Abstract

Buildings require energy to maintain their performance. In consequence, built environments cause a surge in the world’s energy demand. Providing passive measures is an effective method of optimizing operational energy usage. In this study, we propose insulation materials (thermal barrier type and resistive insulation) for the walls of a building. Experiments were performed on small-scale physical models constructed with; (a) no insulation, (b) sawdust–cement mortar, and (c) retro-reflective (RR) material for external walls. In addition, regression models were developed to predict indoor air temperature with insulation. Subsequently, associated operational energy-saving and decrease in emissions were estimated for each material. The comparison reveals RR (sawdust–cement mortar) is effective in warm (overcast) climatic conditions. Developed regression models have shown a good agreement with experimental results (R > 0.8). Moreover, sawdust–cement mortar (RR) materials contributed a 9% (13.4%) reduction in operational energy and a 9% (13.3%) decrease in CO2 emissions. The project highlights the potential to utilize sawdust—a waste material—and RR material as wall insulation to decrease intense operational energy demand.

Similar content being viewed by others

Abbreviations

- A/C:

-

Air conditioning

- CO2 :

-

Carbon dioxide

- HVAC:

-

Heating ventilation and air conditioning

- RR:

-

Retro-reflective

- RH:

-

Relative humidity

- M1:

-

Model house without any insulation

- M2:

-

Model house insulted with sawdust and cement

- M3:

-

Model house insulated with RR tape

- h:

-

Hours

- BTU:

-

British thermal unit

- K 1 :

-

Thermal conductivity of composite material sawdust and cement insulation

- K sawdsut :

-

Thermal conductivity of sawdust

- K cement-grout :

-

Thermal conductivity of cement grout

- Ø:

-

Volume fraction of cement grout.

- R 2 :

-

Coefficient of determination

- R :

-

Correlation coefficient

- MAE:

-

Mean absolute error

- RMSE:

-

Root mean square error

- T P :

-

Predicted indoor air temperature

- T E :

-

Experimental indoor air temperature

- \({\overline{T} }_{\mathrm{E}}\) :

-

Mean value of data set

- N :

-

Total number of readings

References

Aditya, L., Mahlia, T. M. I., Rismanchi, B., Hasan, M. H., & Metseelar, H. S. C. (2017). A review on insulation materials for energy conservation in buildings. Renewable and Sustainable Energy Reviews, 73, 1352–1365. https://doi.org/10.1016/j.rser.2017.02.034

Alausa, S., Adekoya, B., Aderibigbe, J., & Nwaokocha, C. (2013). Thermal characteristics of laterite-mud and concrete-block for walls in building construction in Nigeria. International Journal of Engineering and Applied Sciences, 4(4), 1–4.

Al-Tamimi, A. S., Baghabra Al-Amoudi, O. S., Al-Osta, M. A., Ali, M. R., & Ahmad, A. (2020). Effect of insulation materials and cavity layout on heat transfer of concrete masonry hollow blocks. Construction and Building Materials, 254, 119300. https://doi.org/10.1016/j.conbuildmat.2020.119300

Andiç-Çakir, Ö., Son, A. E., Sürmelioğlu, S., Tosun, E., & Sarikanat, M. (2021). Improvement of traditional clay bricks’ thermal insulation characteristics by using waste materials. Case Studies in Construction Materials, 15, e00560. https://doi.org/10.1016/j.cscm.2021.e00560

Annibaldi, V., Cucchiella, F., Berardinis, P. D., Gastaldi, M., & Rotilio, M. (2019). An integrated sustainable and profitable approach of energy efficiency in heritage buildings. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2019.119516

Annibaldi, V., Cucchiella, F., & Rotilio, M. (2021). Economic and environmentalassessment of thermal insulation. A case study in Italian context. Case Studies in Construction Materials. https://doi.org/10.1016/j.cscm.2021.e00682

Ariyadasa, G. L. M., Muthurathne, S. S. K., & Adikary, S. U. (2015). Investigating the physical, mechanical and thermal properties of common roofing materials in Sri Lanka. In Proceedings of 6th annual national building research symposium, Sri Lanka.

