoint source pollution [12], degrading the quality of water and soil [13], and surging air emissions [14]. Moreover, pesticide use in crop production is responsible for the pollution of water, air, and soil [15]. It is estimated that 24% of total GHGs are contributed by forestry and land use, and greenhouse gases are mainly responsible for global warming and climate change. Green agriculture comprising low carbon emissions, recycling, and ecologically friendly production has been given more development priority worldwide due to the obvious reason for the increased impact of agriculture on global warming. Therefore, for the sustainable development of agriculture, green agricultural production is inevitable [63].

Sustainable agriculture is crucial for human existence. There is a two-way dependence between sustainable agriculture and a sustainable environment. The environment has a great influence on agriculture, and agriculture depends on the environment in many ways. This dependence on the environment by agriculture is greater than that of all other sectors. Sustainable production in agriculture provides food security while limiting the impacts on the environment through the efficient use of resources [32]. For sustainable agriculture, the efficient use of energy is considered to be an essential condition [16]. For sustainable agricultural development, energy efficiency is very important because it ensures competitiveness, economic savings, profitability, conservation of resources, and reduction in environmental pollution [17].

Analysis of energy consumption and greenhouse gas emissions can transform the pattern of energy consumption and lead to eco-friendly production. For these reasons, researchers are showing a keen interest in modeling energy consumption in agricultural production. Modeling of energy consumption has been done by researchers from developed to developing countries. Many researchers from Turkey have also analyzed energy use in different crops: vegetables [6], cotton [18], Canola [19], pomegranate [20], and Banana [21]. However, most of them relied on simple input–output, regression, and Cobb–Douglas production functions for analysis purposes. A more improved approach is needed to model energy use efficiency in agricultural production rather than simplistic input–output approaches. The data envelopment analysis (DEA) method has been widely used by business organizations to evaluate their activities and look for opportunities to improve. Recently, DEA has been used by many scholars to model energy consumption in agriculture. Table 1. Presents information of such studies.

Researchers have also used DEA to estimate energy efficiency in some other crops. For example, Mohammadi et al. [33] estimated the energy efficiency of farming systems in North Iran by using DEA. DEA was also applied by Mousavi-Avval et al. [34]. Imran et al. [54] estimated energy use efficiency in cotton production using DEA in Pakistan, Powar et al. [35] in Sugarcane in India, Ilyas et al. [36] in dairy farming in New Zealand, Kaab et al. [37] in sugarcane in Iran, and Raheli et al. [38] in tomato production in Iran. A nonparametric DEA was used in this study to analyze the energy use efficiency of wheat growers (Additional file 1).

Agriculture plays an important role in the economy of Turkey. Although its continuation to GDP has declined over time, its contribution to industrial raw material, employment, and exports is still significant. Wheat is one of the important crops grown in Turkey. Turkey is among the top ten largest wheat producers in the world. Wheat constitutes 98% of the grain area and contributes 61% of the grain production in the country. The importance of wheat for the population in Turkey and the demand for sustainable products has led us to evaluate energy efficiency in wheat production. The main objective of this study is to analyze the energy consumption patterns of rain-fed wheat and related GHG emissions and efficiencies of wheat producers and to provide an opportunity to farmers and policymakers to evaluate the current production system and benefits attached to the efficient use of energy.

2 Methodology

2.1 Dataset

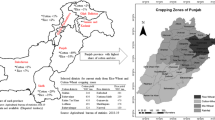

The study was carried out in Antalya Province of Turkey during the production period of 2017–18. Antalya is located in southern Turkey, within 36.89° north latitude and 30.71° east longitude. Wheat is grown on 92,625 hectares in Antalya, which makes Antalya an important wheat-producing province in Turkey. Sample farms were randomly selected from the villages in the study area using a multistage random sampling technique, and the sample volume was determined by [39]

