Abstract

Some of the most promising potential applications of nanotechnology to hydraulic fracturing of coal seam gas (CSG) are reviewed with a focus on Australian CSG wells. Three propitious applications were identified: (1) Nanoparticle enhanced viscoelastic surfactants (VES) fracturing fluids to prevent fluid loss by up to 30%, made possible by the formation of pseudo-filter cakes and reducing the viscosity of the VES fluids. Besides, there is no requirement of clay control additives or biocides. (2) Nano-proppants to extend fracture networks and reduce proppant embedment by introducing them prior to the emplacement of larger proppants. Fly Ash nanoparticles can be particularly effective because of their high sphericity and mechanical strength. (3) Nanoparticle-coated proppants, to mitigate the migration of particle fines by restricting them close to their source by adsorption, with MgO being the most effective. The use of nanotechnology in hydraulic fracturing applications is currently hindered due to a discordant regulatory environment compounded by the cost of the nanoparticles themselves, as well as, a lack of field data to validate the technology under real downhole conditions. Although the necessary field tests are unlikely to be conducted for as long as abundant natural gas is available, exploratory studies could pave the way for future applications.

Graphical abstract

Similar content being viewed by others

1 Introduction

Coal seam gas (CSG) or coalbed methane (CBM) is an unconventional natural gas adsorbed on the internal surfaces of coal seams, in equilibrium with the free gas within the natural fractures or coal cleats. A minor proportion of CSG is also dissolved in the formation fluid present in the pore spaces (Cleveland and Morris 2015). The gas is held in place because the coals are saturated with water (Roarty 2011). Coal seams can hold larger quantities of gas per unit volume of rock than conventional reservoirs (Seidle 2011). Depending on the burial history, rank of the coal, precursor maceral composition and subsequent migration of the gas, the methane content varies from less than 1 to more than 25 m3 gas per ton of coal (Laxminarayana and Crosdale 1999; Jenkins and Boyer 2008; Zou et al. 2017). Under these scenarios, global CSG resources are estimated in excess of 256 trillion cubic metres (Seidle 2011; Islam 2015). In Eastern Australia, CSG has been linked to the development of the liquified natural gas (LNG) export industry, with its promised direct economic benefits (Simshauser and Nelson 2015; Marcos-Martinez et al. 2019).

CSG is extracted from coal seams occurring at depth of more than 200 m from the ground surface. Extending the extraction depth from 200 to 500 m, can increase the measured gas content by 2.5 times (Esterle et al. 2006). This makes extraction from greater depth, up to 1500 m, economically attractive (Unconventional Gas Mining Submission 121 2014). The vast quantity of water extraction required to depressurize the coal seam that can lead to aquifer depletion, is one of the greatest environmental concern surrounding CSG extraction in Australia, where many regions suffers from chronic water shortages (Dingsdag 2016). As of 2016, the water produced from CSG development in Queensland was 60.5 Giga litres/year, equivalent to 1700 Giga litres of water to be produced over the life of one development (Salmachi and Yarmohammadtooski 2015; Underschultz et al. 2018). Another potential risk associated with CGS extraction is groundwater contamination with chemicals, methane and dissolved salts (Dingsdag 2016). Contamination can occur as the stray gas migrate to an aquifer above the gas deposit along poorly sealed gas production wells and along new fractures and existing faults enhanced and re-activated by fraccing (Jackson et al. 2013; Vengosh et al. 2014). The management and environmental impact of the water co-produced with CSG extraction has been the object of other reviews (Hamawand et al. 2013; Davies et al. 2015; Mallants et al. 2018), which also stressed the need for efficient innovative technologies to achieve a sustainable CSG extraction. Such breakthrough may be brought about by existing knowledge base currently applied for other conventional and unconventional hydrocarbons extraction. We consider here the viable applications of nanotechnology to enhance CSG extraction by fraccing, with focus on the Australian CSG landscape.

1.1 Coal seam gas in Australia

One of the first countries to effectively take advantage of CSG as a clean-burning fuel is Australia. As shown in Fig. 1a, production of CSG began in 1995 and has grown almost exponentially since (Evershed 2018; Roarty 2011). The majority of CSG is found in the state of Queensland, in the Bowen and Surat Basins (Fig. 1b). In 2017, CSG reserves in Australia (both proven and probable) were estimated to total nearly 40,000 PJ in Queensland alone (Gas Resourecs in Australia: resources assessment and operation overview 2017). CSG makes up almost one third of natural gas production in Australia (Evershed 2018), compared to only 3% in the USA (Natural Gas Explained 2019). It is an important resource to the Australian economy with strong implications for its national energy security. Indeed, the gas produced is used domestically, and the vast surplus is exported. To access the global marketplace, LNG plants (i.e. Gladstone) as well as thousands of kilometres of pipelines are being built along the Queensland coast (Roarty 2011). It is expected that as conventional gas fields such as the Cooper Basin are depleted and the mining of solid coal drops, CSG production will play a major role in Australian energy exports (Australian Energy Update 2018 2018).