Asdrubali, F., Baldassarri, C., & Fthenakis, V. (2013). Life cycle analysis in construction sector: Guiding optimization of conventional Italian buildings. Energy and Buildings, 64, 73–89. https://doi.org/10.1016/j.enbuild.2013.04.018

Barrau, J., Ibañez, M., & Badia, F. (2014). Impact of optimization criteria on determination of insulation thickness. Energy and Buildings, 76, 459–469. https://doi.org/10.1016/j.enbuild.2014.03.017

Biswas, K., Shrestha, S. S., Bhandari, M. S., & Desjarlais, A. O. (2016). Insulation materials for commercial buildings in North America: An assessment of lifetime energy and environmental impacts. Energy and Buildings, 112, 256–269. https://doi.org/10.1016/j.enbuild.2015.12.013

Braulio-Gonzalo, M., & Bovea, M. D. (2017). Environmental and cost performance of building’s envelope insulation materials to reduce energy demand: Thickness optimisation. Energy and Buildings, 150, 527–545. https://doi.org/10.1016/j.enbuild.2017.06.005

Calculator, b. (2021). BTU Calculator. [online] Calculator.net. Available at: https://www.calculator.net/btu-calculator.html. Accessed 27 October 2020.

Casini, M. (2016). 4—Advanced insulating materials. In M. Casini (Ed.), Smart buildings (pp. 127–177). Woodhead Publishing.

Castellani, B., Gambelli, A., Nicolini, A., & Rossi, F. (2020). Optic-energy and visual comfort analysis of retro-reflective building plasters. Building and Environment, 174, 106781.

Cetiner, I., & Shea, A. D. (2018). Wood waste as an alternative thermal insulation for buildings. Energy and Buildings, 168, 374–384. https://doi.org/10.1016/j.enbuild.2018.03.019

Claudiu, A. (2014). Use of sawdust in composition of plaster mortars. ProEnvironment, 7, 30–34.

Costes, J., Evrard, A., Biot, B., Keutgen, G., Daras, A., Dubois, S., Lebeau, F., & Courard, L. (2017). Thermal conductivity of straw bales: full size measurements considering direction of heat flow. Buildings, 7(4), 11.

de Dear, R., Akimoto, T., Arens, E., Brager, G., Candido, C., Cheong, K., Li, B., Nishihara, N., Sekhar, S., Tanabe, S., Toftum, J., Zhang, H., & Zhu, Y. (2013). Progress in thermal comfort research over last twenty years. Indoor Air, 23(6), 442–461.

Dhakal, U., Berardi, U., Gorgolewski, M., & Richman, R. (2017). Hygrothermal performance of hempcrete for Ontario (Canada) buildings. Journal of Cleaner Production, 142, 3655–3664. https://doi.org/10.1016/j.jclepro.2016.10.102

Dissanayake, D. M. K. W., Jayasinghe, C., & Jayasinghe, M. T. R. (2009). A comparative embodied energy analysis of a house with recycled expanded polystyrene (EPS) based foam concrete wall panels. Energy and Buildings, 135, 85–94. https://doi.org/10.1016/j.enbuild.2016.11.044

Dudzińska, A., & Kotowicz, A. (2015). Features of materials versus thermal comfort in a passive building. Procedia Engineering, 108, 108–115.

Đurović-Petrović, M. (2015). Experimental investigation of rockwool insulation hygrothermal properties related to material structure. Thermal Science, 19, 923–928. https://doi.org/10.2298/TSCI131216168D

Ebtehaj, I. H., Bonakdari, H., Zaji, A. H., Azimi, H., & Khoshbin, F. (2015). GMDH-type neural network approach for modeling discharge coefficient of rectangular sharp-crested side weirs. International Journal of Engineering Science and Technology, 18(4), 746–757. https://doi.org/10.1016/j.jestch.2015.04.012

Feidt, M. (2018). Finite physical dimensions optimal thermodynamics 1: Fundamentals (1st ed., pp. 1–41). Amsterdam: Elsevier.

