Abstract

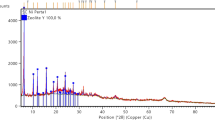

The reuse of waste materials helps to alleviate the pressure on sustainable economic development caused by the rapid consumption of natural resources. In this paper, a new process for the recovery of Li and Mn from spent LiMn2O4 cathode materials was studied. LiMn2O4 was mixed with NaHSO4·H2O according to a certain mass ratio and roasted, and then the roasted products were leached with deionized water. The chemical changes during roasting were studied by thermogravimetric analysis, differential scanning calorimetry, X-ray diffraction, X-ray photoelectron spectroscopy, and scanning electron microscopy. After roasting, Li exists in the form of LiNaSO4, while the form of Mn is affected by the content of NaHSO4·H2O in the mixture. Within the corresponding temperature range, the chemical reaction between LiMn2O4 and NaHSO4·H2O can proceed spontaneously. During the reaction, the following reactions will occur in the II and IV stages: NaHSO4⋅H2O → NaHSO4 + H2O(g), Na2S2O7 → Na2SO4 + SO3(g) and reaction of different metal oxides with SO3, and their average activation energies are 153.07 kJ/mol and 533.81 kJ/mol, respectively, and the restrictive link is three-dimensional diffusion. The roasted products were leached with deionized water, the extraction rate of Li and Mn elements increases with the decrease of mixing mass ratio, when the mass ratio of LiMn2O4 to NaHSO4·H2O is 1:1.07, the roasting temperature is 873 K, the roasting time is 0.5 h, under the condition of water leaching temperature of 333 K, the extraction rates of Li and Mn were 96.6% and 9.7%, respectively.

Graphical Abstract

Similar content being viewed by others

References

Zhang JL, Hu JT, Zhang WJ, Chen YQ, Wang CY (2018) Efficient and economical recovery of lithium, cobalt, nickel, manganese from cathode scrap of spent lithium-ion batteries. J Clean Prod 204:437–446. https://doi.org/10.1016/j.jclepro.2018.09.033

Yang YX, Zheng XH, Cao HB, Zhao CL, Lin X, Ning PG, Zhang Y, Jin W, Sun Z (2017) A closed-loop process for selective metal recovery from spent lithium iron phosphate batteries through mechanochemical activation. ACS Sustain Chem Eng 5:9972–9980. https://doi.org/10.1021/acssuschemeng.7b01914

Liu PC, Li X, Tang YW, Zhu YR, Chen H, Chen YF (2018) Resynthesis and electrochemical performance of LiNi0.5Co0.2Mn0.3O2 from spent cathode material of lithium-ion batteries. Vacuum 156:317–327. https://doi.org/10.1016/j.vacuum.2018.08.002

Barik SP, Prabaharan G, Kumar B (2016) An innovative approach to recover the metal values from spent lithium-ion batteries. Waste Manag 51:222–226. https://doi.org/10.1016/j.wasman.2015.11.004

Huang T, Liu LF, Zhang SW (2019) Recovery of cobalt, lithium, and manganese from the cathode active materials of spent lithium-ion batteries in a bio-electro-hydrometallurgical process. Hydrometallurgy 188:101–111. https://doi.org/10.1016/j.hydromet.2019.06.011

Chen S, He T, Lu Y, Su YF, Tian J, Li N, Chen G, Bao LY, Wu F (2016) Renovation of LiCoO2 with outstanding cycling stability by thermal treatment with Li2CO3 from spent Li-ion batteries. J Energy Storage 8:262–273. https://doi.org/10.1016/j.est.2016.10.008

Meng XQ, Hao J, Cao HB, Lin X, Ning PG, Zheng XH, Chang JJ, Zhang XH, Wang B, Sun Z (2019) Recycling of LiNi1/3Co1/3Mn1/3O2 cathode materials from spent lithium-ion batteries using mechanochemical activation and solid-state sintering. Waste Manag 84:54–63. https://doi.org/10.1016/j.wasman.2018.11.034

Shi Y, Chen G, Chen Z (2018) Effective regeneration of LiCoO2 from spent lithium-ion batteries: a direct approach towards high-performance active particles. Green Chem 20:851–862. https://doi.org/10.1039/c7gc02831h

