Abstract

The leaching processes and mechanisms of weathered crust elution-deposited rare earth (RE) ores with ammonium sulfate were investigated for their high efficiency and low consumption exploitation. The leaching process is a typical reversible heterogeneous ion exchange reaction in liquid–solid systems. The raw ore and leached tailings were analyzed by SEM and FTIR. Results indicated that no dissolution or structural changes of the ores occurred during the leaching process. The migrations of RE3+, Al3+, and \( {\mathrm{NH}}_4^{+} \) in the leaching process were studied under various liquid–solid ratios. With increasing liquid–solid ratio, the content of \( {\mathrm{NH}}_4^{+} \) adsorbed on clay mineral by physical effect decreased, \( {\mathrm{NH}}_4^{+} \) adsorbed by ion-exchange increased, and the content of exchanged RE and Al increased until reaching equilibrium. The adsorption capacity of the RE ores for \( {\mathrm{NH}}_4^{+} \) remained about 0.61–0.63 mg/g. It was difficult to desorb \( {\mathrm{NH}}_4^{+} \) from RE ores with washing water alone. The leaching mechanism of Al was the same as RE, but the leaching of Al slightly lagged behind RE. At the optimal liquid–solid ratio of 0.4:1, the leaching efficiencies of RE and Al were 95.51% and 90.99%, respectively, and 56.65% of \( {\mathrm{NH}}_4^{+} \) remained in the leachate. After impurity removal and RE precipitation, the leachate can be reused by replenishing fresh leaching agent. The aim of this study is to enhance the leaching process of RE, restrain the leaching of impurities, and decrease the consumption of leaching agents.

Similar content being viewed by others

References

Jha MK, Kumari A, Panda R, Kumar JR, Yoo K, Lee JY (2016) Review on hydrometallurgical recovery of rare earth metals. Hydrometallurgy 165:2–26

Yang XJ, Lin AJ, Li XL, Wu YD, Zhou WB, Chen ZH (2013) China’s ion-adsorption rare earth resources, mining consequences and preservation. Environ Dev 8:131–136

Nesbitt HW (1979) Mobility and fractionation of rare earth elements during weathering of a granodiorite. Nature 279:206–210

Gupta CK, Krishnamurthy N (2015) Extractive metallurgy of rare earths. CRC, Boca Raton

Chi RA, Tian J (2008) Weathered crust elution-deposited rare earth ores. Nova Science, New York

He ZY, Zhang ZY, Yu JX, Xu ZG, Chi RA (2016) Process optimization of rare earth and aluminum leaching from weathered crust elution-deposited rare earth ore with compound ammonium salts. J Rare Earths 34:413–419

Yang XL, Zhang JW (2015) Recovery of rare earth from ion-adsorption rare earth ores with a compound lixiviant. Sep Purif Technol 142:203–208

Xiao YF, Feng ZY, Hu GH, Huang L, Huang XW, Chen YY, Long ZQ (2016) Reduction leaching of rare earth from ion-adsorption type rare earths ore with ferrous sulfate. J Rare Earths 34:917–923

Li KZ, Liu HP, Lai FG, Xiao YF, Hu YM, Wang C, Xu HB (2017) Migration of natural radionuclides in the extraction process of the ion-adsorption type rare earths ore. Hydrometallurgy 171:236–244

Qiu TS, Fang XH, Wu HQ, Zeng QH, Zhu DM (2014) Leaching behaviors of iron and aluminum elements of ion-absorbed rare earth ore with a new impurity depressant. Trans Nonferrous Metals Soc China 24:2986–2990

Zhang ZY, He ZY, Yu JX, Chi RA (2016) Novel solution injection technology for in-situ leaching of weathered crust elution-deposited rare earth ores. Hydrometallurgy 164:248–256

Xiao YF, Feng ZY, Huang XW, Huang L, Chen YY, Wang LS, Long ZQ (2015) Recovery of rare earths from weathered crust elution-deposited rare earths ore without ammonia nitrogen pollution: I. leaching with magnesium sulfate. Hydrometallurgy 153:58–65

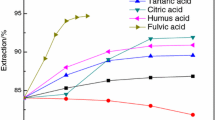

Wang L, Liao CF, Yang YM, Xu HB, Xiao YF, Yan CH (2017) Effects of organic acids on the leaching process of ion-adsorption type rare earth ore. J Rare Earths 35:1233–1238