Gopinath, K., Anuratha, K., Harisundar, R., & Saravanan, M. (2015). Utilization of saw dust in cement mortar & cement concrete. International Journal of Scientific & Engineering Research (IJSER), 6(8), 665–682.

Grabarz, R. C., Souza, L. C. L., & Parsekian, G. A. (2012). Theoretical analysis of thermal performance of clay and concrete masonry structural under various conditions. In 15th International brick and block masonry conference, Florianópolis, Brazil.

Hafed, S. (2017). Study of thermal insulation and some mechanical properties for hybrid composites (cement – wood sawdust). International Journal of Computation and Applied Sciences IJOCAAS, 3(2), 212–216.

Haik, R., Peled, A., & Meir, I. A. (2020). Thermal performance of lime hemp concrete (LHC) with alternative binders. Energy and Buildings, 210, 109740. https://doi.org/10.1016/j.enbuild.2019.109740

Halwatura, R. (2014). Performance of insulated roofs with elevated outdoor conditions due to global warming. Journal of Environmental Treatment Techniques, 2, 134–142.

Halwatura, R. U., & Jayasinghe, M. T. R. (2008). Thermal performance of insulated roof slabs in tropical climates. Energy and Buildings, 40(7), 1153–1160. https://doi.org/10.1016/j.enbuild.2007.10.006

Halwatura, R. U., & Jayasinghe, M. T. R. (2009). Influence of insulated roof slabs on air conditioned spaces in tropical climatic conditions—A life cycle cost approach. Energy and Buildings, 41, 678–686.

Handara, V., Illya, G., Tippabhotla, S. K., Shivakumar, R., & Budiman, A. (2016). Center for Solar Photovoltaics (CPV) at Surya University: Novel and innovative solar photovoltaics system designs for tropical and near-ocean regions (an overview and research directions). Procedia Engineering, 139, 22–31. https://doi.org/10.1016/j.proeng.2015.09.211

James, G., Witten, D., Hastie, T., & Tibshirani, R. (2017). An introduction to statistical learning (8th ed., pp. 244–255). Springer.

Karamanos, A., Hadiarakou, S., & Papadopoulos, A. (2008). Impact of temperature and moisture on thermal performance of stone wool. Energy and Buildings, 40(8), 1402–1411.

Khoukhi, M. (2018). Combined effect of heat and moisture transfer dependent thermal conductivity of polystyrene insulation material: Impact on building energy performance. Energy and Buildings, 169, 228–235. https://doi.org/10.1016/j.enbuild.2018.03.055

Kim, D., Kim, G., & Baek, H. (2016). Thermal conductivities under unsaturated condition and mechanical properties of cement-based grout for vertical ground-heat exchangers in Korea—A case study. Energy and Buildings, 122, 34–41. https://doi.org/10.1016/j.enbuild.2016.02.047

Leo Samuel, D., Dharmasastha, K., Shiva Nagendra, S., & Maiya, M. (2017). Thermal comfort in traditional buildings composed of local and modern construction materials. International Journal of Sustainable Built Environment, 6(2), 463–475.

Lin, B., & Liu, H. (2015). China’s building energy efficiency and urbanization. Energy and Buildings, 86, 356–365.

Madrid, M., Orbe, A., Carré, H., & García, Y. (2018). Thermal performance of sawdust and lime-mud concrete masonry units. Construction and Building Materials, 169, 113–123.

