Abstract

Over 13% of the global population (most of which are rural communities) still lack access to electricity. A typical resolution to this would be to generate more electricity from existing power generation infrastructure. However, the urgency to meet net-zero global greenhouse gas emissions means that this resolution may not be the way forward. Instead, policymakers must consider decarbonization strategies such as renewable energy systems to generate more electricity in rural communities. As policymakers aim to encourage renewable energy generation, existing power plant operators may not share the same perspective. Operators typically wish to ensure profit margins in their operations as decarbonization efforts may be costly and reduce the profit. A balance must be struck between both parties so that the energy sector can continue to meet rising energy demands and decarbonization needs. This is a classic leader–follower situation where it involves the interplay between policymaker (as energy sector regulator) and industry (as energy sector investor). This work presents a bi-level optimization model to address the leader–follower interactions between policymakers and industry operators. The proposed model considers factors such as total investment, co-firing opportunities, incentives, disincentives, carbon emissions, scale, cost, and efficiency to meet electricity demands. To demonstrate the model, two Malaysian case studies were evaluated and presented. The first optimized networks is developed based on different energy demands. Results showed that when cost was minimized, the production capacity of the existing power plants was increased and renewable energy systems were not be selected. The second case study used bi-level optimization to determine an optimal trade-off $ 1.4 million in incentives per year, which serves as a monetary sum needed by policymakers to encourage industry operators to decarbonize their operations. Results from the second case were then compared to the ones in the first.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

According to the United Nations (United Nations n.d), about 13% of the global population currently lack access to electricity. This gap is commonly associated with underdevelopment in rural areas (de Coninck et al. 2018). Ideally, this would prompt the need to ramp up electrification in these areas using fossil fuel-based power plants. However, the increase in electricity generation and demand must be managed within the constraints pledged to reduce greenhouse gases (GHG) emission (Handayani et al. 2017). Actions to meet these pledges were further refined in 2021 at the 26th Conference of Parties (COP26), where actions such as moving away from fossil fuels delivering on climate finance and stepping up support climate change adaptation were agreed (United Nations 2022). With these points in mind, the electrification of rural areas should rely heavily on indigenous renewable energy resources to avoid large increases in generation from fossil fuels (International Energy Agency (IEA) 2022) or import of renewable energy sources. The progressive electrification of developing rural regions should also integrate a broader energy sector decarbonization program (Papadis and Tsatsaronis 2020). The challenges of implementing modern electricity for rural areas in a carbon-constrained world would be the adaptation of renewable resources following institutional, technical, and economic constraints (de Coninck et al. 2018). The presence of multiple sustainability dimensions and multiple stakeholders makes planning of rural electrification an inherently complex task. Optimization models are thus expected to play an important role in facilitating rural electrification planning in the context of decarbonization targets (Akbas et al. 2022).

Since actual investment decisions in the energy sector are undertaken by industry, policymakers should develop subsidies and other economic incentives to promote the growth of renewable energy in rural areas. In addition, mature renewable technologies such as biomass (Patrizio et al. 2021), hydropower (Kumar et al. 2021), and wind energy (Zhang et al. 2021) have higher opportunities to be implemented compared to immature renewable technology (Linking renewable energy to rural development executive summary brief for policy makers n.d.). Selection of mature technology will reduce the technical constraints of implementation for rural areas. Dispatchability is also important in regions with poor grid connectivity or energy storage capacity (Baik et al. 2022). Local economic development strategies can also be embedded to reflect the potential of renewable energy by creating a regional energy plan that can estimate the overall cost of implementation and GHG emissions reduction while satisfying rural energy demand (Linking renewable energy to rural development executive summary brief for policy makers n.d.).

Regional energy planning is an integrated management of energy generation and consumption based on the economic development, environmental, and social resources within an area (Shah et al. 2020). Regional energy planning models are typically developed via mathematical programming (MP), which specify the optimization of a specific function (i.e., minimizing emissions and maximizing efficiency) subject to constraints that reflect real-life conditions in an algebraic form (Chen and Zhu 2019). Solving the MP would then produce a result that can be interpreted as the optimal design of an energy system (Akbas et al. 2022). This solution can support decision-making by identifying how investments should be allocated to meet energy demand under previously specified restrictions. Using MP models, effective regional energy plans with a focus on investment in renewable energy technologies and policy support for renewable energy can be developed within resource and emission limits (Kwon et al. 2020).

In recent years, regional energy planning models that consider investment in renewable energy technologies have been widely reported. Han and Kim (Han and Kim 2019) proposed a method to analyze strategic investment for renewable energy supply systems in Korea. This method employs a network optimization model using MILP to determine the best investment timing. Besides, Deveci and Guler (Hartono et al. 2020) established a framework to ascertain an economical energy plan to encourage expedited funding of renewables in the Turkish market. A framework for two-step multiobjective optimization has been done to select a minimized levelized cost of energy plan with maximized short-term electrical generation. Aside from that, Kozlova and Collan (Deveci and Güler 2020) have evaluated renewable energy investment attractiveness for Russia from an investors’ perspective. An indicator for renewable energy investment attractiveness created a policy framework with cross-regional analysis. Furthermore, (Kozlova and Collan 2020) developed a multi-actor multi-objective regional energy planning method for optimal funding. The method merged multi-objective optimization with the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) to determine optimal energy investments. In addition, Wang et al. (Wang et al. 2020) presented a model of bi-level decentralized optimization for an integrated energy system to curtail environmental and energy impacts. The regional integrated energy planning model was used for energy management in China with low-priced energy costs and an optimal system economy. Koponen and Net (Wang et al. 2019) have considered a Pareto optimal solution for robust renewable energy investment. Climate change mitigation following the Paris Agreement and minimized levelized cost of energy were considered in this model. Kwon et al. (Kwon et al. 2020) developed a bi-level MP model to optimize energy sector investments considering demand and resource constraints. Unlike centralized planning formulations, their game theoretic approach accounted for the profit-maximizing behavior of individual firms.

These papers presented comprehensive regional planning models to address the lack of investment in renewable energy. However, they have not considered policy support for renewable energy. Policy support is important as it will facilitate more involvement of investors in renewable energy generation (Koponen and Net 2021). Several regional planning models were developed in the past based on renewable energy policy support. Firstly, (Liu 2015) created a multiregional power system planning model to forecast time-based demand and renewable resource fluctuation. Scenario analysis was performed in Southwest China to approach uncertainties in carbon tax and power substitution policy. Besides, (Li et al. 2020) proposed a regional planning method for a robust low-carbon electricity system in Shandong Province, China. The model was developed through interval multistage stochastic robust programming with complex policy uncertainties and carbon capture storage integration. (Ji et al. 2020) proposed a study that extracts optimal policy support for renewable energy technologies in China. A dynamic programming model was accomplished to extract policy support for renewable energy technologies that is optimal. Furthermore, (Ding et al. 2020) proposed a cross-regional integrated energy system model with renewable resources that integrates a time constraint. This model also considers long-term fluctuations in energy prices and economic policy for Yangzhong City, China. (Lei et al. 2020) used a bi-level optimization model for technology selection. This considers the policymakers’ financial incentives for renewable energy support to reduce overall carbon emissions. (Aviso et al. 2021) developed a graph-theoretic approach to solving a special class of Stackelberg games, where policies in the form of technology choice restrictions are used to induce favorable decarbonization investments with negative emission technologies.