Zheng RJ, Wang WH, Dai YK, Ma QX, Liu YL, Mu DY (2017) A closed-loop process for recycling LiNixCoyMn(1–x-y)O2 from mixed cathode materials of lithium-ion batteries. Green Energy Environ 2:42–50. https://doi.org/10.1016/j.gee.2016.11.010

Joulié M, Laucournet R, Billy E (2014) Hydrometallurgical process for the recovery of high value metals from spent lithium nickel cobalt aluminum oxide based lithium-ion batteries. J Power Sources 247:551–555. https://doi.org/10.1016/j.jpowsour.2013.08.128

Meshram P, Pandey BD, Mankhand TR (2015) Recovery of valuable metals from cathodic active material of spent lithium ion batteries: leaching and kinetic aspects. Waste Manag 45:306–313. https://doi.org/10.1016/j.wasman.2015.05.027

Hu QY (2010) Materialized metallurgical technology and basic research on waste pole piece of aluminum foil-based LiCoO2 coated film. Central South University, Changsha

Chen XQ, Ma HR, Luo CB, Zhou T (2017) Recovery of valuable metals from waste cathode materials of spent lithium-ion batteries using mild phosphoric acid. J Hazard Mater 326:77–86. https://doi.org/10.1016/j.jhazmat.2016.12.021

Zhuang LQ, Sun CH, Zhou T, Li H, Dai AQ (2019) Recovery of valuable metals from LiNi0.5Co0.2Mn0.3O2 cathode materials of spent Li-ion batteries using mild mixed acid as leachant. Waste Manag 85:175–185. https://doi.org/10.1016/j.wasman.2018.12.034

Li L, Jennifer BD, Zhang XX, Gaines LD, Chen RJ, Wu F (2013) Recovery of metals from spent lithium-ion batteries with organic acids as leaching reagents and environmental assessment. Amine K J Power Sourc 233:180–189. https://doi.org/10.1016/j.jpowsour.2012.12.089

Li L, Bian YF, Zhang XX, Guan YB, Fan E, Wu F, Chen RJ (2018) Process for recycling mixed-cathode materials from spent lithium-ion batteries and kinetics of leaching. Waste Manag 71:362–371. https://doi.org/10.1016/j.wasman.2017.10.028

Nayaka GP, Zhang YJ, Dong P, Wang D, Pai KV, Manjanna J, Santhosh G, Duan JG, Zhou ZR, Xiao J (2018) Effective and environmentally friendly recycling process designed for LiCoO2, cathode powders of spent Li-ion batteries using mixture of mild organic acids. Waste Manag 78:51–57. https://doi.org/10.1016/j.wasman.2018.05.030

He LP, Sun SY, Mu YY, Song XF, Yu JG (2017) Recovery of lithium, nickel, cobalt and manganese from spent lithium-ion batteries using L-tartaric acid as a leachant. ACS Sustain Chem Engg 5:714–721. https://doi.org/10.1021/acssuschemeng.6b02056

Gao WF, Song JL, Cao HB, Lin X, Zhang XH, Zheng XH, Zhang Y, Sun Z (2018) Selective recovery of valuable metals from spent lithium-ion batteries-Process development and kinetics evaluation. J Clean Prod 178:833–845. https://doi.org/10.1016/j.jclepro.2018.01.040

Ma LW, Nie ZR, Xi XL, Han XG (2013) Cobalt recovery from cobalt-bearing waste in sulphuric and citric acid systems. Hydrometallurgy 136:1–7. https://doi.org/10.1016/j.hydromet.2013.01.016

Meng Q, Zhang YJ, Dong P (2018) Use of electrochemical cathode-reduction method for leaching of cobalt from spent lithium-ion batteries. J Clean Prod 180:64–70. https://doi.org/10.1016/j.jclepro.2018.01.101

Vishvakarma S, Dhawan N (2019) Recovery of cobalt and lithium values from discarded Li-ion batteries. J Sustain Metall 5:204–209. https://doi.org/10.1007/s40831-018-00208-4

Sunil SR, Vishvakarma S, Barnwal A, Dhawan N (2019) Processing of spent Li-ion batteries for recovery of cobalt and lithium values. JOM 71:4659–4665. https://doi.org/10.1007/s11837-019-03540-6