where N is the number of wheat producers in the area, s is the standard deviation in the data, t is the t value at the 95% confidence interval, d is an acceptable error, and n is the required sample size. The sample size was found to be 140 by setting permissible error in the sample size at 5% for 95% confidence. Wheat producers in 12 villages were surveyed to collect data in the study area. In the first stage, 4 districts with the largest area under wheat cultivation were selected from the 19th districts. In the second stage, three villages from each district and 10–12 farmers from each village were selected randomly. Data were collected from the 140 wheat growers by using a face-to-face questionnaire. A semistructured pretested questionnaire was used to collect information from the sampled farmers. The collected data included information about hours or amounts of different input energy resources used in wheat production, such as human labor, seeds, machinery, diesel fuel, fertilizers, and weedicides. Wheat yield as the output energy source was also collected. Energy equivalents provided in Annexure-I were used to estimate the energy of inputs and output expressed in a uniform unit.

2.2 Energy parameters

A range of energy inputs are used in the production of wheat, such as human labor, agricultural machinery, chemical fertilizers, and diesel fuel. The data related to per hectare use of energy inputs and yield were recorded during interviews of the respondents. To have a standard unit of energy MJ ha−1, the quantity of inputs was multiplied by their corresponding energy equivalents given in Table 10 in Appendix. Analysis of the ratios between energy inputs and energy outputs can help in assessing the energy efficiency of agricultural systems [17]. To assess the energy efficiency of wheat production, energy indices such as energy use efficiency, net energy, energy productivity, and specific energy were calculated. The efficiency of energy use in wheat production was assessed by calculating the energy use efficiency (input–output ratio). This method has been used in many developing countries to assess the effectiveness of crop production [40]. Energy used in wheat production can be divided into four categories: direct energy (DE), indirect energy (IDE), renewable energy (RE), and nonrenewable energy (NRE). These categories are further explained in Table 2.

2.2.1 Quantification of GHG emissions

The use of agricultural inputs such as chemical fertilizer and chemicals and fossil fuels leads to the emission of carbon dioxide emissions. Crop production uses millions of tons of chemical fertilizer each year. Although synthetic nitrogen fertilizer keeps half of the world population adequately fed by enhancing food production [41], imbalance or overuse causes pollution of water, air, and soil. Moreover, excessive use of fertilizers in wheat production causes the emission of greenhouse gases. Greenhouse gas emissions from wheat production were calculated by multiplying the quantity of inputs by their corresponding emission coefficients.

2.2.2 Efficiency estimation

A data envelopment analysis (DEA) technique was used to estimate the efficiency of wheat production. The advantage of DEA over other methods is that it does not require any prior assumption on the underlying functional relationship between inputs and outputs [42,43,44]. DEA measures the relative efficiency of homogenous organizations that perform the same task. In this study, those homogenous organizations are farms producing wheat, and a farm is a decision-making unit (DMU). The criterion for deciding an efficient DMUS is that if any DMU produces a level of output that cannot be produced by another DMU using the same or a lesser amount of inputs, then it can be considered an efficient DMU [45]. There are two types of DEA applications: output-oriented DEA or input-oriented DE. In an input-oriented method, a DMU can be made efficient by keeping the output at the same level and reducing inputs. On the other hand, in the output-oriented method, a DMU can be made efficient by increasing the level of output and maintaining the same level of inputs. In this study, an input-oriented DEA was used because there are multiple inputs and one output.

At the farm level DEA, we assumed the output energy of wheat as output and all input energy as inputs. The data from all the wheat growers were represented by the input matrix K × N input matrix (X) and M × N output matrix (Y). The TE score of the ith wheat grower was estimated by using the following functional form via linear programming.

where θ is the TE score and the vector λ is an N × 1 vector of weights that defines the linear combination of the peers of the ith wheat grower. A TE score equal to 1 describes the efficient wheat grower in the use of input energy to attain the given level of output energy. A TE less than 1 describes the inefficiency of wheat growers in the use of input energy.