The above-mentioned papers are useful regional energy planning models which have covered aspects such as investments, policy support, involvement of multiple stakeholders, and rural electrification. These aspects are summarized in Table 1. As indicated in Table 1, previous studies did not integrate these aspects in their regional energy planning models. To develop more realistic and inclusive candidate solutions, all the above aspects must be integrated into energy planning models. If the perspectives of multiple stakeholders are not considered, results obtained from energy planning models may be bias to a specific decision-maker’s preference. For example, policymakers may wish to opt for decisions that fulfill their objectives, which may differ from those of industry. Decision-makers from government would aim to decarbonize the energy sector but those in industry will look to secure their financial returns. Therefore, a trade-off or compromise between these perspectives must be determined, especially when both decarbonization and rural electrification are considered simultaneously. This is where cooperative group decision-making such as game-theoretic approach is required (Tan et al. 2021) (Kalashnikov et al. 2015). Table 1 suggests that a few studies presented game-theoretic models but such studies were not applied in the context of rural electrification. These gaps serve as the motivation for this paper. This paper develops an MP model to aid in regional planning for rural electrification using a novel Stackelberg game framework that accounts for government-industry interplay. This requires the consideration of investment in renewable energy technologies and policy support for renewable energy.

The rest of this paper is organized as follows: “Problem Statement” presents a formal problem statement for this work. “Methodology” will provide a detailed description of the methodology. The methodology is then applied to a case study in “Case Study.” Results from the case study are then discussed and analyzed in “General Implication for Decarbonization.” Lastly, conclusions and future work are drawn in “Conclusion.”

Problem Statement

Given that policy-makers are looking to achieve carbon emissions reductions, a set of power plants i ϵ I in a given region (as shown in the general superstructure in Fig. 1) is considered. Each power plant i has unique fuel consumption requirements, efficiency, co-firing limits, costs, and emissions. In addition, each plant is operated by operators with individual interests to remain cost-effective while reducing carbon emissions. Herein lies a problem where conflicting objectives among stakeholders (i.e., policy-makers and operators) are present. The objective of this work is to determine a trade-off between the policy-maker’s goal to reduce emissions in the region and the operators’ goal to remain cost-effective. The policy-maker may provide incentives or disincentives to influence the operators to adjust their operations to meet the policy-makers’ goal. The following section provides a detailed account of the methodology used to determine this trade-off.

Methodology

The methodological framework used in this work is illustrated in Fig. 2. Note that the methodology is categorized into four stages: superstructure development, data collection, mathematical model development, and analysis of results. The following subsections will give further detail into each step of the methodology.

Superstructure Development and Data Collection

As shown in Fig. 2, the first step of the methodology is superstructure development. A superstructure is a diagram used to represent all the possible configurations of a system (including component processes and interconnections). It shows in graphical form the same features that are reflected in an optimization model. In this work, existing and potentially new plants (alongside their possible interconnections) are presented using a superstructure. The next step would be to collect data for all these plants. Data collection is done to acquire data on plant technology, efficiency, capacity, carbon emission factor, and operations and maintenance (O&M) cost factors for current implemented plants. Similar data is collected for new renewable plants that have yet to be constructed. These new renewable plants also require capital cost factors as they have yet to be implemented. Using the data collected through this step in the methodology, a mathematical model is developed.

Bi-level Model

Mathematical model development essentially refers to developing a set of equations that represent or model the behavior of the technologies included in the superstructure and use it to optimize a specific optimization objective function. In this work, the presence of two decision-makers, each with its own objective, needs to be reflected in the model. To recommend an optimal regional energy plan with these criteria, conventional models will not appropriately represent real-world industrial energy systems with several decision-makers (Dempe and Zemkoho 2020). However, a bi-level model can be used to represent a noncooperative game with two players classified as the leader and the follower. Unlike a bi-objective optimization model where a solution can be reached simply by indicating the preference between objectives, bi-level optimization is an optimization problem nested within another optimization problem. Each decision-maker or player controls its own set of variables, whose chosen values determine the objective functions of both players. The resulting Stackelberg game seeks a solution where the leader chooses a strategy that optimizes its objective in anticipation of the follower’s rational reaction (i.e., the follower optimizes its objective function subject to the leader’s prior decision). The leader’s optimization problem is constrained by the follower’s anticipated rational reaction. This solution is called the Stackelberg strategy and is often applied to government-industry interactions. Bi-level models are generally computationally challenging and cannot be solved directly with conventional optimization algorithms (Yavari and Ajalli 2021).

In this work, the bi-level optimization model is formulated as follows. The leader is the policy-maker while the plants are the followers. The leader’s objective is to minimize the total carbon emissions, TTLCE (Eq. 1) which is determined using Eq. 2. The total carbon emissions from all plants is expressed in ton of carbon dioxide equivalent per year (tCO2 eq./year) and calculated based on the amount of fuel source r utilized in plant i along with the corresponding carbon emission factor, \({\mathrm{CE}}_{r}^{\text{fact}}\). In this work, renewable fuels are assumed to have minimal carbon emissions which can be assumed as zero in the model. Therefore, \({\mathrm{CE}}_{r}^{\text{fact}}\) values for renewable fuels is taken as zero. Similarly, plants with the option of co-firing renewables will only exhibit emissions from its fossil fuel share.

The leader’s objective is subject to the follower’s objective function of minimizing total cost (Eq. 3). The follower’s objective is further subject to the constraints given in Eqs. 4–15.