Binder JO, Culver SP, Zeier WG, Janek J (2021) A rapid and facile approach for the recycling of high performance LiNi1-x-yCoxMnyO2 active materials. Chemsuschem 14:441–448. https://doi.org/10.1002/cssc.202001915

Jiang YZ, Chen XP, Yan SX, Li SZ, Zhou T (2021) Pursuing green and efficient process towards recycling of different metals from spent lithium-ion batteries through Ferro-chemistry. Chem Eng J 426:131637. https://doi.org/10.1016/j.cej.2021.131637

Chen XP, Kang DZ, Li JZ, Zhou T, Ma HR (2020) Gradient and facile extraction of valuable metals from spent lithium ion batteries for new cathode materials re-fabrication. J Hazard Mater 389:121887. https://doi.org/10.1016/j.jhazmat.2019.121887

Liu K, Liu LL, Tan QY, Li JH (2021) Selective extraction of lithium from a spent lithium iron phosphate battery by mechanochemical solid-phase oxidation. Green Chem 23:1344. https://doi.org/10.1039/D0GC03683H

Xiao L, Li L, Fu FY, He MZ (2012) Studies on non-isothermal and isothermal dehydration kinetics of FePO4·2H2O. Thermochim Acta 541:57–61. https://doi.org/10.1016/j.tca.2012.04.028

Boonchom B, Puttawong S (2010) Thermodynamics and kinetics of the dehydration reaction of FePO4 ·2H2O. Physica B 405:2350–2355. https://doi.org/10.1016/j.physb.2010.02.046

Wen YX, Zhou KW, Li HF, Tong ZF (2005) Thermal decomposition kinetics of LiMn2O4 in air. Guangxi University, Nanning

Zhang XD, Wang DH, Chen HJ, Yang LX, Yu YS, Xu L (2019) Chemistry evolution of LiNi1/3Co1/3Mn1/3O2-NaHSO4·H2O system during roasting. Solid State Ionics 339:3774–3782. https://doi.org/10.1016/j.ssi.2019.05.018

Wang DH, Wen H, Chen HJ, Yang YJ, Liang HY (2016) Chemical evolution of LiCoO2 and NaHSO4·H2O mixtures with different mixing ratios during roasting process. Chem Res Chin Univ 32:674–677. https://doi.org/10.1007/s40242-016-5490-2

Yan ST, Wang RZ, Shao CY, Tong ZQ, Li T, Yuan LJ, Sheng GH, Xu KH (2019) The strategy of entire recovery: From spent cathode material with high nickel content to new LiNi0.5Co0.2Mn0.3O2 and Li2CO3 powders. J Power Sources 440:1–6. https://doi.org/10.1016/j.jpowsour.2019.227140

Zhao MY, Ji ZY, Zhang YG, Guo ZY, Zhao YY, Liu J (2017) Yuan JS, Study on lithium extraction from brines based on LiMn2O4/Li1-xMn2O4 by electrochemical method. Electrochim Acta 252:350–361. https://doi.org/10.1016/j.electacta.2017.08.178

Pang WL, Zhang XH, Guo JZ, Li JY, Yan X, Hou BH, Guan HY, Wu XL (2017) P2-type Na2/3Mn1-xAlxO2 cathode material for sodium-ion batteries: Al-doped enhanced electrochemical properties and studies on the electrode kinetics. J Power Sources 356:80–88. https://doi.org/10.1016/j.jpowsour.2017.04.076

Nesbitt HW, Banerjee D (1998) Interpretation of XPS Mn2p spectra of Mn oxyhydroxides and constraints on the mechanism of MnO2 precipitation. Am Miner 83:305–315. https://doi.org/10.2138/am-1998-3-414

Nelson AJ, Reynolds JG, Roos JW (2000) Core-level satellites and outer core-level multiplet splitting in Mn model compounds. J Vac Sci Technol 18:1072–1076. https://doi.org/10.1116/1.582302

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (No. 51864032) and the Joint fund between Shenyang National Laboratory for Materials Science and State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals (No. 18LHZD002).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was Zhi Sun.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Z., Chen, H., Wang, D. et al. Metal Recovery from Spent LiMn2O4 Cathode Material Based on Sulfating Roasting with NaHSO4·H2O and Water Leaching. J. Sustain. Metall. 8, 684–699 (2022). https://doi.org/10.1007/s40831-022-00519-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-022-00519-7