a A significant increase in yearly production of CSG in Australia and from the Bowen and Surat basins from 2009 to 2018, as compared to conventional gas production. Data from Australian Government Geoscience Australia (2021) and Queenland Government, Open Data Portal. b Map of Australia, showing the most promising areas for future CSG production—The Bowen and Surat Basins in Queensland and the Sydney Basin in New South Wales. Cooper Basin has also been the focus of CSG appraisal. Image modified after Moore (2012)

The percentage of CSG wells requiring stimulation is increasing. Mallants et al. (2018) estimated that although only 6% of the CSG wells drilled in Queensland have so far undergone hydraulic fracturing, 40% will require stimulation over the next few decades. Maximising the efficiency of the fraccing process is essential to minimise the overall production costs. One major technical challenge lies in the fact that the permeability of coal seams is reduced by the closure of the cleats as the fluid pressure declines during water production and fraccing (Underschultz et al. 2018). This challenge can be complicated by the complexity of both mineralogy and the natural fracture system of coal seams. Quartz, calcite, pyrite, kaolinite and other clays are typically present in different proportions (e.g. Zhang et al. 2019), resulting in high anisotropy in strength and high sensitivity to stress of the formations, compounded by differences in methane adsorption capacities of different clay minerals (Wang et al. 2020).

1.2 Hydraulic fracturing in coal seam gas

The productivity of an unconventional formation correlates with the permeability of the correspondent rocks. Coal seams permeability is determined by their cleats network, the matrix porosity being comparatively insignificant (Moore 2012; Seidle 2011), in addition to the interconnectivity between the pores and the fractures, the stress state and other physical properties. Sometimes, coal seams have sufficient permeability (> 1 mD) to allow the desorbed gas to flow to the wellbore. However, in most cases, hydraulic fracturing, referred to as fraccing herein, or other forms of stimulation are necessary to achieve a higher fluid conductivity (APLNG; Huang et al. 2012; St John 2017; Alexeev et al. 2010; Sampath et al. 2019).

Fraccing involves pumping a fluid into the formation at high pressure in order to create flow pathways in the rock (Cuss et al. 2015; Li et al. 2015a). The fraccing fluid, which is typically water-based or an inert gas such as nitrogen, contains a variety of chemical additives with various functions (Cuss et al. 2015; Gottardo et al. 2016), one of which is a proppant. This crush-resistant material, often sand or ceramic, acts to keep the fractures open once the hydraulic pressure is relieved, so that fluid can flow to the wellbore (Cuss et al. 2015; Yekeen et al. 2019). After fraccing, the fracture network consists of new fractures connected with existing natural ones (APLNG). In gas shales, where fraccing has been successfully applied, up to 90% of the fraccing fluid can be retained in the formation and the flow-back water can have very high salt content (e.g. Yethiraj and Striolo 2013). In contrast, natural gas extraction from coal seams occurs by desorption as the water is pumped out of the fractures, thereby reducing the confining pressure. While CGS recovery can be relatively slow (Roarty 2011), fraccing in coal seams is less aggressive than in gas shales as it requires lower pressures (SEPA, version 121119).

Fraccing can be used to recover CGS from unexploited coal beds as well as from either active or abandoned coalmines. Indeed, existing underground tunnels in coalmines offer pathways for fraccing operations. Fraccing can be used to increase the drainage area of an individual well (APLNG), thus increasing the yield per wellbore and reducing the number of wells required to produce a given formation. In addition to assisting in meeting the growing demand of energy, CSG extraction can also help in preventing environmental accidents and disasters due to methane gas leaks and outbursts from coal seams (Zhang et al. 2018).

1.3 Nano-fraccing technology

The efficiency of hydraulic fracturing can be improved via the use of nanoparticles and of nanotechnology in general, a technique sometimes referred to as ‘nano-fraccing’. Nanoparticles have unique properties due to their small size (on the order of tens of 10−9 m). They have high surface area to volume ratio, as well as high strength (Yekeen et al. 2019). Although, by definition, a nanoparticle has dimensions below 100 nm, in the field of hydraulic fraccing the term ‘nanoparticle’ has been used to refer to both nano- and micro-scale particles (e.g. 1–1000 nm) (Gottardo et al. 2016). The physical and chemical properties of nanoparticles differ from their bulk counterparts, with significant effects below 10–20 nm (Montaño et al. 2014). For instance, stable emulsions/foams for enhanced oil recovery were achieved by using small particles with nominal diameters of 5 nm (Kim et al. 2016). Academic interest in nanotechnology applications to the petroleum industry has grown sharply in recent years (Nur Agista et al. 2018). Nanoparticles have found wide application in the hydrocarbon industry as nanosensors, drilling fluid and cement additives as well as for improving oil recovery and hydraulic fraccing (Nur Agista et al. 2018). Although, so far, little effort has been targeted specifically to applying nanotechnologies to the fraccing of coal seams, studies conducted in adjacent research fields may provide useful insights. For example, since the adsorption of nanoparticles on different rock types is not only controlled by the flow rate but is also strongly influenced by the presence of clay minerals (Omurlu et al. 2016; Zhou et al. 2017), titanium nanoparticles can be used as coatings on carbon nanotubes to influence residual gas adsorption/desorption (Zhang et al. 2019).