The follower’s variables are Fr,, Pi, bi, br,, OPi, and CAPi. Fr,i represents the flow of fuel source r utilized in plant i. Fr,i is limited by the available supply of fuel source r, \({\mathrm{F}}_{r}^{\mathrm{AV}}\) as seen in Eq. 4. The energy from fuel source r can then be utilized to generate power in plant i (expressed by Pi) with efficiency Ei, as shown in Eq. 5. The operation of plant i is dictated by the operating range shown in Eq. 6. Here, a binary variable bi is used to indicate each plant’s ON/OFF status. If a given plant i is selected, the binary variable would take the value of one. This would then activate the minimum and maximum operating range given by \({\mathrm{F}}_{i}^{\mathrm{min}}\) and \({\mathrm{F}}_{i}^{\mathrm{max}}\), respectively. \({\mathrm{F}}_{i}^{\mathrm{max}}\) is used to express the plant’s maximum operating limit typically given by its available capacity. \({\mathrm{F}}_{i}^{\mathrm{min}}\) describes the minimum flow required for a plant to feasibly operate. Meanwhile, if plant i is not selected, the binary variable will be zero to indicate that the plant is not in operation. For plants with the option of co-firing, the co-firing percentage must be considered. This is modeled via Eq. 7. Equation 7 introduces a separate binary variable br,i for plant i. Binary br,i indicates the presence of fuel source r in the co-firing of plant i. Fuel source r in this equation is particularly aimed at fossil fuel power plant co-firing biomass fuel. If plant i is selected for co-firing with fuel source r, then the binary variable, br,i, will take the value of one. This would activate the minimum and maximum co-firing percentage for fuel source r in plant i (i.e., \({\mathrm{R}}_{r,i}^{\mathrm{min}}\) and \({\mathrm{R}}_{r,i}^{\mathrm{max}}\)). The upper limit (i.e., \({\mathrm{R}}_{r,i}^{\mathrm{max}}{\mathrm{F}}_{i}^{\mathrm{max}}\)) in Eq. 7 essentially refers to the maximum percentage of the total capacity in plant i that is available for cofiring fuel source r and vice versa. If the range in Eq. 7 is not met, br,i would take the value of zero and it deactivates the range. This would mean that plant i is selected to use a single fuel source instead of co-firing.

The power generated by each power plant i is then directed to a specific substation s as shown in Eq. (8). Each substation s is responsible for distributing the power generated to users in its vicinity. Therefore, the demand for each substation s is expressed in Eq. 9.

The cost of the entire system is determined based on the O&M as well as capital costs. The O&M cost OPi in $/year of current power plants and new renewable plants both utilize Eq. 10. The O&M cost of any one plant would be equal to the O&M cost factor \({\mathrm{OP}}_{i}^{\text{fact}}\) in $/kW, which is found during data collection, multiplied by the power generated in a year Pi, as shown in Eq. 10. New renewable plants that are chosen will have an added capital cost in $/year. The annualized capital cost of new renewable plants CAPi would be equal to the capital cost factor \({\mathrm{CAP}}_{i}^{\text{fact}}\) in $/kW, found during data collection, multiplied by the power generated Pi and the annualizing factor AFi (see Eq. 11). Note that the value for AFi is determined based on the lifetime of a given plant and the interest rate considered. These values would depend on the data available to the decision-maker. Equation 11 however, provides a generalized concept on how AFi can be included in the model. It is worth mentioning that the capital cost does not account for the cost of cable connections within the region. It was assumed that this model is used only for strategic planning purposes and the cost of cable connections will be considered during the tactical planning stage. The total O&M costs of existing power plants and new renewable plants can be determined via Eq. 12. Equation 13 shows the total annualized capital costs of new renewable plants. Equation 14 computes the difference between the total carbon emissions generated and the target carbon emissions (i.e., MCE) defined by policymakers. If the distance is a positive value, it would suggest that the emissions are larger than the target carbon emissions. Therefore, CTax will act as a carbon tax that plants need to pay for emitting higher than the set target. Meanwhile, if the difference results in a negative value, it means that total emissions are below the target. As a result, CTax functions as monetary subsidies or incentives for the plants and subsequently reduces overall combined cost in Eq. 15.

There are different approaches to solving bi-level optimization problems, ranging from deterministic techniques (based on reformulation as equivalent single-level problems) to various heuristic procedures (Bard 1998). One class of techniques relies on the use of interactive, multistep heuristic algorithms to determine approximate Stackelberg solutions (Sinha et al. 2018). These procedures generally involve identifying the ideal solutions of each player and then determining a compromise solution in the final stage (Emam 2006). The interactive heuristic algorithm provided in Fig. 3 describes how an approximate solution is determined for this bi-level optimization problem (Zhang et al. 2016).

The first stage represents the leader’s single-level ideal solution (i.e., the solution if the leader could control the decisions of the follower). In the context of the power industry, the objective function of the leader is to minimize total carbon emissions (Eqs. L.1–L.14 in Supplementary Information) with no consideration of the follower’s objective, assuming that the leader directly controls the follower’s variables. The corresponding TTLCE value obtained from the leader stage would then function as the lower limit for total carbon emissions, CEmin. The corresponding ideal values of the leader’s variables are also identified for later use.

The second stage then seeks a solution that optimizes the follower’s objective function, without considering the leader’s objective and assuming that the follower also directly controls leader’s variables. Thus, the follower’s objective function is to minimize the combined cost, TTLCOST of power plants (Eq. F.1–F.14 in Supplementary Information). The value obtained for TTLCE in the follower stage is used as the upper limit for total carbon emissions, CEmax. The follower’s ideal values of the leader’s variables are also identified for later use.

Following this, the final stage of the interactive solution algorithm is to find an approximate Stackelberg solution bounded by the ideal solutions of the two players (Zhang et al. 2016). In this stage, an auxiliary single-level model is developed using the ideal solutions obtained from the previous stages. The auxiliary model is written as follows:

As shown, the objective function for this stage (i.e., Eq. 16) is the same as Eq. 1. The auxiliary model also has an additional constraint, i.e., Eq. 30. The CEmin and CEmax values in Eq. 30 are obtained in the leader’s and follower’s stages, respectively. However, this constraint forces the follower’s final solution to be similar to the leader’s ideal, within an allowable margin of deviation. The parameter φ in Eq. 30 is the fraction of CEmax the leader would like the followers to abide by.

It is important to note that Eq. 28 is the sum of O&M costs, annualized capital costs, and the potential incentives or disincentives obtained. The potential economic incentives or disincentives can be imposed by the policymaker to influence the decision of the followers. In addition, this work did not include other cost elements such as initial cost, net present cost, and electricity cost. Instead, it focused on basic cost variables such as total annualized cost and O&M costs. This is because such costs are commonly used to evaluate the feasibility at the preliminary stage of planning. In other words, if the network is deemed feasible at the preliminary evaluation stage, further studies can be conducted in the future to analyze the impact of net present cost and electricity cost in detail. If the network is not feasible based on such costs, the subsequent stage of analysis will be discarded.

Analysis of Results

The final step in the methodology would be to analyze the results produced by the optimization model. Analyzing the optimization model’s results would allow the determination of whether the results provided are feasible to be recommended as the optimal solution. If the results are deemed to be infeasible, the data collection will be revisited. If there are no issues identified in the data collected, the next steps in the methodology will be revisited accordingly. The “Case Study” section presents a case study to demonstrate the methodology discussed in the Methodology section. The purpose of the case study is to illustrate application of the proposed mathematical model and to discuss possible insights as well as implications.