Considering the TE scores of wheat growers, the optimum level of different energy categories was determined.

3 Results and discussion

3.1 Energy balances

Energy consumption was computed using different energy equivalents and is presented in Table 3. The total energy consumption per hectare of wheat was 2.1 GJ. Our results are close to the finding of [46], who found 2.5 GJ energy consumption in one hectare of wheat in Turkey. The distribution of energy consumption by different inputs revealed that chemical fertilizer was the highest energy consumer in wheat production. Gokdogan and Sevim [46] also reported the highest share of fertilizer in total energy consumption in their study on energy use in wheat production in Turkey. Houshyar et al. [22], Bahrami et al. [23], Khoshnevisann et al. [3], and Masuda [26] also reported that fertilizer has the highest share of total energy consumption in wheat production. Among fertilizers, nitrogen has the highest share of 49.97% of the total input energy consumption and 90% of fertilizers. Diesel fuel was the second-highest energy consumer, followed by seed, chemicals, and human labor. The distribution of energy consumption by operation given in Table 11 in Appendix also shows that fertilization is the higehst energy consumer (55.5% of total input energy), followed by sowing (24.21%), land preparation (10.71%), harvesting (4.72%), weeding (2.59%), and transportation (2.53%). The total output energy from one hectare of wheat production was calculated as 50,989.96 MJ ha−1.

Analysis of the ratios between energy inputs and energy outputs can help in assessing the energy efficiency of agricultural systems [47]. Table 4 presents different energy indices, such as energy efficiency (2.41 kg MJ−1), energy productivity (0.16 kg MJ−1), specific energy (6.07 1 MJ kg−1), and net energy (29,916 MJ ha−1). Energy use efficiency shows that wheat production in the area is efficient. An energy ratio greater than one indicates that the system is earning energy if it is less than one, which means that the system is losing energy (Conforti and Giampietro, 1997). Energy efficiency was reported as 3.09 [48], 2.51 [49], and 2.36 [50] by other studies in Turkey. Indirect energy constituted almost 94.30%, while the share of direct energy was 5.70% of the total energy consumption. Similarly, nonrenewable energy accounted for the highest proportion (62.14%) compared to renewable energy (37.86%). Higher use of fertilizers is mainly responsible for a larger share of non-renewable and indirect energy in total energy consumption. The results are in line with [46] and [20].

3.2 GHG Emissions

The total GHG emissions from one hectare of wheat were estimated to be 592.12 kg CO2eq (Table 5). The main contributor was diesel fuel, followed by fertilizers, seeds, and chemicals (Fig. 1). The results of the study are in line with [51]. Aday et al. [51] showed that GHG emissions related to diesel fuel were between 0.48 and 3.75 Tg CO2eq for wheat, 17.15 to 65.45 Gg CO2eq for chickpea, and 0.088 to 0.153 Tg CO2eq for Tomato in Turkey.

3.3 Results of DEA

3.3.1 Ranking efficient farms

The performance of a farm (DMU) can be assessed by comparing it with another farm performing the same function. Farms are ranked efficient by using a benchmark method. In the benchmarking method, efficient farms are ranked based on the frequency of their appearance in the reference set [36]. Efficient farms (DMUS) are a benchmark for inefficient DMUS, and efficient DMUs are segregated on the basis of similar input–output levels with inefficient DMUs. Table 6 shows that for DMU 1, the combination of DMU 49 and 71 forms the best practice or composite benchmark. This means that the efficient frontier segment formed by these DMUs is near DMU 1. Furthermore, DMU 71 was considered the most efficient or superior because it appeared 86 times in reference sets of inefficient DMUs. By looking at the result, it can be seen that among other efficient DMUs are 33, 87, 44, 86, 92, 40, 65, 4, and 80 (Table 6). The reason for declaring these DMUs as the most efficient or superior ones is because their input levels are close to inefficient DMUs and they frequently appeared in the reference set of inefficient DMUs.