It should be recognised that the use of nanoparticles in the characterisation and eventually exploitation of unconventional hydrocarbons has been enabled by a wealth of fundamental studies. For example, Fakhri et al. (2010) quantified the transport of carbon nanotubes in porous materials, and showed that the nanotubes mobility can be controlled by tailoring their stiffness. Saha et al. (2011) showed that single walled carbon nanotubes can adsorb on porous silicate materials maintaining many of the characteristics of the pristine carbon nanotubes. Worthen et al. (2016) demonstrated how it is possible to stabilise nanoparticles dispersions in highly concentrated brines and Urena-Benavides et al. (2016) demonstrated that uniform polyelectrolyte coatings reduce the adsorption of magnetite nanoparticles in sandstone. The feasibility of advanced applications also depends on our detailed understanding of interfacial properties, facilitated by multi-scale modelling (e.g., Zheng et al. 2020; Phan and Striolo 2019; Striolo 2019).

Gottardo et al. (2016) identified 25 types of nanoparticle applications for fraccing unconventional reservoirs, including 31 commercial products. Here, we first discuss the available literature on nanotechnology applied to the fraccing of unconventional reservoirs, and we subsequently idenitfy the most potentially useful applications in CSG. In the following discussion, common problems encountered during the fraccing of coal seams are first identified, before reviewing nanotechnology-based materials and methods that have the potential to mitigate these issues. At last, recommendations are presented for the next steps in applying nanotechnology to fraccing of CSG wells in Australia, towards improving both economic and environmental performance.

2 Nanotechnology opportunities for coal seam gas

2.1 Environmental implications of fraccing leak-off during CSG operations

Sometimes, shallow coal seams, located just several hundred metres below the surface, have such low permeability (< 1 mD) to warrant stimulation (Palmer 2010; Peduzzi and Harding 2013; Seidle 2011). These coal seams may only have thicknesses on a decimetre to metre scale (Rodvelt 2014) and are often close to aquifers. Cracks induced by fraccing could propagate out of the coal and into the surrounding formation, providing pathways for both fracturing fluid and produced gas to potentially contaminate groundwater, used for drinking or agriculture, as in Queensland (Espig and de Rijke 2016; Mallants et al. 2018). Also, poor environmental performance leads to a negative image for the industry compromising social acceptability (Lock the Gate 2020).

Another form of leak-off is observed when the gas migrates through the overlying formation, with methane ultimately venting into the atmosphere (Peduzzi and Harding 2013), thereby increasing the greenhouse footprint of CSG to 20–100 times that of solid coal (Roarty 2011). Furthermore, fluid leaking reduces the pressure in the formation, lowering the efficiency of the fraccing as well as producing operations themselves (Cuss et al. 2015). As a result, the volume of coal drained by each well is reduced, the surface footprint of the operation increases requiring additional associated infrastructure (Peduzzi and Harding 2013) related to environmental impacts such as increased land clearing and loss of habitat, as well as an increase in cost.

Despite the risks just listed, it should be recognised that a recent investigation on the impacts of hydraulic fracturing for CSG in the Surat Basin Queensland Australia, suggests that any effect on soil, water and air quality is minimal (GISERA 2020). The study reported that elevated concentrations of salts, ammonia, metals, organic carbon and other compounds reduced to pre-fractured conditions within 40 days; in addition, current water treatment operations effectively removed most fraccing and geogenic chemicals from the produced water. Yet, an overall reduction in the microbial activity was noted, which had a pronounced impact on nitrifying microorganisms (GISERA 2020). Findings being somewhat contradicting (IESC 2014; GISERA 2020), long-term evaluations may be needed to gain a better understanding of the overall environmental impact of fraccing related to CSG operations.

2.2 Leakage-mitigation potential of nano-fraccing fluids

There are three main types of fraccing fluids; their comparative advantages and disadvantages are outlined in Table 1: (1) Slickwater, made almost exclusively of water and proppants, is very commonly used in CSG due to its low cost, and the ability of coal to tolerate large volumes of water (Barati and Liang 2014). However, because little can be done to prevent slickwater fluid leak-off, this fluid is not considered further here. (2) Polymer-based fraccing fluids can display excellent fluid-leak off prevention through the formation of a filtercake, a very low permeability layer that forms on the fracture surfaces (Das et al. 2018; Vipulanandan et al. 2014). Nanoparticles can be applied to polymer-based fluids to improve several characteristics, including fluid leak-off prevention (Liang et al. 2015; Wang et al. 2017; Zhang et al. 2017). However, polymers can be adsorbed to coal surfaces; because the fractured surfaces present surface areas of up to 3 m2 per cm3 (Ren et al. 2014), polymer adsorption can lead to residues that block fractures and prevent the gas migration to the wellbore (Zhang et al. 2017). As such, polymer-based fluids do not show promise in CSG applications and will not be discussed further. (3) Viscoelastic surfactant (VES) fluids are a relatively recent introduction to hydraulic fracturing technologies. It has been reported that, by using VES fluids, it is possible to limit fracture growth height (Fontana et al. 2007); VES generally do not leave a residue due to the low molecular weight of surfactants (Wu et al. 2018). Although they do not lend themselves to the formation of a filtercake (Yekeen et al. 2019), nanotechnology can provide useful properties to VES fluids used in CSG stimulation.