Case Study

Sarawak is the largest state located in the east of Malaysia. Currently, the rural electrification of Sarawak is at 93%, with 22,000 households still inaccessible to the state grid due to the remote locations (Sinha and Sinha 2004). The remoteness of these locations poses a challenge in the cost of connectivity to the grid (Sarawak Energy Berhad 2020). On the other hand, Sarawak is a region with abundant renewable energy resources that can be utilized and developed to produce clean and accessible energy. Increasing power production using renewable resources would also assist in reducing carbon emissions and mitigating climate change impact (Khengwee et al. 2017). To date, a total of 20.8 thousand GWh of renewable energy has been generated for the state via hydropower and solar energy (IPCC 2018). Besides, many untapped biomass resources exist in the region, such as agricultural wastes (Sarawak Energy Berhad 2018). The deployment of centralized power plants would require high costs for connectivity in rural areas. Therefore, it would be critical to consider regional renewable energy resources for decentralized electrification instead of centralized power plants. However, several factors need to be addressed before upscaling renewable energy generation in the region.

Firstly, tax exemptions and subsidies can be implemented to reduce the overall cost of renewable energy projects (Then 2018). This will provide the region an opportunity to reduce the cost of renewable energy projects until they become more cost attractive (Sarawak Government(2021)). Although investment tax allowances and exemptions are available for green technologies, only selective renewable resources such as solar and hydropower benefit from these tax allowances and exemptions (The Borneo Post 2020). On the other hand, large infrastructure projects and mega-hydro dams often take over a decade to complete (Conventus Law 2020). This then increases the need for low-cost, reliable, and renewable electricity (Kammen 2019). Renewable energy technologies that use biomass and solar power can contribute to the generation mix in Sarawak for low-cost and more sustainable sources of power (Kammen 2019). Hence, suitable investment in other renewable energy sources is required.

Apart from this, increased policy support for renewable energy will allow renewable energy generation to thrive further in the region. Malaysia’s National Green Technology Policy focuses on urban areas and can be extended to rural areas (Shirley and Kammen 2015). For instance, tariffs in the region can be explored for renewable energy technologies (Shabdin and Padfield 2017). Tax exemptions and tariffs for eliminating emissions to the atmosphere would also be a financial incentive to develop renewable energy technologies (Gomez 2018). Besides, renewable energy technologies that are not mature can be given priority for financial investment (Gomez 2018). These examples offer great opportunities for the region to extend its renewable energy potential to rural communities. Regional energy planning is important to realize these opportunities as it allows policymakers to analyze optimal policy measures to induce green investments by industry and to enable low-carbon rural electrification. Therefore, the objective of this case study is to develop a regional energy planning model that will aid in determining insights for such policy measures.

The first step in developing the model is the superstructure. Figure 4 below shows the developed superstructure of power plants that generate power in districts in Sarawak. This superstructure also considers the 11 substations currently being used in Sarawak.

Superstructure of Sarawak Energy Grid (Zakaria et al. 2019)

The plants already existing and operating in Sarawak are diesel, coal, natural gas, and hydroelectric power plants (as indicated in Fig. 4). These plants supply power to specific substations around Sarawak which will then be transmitted and distributed to sub-transmission customers, primary customers, and secondary customers (Sarawak Energy Berhad (2018)). The new renewable power plants powered by biomass and solar were included in the superstructure to be considered for increased rural electrification. The possibility of co-firing palm oil-based biomass was also considered for coal-powered plants in Fig. 4. Tables 2 and 3 show the power plant technology and cost factors for existing plants. As power plants in Tables 2 and 3 are existing and commissioned facilities in the region, capital costs were not included the analysis. Meanwhile, Table 3 shows the O&M and capital cost factors for new renewable plants that could potentially be implemented.

As mentioned earlier, coal power plants can implement co-firing with palm oil-based biomass (Walker et al. 2020). However, this would give a separate additional O&M cost and capital cost required to modify the coal power plants for co-firing operations. The maximum capacity of plants, operational carbon emission factors, and average energy efficiency data were obtained from Sarawak Energy’s 2018 Sustainability Report (Darmawan et al. 2017). Table 4 shows the data collected for power plants currently operating, whereas Table 5 shows data for new renewable plants. Note that the emission factors shown in Table 4 are empirical emissions (i.e., emissions noted during operation) of the existing power plants in Sarawak.

Based on the data provided in Tables 4 and 5, the regional energy planning model is developed. This is done using the steps described in “Bi-level Model,” coded in a commercial optimization software, i.e., LINGO v18 and solved using the Branch-and-Bound algorithm. Note that the proposed methodology in “Methodology” is flexible and can be applied in other commercially available optimization software. The developed model is then subjected to two case studies to demonstrate its applicability. The first case study (i.e., Case Study 1) is aimed at determining optimal networks that provide investments in renewable energy technologies. The objective function considered for Case Study 1 was the minimization of total costs. This case study then evaluates and compares optimal networks from three scenarios. The first scenario considered power demands for business-as-usual operations (i.e., 4,100 MW). The second scenario extended the analysis by considering additional 171 MW demand from rural electrification (i.e., 4,271 MW total demand). The third scenario analyzed a situation where Sarawak’s projected energy demand is expected to rise to 5,600 MW by 2026, including the previous 171 MW rural electrification demand (Walker et al. 2020). This would help provide sustainable and reliable electricity for over 22,000 households in the rural regions (Sarawak Energy Berhad (2018)). The unelectrified rural areas in Sarawak are mostly located in Kapit, Sarikei, Miri, and Limbang districts which correspond to substations S5, S6, S7, and S10 (Sarawak Energy Berhad (2018)). Therefore, constraints to ensure total rural electrification have been provided in the model as seen in Table 6.

It is worth noting that the demands shown in Table 6 include the power demands for rural electrification and the power demands currently being serviced in rural regions. Based on this, the developed model will be optimized to determine which of the 29 current power plants in Sarawak (powered by diesel, coal, natural gas, and hydropower resources) is needed to generate power for power demands in Table 6. Some of these plants may operate below their maximum capacity at the present time and, therefore, may some unused capacity to spare for meeting the demands stated previously. Moreover, the option of co-firing current coal power plants with biomass has been included in the model. If these plants are unable to meet the demands, the model will consider the potential of 4 new biomass plants (i.e., Plants 30, 31, 32, and 37) and 4 solar power plants (i.e., Plants 33–36). Carbon emission constraints are not considered for this case.

Case Study 2 looks at the policy support needed to achieve 10% carbon emission reduction from business-as-usual operations in the region to meet increased demands (i.e., 5,600 MW). This is achieved using the bi-level optimization strategy explained in “Analysis of Results.” The monetary results from Case Study 2 will then indicate how much policy support would be required to induce green investments in the region. The results from Case Study 1 and 2 are described further in the following sub-sections. These subsections describe the economic analysis, corresponding emissions, and optimal networks obtained for each case study.