Mallik, F. H. (1996). Thermal comfort and building designing in tropical climates. Energy and Buildings, 23(3), 161–167. https://doi.org/10.1016/0378-7788(95)00940-X

Manni, M., Lobaccaro, G., Goia, F., & Nicolini, A. (2018). An inverse approach to identify selective angular properties of retro-reflective materials for urban heat island mitigation. Solar Energy, 176, 194–210. https://doi.org/10.1016/j.solener.2018.10.003

Meddage, D. P. P., & Jayasinghe, M. T. R. (2022). Use of EPS based light-weight concrete panels as a roof insulation material for NERD slab system. In R. Dissanayake, P. Mendis, K. Weerasekera, S. De Silva, & S. Fernando (Eds.), ICSBE 2020 (pp. 375–384). Springer.

Meng, X., Huang, Y., Cao, Y., Gao, Y., Hou, C., Zhang, L., & Shen, Q. (2018). Optimization of wall thermal insulation characteristics based on intermittent heating operation. Case Studies in Construction Materials, 9, e00188. https://doi.org/10.1016/j.cscm.2018.e00188

Meng, X., Luo, T., Wang, Z., Zhang, W., Yan, B., Ouyang, J., & Long, E. (2016). Effect of retro-reflective materials on building indoor temperature conditions and heat flow analysis for walls. Energy and Buildings, 127, 488–498.

Meng, X., Wang, C., Liang, W., Wang, S., Li, P., & Long, E. (2015). Thermal performance improvement of prefab houses by covering retro-reflective materials. Procedia Engineering, 121, 1001–1007.

Nandapala, K., & Halwatura, R. U. (2016). Design of a durable roof slab insulation system for tropical climatic conditions. Cogent Engineering, 3, 1196526.

Oluyamo, S., & Bello, O. (2014). Particle sizes and thermal insulation properties of some selected wood materials for solar device applications. IOSR Journal of Applied Physics (IOSR-JAP), 6(2), 54–58.

Powell, A. (2011). 370_07_SD01 Construction carbon calculator, electronic data set. Environment Agency, viewed 22 November 2020; https://data.gov.uk/data/contracts-finder-archive/download/355422/39ef8800-9ca6-43b3-b893-5b6399cf7374.

Progelhof, R. C., Throne, J. L., & Ruetsch, R. R. (1976). Methods for predicting thermal conductivity of composite systems: A review. Polymer Engineering & Science, 16(9), 615–625.

Rosas-Flores, J. A., & Rosas-Flores, D. (2020). Potential energy savings and mitigation of emissions by insulation for residential buildings in Mexico. Energy and Buildings, 209, 109698. https://doi.org/10.1016/j.enbuild.2019.109698

Rossi, B., Marique, A.-F., Glaumann, M., & Reiter, S. (2012). Life-cycle assessment of residential buildings in three different European locations, basic tool. Building and Environment, 51, 395–401. https://doi.org/10.1016/j.buildenv.2011.11.017

Sair, S., Mandili, B., Taqi, M., & El Bouari, A. (2019). Development of a new eco-friendly composite material based on gypsum reinforced with a mixture of cork fibre and cardboard waste for building thermal insulation. Composites Communications, 16, 20–24.

Sartori, I., & Hestnes, A. G. (2007). Energy use in life cycle of conventional and low-energy buildings: A review article. Energy and Buildings, 39(3), 249–257. https://doi.org/10.1016/j.enbuild.2006.07.001

Schiavoni, S., D’Alessandro, F., Bianchi, F., & Asdrubali, F. (2016). Insulation materials for building sector: A review and comparative analysis. Renewable and Sustainable Energy Reviews, 62, 988–1011. https://doi.org/10.1016/j.rser.2016.05.045

Streimikiene, D., Skulskis, V., Balezentis, T., & Agnusdei, G. P. (2020). Uncertain multi-criteria sustainability assessment of green building insulation materials. Energy and Buildings, 219, 110021. https://doi.org/10.1016/j.enbuild.2020.110021

Sun, Y., Wilson, R., & Wu, Y. (2018). A review of transparent insulation material (TIM) for building energy saving and daylight comfort. Applied Energy, 226, 713–729.

