Abstract

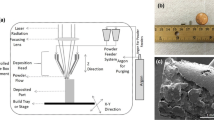

In this study we describe the fabrication of a variety of open-cellular titanium alloy (Ti-6Al-4V) implants, both reticular mesh and foam structures, using electron beam melting (EBM). These structures allow for the elimination of stress shielding by adjusting the porosity (or density) to produce an elastic modulus (or stiffness) to match that of both soft (trabecular) and hard (cortical) bone, as well as allowing for bone cell ingrowth, increased cell density, and all-matrix interactions; the latter involving the interplay between bone morphogenetic protein (BMP-2) and osteoblast functions. The early formation and characterization of elementary vascular structures in an aqueous hydrogel matrix are illustrated. Preliminary results for both animal (sheep) and human trials for a number of EBM-fabricated, and often patient-specific Tialloy implants are also presented and summarized. The results, while preliminary, support the concept and development of successful, porous, engineered “living” implants.

摘要

本文采用电子束增材(EBM)制造技术制备了多种具有开放孔隙结构的多孔钛合金(Ti-6Al-4V)植入物, 包括网状和泡沫状结构. 该多孔钛合金植入物可以通过调节孔隙率(或密度)降低其弹性模量(或刚度)以减轻 “应力屏蔽” 效应, 实现与软(小梁)和硬(皮质)骨的弹性模量(或刚度)匹配; 同时还可以促进骨组织长入, 增加细胞密度和细胞外基质间的相互作用, 后者涉及骨形态发生蛋白(BMP-2)和成骨细胞功能之间的相互影响. 总结了在水性水凝胶基质中初级血管结构的早期形成和特征, 报道了EBM技术制备的个性化钛合金植体在动物(羊)和人体临床试验的初步结果. 本文结果为钛合金多孔材料作为组织工程“活性”植入物的应用可行性研究提供了有力支持.

Similar content being viewed by others

References

Maradit Kremers H, Larson DR, Crowson CS, et al. Prevalence of total hip and knee replacement in the united states. J Bone Joint Surgery-Am Volume, 2015, 97: 1386–1397

Murr LE, Gaytan SM, Medina F, et al. Next-generation biomedical implants using additive manufacturing of complex, cellular and functional mesh arrays. Philos Trans R Soc A-Math Phys Eng Sci, 2010, 368: 1999–2032

Koike M, Greer P, Owen K, et al. Evaluation of titanium alloys fabricated using rapid prototyping technologies-electron beam melting and laser beam melting. Materials, 2011, 4: 1776–1792

Sing SL, An J, Yeong WY, et al. Laser and electron-beam powderbed additive manufacturing of metallic implants: a review on processes, materials and designs. J Orthop Res, 2016, 34: 369–385

Bezuidenhout MB, Dimitrov DM, van Staden AD, et al. Titaniumbased hip stems with drug delivery functionality through additive manufacturing. BioMed Res Int, 2015, 2015: 1–11

Carmeliet P. Mechanisms of angiogenesis and arteriogenesis. Nat Med, 2000, 6: 389–395

Anderson CR, Ponce AM, Price RJ. Immunohistochemical identification of an extracellular matrix scaffold that microguides capillary sprouting in vivo. J Histochem Cytochem, 2004, 52: 1063–1072

Matena J, Petersen S, Gieseke M, et al. SLM produced porous titanium implant improvements for enhanced vascularization and osteoblast seeding. IJMS, 2015, 16: 7478–7492

Kumar A, Nune KC, Murr LE, et al. Biocompatibility and mechanical behaviour of three-dimensional scaffolds for biomedical devices: process-structure-property paradigm. Int Mater Rev, 2016, 61: 20–45

Lieberman JR, Daluiski A, Einhorn TA. The role of growth factors in the repair of bone. J Bone Joint Surgery-Am Volume, 2002, 84: 1032–1044

Nune KC, Kumar A, Murr LE, et al. Interplay between self-assembled structure of bone morphogenetic protein-2 (BMP-2) and osteoblast functions in three-dimensional titanium alloy scaffolds: stimulation of osteogenic activity. J Biomed Mater Res, 2016, 104: 517–532

Kang HW, Lee SJ, Ko IK, et al. A 3D bioprinting system to produce human-scale tissue constructs with structural integrity. Nat Biotechnol, 2016, 34: 312–319

Petrovic V, Haro JV, Blasco JR, et al. Additive manufacturing solutions for improved medical implants. In: Lin C (Ed.), Biomedicine. Shanghai: In Tech China, 2012: 147–180

Li SJ, Murr LE, Cheng XY, et al. Compression fatigue behavior of Ti-6Al-4V mesh arrays fabricated by electron beam melting. Acta Mater, 2012, 60: 793–802

Gibson LJ, Ashby MF. Cellular Solids: Structural Properties. New York: Cambridge University Press, 1997

Wu SH, Li Y, Zhang YQ, et al. Porous titanium-6 aluminum-4 vanadium cage has better osseointegration and less micromotion than a poly-ether-ether-ketone cage in sheep vertebral fusion. Artif Organs, 2013, 37: E191–E201