Case Study 1

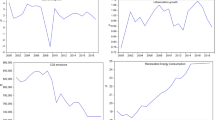

The results of Case Study 1 are summarized in Fig. 5. The objective function for Case Study 1 was to minimize the total costs for all plants. The results in Fig. 6 show the TTLOP for scenarios (1) power demands in 2020 (i.e., 4,100 MW), (2) increased demand without rural electrification in 2020 (i.e., 4,271 MW), and (3) increased demands from rural electrification by 2026 (i.e., 5,600 MW). As shown, the total costs for the first, second, and third scenarios are $125 million/year, $132 million/year, and $205 million/year, respectively.

Summary of Case Study 1 optimization results

Figure 5 also shows that the power is generated mostly from hydropower plants, followed by coal and natural gas for the first two scenarios, whereas the third scenario has a small amount of power generated from diesel power plants to fulfill the large energy demand. The third scenario utilized a small amount of power generated from diesel as it had a lower O&M cost factor and high energy efficiency than other power plants. Besides that, the total carbon emissions are 0.5, 0.7 and 1.9 million tCO2 eq./year. The carbon intensity for scenarios 1, 2, and 3 is 0.00012, 0.00016, and 0.00034 million andtCO2eq/MW respectively. Figure 6 below shows the optimal network for the third scenario.

The network in Fig. 6 shows the plants chosen are the ones that are currently operating. These include power plants using diesel, coal, natural gas, and hydropower resources. No policies were included in the total combined cost calculation for Case Study 1; therefore, conventional power plants already operating in Sarawak were selected to avoid the capital costs of new renewable plants. Hence, no new renewable plants were chosen to achieve the objective function of minimizing total combined cost. As a result, the total combined cost then only consisted of the overall O&M costs of the conventional power plants. However, it is worth noting that the distance between energy resources and power plants was not considered in this analysis. This is because the preliminary planning performed is focused at the strategic level where initial feasibility is investigated. Insights from this will then be used in the network design stage, where network optimization is done considering distances and detailed costing.

Case Study 1 was aimed at achieving the first objective of creating optimal networks that provide investments in renewable energy technologies. It was found that no investments were made in new renewable plants. This is because the additional capital cost for renewable plants is not required when some fossil fuel plants may operate lower than their maximum capacity. Hence, new renewable plants were not selected when minimizing the total combined cost of power plants. This, however, showed an increase in overall carbon emissions following the increase in power generated. This is attributed to the usage of more conventional power plants such as coal, diesel, and natural gas to meet the increasing power demand of the region. Figure 7 shows the carbon emissions and total cost for each scenario in Case Study 1.

As shown, the first scenario provides the lowest total costs of plants and the lowest carbon emissions produced as it relies only on hydropower, coal, and natural gas plants. The second scenario includes more power produced from more coal power plants than the first scenario. This also presents an increase of 5.6% in O&M cost and a 30% increase in total carbon emissions compared to the first scenario. The third scenario includes more hydropower, coal, natural gas, and even diesel power plants to meet the increased energy demand (including rural electrification) by 2026. This presented an increase of 64% in O&M cost and a 262% increase in total carbon emissions compared to the first scenario. This is due to an increase in overall power generation. Since the objective of this optimization model is to minimize total cost, the first and second scenarios selected power plants with the highest energy efficiency and lowest O&M cost factors. The third scenario prioritized low to average energy efficiencies and O&M cost factors. All three scenarios showed that the all plants were required to operate at their maximum capacity. Only one coal plant (C19) did not utilize full capacity for the first two scenarios as the demand was already met using other plants with lower costs and higher efficiencies. As for the third scenario, only one diesel plant (D11) did not utilize its full capacity for the same reason. Results from the third scenario were compared with results obtained in Case Study 2.

Case Study 2

As mentioned previously, Case Study 2 used bi-level optimization to determine the optimal policy support strategy for increasing green investments and meeting increased demands from rural electrification by 2026 (i.e., 5,600 MW). It is worth noting that the CTax value used for this case study is $600 per tCO2 eq. This is considered a financial incentive for renewables if the value obtained is negative and acts as a financial disincentive for when carbon emissions released do not achieve the 10% carbon emission reduction when the value is positive (Sarawak Energy Berhad (2017); Joshi 2021).

The results of Case Study 2 for the leader, follower, and bi-level stages can be seen in Fig. 8. The objective function in the leader stage was to minimize total carbon emissions. This produced a total combined cost of $404 million/year at this stage. From this combined cost, $3 million/year is attributed to the financial incentives proposed for the Sarawak government to provide. Doing this will reduce the carbon emissions by 14% compared to the emissions obtained in Case Study 1. The total carbon emissions released in this stage was 1.6 million tCO2 eq./year. The leader stage also shows that the power generated is mostly from hydropower plants, followed by coal, biomass, natural gas, diesel, and, lastly, solar power plants.

Summary of Case Study 2 optimization results

The network in Fig. 9 shows the chosen power plants in the leader stage that include new renewable plants such as biomass and solar plants. The model also selects the co-firing with biomass for one coal power plant that produces 23 MW of power per year from biomass and 270 MW in total from the entire plant. Besides that, the objective function in the follower stage was to minimize the total combined cost. This produced a total cost of $301 million/year in this stage (Fig. 8). In addition to the $301 million/year, the $9.7 million/year in financial disincentives is proposed to be paid to the Sarawak Government, making it a total of $311 million/year in total combined cost. Compared to Case Study 1, this stage was only able to reduce its overall carbon emissions by 2%. The total carbon emissions released in this stage were 1.9 million tCO2 eq./year. The follower stage also shows that the power generated is mostly from the hydropower plants, followed by coal, natural gas, diesel, and solar power plants. The optimal network in Fig. 10 shows the current chosen power plants in the follower stage that include only one renewable solar power plant. The model does not select cofiring for any coal power plants.

Lastly, the objective function in the bi-level optimization was to minimize total combined cost. As shown in Fig. 7, this yielded a total combined cost of $317.4 million/year in this stage. This combined cost includes a proposal of $1.4 million/year of financial incentives from the Sarawak Government as this stage manages to reduce exactly 10% of carbon emissions compared to Case Study 1 emissions with 5,600 MW demand. The total carbon emissions released in this stage were 1.7 million tCO2 eq./year. The bi-level optimization results also show that the power generated is mostly from hydropower plants, followed by coal, natural gas, diesel, biomass, and, lastly, solar power plants.

The network in Fig. 11 shows the chosen power plants in the bi-level optimization results, which include all current operating fossil-fuel power plants and three new renewable plants such as biomass and solar plants. In addition, biomass co-firing was selected for one coal power plant. This plant will produce 23 MW/year from biomass from its total output of 226 MW.