Tettey, U. Y. A., Dodoo, A., & Gustavsson, L. (2014). Effects of different insulation materials on primary energy and CO2 emission of a multi-storey residential building. Energy and Buildings, 82, 369–377. https://doi.org/10.1016/j.enbuild.2014.07.009

Vera, S., Pinto, C., Velasco, P. C., & Bustanmante, W. (2017). Influence of vegetation, substrate, and thermal insulation of an extensive vegetated roof on thermal performance of retail stores in semiarid and marine climates. Energy and Buildings, 146, 312–321. https://doi.org/10.1016/j.enbuild.2017.04.037

Wang, C., Zhu, Y., & Guo, X. (2019). Thermally responsive coating on building heating and cooling energy efficiency and indoor comfort improvement. Applied Energy, 253, 113506.

Wang, J., Liu, S., Meng, X., Gao, W., & Yuan, J. (2021). Application of retro-reflective materials in urban buildings: A comprehensive review. Energy and Buildings, 247, 111137.

Wijesena, G., & Amarasinghe, R. (2018). Solar energy and its role in Sri Lanka. International Journal of Engineering Trends and Technology (IJETT), 65(3), 142–148.

Yarbrough, D., Wilkes, K., Olivier, P., Graves, R., & Vohra, A. (2005). Apparent thermal conductivity data and related information for rice hulls and crushed pecan shells.

Yuan, J. H., Emura, K., Sakai, H., Farnham, C., & Lu, S. Q. (2016). Optical analysis of glass bead retro-reflective materials for urban heat island mitigation. Solar Energy, 132, 203–213.

Yuan, J., Farnham, C., & Emura, K. (2015). Development of a retro-reflective material as building coating and evaluation on albedo of urban canyons and building heat loads. Energy and Buildings, 103, 107–117.

Zhang, T., & Yang, H. (2018). Optimal thickness determination of insulating air layers in building envelopes. In Low carbon cities and urban energy systems. CUE2018-Applied energy symposium and forum.

Acknowledgements

Authors like to convey their sincere gratitude to the Sri Lanka Institute of Information Technology for facilitating experiments and research work. Further, we thank the reviewers for their constructive suggestions to improve the quality of the paper.

Funding

No funding was recieved to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they do not have any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Annexure

Annexure

Annex 01: Cost for different model houses

The construction cost for each model house was calculated. All prices are in Sri Lankan Rupees (LKR). size of the house is 0.9 × 0.9 × 0.9 m with an opening of 0.3 × 0.3 m. size of asbestos sheets was 1 × 1 m and the size of standard engineering bricks was 0.195 × 0.090 × 0.055 m.