3.3.2 Efficiency estimates

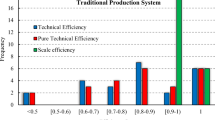

The CCR model was used to evaluate technical efficiency, and pure technical and scale efficiencies were determined by using the BCC model. Figure 2 presents the results of the CCR and BCC model. The results revealed that only 9% of the farmers had a technical efficiency score of unity and global efficiency. While 14% of the farmers were pure technically efficient and among them, 35% were just locally efficient. The results of the CCR model demonstrate that 24% of wheat producers have technical efficiency scores less than 0.5 and 16% have between 0.9 and < 1. The BCC model showed that the pure technical efficiency scores of 27.5% of farmers were less than 0.5 and that 6% had scores between 0.9 and < 1. Mousavi-Avval et al. [34] used DEA to analyze the TE, PTE, and SE of soybean farmers in Iran; they reported that 27.66% were globally efficient and 42.55% of farmers were pure technically efficient. Khoshnevisan et al. [3] found that 59% of wheat farms were efficient, and others’ efficiency scores were less than 1.

Close observation of efficiency scores presented in Table 7 shows that the average efficiency of farms was 0.80, varied between 0.12 and 1 and had the highest standard deviation (0.80). Further decomposition of technical efficiency measures revealed that the pure technical efficiency and scale efficiency of wheat farmers were 0.65 and 0.76, respectively. Mousavi-Avval et al. [34] reported TE, PTE, and SE as 0.74, 0.88, and 0.84, respectively, in canola production. Other studies reported 0.82 technical efficiency for wheat [3], 0.75 for tomato [52], and 0.78 for apple [34]. In India, Chauhan et al. [53] found TE, PTE, and SE to be 0.83, 0.92, and 0.77, respectively, in canola production.

3.3.3 Input use pattern of efficient and inefficient Farms

A comparison of 10 efficient and inefficient farmers reveals that except for phosphate, the average quantity of inputs used by inefficient farmers is comparatively higher than that of efficient farmers. The output of efficient farms was found to be 131% higher than that of inefficient farms. Inefficient farms used 28.91% more labor hours, 7.66% seeds, 27.62% diesel, 80.89% chemicals, 6.08% nitrogen, and 23.13% potash (Table 8). One possible reason for the higher use of input by farmers is the common belief that yield increases with a higher quantity of inputs [23]. Considering the intensive use of resources by inefficient farmers, the results reveal that the output of inefficient farmers has increased proportionately less than inputs. Mousavi-Avavl et al. [34, 37] also found that the increase in output is proportionately low.

3.3.4 Energy savings

Using the results of the BCC model, the energy saving potential and optimal energy requirements were determined and are presented in Table 9. The total optimum energy requirement was found to be 18,139.12 MJ ha−1. The results show that the highest optimum energy requirement was for nitrogen (8361.52 MJ ha−1), followed by diesel (4663.32 MJ ha−1), seed (4055.98 MJ ha−1), phosphate (515.87 MJ ha−1), potash (358.11 MJ ha−1), chemicals (145.84 MJ ha−1), and labor (38.46 MJ ha−1). The energy-saving target ratios (ESTRs) given in the last column of Table 9 showed that 45.95% of chemical energy, 23.44% of phosphate energy, 20.60% of nitrogen energy, and 14.43% of potash energy could be saved without reducing output. Moreover, energy usage from diesel, labor, and seed inputs could be saved by 5.44%, 5.11%, and 3.59%, respectively. It is also evident from the results that if the optimum energy requirement is followed, then 13.92% (2934.16 MJ ha−1) of total energy could be saved per hectare of wheat production. The efficient use of energy is an important factor contributing to the green economy. Wheat is an energy-intensive crop, and any effort to improve energy use efficiency in wheat production will yield agricultural green production.