Since Case Study 2 used a bi-level optimization strategy, the leader stage, follower stage, and bi-level optimization can be compared based on carbon emissions and total combined cost (Fig. 12). Compared to the third scenario in Case Study 1, the financial incentives for renewables in the leader stage and bi-level optimization reduce the total combined cost as both these stages have managed to reduce their overall carbon emissions by 10%. However, the follower stage shows a total combined cost that is much less than the leader and bi-level stages. This is because the follower stage puts emphasis on the power industry’s decision-making behavior, and as a result, this stage favors the low-cost option, i.e., the conventional and currently operating power plants. The combined cost in the leader and the bi-level stages were higher because new renewable plants were selected to help achieve carbon emission reduction. This incurred additional capital costs for the new plants.

Other than that, the leader stage yields the lowest carbon emissions as most of its power comes from hydropower, coal, and biomass plants. Moreover, this stage also chose co-firing one coal power plant (C20) with biomass. The follower stage selected more hydropower, coal, natural gas, and diesel power plants than the leader stage. This also presented a decrease of 22% in combined cost and a 19% increase in total carbon emissions compared to the leader stage. This stage does not choose any biomass power plants or coal power plants with biomass co-firing. This is because this stage has the objective of minimizing combined costs. Hence, power plants with the lowest cost factors and highest efficiencies were chosen here.

Lastly, the bi-level optimization selected more renewable plants than the follower stage. This included two solar plants (S33 and S34), one biomass plant (B31), and one coal plant with biomass co-firing (C20). Compared to the leader stage, the bi-level stage presented a 21% decrease in combined cost and a 6% increase in total carbon emissions. This stage has an objective of minimizing combined cost; therefore, it chose power plants with low to medium cost factors and carbon emission factors, as well as high efficiencies. The bi-level stage suggests a trade-off between the objectives of the Sarawak Government (leader stage) and the power industry (follower stage) Fig. 13

Comparison between carbon emissions and total combined cost for Case Study 1 and bi-level of Case Study 2

Figure 13 compares the third scenario in Case Study 1 and the bi-level in Case Study 2. As shown, there is a 54% increase in total combined cost and 11% decrease in total carbon emissions in the bi-level model compared to Case Study 1. As mentioned earlier, the increase in total combined cost is due to the selection of new renewable plants in the bi-level stage. This contrasts with Case Study 1, where new renewable plants were not selected due to high capital costs. With the help of new renewable plants, the carbon emissions in the bi-level stage were reduced compared to Case Study 1. Thus, the bi-level model was able to determine the numerical value for monetary support required to achieve a 10% carbon emission reduction among power plants considered in Case Study 2. The numerical value for monetary support appears to have impacted investments in renewable energy technology and reductions in carbon emissions. It is worth noting that the bi-level stage only identifies the required numerical monetary value for policy support. In other words, the numerical monetary value obtained serves as the cost to nudge the industry to reduce emission. However, research is still needed to determine how this monetary value can be rolled out as implementable policy. These could be in the form of either carbon tax charges or carbon abatement fee to encourage the implementation of renewable plants that can reduce carbon emissions.

General Implication for Decarbonization

The results of the Sarawak case study have implications that can be generalized to carbon-constrained rural electrification scenarios in many developing and emerging economies. In such cases, governments generally seek to improve the quality of life in rural communities through the provision of clean energy that meets both national decarbonization targets and SDG 7. MP-based energy planning models allow climate-friendly development trajectories to be mapped out by capitalizing on locally available renewable energy potential. The game-theoretic approach enables the interplay of government and industry to be properly reflected in the modeling framework in a manner that would not be possible using a centralized or monolithic model. Such tools can allow developing countries to meet their nationally determined contributions to the Paris Agreement cost-effectively (PWC n.d.) while still achieving economic development in depressed rural regions.

The major implication for decarbonization with the usage of renewable energy for total rural electrification would be the impact on rural communities by decoupling development from GHG emissions. Clean and sustainable power can be provided to rural communities to promote climate protection and reduce exposure to hazardous pollutants from fossil fuel-based plants. The addition of new renewable plants will create new jobs and give rise to economic opportunities in rural areas. Implementing renewable energy will provide connectivity to rural households and reduce the digital divide between urban and rural areas. Electricity can also be supplied at an affordable rate due to the abundant renewable resources in an area. Providing electricity to underdeveloped regions can also act as a key catalyst for poverty alleviation through multiple positive socio-economic ripple effects (Siriwardana and Nong 2021). For example, access to electricity can improve agricultural productivity to promote food security or improve educational outcomes to enhance future livelihood prospects.

Conclusion

This paper developed a regional planning model to optimize renewable energy sources for improved rural electrification based on the Stackelberg game framework. A bi-level optimization model was used to determine the trade-off between the leader (government) and the follower (the power industry). The modeling framework was applied to carbon-constrained electrification in Sarawak, Malaysia, as an illustrative case. The model and the Sarawak case study gave insights into how incentives and monetary support can be strategized to improve electrification in rural parts of developing countries. The developed model essentially determined a numerical value for monetary support required to achieve a 10% carbon emission reduction among power plants considered. It does not account for a step-by-step strategy on how this sum can be rolled out. This, however, can serve as a basis for future work and analysis. Furthermore, the model developed can be extended in the future to consider the planning of energy storage for renewables and development of control strategies to prevent intermittency. Besides that, the current model assumes a deterministic scenario where variations and uncertainties are not present. Hence, a future work can be directed to consider uncertainties in the model and performing economic risk assessments. Implementing carbon trading and financial incentives for carbon abatement can also be considered for a future work.

Data Availability

All data generated or analyzed during this study are included in this published article.

Abbreviations

- i :

-

Plant

- r :

-

Fuel

- s :

-

Substation

- AFi :

-

Annualizing factor of plant i

- \({\mathrm{CAP}}_{\mathrm{i}}^{\text{fact}}\) :

-

Capital cost factor of plant i

- \({\mathrm{CE}}_{\mathrm{r}}^{\text{fact}}\) :

-

Carbon emission factor of fuel r

- CEmin :

-

Lower bound of total carbon emissions

- CEmax :

-

Upper bound of total carbon emissions

- Ei :

-

Efficiency of plant i

- \({\mathrm{F}}_{\mathrm{r}}^{\mathrm{AV}}\) :

-

Available supply of fuel r

- \({\mathrm{F}}_{\mathrm{i}}^{\mathrm{min}}\) :

-

Minimum capacity into plant i

- \({\mathrm{F}}_{\mathrm{i}}^{\mathrm{max}}\) :

-

Maximum capacity into plant i

- \({\mathrm{F}}_{\mathrm{r},\mathrm{i}}^{\mathrm{min}}\) :

-

Minimum flow of fuel r into plant i

- \({\mathrm{F}}_{\mathrm{r},\mathrm{i}}^{\mathrm{max}}\) :

-

Maximum flow of fuel r into plant i

- \({\mathrm{OP}}_{\mathrm{i}}^{\text{fact}}\) :

-

Operating cost factor of plant i

- \({\mathrm{P}}_{\mathrm{s}}^{\text{Demand}}\) :