2.3 Nanoparticle-enhanced VES fluids

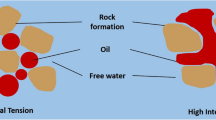

VES fluids are composed of a three-dimensional entangled network of worm-like micelles (Huang et al. 2010) (Fig. 2). The viscosity of VES fluids depends on the type of the salt solutions and the concentration of surfactants (Fig. 3), as these quantities affect the structure of the micelles. Adding nanoparticles can result in the pseudo-crosslinking of the micelles due to the high surface forces (Van der Waals) associated with the nanoparticles (Huang et al. 2010). As the micelles become physically cross linked (Fakoyah and Shah 2013), this increases the viscosity of the VES fluids (Fig. 3) even at high temperatures of up to approx. 135 °C, thus improving their proppant carrying capacity (Gurluk et al. 2013; Crews and Huang 2008). The phenomenon also leads to the formation of pseudo-filtercakes, which reduce the rate of fluid leak-off (Huang et al. 2010). Furthermore, while a polymer-generated filtercake requires chemical breakers to breakdown post-fracture, appropriate internal breakers such as polyols, for a VES filtercake can be applied within the micelles (Crews and Huang 2008; Yekeen et al. 2019). The internal breakers work by rearranging the more entangled elongated micelles to non-viscous spherical structures (Fig. 2), allowing for easy clean up and restoration of the conductive pathways (Crews and Huang 2008). As an additional benefit, VES fracturing fluids do not require clay control additives as the cationic surfactant in the system can function as a temporary clay control agent (Gomaa et al. 2011), nor biocides since they do not contain any biopolymers (Gandossi 2013; Gandossi and Von Estorff 2015).

Schematic representation of the mechanism of nanoparticle-enhanced VES fluid. Modified after Li et al. (2019) and Shibaev et al. (2021)

The apparent viscosity of 2 vol% and 4 vol% VES in salt solutions of a CaBr2, b CaCl2. The addition of MgO nanoparticles (+ NP) results in an improvement of viscosity which varies with the surfactant content, and the salt concentration indicated in parentheses in units of milligrams/cm3 against their respective curves in b. Modified after Gurluk et al. (2013)

Xiao et al. (2017) investigated a nanoparticle-enhanced VES fracturing fluid specific to coals. By introducing a low concentration (0.5%) of silica nanoparticle-modified polyester fibre to an anionic VES fracturing fluid, they were able to effectively reduce the velocity of leak-off by over 30%. The silica nanoparticles adhered to the micelles and acted as crosslinkers because of the high density of charged groups on the nanoparticle surfaces. This formed a filtercake-like structure that obstructed fluid flow. The addition of the nanocomposite fibre also reduced the amount of surfactant required to achieve the viscosity, by reducing the frictional resistance up to 20% at a shearing rate of 5000 s−1; this lowers the potential of the surfactant to adsorb onto the coal surface (and thus block conductive pores and fractures for gas flow). It also reduces cost, which is often a fundamental barrier to the implementation of VES fracturing fluids, as the cost depend on the amount of nanoparticles used. Maxey et al. (2008) demonstrated that nanoparticle concentrations below 1.12 wt% can be sufficient to improve fluid loss properties. Together, these works indicate that the nanoparticle concentrations required to reduce fluid leak off are relatively low. The additional cost associated with nanoparticles used as additives may not be a deterrant if it is accompanied by a reduction in the surfactant concentration from 2.5% to 1.0% to achieve an equivalent proppant-carrying capacity (Xiao et al. 2017).

The nanoparticles can also block nano- as well as micro-sized pores (Fig. 4) that conventional fluid loss control additives could not. Abrams (1977) reported that particle diameters must be no more than one third of the size of the pore throat if they are to effectively block it, as the particles need to penetrate into the pores to cause bridging. As the permeability of coal drops with depth (Fig. 5), so does its porosity and pore throat diameter (Barati 2015). The throat radius distribution of different coal samples varies considerably, with a range of 0.72–8.66 µm (Pan et al. 2019). The simple addition of SiO2 and polyecletrolyte complex nanoparticles to a fraccing fluid was found to reduce the volume of fluid loss by more than half, for those samples with a permeability of 0.1 mD and below (Fig. 6).