Item no | Material | Unit price (LKR) | Quantity | Price (LKR) |

|---|---|---|---|---|

01 | Bricks | 12.50 | 350 bricks | 4375.00 |

02 | Cement bags | 950.00 | 0.8 bags | 760.00 |

03 | Sand | 16,000.00 | 0.15 cube | 2400.00 |

04 | Asbestos sheet | 2975.00 | 1/3 | 991.67 |

05 | Mason | 3000.00 | 0.7 days | 2100.00 |

Total price (LKR) | 10,626.67 | |||

Annex 02: Cost for the model with RR insulation

Item no | Material | Unit price (LKR) | Quantity | Price (LKR) |

|---|---|---|---|---|

01 | Bricks | 12.50 | 350 bricks | 4375.00 |

02 | Cement bags | 950.00 | 0.8 bags | 760.00 |

03 | Sand | 16,000.00 | 0.15 cube | 2400.00 |

04 | Asbestos sheet | 2975.00 | 1/3 | 991.67 |

06 | Diamond cut RR tape (white color) | 430.00 | 9 ft2 | 3870.00 |

05 | Mason | 3000.00 | 0.7 days | 2100.00 |

Total price (LKR) | 14,496.67 | |||

Annex 03: Cost for the model with sawdust insulation

Item no | Material | Unit price (LKR) | Quantity | Price (LKR) |

|---|---|---|---|---|

01 | Bricks | 12.50 | 350 bricks | 4375.00 |

02 | Cement bags | 950.00 | 1.55 bags | 1472.50 |

03 | Sand | 16,000.00 | 0.15 cube | 2400.00 |

04 | Asbestos sheet | 2975.00 | 1/3 | 991.67 |

05 | Saw dust | 30.00 | 5 kg | 150.00 |

06 | Mason | 3000.00 | 1.3 days | 3900.00 |

Total price (LKR) | 13,290.00 | |||

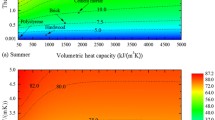

Annex 04: Solar radiation graphs

Solar radiation graphs for Colombo Sri Lanka were taken using the Metenorm application.

Solar radiation graph for Colombo

Annex 05: Thermal properties of various materials and their application

Name of material | Thermal conductivity (W/m K) | Thermal resistance (m2K/W) | Thermal diffusivity (m2/s) ×10−6 | Specific heat capacity (J/kg K) | Solar reflectance (albedo value) | Density (kg/m3) | Possible ways to use in a model house (insulation) |

|---|---|---|---|---|---|---|---|

Fiber glass (recycled) | 0.031 (Schiavoni et al., 2016) | 830 (Schiavoni et al., 2016) | 450 (Schiavoni et al., 2016) | Fix in windows | |||

Foam glass | 0.04 (Braulio-Gonzalo & Bovea, 2017) | 1000 (Braulio-Gonzalo & Bovea, 2017) | 110 (Braulio-Gonzalo & Bovea, 2017) | Fix in windows | |||

Stone wool | 0.033–0.040 (Karamanos, et al., 2008) | 800–1000 (Schiavoni et al., 2016) | 40–200 (Karamanos, et al., 2008) | Insulate in internal walls | |||

Cellulose | 0.037–0.042 (Schiavoni et al., 2016) | 1300–1600 (Schiavoni et al., 2016) | 30–80 (Schiavoni et al., 2016) | Insulate in internal walls by blown or damp sprayed | |||

Polyurethane foam (PIR) | 0.0236 (Biswas et al., 2016) | 1300–1450 (Schiavoni et al., 2016) | 29 (Biswas et al., 2016) | Insulate between walls | |||

Expanded polystyrene (EPS) | 0.041 (Meng et al., 2018) | 1280 (Meng et al., 2018) | 22 (Meng et al., 2018) | Insulate between walls | |||

Silica aerogel | 1.010–0.030 (Casini, 2016) | 1000 (Schiavoni et al., 2016) | 5–200 (Casini, 2016) | Sandwiched within double glazed window units | |||

Concrete block | 0.435 (Alausa et al., 2013) | 2.299 (Alausa et al., 2013) | 1.022 (Alausa et al., 2013) | 2100–2300 (Grabarz et al., 2012) | Construct model house structure | ||

Laterite mud | 0.523 (Alausa et al., 2013) | 1.912 (Alausa et al., 2013) | 1.126 (Alausa et al., 2013) | Construct model house structure | |||

Cement mortar | 0.840 (Meng et al., 2018) | 840 (Meng et al., 2018) | 1860 (Meng et al., 2018) | Apply between two bricks or blocks as a binding agent | |||

Silicate blocks (0.25 m) | 0.41 (Dudzińska & Kotowicz, 2015) | 880 (Dudzińska & Kotowicz, 2015) | 1400 (Dudzińska & Kotowicz, 2015) | Construct model house structure | |||