-

Power demand at substation s

- \({\mathrm{R}}_{\mathrm{r},\mathrm{i}}^{\mathrm{min}}\) :

-

Maximum percentage of capacity in plant i available for co-firing fuel r

- \({\mathrm{R}}_{\mathrm{r},\mathrm{i}}^{\mathrm{max}}\) :

-

Maximum percentage of capacity in plant i available for co-firing fuel r

- TTLCE :

-

Total carbon emissions

- MCE:

-

Targeted total carbon emissions

- TTLFIN :

-

Total financial incentives or disincentives

- φ:

-

Fraction of upper bound in total carbon emissions

- \({\mathrm{b}}_{\mathrm{i}}\) :

-

Binary variable denoting ON/OFF status of plant i

- \({\mathrm{b}}_{\mathrm{r},\mathrm{i}}\) :

-

Binary variable denoting existence of co-firing fuel r in plant i

- CAP i :

-

Capital cost for plant i

- \({\mathrm{F}}_{\mathrm{r},\mathrm{i}}\) :

-

Flow of fuel r into plant i

- OP i :

-

Operating cost for plant i

- P i :

-

Power generated by plant i

- \({\mathrm{P}}_{\mathrm{i},\mathrm{s}}\) :

-

Power distributed to substation s from plant i

- TTLCOST :

-

Total combined cost

- TTLCAP :

-

Total capital cost

- TTLOP :

-

Total operating cost

References

Akbas B, Kocaman AS, Nock D, Trotter PA (2022) Rural electrification: an overview of optimization methods. Renew Sustain Energy Rev 156:111935

Amirante R, Bruno S, Distaso E, La Scala M, Tamburrano P (2019) A biomass small-scale externally fired combined cycle plant for heat and power generation in rural communities. Renew Energy Focus 28:36–46. https://doi.org/10.1016/J.REF.2018.10.002

Arief YZ, Roslan NI, Hafiez M, Saad I, Gurusamy L (2020) Transient overvoltage simulation in 500 kV transmission line plan of Sarawak, Malaysia using PSCAD. Int J Innov Technol Explor Eng 9:2481–90. https://doi.org/10.35940/ijitee.d1458.029420

Aurecon (2019) Costs and technical parameter review 57

Aviso KB, Chiu ASF, Ubando AT, Tan RR (2021) A bi-level optimization model for technology selection. J Ind Prod Eng 38(8):573–580. https://doi.org/10.1080/21681015.2021.1950226

Baik E, Siala K, Hamacher T, Benson SM (2022) California’s approach to decarbonizing the electricity sector and the role of dispatchable, low-carbon technologies. Int J Greenhouse Gas Control 113:103527

Bard JF (1998). Practical bilevel optimization : algorithms and applications. Nonconvex optimization and its applications 30

Baurzhan S, Jenkins GP (2017) On-grid solar PV versus diesel electricity generation in sub-Saharan Africa: Economics and GHG Emissions. Sustainability 9:372. https://doi.org/10.3390/SU9030372

Carvalho M, Romero A, Shields G, Millar DL (2014) Optimal synthesis of energy supply systems for remote open pit mines. Appl Therm Eng 64:315–30. https://doi.org/10.1016/J.APPLTHERMALENG.2013.12.040

Chen Y, Zhu J (2019) A graph theory-based method for regional integrated energy network planning a case study of a china–U.S. low-carbon demonstration city. Energies (Basel) 12:4491. https://doi.org/10.3390/en12234491

de Coninck H, Revi A, Babiker M, Bertoldi P, Buckeridge M, Cartwright A, et al. (2018) Strengthening and Implementing the Global Response. In: Masson-Delmotte V, Zhai P, Pörtner H-O, Roberts D, Skea J, Shukla PR, et al., editors. In: Global Warming of 1.5°C. An IPCC Special Report on the impacts of global warming of 1.5°C above pre-industrial levels and related global greenhouse gas emission pathways, in the context of strengthen, Cambridge and New York: Cambridge University Press

Conventus Law (2020). Wind energy landscape In Malaysia. Conventus Law

Darmawan A, Budianto D, Aziz M, Tokimatsu K (2017) Hydrothermally-treated empty fruit bunch cofiring in coal power plants: a techno-economic assessment. Energy Procedia 105:297–302. https://doi.org/10.1016/J.EGYPRO.2017.03.317

Dempe S, Zemkoho A. (2020) Bilevel optimization: advances and next challenges

Deveci K, Güler Ö (2020) A CMOPSO based multi-objective optimization of renewable energy planning: case of Turkey. Renew Energy 155:578–90. https://doi.org/10.1016/j.renene.2020.03.033

Ding H, Zhou D, Zhou P (2020) Optimal policy supports for renewable energy technology development: a dynamic programming model. Energy Econ 92:104765. https://doi.org/10.1016/j.eneco.2020.104765

Emam OE (2006) A fuzzy approach for bi-level integer non-linear programming problem. Appl Math Comput 172:62–71. https://doi.org/10.1016/j.amc.2005.01.149.

Gomez OC (2018). Deregulate renewables, power generation. The Edge Malaysia. https://www.theedgemarkets.com/article/deregulate-renewables-power-generation

Han S, Kim J (2019) A multi-period MILP model for the investment and design plan Comparing the impacts of fossil and renewable energy investments in Indonesia. Renew Energy 141:736–50. https://doi.org/10.1016/j.renene.2019.04.017

Handayani K, Krozer Y, Filatova T (2017) Trade-offs between electrification and climate change mitigation: an analysis of the Java-Bali power system in Indonesia. Appl Energy 208:1020–37

Hartono D, Hastuti SH, Halimatussadiah A, Saraswati A, Mita AF, Indriani V (2020) Comparing the impacts of fossil and renewable energy investments in Indonesia. Renew Energy 141:736–50

IEA ESTAP (2010). Combined heat ad power highlights

International Energy Agency (IEA) (2022) Global electricity demand is growing faster than renewables, driving strong increase in generation from fossil fuels 2021. https://www.iea.org/news/global-electricity-demand-is-growing-faster-than-renewables-driving-strong-increase-in-generation-from-fossil-fuels. Accessed 23 June 2022

IPCC (2018) Summary for Policymakers. https://www.ipcc.ch/sr15/chapter/spm/

Ji L, Zhang B, Huang G, Cai Y, Yin J (2020) Robust regional low-carbon electricity system planning with energy-water nexus under uncertainties and complex policy guidelines. J Clean Prod 252:119800. https://doi.org/10.1016/j.jclepro.2019.119800

Joshi D (2021). A proposal for carbon price-and-rebate (CPR) in Malaysia – Penang Institute n.d. https://penanginstitute.org/publications/issues/a-proposal-for-carbonprice-and-rebate-cpr-in-malaysia/

Kalashnikov VV, Dempe S, Pérez-Valdés GA, Kalashnykova NI, Camacho-Vallejo JF (2015). Bilevel programming and applications. Math Probl Eng. https://doi.org/10.1155/2015/310301.