SEM picture of coal sample. Nano SiO2 (white spheres) plugs into the nanosized pores in the coal matrix. Image reproduced with permission from Cai et al. (2016)

Fluid loss coefficient (Cw) calculated for silica and polyelectrolyte complex (PEC) nanoparticles (NP), mixed with 2% KCl and hydroxypropyl guar (HPG) gum and, compared with the results for HPG solutions made in 2% KCl with no added NP. Modified after Barati (2015)

2.4 Fluid loss volume and permeability: effect of nanoparticles

Coal seams over 2.5 km deep have a reduced permeability (Fig. 5), thereby reducing the ease of extraction (Moore 2012). A larger lithostatic load presents further complications related to fracture collapse/conductivity during hydraulic stimulation. For instance, halving a fracture width can decrease its local permeability by eight times (Seidle 2011). Using proppants is critical to maintain fracture aperture (Seidle 2011; Keshavarz et al. 2015). The proppants must be strong enough to withstand the closure stresses experienced at depth, which could be greater than 20,000 psi (approx. 140,000 kPa) in the deepest wells (Ottestad 2014; Wanniarachchi et al. 2017). For coal seams at depths less than 1200 m, quartz sand is sufficient (Rodvelt 2014). However, deeper seams may require advanced proppants with higher mechanical strength. It has been observed that SiO2 and Fe2O3 nanoparticles can improve the compressive strength of cement mortar (Li et al. 2004), and that spinel (MgAl2O4), a nano-porous oxide, is capable of withstanding pressures of up to 13,000 psi (approx. 90,000 kPa) (Ottestad 2014). For these strategies to succeed, placing the proppants within every cleat and induced fracture is required for sustaining complex fracture networks able to effectively drain the seam. This is challenging because particle agglomeration or their attachment to the coal matrix can inhibit deep penetration of the injected proppants (Keshavarz et al. 2015).

2.5 Nano-proppants and conductivity

Coal is a relatively ductile rock, which can undergo creep (Ren et al. 2014). At high closure stresses, a proppant particle may be embedded into the fracture surface rather than holding it open, reducing the fracture aperture by 10% to 60% and the conductivity by 100 times (Zhi and Elsworth 2020). A recent study has shown that using a proppant size smaller than 16/30 Tyler Mesh Size (particle size range of 600–1180 micron) showed only 0.1 mm embedment, compared to 0.56 mm for proppants 16/30 in Mesh Size (Bandara et al. 2021). Despite having the capacity to greatly reduce methane production, proppant embedment in coals has received little academic attention.

Gottardo et al. (2016) identified three main applications of nanoparticles as proppants, as shown in Table 2. Out of these, ultra-lightweight proppants (ULWPs) appear to be the most promising in CSG, particularly in tackling the problem of embedment. A product, used in commercial CSG completions in China, already utilises this technology: FracBlack HT™ ('FracBlack HT: Ultra-lightweight Proppant' 2018). ULWPs are nanocomposites made of a thermoset polymer matrix and a nano-filler, which yields a density close to that of water (see Table 3). This allows for effective transport of the proppants through the fracture network ('FracBlack HT: Ultra-lightweight Proppant' 2018), which promotes even distribution, thereby lowering the likelihood of embedment (Zhi and Elsworth 2020). FracBlack HT™ is reportedly capable of withstanding closure stresses of up to 8000 psi (approx. 55,000 kPa), in part due to its particle sphericity.

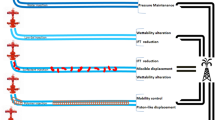

Bicerano (2012) performed conductive tests on proppant particles subjected to heat treatment and, reported that using thermoset nanocomposite ULWPs can improve conductivity by up to 50%, with the most suitable nano-filler materials being fumed silica and fumed alumina or carbon black. ULWPs can also be produced as hollow materials, which have an inherently low density (Gottardo et al. 2016). For example, Oxane Materials Inc. produces a range of hollow proppants designed with a ceramic shell of sintered nanoparticle-reinforced polymers that could improve productivity by 25% (Johnson 2010; Smith et al. 2011). The resultant proppant—OxThor™—is 100 micron in size and crush resistant up to 20,000 psi (Approx. 140,000 kPa) (Garneau 2014); the—OxFrac™ proppant is 100 s of microns in size and specifically designed with controlled manufacturing process to create perfectly spherical, hollow, mono-dispersed size particles, for conditions relevant to CSG (Gottardo et al. 2016). Shilova and Rybalkin (2018) found that the effectiveness of similar hollow aluminosilicate ULWPs increases with depth. The performance can be further improved by combining ULWPs with nano-sized proppants (Fig. 7). The smaller proppants would be injected first, followed by the larger ones. In this way, the nano-sized proppants are transported into the smallest fractures without compromising the conductivity of the main proppant pack in the larger structures (Bose et al. 2015). This allows for the propping of maximum fracture length, enhancing productivity. Besides, silica and polyelectrolyte (PEC) nanoparticles can be used as fluid loss control additives during fraccing of low permeability reservoirs, to improve the propagation of the hydraulic fractures (Fig. 6). The fluid loss was reduced to zero when PEC was mixed with 2% KCl or, when silica nanoparticles were used with HPG (hydroxypropyl guar) solution (Barati 2015).