Mousavi-Avval et al. (2011) reported that fertilizers, diesel fuel, water for irrigation, chemicals, labor, and seed energy inputs could be saved by 8.68%, 8.88%, 8.68%, 2.63%, 6.01%, and 1.52%, respectively, in soybean production in Iran. Total energy inputs that could be saved were reported as 11.65% in paddies in India [53], 11.29% in apple production in Iran [34] and 22.5% in cotton production in Pakistan [54].

3.3.5 Energy indices and GHG emissions under optimal conditions

The improvements in energy indices for wheat production after optimization of energy inputs were also investigated. Under optimum conditions, the output-input ratio was found to be 2.80, indicating an improvement of 13.92% over the current energy use ratio (2.41). Energy productivity and specific energy under optimum conditions would improve to 0.19 kg MJ−1 and 5.22 MJ kg−1, indicating improvements of 15.78% and 16.28%, respectively. Moreover, net energy would increase to 32,750 MJ ha−1, showing 8.65% improvements. Similarly, a comparison between the present condition and optimum condition illustrated that GHG emissions for the optimum condition were 514.27 kg CO2 eq ha−1, while they were 592.12 kg CO2 eq ha−1 for the present condition (Table 7). As mentioned before, GHG emissions can be decreased by improving the use of different energy inputs and agricultural practices. As a result of decreased carbon emissions, green wheat production will occur.

4 Conclusion

Wheat is an important crop in the agriculture sector of Turkey as well as many other parts of the world. A major proportion of the population uses wheat as a staple food in the country. Energy is an important input in the production of wheat and all other crops. The agriculture sector is a consumer as well as a producer of energy. Increasing demand for food has increased the use of energy in agriculture. Intensive and overuse input energy in crop production is a threat to energy security as well as a sustainable environment. Sustainable agriculture and sustainable environments are dependent on each other; therefore, the efficient use of energy in crop production is a necessary condition for sustainable agriculture.

Results of the study showed that 2.1 GJ of energy is used per hectare of wheat. Chemical fertilizers were the main energy consumer in wheat production, followed by diesel fuel. Fertilizer and diesel fuel also have the highest share of GHG emissions. GHG emission analysis showed that a total of 592 kg CO2eq was emitted in wheat production. Therefore, to optimize the use of energy and reduce GHG emissions from wheat production, the use of diesel fuels and chemical fertilizers should be optimized. Efficiency analysis results revealed that 91% of the wheat farmers were using energy inefficiently. There is substantial potential for energy savings; if optimum requirement levels are followed, it will increase energy efficiency and reduce GHG emissions, which will lead to sustainable and green production.

Data availability statement

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Zangeneh M, Omid M, Akram A. A comparative study on energy use and cost analysis of potato production under different farming technologies in Hamadan province of Iran. Energy. 2010;35:2927–33.

Omid M, Ghojabeige F, Delshad M, Ahmadi H. Energy use pattern and benchmarking of selected greenhouses in Iran using data envelopment analysis. Energy Convers Manage. 2011;52:153–62.

Khoshnevisan B, Rafiee S, Omid M, Mousazadeh H. Applying data envelopment analysis approach to improve energy efficiency and reduce GHG (greenhouse gas) emission of wheat production. Energy. 2013;58:588–93.

Safa M, Samarasinghe S, Mohssen M. A field study of energy consumption in wheat production in Canterbury New Zealand. Energy Conver Manag. 2011;52:2526–32.

Pimentel D, Marklein A, Toth MA, Karpoff MN, Paul GS, Mccormack R, Kyriazis J, Krueger T. Food versus biofuels: environmental and economic costs. Hum Ecol. 2009;37:1–12.

Canakci M, Topakci M, Akinci I, Ozmerzi A. Energy use pattern of some field crops and vegetable production: case study for Antalya region. Turkey Energy Convers Manage. 2005;46:655–66.

Moore SR. Energy efficiency in small-scale biointensive organic onion production in Pennsylvania, USA. Renewable Agric Food Syst. 2010;25:181–8.