Kammen D. Sarawak can invest in or give away its future. The Borneo Project 2019. https://borneoproject.org/sarawak-can-invest-in-or-give-away-its-future/

Koponen K, Le Net E (2021) Towards robust renewable energy investment decisions at the territorial level. Appl Energy 287:116552. https://doi.org/10.1016/J.APENERGY.2021.116552

Kozlova M, Collan M (2020) Renewable energy investment attractiveness: Enabling multi-criteria cross-regional analysis from the investors’ perspective. Renew Energy 150:382–400. https://doi.org/10.1016/j.renene.2019.12.134

Kumar A, Yu ZG, Klemeš JJ, Bokhari A (2021) A state-of-the-art review of greenhouse gas emissions from Indian hydropower reservoirs. J Clean Prod 320:128806

Kwon J, Zhou Z, Levin T, Botterud A (2020) Resource adequacy in electricity markets with renewable energy. IEEE Trans Power Syst 35:773–81

Lei Y, Wang D, Jia H, Chen J, Li J, Song Y et al (2020) Multi-objective stochastic expansion planning based on multi-dimensional correlation scenario generation method for regional integrated energy system integrated renewable energy. Appl Energy 276:115395. https://doi.org/10.1016/j.apenergy.2020.115395

Li T, Li Z, Li W (2020) Scenarios analysis on the cross-region integrating of renewable power based on a long-period cost-optimization power planning model. Renew Energy 156:851–63. https://doi.org/10.1016/j.renene.2020.04.094

Liu Z (2015) Supply and Demand of Global Energy and Electricity in Global Energy Interconnection. Academic Press

OECD (n.d.) Linking Renewable Energy to Rural Development Executive Summary Brief for Policy Makers

Papadis E, Tsatsaronis G (2020) Challenges in the decarbonization of the energy sector. Energy 205:118025

Patrizio P, Fajardy M, Bui M, MacDowell N (2021) CO2 mitigation or removal: the optimal uses of biomass in energy system decarbonization. IScience 24:102765

Power Technology (n.d.). Power plant O&M: how does the industry stack up on cost?

PWC (n.d.). Corporate - Tax credits and incentives. PWC

Sarawak Energy Berhad (2018). Foundation to low carbon economy delivering sustainable energy

Sarawak Energy Berhad (2017). Lighting up rural Sarawak 2

Sarawak Energy Berhad (2020) SARES lights up 725 more remote households in Telang Usan. Sarawak Energy Berhad

Sarawak Government (2021). Investment Opportunities. Sarawak Government Official Portala

Shabdin NH, Padfield R (2017) Sustainable energy transition, gender & modernisation in rural Sarawak. Chem Eng Trans 56:259–64. https://doi.org/10.3303/CET1756044

Shah KU, Roy S, Chen W-M, Niles K, Surroop D (2020) Application of an Institutional Assessment and Design (IAD)-Enhanced Integrated Regional Energy Policy and Planning (IREPP) Framework to Island States. Sustainability 12:2765. https://doi.org/10.3390/su12072765

Shirley R, Kammen D (2015) Energy planning and development in Malaysian Borneo: assessing the benefits of distributed technologies versus large scale energy mega-projects. Energy Strategy Rev 8:15–29. https://doi.org/10.1016/j.esr.2015.07.001

Sinha SB, Sinha S (2004) A linear programming approach for linear multi-level programming problems. J Oper Res Soc 55:3

Sinha A, Malo P, Deb K. (2018) A review on bilevel optimization: from classical to evolutionary approaches and applications. IEEE Trans Evol Comput 22:2. https://doi.org/10.1109/TEVC.2017.2712906.

Siriwardana M, Nong D (2021) Nationally Determined Contributions (NDCs) to decarbonise the world : a transitional impact evaluation ☆. Energy Econ 97:105184

Tan RR, Aviso K, Walmsley T (2021) P-graph approach to solving a class of Stackelberg games in carbon management. Chem Eng Trans 89:463–8

The Borneo Post (2020) 350 schools in S’wak face power supply issues — Deputy Minister. Borneo Post Online

Then S (2018) Explore potential of biomass. Star. https://www.thestar.com.my/metro/metro-news/2018/01/22/explore-potential-of-biomass-state-and-industry-urgedto-develop-green-products-to-meet-market-needs

United Nations (n.d) Energy - United Nations Sustainable Development (n.d) https://www.un.org/sustainabledevelopment/energy/ (accessed June 23, 2022).

United Nations (2022) COP26 Together for our planet 2021. https://www.un.org/en/climatechange/cop26 (accessed November 21, 2022).

Vijay V, Subbarao PMV, Chandra R (2021) An evaluation on energy self–sufficiency model of a rural cluster through utilization of biomass residue resources: a case study in India. Energy Clim Change 2:100036. https://doi.org/10.1016/J.EGYCC.2021.100036

Walker A, Lockhart E, Desai J, Ardani K, Klise G, Lavrova O, et al. (2020) Model of operation-and-maintenance costs for photovoltaic systems, Technical Report. https://www.nrel.gov/docs/fy20osti/74840.pdf

Wang Y, Wang Y, Huang Y, Li F, Zeng M, Li J et al (2019) Planning and operation method of the regional integrated energy system considering economy and environment. Energy 171:731–50. https://doi.org/10.1016/j.energy.2019.01.036

Wang N, Heijnen PW, Imhof PJ (2020) A multi-actor perspective on multi-objective regional energy system planning. Energy Policy 143:111578. https://doi.org/10.1016/j.enpol.2020.111578

Yavari M, Ajalli P (2021)Suppliers’ coalition strategy for green-resilient supply chain network design. 38:197–212. https://doi.org/10.1080/21681015.2021.1883134

Zakaria SU, Basri S, Kamarudin SK, Majid NAA (2019) Public awareness analysis on renewable energy in Malaysia. IOP Conf Ser Earth Environ Sci 268. https://doi.org/10.1088/1755-1315/268/1/012105.

Zhang G, Han J, Lu J. (2016) Fuzzy Bi-level decision-making techniques: a survey. I J Comput Intell Syst 9:. https://doi.org/10.1080/18756891.2016.1180816.

Zhang C, Lu X, Ren G, Chen S, Hu C, Kong Z, et al. (2021) Optimal allocation of onshore wind power in China based on cluster analysis. Appl Energy 285:116482

Acknowledgements

The authors would like to acknowledge LINDO systems for providing the academic license for LINGO v18 software to conduct this research.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shahrom, S.F., Aviso, K.B., Tan, R.R. et al. Regional Planning and Optimization of Renewable Energy Sources for Improved Rural Electrification. Process Integr Optim Sustain 7, 785–804 (2023). https://doi.org/10.1007/s41660-023-00323-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41660-023-00323-0