Yang LF, Li CC, Wang DS, Li FY, Liu YZ, Zhou XZ, Liu MB, Wang ZF, Li YX (2019) Leaching ion adsorption rare earth by aluminum sulfate for increasing efficiency and lowering the environmental impact. J Rare Earths 37:429–436

Tian J, Yin JQ, Tang XK, Chen J, Luo XP, Rao GH (2013) Enhanced leaching process of a low-grade weathered crust elution-deposited rare earth ore with carboxymethyl sesbania gum. Hydrometallurgy 139:124–131

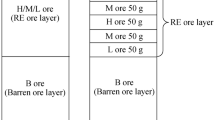

Zhang ZY, Sun NJ, He ZY, Chi RA (2018) Local concentration of middle and heavy rare earth elements in the col on the weathered crust elution-deposited rare earth ores. J Rare Earths 36:552–558

Zhou F, Feng J, Wang ZQ, Xu YL, Zhang ZY, Chi RA (2017) One step purification of impurities in the leachate of weathered crust elution-deposited rare earth ores. Physicochem Probl Miner Process 53:1188–1199

Lai FG, Huang L, Gao GH, Yang R, Xiao YF (2018) Recovery of rare earths from ion-absorbed rare earths ore with MgSO4-ascorbic acid compound leaching agent. J Rare Earths 36:521–527

Lai FG, Gao GH, Huang L, Xiao YF, Li KZ (2018) Compound leaching of rare earth from the ion-adsorption type rare earth ore with magnesium sulfate and ascorbic acid. Hydrometallurgy 179:25–35

Tian J, Yin JQ, Chi RA, Rao GH, Jiang MT, Ouyang KX (2010) Kinetics of leaching rare earth from the weathered crust elution-deposited rare earth ores with ammonium sulfate solution. Hydrometallurgy 101:166–170

Hu GH, Feng ZY, Dong JS, Meng XL, Xiao YF, Liu XS (2017) Mineral properties and leaching characteristics of volcanic weathered crust elution-deposited rare earth ore. J Rare Earths 35:906–910

Moldoveanu GA, Papangelakis VG (2013) Recovery of rare earth elements adsorbed on clay minerals: II. Leaching with ammonium sulfate. Hydrometallurgy 131:158–166

Moldoveanu GA, Papangelakis VG (2012) Recovery of rare earth elements adsorbed on clay minerals: I. desorption mechanism. Hydrometallurgy 117:71–78

He ZY, Zhang ZY, Yu JX, Zhou F, Xu YL, Xu ZG, Chen Z, Chi RA (2016) Kinetics of column leaching of rare earth and aluminum from weathered crust elution-deposited rare earth ore with compound ammonium salt. Hydrometallurgy 163:33–39

He ZY, Zhang ZY, Yu JX, Xu ZG, Xu YL, Zhou F, Chi RA (2016) Column leaching process of rare earth and aluminum from weathered crust elution-deposited rare earth ore with ammonium salt. Trans Nonferrous Metals Soc China 26:3024–3033

Acknowledgments

The work is financially supported by grants from the National Natural Science Foundation of China (No. 51704339, No. 51734001, and No. 41472071) and “the Fundamental Research Funds for the Central Universities”, South-Central University for Nationalities (No. CZY19033, No. CZP19002, and No. YZZ16002).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The leaching process of RE and impurity was a typical reversible heterogeneous ion exchange reaction in liquid–solid systems.

• The leaching mechanism of Al was the same as RE, but the leaching of Al slightly lagged behind RE.

• 56.65% of \( {\mathrm{NH}}_4^{+} \) remaining in the leachate can be reused after impurity removal and RE precipitation.

• The residual \( {\mathrm{NH}}_4^{+} \) in RE ores was about 0.61–0.63 mg/g that was difficult to desorb for washing water.

Rights and permissions

About this article

Cite this article

He, Z., Zhang, R., Nie, W. et al. Leaching Process and Mechanism of Weathered Crust Elution-Deposited Rare Earth Ore. Mining, Metallurgy & Exploration 36, 1021–1031 (2019). https://doi.org/10.1007/s42461-019-00116-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-019-00116-5