Schematic representation of proppants and nano-proppants distributed in fractures and micro-fractures respectively, injected in stages during hydraulic fraccing for CSG. Modified after Bose et al. (2015)

Fly-ash a by-product of coal-fired power stations, because of its properties has been suggested as an attractive nano-sized proppant (Table 3). The strength of fly-ash particles is adequate to resist typical closure stresses, and it is enhanced by a high degree of sphericity (Fig. 8), which is also favourable for securing fracture conductivity (Bose et al. 2015). Fly-ash may also have fluid loss control properties (Barati and Bose 2017), in addition to being cheap.

a TEM images of fly-ash nanoparticles, illustrating their sphericity; and b Measured hardness of Class C and Class F fly-ash nanoparticles. Image adapted from Bose et al. (2015)

Other, more complex proppant technologies also utilise nanomaterials. For example, Liu et al. (2018), investigated a nanoparticle-stabilised emulsion that breaks down at depth as it interacts with the fracture surfaces, releasing the nanoparticles. The nanoparticles then adsorb onto the rock surfaces and act as proppants, with exceptional proppant placement throughout the fracture network. Likewise, carbon nanotubes offer low density coupled with strength higher than diamond (Yekeen et al. 2019), making them potentially suitable as proppants. This is promising as carbon nanotubes, now only obtained from synthetic precursors, may be obtained commercially from renewable sources such as essentials oils or plant shoots (Janas 2020).

2.6 Nanotechnology for fines mitigation

Mechanical failure of coal seams is a fairly regular occurrence (Lu and Connell 2020), typically resulting in the formation of fines. Fines are small particles of the rock material that break away and can be carried by the fluids (Zheng et al. 2018). They could block channels and pore throats, reducing conductivity and productivity (Barati and Bose 2017; Moghadasi et al. 2019; Rodvelt 2014). Coal fines can migrate to the wellbore, where they both block and damage the equipment. Fines can also be created during downhole proppant crushing, a phenomenon aggravated for smaller proppants, and yet can be reduced to some extent, by using high proppant concentration (Bandara et al. 2021). To mitigate the effects of fines, nanoparticle-enhanced VES fluids may be employed.

Even with prevention measures in place, fines formation is always to be expected and requires mitigation. Nanoparticles can be applied as surface modification agents, which can effectively mitigate fines migration (Rodvelt 2014). The nanoparticle readily stick to the proppant surface and also interact with fine particles; any fine particle in the vicinity will be attracted to the nanoparticle and captured (Barati and Bose 2017). Thereby, nanoparticle-modified proppants can flocculate fines such as colloidal silica, charged and non-charged rock particles as well as clays, and restrict them closer to their source (Huang et al. 2008). This prevents blockage of critical fracture channels and stops the fines from reaching the wellbore (Belcher et al. 2010), potentially extending the life of a given well. In laboratory experiments, MgO nanoparticles have been found to be the most effective proppant-coating for fixing fines (Ahmadi et al. 2013) and TiO2 is reported to have the highest adhesion force, i.e. better at holding the fines in place (Zheng et al. 2018). Metal oxide nanoparticles have also been investigated as additives for fines fixation (Gottardo et al. 2016). Habibi et al. (2012) compared the performance of Al2O3, MgO and SiO2 nanoparticles and found that, like with proppant coatings, MgO was the most effective at fixing fines by adsorption; fines migration was reduced by 15% when just 0.1 wt% of MgO nanoparticles were used. Nanoparticles have been successfully used for a similar purpose in drilling fluids in CSG completions (Cai et al. 2016).

3 Limitations to the implementation of nanotechnology in CSG in Australia

3.1 Regulations

Fraccing is a highly regulated procedure (APLNG), which is important in building public trust. Generally, any new chemical additive, including nanoparticles, must be assessed on factors such as environmental compatibility and possible hazards to human health before they can be used in the field. A new chemical must be submitted to the Australian Industrial Chemicals Introduction Scheme and then listed on the Australian Inventory of Industrial Chemicals (AICIS Fact Sheet 2020). Toxicology is a particular concern if nanoparticles were to end up in aquifers used for drinking water and agriculture (Abbott Chalew et al. 2013; Tosco and Sethi 2018). Materials that are not harmful in their macroscopic dimensions may become so in the form of nanoparticles (Warheit et al. 2008; Yang et al. 2010). Besides size, since the toxicity of nanoparticles depend on a large number of parameters such as surface charge, shape, stability and ability to aggregate and dissolve, each nanomaterial needs individual consideration (Gicheva and Yordanov 2013). Nanoparticles stability, both short and long-term in the porous media need to be addressed with testing under real environmental conditions (Batley and McLaughlin 2010). The nanoparticles’ manufacturing should also be considered when quantifying the life cycle assessment of the technology; for example, Sengul et al. (2008) identified high energy and water demands and high waste production that are related to the manufacture of nanoparticles. However, some nanoparticles such as fly-ash and carbon black are by-products of existing industrial processes and do not require additional manufacturing.