Ziaei S, Mazloumzadeh S, Jabbary M. A comparison of energy use and productivity of wheat and barley (case study). J Saudi Soc Agric Sci. 2015;14:19–25.

Omani A, Chizari M. Analysis of farming system sustainability of wheat farmers in Khuzestan province of Iran. Green Farm Int J Agric Sci. 2008;6:5–8.

Nemecek T, Dubois D, Huguenin-Elie O, Gaillard G. Life cycle assessment of Swiss farming systems: I. Integrated and organic farming. Agric Syst. 2011;104:217–32.

IPCC. Climate change; impacts adaptation and vulnerability. In: Parry ML, Canziani OF, Palutikof JP, van der Linden PJ, Hanson CE, editors. Contribution of working group II to the fourth assessment report of the intergovernmental panel on climate change. Cambridge: Cambridge University Press; 2007. p. 976.

Liu R, Zhang P, Wang X, Chen Y, Shen Z. Assessment of effects of best management practices on agricultural non-point source pollution in Xiang xi River watershed. Agric Water Manage. 2013;117:91.

Ju XT, Kou CL, Christie P, Dou ZX, Zhang FS. Changes in the soil environment from excessive application of fertilizers and manures to two contrasting intensive cropping systems on the North China Plain. Environ Pollut. 2007;145:497–506.

Wang Z, Zhang X, Mu Y. Effects of rare-earth fertilizers on the emission of nitrous oxide from agricultural soils in China. Atmos Environ. 2008;42:3882–7.

Toan PV, Sebesvari R, Bläsing M, Rosendahl I, Renaud FG. Pesticide management and their residues in sediments and surface and drinking water in the Mekong Delta. Vietnam Sci Total Environ. 2013;452:28–39.

Uhlin H. Why energy productivity is increasing: an I-O analysis of Swedish agriculture. Agric Syst. 1998;56(4):443–65.

Taghavifar H, Mardani A. Prognostication of energy consumption and greenhouse gas (GHG) emissions analysis of apple production in West Azarbayjan of Iran using Artificial Neural Network. J Clean Prod. 2015;87:159–67.

Yilmaz I, Akcaoz H, Ozkan B. An analysis of energy use and input costs for cotton production in Turkey. Renew Energy. 2005;30:145–55.

Unakitan G, Hurma H, Yilmaz F. An analysis of energy use efficiency of canola production in Turkey. Energy. 2010;35:3623–7.

Akcaoz H, Ozcatalbas O, Kizilay H. Analysis of energy use for pomegranate production in Turkey. J Food Agric Envoirn. 2009;7(2):475–80.

Akcaoz H. Analysis of energy use for banana production: a case study from Turkey. Afr J Agric Res. 2011;6:78.

Houshyar E, Sheikh Davoodi MJ, Nassiri SM. Energy efficiency for wheat production using data envelopment analysis (DEA) technique. Journal of Agricultural Technology. 2010;6(4):663–72.

Bahrami H, Taki M, Monjezi N. Optimization of energy consumption for wheat production in iran using data envelopment analysis (DEA) technique. Afr J Agric Res. 2011;6(27):5978–86.

Moghimi MR, Alasti BM, Drafshi MAH. Energy input-output and study on energy use efficiency for wheat production using DEA technique. 2013.

Aravindakshan S, Rossi FJ, Krupnik TJ. What does the benchmarking of wheat farmers practicing conservation tillage in the eastern Indo-Gangetic Plains tell us about energy use efficiency? An application of slack-based data envelopment analysis. Energy. 2015;90(1):483–549.

Masuda K. Measuring eco-efficiency of wheat production in Japan: a combined application of life cycle assessment and data envelopment analysis. J Clean Prod. 2016;126(10):373–81.

Nabavi-Pelesaraei A, Hosseinzadeh-Bandbafha H, Qasemi-Kordkheili P, Kouchaki-Penchah H, Riahi-Dorcheh F. Applying optimization techniques to improve of energy efficiency and GHG (greenhouse gas) emissions of wheat production. Energy. 2016;103:672–8.

