Abstract

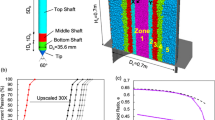

Earth loads acting on buried structures are known to be influenced by the characteristics of the soil, and the stiffness and geometry of the structure. To reduce earth pressure acting on buried structures, the induced trench installation technique has been recommended and applied in practice for several decades. It involves the installation of a soft zone immediately above the buried structure to mobilize shear strength in the backfill material. In this study an experimental investigation is conducted to measure the changes in contact pressure on the walls of a rigid structure buried in granular backfill with a U-shaped geofoam wrap. The results are compared with the conventional induced trench method as well as the positive projection installation with no geofoam. Contact pressures on the walls of the structure are measured using the tactile sensing technology. The experimental results are used to validate a finite element model that has been developed to analyze this soil–geosynthetic–structure interaction problem. The numerical model is then used to study the soil arching and the stresses developing in the backfill material for three different EPS densities. In addition, the role of geofoam density and the maximum fill height that can be carried safely without exceeding the design strain levels are examined. Conclusions are made regarding the effectiveness of this type of EPS inclusion on the earth pressure distribution around the buried structure.

Similar content being viewed by others

References

Marston A (1922) Second progress report to the Joint Concrete Culvert Pipe Committee. Iowa Engineering Experimental Station, Ames, IA, USA

Marston A (1930) The theory of external loads on closed conduits in the light of the latest experiments. In: The 9th annual meeting of the highway research board. Highway Research Board, Washington, D.C., USA, pp 138–170

Spangler MG (1950) Field measurements of the settlement ratios of various highway culverts, Bulletin No. 170. Iowa Engineering Experiment Station, Ames, Iowa, USA, p 99

Spangler MG (1951) A theory on loads on negative projecting conduits. In: The 13th annual meeting of the highway research board. Washington, D.C., USA, pp 153–161

Sladen JA, Oswell JM (1988) The induced trench method—a critical review and case history. Can Geotech J 25(3):541–549

Vaslestad J, Johansen TH,Holm W (1993) Load reduction on rigid culverts beneath high fills: long-term behavior. Transp Res Record 1415:58–68

Liedberg NSD (1997) Load reduction on a rigid pipe: pilot study of a soft cushion installation. Transp Res Record 1594:217–223

Sun L, Hopkins T, Beckham T (2011) Long-term monitoring of culvert load reduction using an imperfect ditch backfilled with geofoam. Transp Res Record 2212:56–64

Oshati OS, Valsangkar AJ, Schriver AB (2012) Earth pressures exerted on an induced trench cast-in-place double-cell rectangular box culvert. Can Geotech J 49(11):1267–1284

Kim K, Yoo CH (2002) Design loading for deeply buried box culverts. Highway Research Center, Report No. IR-02-03. Auburn University, Alabama, p 215

Kang J, Parker F, Kang YJ, Yoo CH (2008) Effects of frictional forces acting on sidewalls of buried box culverts. Int J Numer Anal Methods Geomech 32(3):289–306

Sun C, TC H, Benkham TL (2009) Reduction of stresses on buried rigid highway structures using the imperfect ditch method and expanded polysterene (geofoam). Kentucky Transportaion Center, Report No. KTC-07-14-SPR-228-01-1F. University of Kentucky, Kentucky, USA, p 49

McGuigan BL, Valsangkar AJ (2010) Centrifuge testing and numerical analysis of box culverts installed in induced trenches. Can Geotech J 47(2):147–163

McGuigan BL, Valsangkar AJ (2011) Earth Pressures on twin positive projecting and induced trench box culverts under high embankments. Can Geotech J 48(2):173–185

Yoo CH, Kang J (2007) Soil-structure interaction for deeply buried corrugated pvc and steel pipes. Highway Research Center, Auburn University

ABAQUS (2013) ABAQUS user’s manuals, version 6.13. Dassault Systems Simulia Corp., Providence

Ahmed MR, Tran VDH, Meguid MA (2015) On the role of geogrid reinforcement in reducing earth pressure on buried pipes: experimental and numerical investigations. Soils Found 55(3):588–599

Meguid MA, Hussein MG (2017) A numerical procedure for the assessment of contact pressures on buried structures overlain by EPS geofoam inclusion. Int J of Geosynth Ground Eng. doi:10.1007/s40891-016-0078-y

Hussein MG, Meguid MA, Whalen J (2015) On the numerical modeling of buried structures with compressible inclusion. In: GeoQuebec 2015, the 68th Canadian Geotechnical Conference. Canadian Geotechnical Society, Quebec City, Canada, Paper No. 577, p 8

Bartlett S, Negussey D, Kimble M, Sheeley M (2000) Use of geofoam as super-lightweight fill for I-15 reconstruction. In: The 79th annual meeting for the transportation research board. Transportation Research Board, Washington, DC, p 21

Stark TD, Arellano D, Horvath JS, Leshchinsky D (2004) Guideline and recommended standard for geofoam applications in highway embankments. National Cooperative Highway Research Program (NCHRP), Report No. 529. Transportation Research Board, Washington, D.C., USA, p 71

Vaid YP, Rinne N (1995) Geomembrane coefficients of interface friction. Geosynth Int 2(1):309–325

Meguid MA, Hussein MG, Ahmed MR, Omeman Z, Whalen J (2017) Investigation of soil-geosynthetic-structure interaction associated with induced trench installation. Geotext and Geomembr. doi:10.1016/j.geotexmem.2017.04.004

Acknowledgements

This research is supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) CRD Project No. 452760-13. The generous support of Plasti-Fab Ltd. throughout this study is appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meguid, M.A., Ahmed, M.R., Hussein, M.G. et al. Earth Pressure Distribution on a Rigid Box Covered with U-Shaped Geofoam Wrap. Int. J. of Geosynth. and Ground Eng. 3, 11 (2017). https://doi.org/10.1007/s40891-017-0088-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-017-0088-4