In Australia, regulation is further compounded because State and Territory governments have primary responsibility for regulating the environmental impact associated with the resource sector (Stilwell and Troy 2000), while the federal Australian government becomes involved when a CSG development is likely to have a significant environmental impact. Typically, matters of national environment significance include potential impacts on water resources. These are protected through the 2013 “water trigger” provisions of the Environment Protection and Biodiversity Conservation Act 1999 (EPBC Act amendment 2013). This means that each state can adopt its own regulations and assessment procedures, thereby possibly creating additional administrative hurdles in the nationwide implementation of new technologies. For example, in Queensland, operations must adhere to the Petroleum and Gas (Production and Safety) Act 2004, while in New South Wales, hydraulic fracturing is regulated by the Petroleum (Onshore) Act 1991 (Hydraulic Fracture Stimulation 2015). Although the National Partnership Agreement on Coal Seam Gas attempts to unify state regulations, it still devolves much of the responsibility to State and Territory governments (National Partnership Agreement on Coal Seam Gas and Large Coal Mining Development 2012). However, it is fundamentally important to take into account the expectations and concerns of local communities, as well as maintain transparency in the operations of CSG. These considerations can be integrated in the state level regulatory framework with costs and benefits, to offer flexibility in the strategic approaches to CSG development (Cronshaw and Grafton 2016).

3.2 Implementation of nanotechnology in CSG operations

Any additional monitoring and treatment of produced waste water due to the use of nanoparticles, is expected increase the gas production costs. Most of the fraccing fluids will be recovered with the produced water along with the desired gas (APLNG) and the nanoparticles will likely need to be removed prior to disposal. Nontheless, it may be the case that the nanoparticles concentration in the produced water is extremely low. It is estimated, for example, that an average CSG well in Queensland will generate around 10000 L of produced water per day (St John 2017). The maximum concentration of specific nanoparticles allowed in produced water before treatment processes are mandated still remains to be identified. The lower this concentration threshold is, the more expensive treatment processes are expected to be. Further, the fraccing fluid that remains in the formation could leak into aquifers, potentially contaminating them with nanoparticles. Potential environmental risks due to nanoparticles both in aquifers and in produced water will have to be quantified, as well as mitigation procedures. Considering the time and resources that must be invested by each applicable state government, companies might be deterred from further developing nanopartucle-based technologies for CSG. The likelihood of this risk is expected to increase over the next few decades as regulation tightens (Seidle 2011) in line with increasingly sceptical public opinion.

3.3 Costs

Principally, the aim of introducing any new technology, including nanoparticles, is to increase profits and reduce environmental risks. Nanoparticles could achieve these goals by yielding higher production per well. However, nanoparticles add extra costs, both in the procurement and potentially in the monitoring and treatment of produced fluids. While some nanoparticles, such as fly-ash, can be acquired cheaply (Yekeen et al. 2019), others, such as carbon nanotubes, are valued at hundreds of dollars per gram (Mohamed 2012). Montgomery (2013) estimates that a typical fracturing fluid should cost no more than $4/US gallon. Since manufacture of nanoparticles is highly energy intensive, addition of nanoparticles, even at concentrations < 1% (APLNG), would add substantial costs. As an estimate, using (8.6–24.3) × 104 kg of nanomagnetite as a downhole contrast agent against fraccing sand and ceramic proppant would be US$ 1–3 billion per well (Morrow et al. 2014). For nanotechnology to be feasible in CSG operations, low cost, large-scale production of custom built nanoparticles of suitable size, shape (e.g. rod-shaped vs. spherical) and surface charge, is required. Silica nanoparticles used to improve the rheological performance of VES could provide one such example (Hanafy et al. 2018).

3.4 Lack of field tests

Another barrier to the implementation of nanotechnology in CSG is the lack of field-scale tests. Yekeen et al. (2019) report that there have been no documented field trials of nano-fraccing, with many possible applications still undergoing research and development. Moreover, almost all the available literature focuses on fraccing in shales, and so more research is required on technologies targeted for coal seams. Alsaba et al. (2020) reported four field trials of applications of nanoparticles in the oil and gas industry. They were related to enhanced oil recovery and shale formation stabilization, as well as evaluating the stability of carbon-based fluorescent as nano sensors under reservoir conditions. However, none of the trials were related to CSG. While laboratory studies have their uses, it is vitally important for field tests to be undertaken early in the development stage to assess how any new technology perform at reservoir conditions where pressure and temperature are high and complex stress states are present, compounded by the variability in coals properties.

One intrinsic risk related to nanoparticles is their possible agglomeration (Wang et al. 2018), with loss of intrinsic characteristics and properties, including the high surface area to volume ratio which bring about the high surface forces expected, and their ability to fit into tiny fractures and pores. One important focus of future research in this field should be on the stabilisation of common nanoparticles like silica in injected fluids and prevention of their aggregation in coal samples of different ranks (Wang et al. 2022). The laboratory findings should be applied to a larger scale in the field for testing, which would need better collaboration between researchers and CSG developers.

4 Other potential solutions

There are other options available for improving recovery of CSG that are currently cheaper and potentially more socially appealing than nanoparticles. One such alternative is chemical stimulation (Jing et al. 2020). In acid stimulation, hydrocholric acid is used to demineralise coal cleats and widen conductive pathways. Oxidant stimulation uses sodium hypochlorite and widens the cleats by dissolving the coal matrix. Both have been tested on samples of Bowen Basin coals and found to successfully increase permability (Jing et al. 2020).