Abbas A, Minli Y, Elahi E, Yousaf K, Ahmad M, Iqbal T. Energy use efficiency in wheat production, a case study of Punjab Pakistan. Fresenius Environ Bull. 2018;27(7):4725–33.

Fathi R, Amjadpor F, Kouchakzadeh A, Azizpanah A. The pattern and efficiency of energy use for wheat production by data envelopment analysis, case study: Chardavol Township, Ilam Province. Iran J Dryland Agric. 2018;7(1):33–46.

Singh P, Singh G, Sodhi GPS. Applying DEA optimization approach for energy auditing in wheat cultivation under rice-wheat and cotton-wheat cropping systems in northwestern India. Energy. 2019;181(15):18–28.

Ilahi S, Wu Y, Raza MAA, Wei W, Imran M, Bayasgalankhuu L. Optimization approach for improving energy efficiency and evaluation of greenhouse gas emission of wheat crop using data envelopment analysis. Sustainability. 2019;11(12):3409.

Pishgar-Komleh SH, Zylowski T, Rozakis S, Kozyra J. Efficiency under different methods for incorporating undesirable outputs in an LCA+DEA framework: a case study of winter wheat production in Poland. J Environ Manag. 2020;260:110138.

Mohammadi A, Rafiee S, Mohtasebi SS, Avval SHM, Rafiee H. Energy efficiency improvement and input cost saving in kiwifruit production using Data Envelopment Analysis approach. Renewable Energy. 2011;36:2573–9.

Mousavi-Avval SH, Rafiee S, Jafari A, Mohammadi A. Improving energy use efficiency of canola production using data envelopment analysis (DEA) approach. Energy. 2011;36(5):2765–72.

Powar RV, Mehetre SA, Patil PR, et al. Study on energy use efficiency for sugarcane crop production using the data envelopment analysis (DEA) technique. J Biosyst Eng. 2020;45:291–309.

Ilyas HMA, Safa M, Bailey A, Rauf S, Khan A. Energy efficiency outlook of New Zealand Dairy Farming Systems: an application of data envelopment analysis (DEA) approach. Energies. 2020;13(1):251.

Kaab A, Sharifi M, Mobli H, Nabavi-Pelesaraei A, Kwok-wing C. Use of optimization techniques for energy use efficiency and environmental life cycle assessment modification in sugarcane production. Energy. 2019;181:1298–320.

Raheli H, Rezaei RM, Jadidi MR, Mobtaker HG. A two-stage DEA model to evaluate sustainability and energy efficiency of tomato production. Inf Process Agric. 2017;4(4):342–50.

Kizilaslan H. Input-output energy analysis of cherries production in Tokat Province of Turkey. Appl Energy. 2009;86:1354–8.

Khojastehpour M, Nikkhah A, Hashemabadi D. A Comparative Study of Energy Use and Greenhouse Gas Emissions of Canola Production. Int J Agric Manag Dev. 2015;5(1):51–8.

Zhang X, Pan H, Cao J, Li J. Energy consumption of China’s crop production system and the related emissions. Renew Sustain Energy Rev. 2015;43:111–25.

Mousavi-Avval SH, Rafiee S, Mohammadi A. Optimization of energy consumption and input costs for apple production in Iran using data envelopment analysis. Energy. 2011;36:909–16.

Farrell MJ. The measurement of productive efficiency. J R Stat Soc. 1957;120:253–90.

Cooper W, Seiford L, Tone K. Data envelopment analysis. In: Conference data envelopment analysis. Massachusetts: Kluwer Academic Publishers.

Khalili-Damghani K, Tavana M, Santos-Arteaga FJ, Mohtasham S. A dynamic multi-stage data envelopment analysis model with application to energy consumption in the cotton industry. Energy Economics. 2015;51:320–8.