Cellular concrete blocks | 0.17 (Dudzińska & Kotowicz, 2015) | 840 (Dudzińska & Kotowicz, 2015) | 600 (Dudzińska & Kotowicz, 2015) | Construct model house structure | |||

Solid brick | 0.77 (Dudzińska & Kotowicz, 2015) | 880 (Dudzińska & Kotowicz, 2015) | 1800 (Grabarz et al., 2012) | Construct model house structure | |||

Rock wool | 0.04 (Rosas-Flores & Rosas-Flores, 2020) | 50–80 (Đurović-Petrović, 2015) | Insulate in ceiling | ||||

Cork | 0.045 (Barrau et al., 2014) | 1500–1700 (Schiavoni et al., 2016) | 110–170 (Schiavoni et al., 2016) | Insulate in ceiling | |||

Sawdust | 0.038–0.050 (Schiavoni et al., 2016) | 1900–2100 (Schiavoni et al., 2016) | 50–270 (Schiavoni et al., 2016) | Use as a cement, sawdust composite mixture and apply in the external wall as a plaster | |||

Extruded polystyrene | 0.0320 (Biswas et al., 2016) | 1450–1700 (Schiavoni et al., 2016) | 30 (Biswas et al., 2016) | Insulate in outer or internal walls | |||

Phenolic foam | 0.018–0.024 (Schiavoni et al., 2016) | 1300–1400 (Schiavoni et al., 2016) | 40–160 (Schiavoni et al., 2016) | Insulate in internal walls | |||

Hempcrete (1:1) | 0.074–0.103 (Dhakal et al., 2017) | 233–388 (Dhakal et al., 2017) | Insulate in external walls | ||||

Hemp fiber | 0.038–0.060 (Schiavoni et al., 2016) | 1600–1700 (Schiavoni et al., 2016) | 20–90 (Schiavoni et al., 2016) | Insulate in external walls | |||

Glass wool | 0.04 (Rosas-Flores & Rosas-Flores, 2020) | 900–1000 (Schiavoni et al., 2016) | 15–75 (Schiavoni et al., 2016) | Insulate in ceiling | |||

Sheep wool | 0.038–0.054 (Schiavoni et al., 2016) | 1300–1700 (Schiavoni et al., 2016) | 10–25 (Schiavoni et al., 2016) | Insulate in internal walls | |||

Recycled cotton | 0.039–0.044 (Schiavoni et al., 2016) | 1600 (Schiavoni et al., 2016) | 25–45 (Schiavoni et al., 2016) | Apply between walls | |||

Straw bale | 0.052–0.06 (Costes et al., 2017) | 600 (Schiavoni et al., 2016) | 75–90 (Costes et al., 2017) | Insulate in internal walls | |||

Rice hulls | 0.046–0.566 (Yarbrough et al., 2005) | 154–168 (Yarbrough et al., 2005) | Insulate in external walls | ||||

Retro-reflective tape (RR) | 2.026 (Meng et al., 2016) | 1324 (Meng et al., 2016) | 0.81 (Yuan et al., 2015) | 307 (Meng et al., 2016) | Insulate in external walls | ||

Clay tile | 0.7106 (Ariyadasa et al., 2015) | 1790 (Ariyadasa et al., 2015) | Provide as a shading material for model house | ||||

Asbestos sheet | 0.4733 (Ariyadasa et al., 2015) | 1630 (Ariyadasa et al., 2015) | Provide as a shading material for model house | ||||

Cement tile | 0.5619 (Ariyadasa et al., 2015) | 2160 (Ariyadasa et al., 2015) | Provide as a shading material for model house |

Rights and permissions

About this article

Cite this article

Dharmasena, P.M., Meddage, D.P.P. & Mendis, A.S.M. Investigating applicability of sawdust and retro-reflective materials as external wall insulation under tropical climatic conditions. Asian J Civ Eng 23, 531–549 (2022). https://doi.org/10.1007/s42107-022-00440-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42107-022-00440-0