Krock BL, Skuli N, Simon MC. Hypoxia-induced angiogenesis: good and evil. Genes Cancer, 2011, 2: 1117–1133

Chen LL, Huang M, Tan JY, et al. PI3K/AKT pathway involvement in the osteogenic effects of osteoclast culture supernatants on preosteoblast cells. Tissue Eng Part A, 2013, 19: 2226–2232

Veschini L, Belloni D, Foglieni C, et al. Hypoxia-inducible transcription factor-1 alpha determines sensitivity of endothelial cells to the proteosome inhibitor bortezomib. Blood, 2007, 109: 2565–2570

Donneys A, Weiss DM, Deshpande SS, et al. Localized deferoxamine injection augments vascularity and improves bony union in pathologic fracture healing after radiotherapy. Bone, 2013, 52: 318–325

Correa-Rodriguez V. Vascularization in interconnected 3D printed Ti-6Al-4V foams with hydrogel matrix for biomedical bone replacement implants. Doctoral Dissertation, El Paso, University of Texas at El Paso, 2016

Nune KC, Misra RDK, Gaytan SM, et al. Biological response of next-generation of 3D Ti-6Al-4V biomedical devices using additive manufacturing of cellular and functional mesh structures. J Biomater Tissue Eng, 2014, 4: 755–771

Nune KC, Misra RDK, Gaytan SM, et al. Interplay between cellular activity and three-dimensional scaffold-cell constructs with different foam structure processed by electron beam melting. J Biomed Mater Res, 2015, 103: 1677–1692

Karageorgiou V, Kaplan D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials, 2005, 26: 5474–5491

Story BJ, Wagner WR, Gaisser DM, et al. In vivo performance of a modified CS Ti dental implant coating. Int J Oral Maxillofac Implants, 1998, 13: 749–757

le Noble F, le Noble J. Bone biology: vessels of rejuvenation. Nature, 2014, 507: 313–314

Ramasamy SK, Kusumbe AP, Wang L, et al. Endothelial notch activity promotes angiogenesis and osteogenesis in bone. Nature, 2014, 507: 376–380

Rapuano BE, Lee JJE, MacDonald DE. Titanium alloy surface oxide modulates the conformation of adsorbed fibronectin to enhance its binding to α5β1 integrins in osteoblasts. Eur J Oral Sci, 2012, 120: 185–194

Olivares-Navarrete R, Gittens RA, Schneider JM, et al. Osteoblasts exhibit a more differentiated phenotype and increased bone morphogenetic protein production on titanium alloy substrates than on poly-ether-ether-ketone. Spine J, 2012, 12: 265–272

Li Z, Xu SF, Li DC, et al. Composite artificial semi-knee joint system. Eur Rev Med Pharmacol Sci, 2014, 18: 1229–1240

Dai KR, Yan MN, Zhu ZA, et al. Computer-aided custom-made hemipelvic prosthesis used in extensive pelvic lesions. J Arthroplasty, 2007, 22: 981–986

Horn TJ, Harrysson OLA. Overview of current additive manufacturing technologies and selected applications. Sci Prog, 2012, 95: 255–282

Acknowledgements

This research was supported in part by the Ministry of Science and Technology Project (2017YFC1104900 and 2016YFC1102601) and the National Natural Science Foundation of China (51271182 and 51631007), Chinese Academy of Sciences Project (QYZDJ-SSW-JSC031), the Department of Metallurgical, Materials and Biomedical Engineering (Nune KC and Misra RDK), and the Office of Research and Sponsored Projects (Correa-Rodriguez VL and Murr LE) at the University of Texas at El Paso.

Author information

Authors and Affiliations

Corresponding author

Additional information

Shujun Li is a tenured professor in Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese Academy of Sciences. His current research interest focuses on additive manufacturing via electron beam melting technology, aiming to understand the structure-process-property relationship of 3D printable metallic materials and explore their practical applications in aerospace and biomedical components, etc.

Xiaokang Li, MD, PhD, is an attending physician at the Department of Orthopaedic Oncology, Xijing Hospital. His research interest focuses on the effect of bone implants made of low modulus titanium or porous titanium alloy.

Zheng Guo is a professor and Chief of the Department of Orthopaedic Oncology, Xijing Hospital. His clinical work has focused on the application of customized 3D-printed titanium implants and digital orthopedic techniques. His research interests have been in both clinical and basic areas. The clinical research involves modifying surgical techniques and R&D of new orthopedic implants. His basic research focuses on low modulus titanium alloy, porous titanium alloy and surface modification for metal materials.

Rights and permissions

About this article

Cite this article

Li, S., Li, X., Hou, W. et al. Fabrication of open-cellular (porous) titanium alloy implants: osseointegration, vascularization and preliminary human trials. Sci. China Mater. 61, 525–536 (2018). https://doi.org/10.1007/s40843-017-9063-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-017-9063-6