Gökdoğan O, Sevim B. Determination of energy balance of wheat production in Turkey: a case study of Eskil district. J Tekirdag Agric Faculty. 2016;13(04):36–43.

Taghavifar H, Mardani A. Prognostication of energy consumption and greenhouse gas (GHG) emissions analysis of apple production in West Azarbayjan of Iran using Artificial Neural Network. J Clean Prod. 2015;87:159–67.

Tipi T, Çetin B, Vardar A. An analysis of energy use and input costs for wheat production in Turkey. J Food Agric Environ. 2009;7(2):352–6.

Cicek A, Altintas G, Erdal G. Energy consumption patterns and economic analysis of irrigated wheat and rainfed wheat production: case study for Tokat Region Turkey. Bulgar J Agric Sci. 2011;17(3):378–88.

Yildiz T. An Input-Output Energy Analysis of Wheat Production in Çarşamba District of Samsun Province. J Agric Faculty Gaziosmanpasa Univ. 2016;33(3):10–20.

Aday B, Ertekin C, Evrendilek F. Emissions of greenhouse gases from diesel consumption in agricultural production of Turkey. Eur J Sust Dev. 2016;5(4):279–88.

Iráizoz B, Rapún M, Zabaleta I. Assessing the technical efficiency of horticultural production in Navarra. Spain Agric Syst. 2003;78:387–403.

Chauhan NS, Mohapatra PK, Pandey KP. Improving energy productivity in paddy production through benchmarking—an application of data envelopment analysis. Energy Convers Manage. 2005;47:1063–85.

Imran M, Ozcatalbas O, Bashir MK. Estimation of energy efficiency and greenhouse gas emission of cotton crop in South Punjab, Pakistan. J Saudi Soc Agric Sci. 2020;19(3):216–24.

Mohammadshirazi A, Akram A, Rafiee S, Mousavi-Avval SH, Bagheri KE. An analysis of energy use and relation between energy inputs and yield in tangerine production. Renew Sust Energy Rev. 2012;16:4515–21.

Mobtaker HG, Keyhani A, Mohammadi A, Rafiee S, Akram A. Sensitivity analysis of energy inputs for barley production. Agric Ecosyst Environ. 2010;137:367–72.

Ozkan B, Akcaoz H, Fert C. Energy input-output analysis in Turkish agriculture. Renew Energy. 2004;29:39–51.

Esengun K, Gunduz O, Erdal G. Input-output energy analysis in dry apricot production of Turkey Energy Conver. Manage. 2007;48:592–8.

Mousavi-Avval SH, Rafiee S, Jafari A, Mohammadi A. Energy flow modeling and sensitivity analysis of inputs for canola production in Iran. J Clean Prod. 2011;19:1464–70.

Mousavi-Avval SH, Rafiee S, Jafari A, Mohammadi A. Improving energy use efficiency of canola production using data envelopment analysis (DEA) approach. Energy. 2014;36(5):2765–3277.

Rafiee S, Mousavi-Avval SH, Mohammadi A. Modeling and sensitivity analysis of energy inputs for apple production in Iran. Energy. 2010;35:3301–6.

Camargo CGT, Ryan MR, Richard TL. Energy use and greenhouse gas emissions from crop production using the farm energy analysis tool. Bioscience. 2013;63:263–73.

Wan B, Tian L, Zhu N, et al. A new endogenous growth model for green low-carbon behavior and its comprehensive effects. Appl Energy. 2018;230:1332–46.

Author information

Authors and Affiliations

Contributions

MI designed the study, collected data, and run an analysis. OO supervised the study and did proofreading. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1.

Energy input-output data for wheat crop

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Imran, M., Ozcatalbas, O. Optimization of energy consumption and its effect on the energy use efficiency and greenhouse gas emissions of wheat production in Turkey. Discov Sustain 2, 28 (2021). https://doi.org/10.1007/s43621-021-00035-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43621-021-00035-w