Another option is enhanced coal bed methane recovery (ECBM) which has a potential role in carbon sequestration (Godec et al. 2014). Due to its molecular shape, CO2 has a higher adsorption affinity to coal than methane does (Moore 2012); by pumping CO2 into the coal seam, methane is displaced and released, while CO2 is adsorbed onto the coal surface and thus stored at depth (Gandossi 2013). In fact, nanoparticles can be applied to improve this process, as discussed by Li et al. (2015b). Other gases such as nitrogen and flue gases can also be used in ECBM (Seidle 2011), in which case, production is enhanced through the reduction of partial pressure created by the injection of gas, which stimulates diffusion of CSG towards the wellbore (Packham et al. 2012). Modelling studies are underway to better understand the molecular mechanisms responsible for these observations (e.g. Le et al. 2015; Cole and Striolo 2019; Badmos et al. 2020).

5 Summary and conclusions

This study presented some of the most promising potential applications for nanoparticles in the hydraulic stimulation of coal seams gas as well as some barriers in implementing them:

-

(1)

Addition of nanoparticles such as MgO to VES fluids can improve their viscosity with the formation of a pseudo-filtercake on the surface of fractures. This prevents fluid loss into the surrounding formation, which is of particular importance in shallow and thin coal seams where fluid leakage could lead to the contamination of aquifers. For deeper coal seams, with permeability values of < 0.1 mD, the application of silica and polyelectrolyte complex (PEC) nanoparticles can be effective in controlling fluid loss.

-

(2)

Sequenced use of nano-proppants can help create a more extensive fracture network and reduce proppant embedment. Nano-sized proppants such as fly-ash are injected first and deposit in the smallest fractures. ULWPs are injected next and evenly prop open the main conductive channels.

-

(3)

Coating conventional proppant particles with nanoparticles encourages the fixation of fines, as a result of strong surface attraction. This prevents fines from blocking critical fractures and damaging equipment at the wellbore.

-

(4)

Meeting regulatory requirements that may become more and more stringent in the coming years, as well as the cost of the nanoparticles themselves may outweigh the benefits of implementing nanotechnology.

-

(5)

There is very little work focusing specifically on nanotechnology in CSG production. Because of the paucity of field studies where these technologies are tested under realistic reservoir conditions, this report advocates cautious at this time, although potential opportunities have been outlined.

In order to ensure that the nanotechnology options become viable in Australia, this study recommends the following:

-

(1)

Experimental laboratory study with nanoparticles on a wide range of coal samples, to account for the materials heterogeneity.

-

(2)

Modelling and experiments conducted at reservoir conditions, towards understanding of how nanoparticles behaves in realistic downhole scenarios.

-

(3)

Taking forward promising laboratory applications to small scale field experiments.

-

(4)

Investigations on the potential risks (or lack thereof) of nanoparticles to health and the environment, to identify produced water treatment processes in anticipation of future approval requirements.

References

Abbott Chalew TE, Ajmani GS, Huang H, Schwab KJ (2013) Evaluating nanoparticle breakthrough during drinking water treatment. Environ Health Perspect 121(10):1161–1166

Abrams A (1977) Mud design to minimize rock impairment due to particle invasion. J Petrol Technol 29(05):586–592. Paper Number: SPE-5713-PA

Ahmadi M, Habibi A, Pourafshary P, Ayatollahi S (2013) Zeta-potential investigation and experimental modelling of nanoparticles deposited on rock surface to reduce fines migration. SPE J 18(3):534–544

AICIS Fact Sheet (2020) AICIS. https://industrialchemicals.gov.au. Accessed 19th July 2020

Alexeev AD, Feldman EP, Vasilenko TA (2010) Kinetics of methane desorption from coal nano- and mesostructures. Energy Fuels 24(8):4375–4379

Alsaba MT, Al Dushaishi MF, Abbas AK (2020) A comprehensive review of nanoparticles applications in the oil and gas industry. J Petrol Explor Prod Technol 10:1389–1399

Australian Energy Update 2018 (2018) Australian Government, Department of the Environment and Energy. DEE. https://www.energy.gov.au/publications/australian-energy-update-2018. Accessed 15 Jan 2021

Australian Government Geoscience Australia (2021). https://www.ga.gov.au/digital-publication/aecr2021/gas. Accessed 4 Feb 2022

Badmos SK, Islam N, Shah U, Striolo A (2020) Competitive adsorption and reduced mobility: N-octane, CO2 and H2S in alumina and graphite pores. Mol Phys 118:e1781944

Bandara KMAS, Ranjith PG, Rathnaweera TD, Wanniarachchi WAM, Yang SQ (2021) Crushing and embedment of proppant packs under cyclic loading: an insight to enhanced unconventional oil/gas recovery. Geosci Front 12:100970

Barati R (2015) Application of nanoparticles as fluid loss control additives for hydraulic fracturing of tight and ultra-tight hydrocarbon-bearing formations. J Nat Gas Sci Eng 27:1321–1327

Barati R, Bose CC (2017) Chapter 3—Improvement of hydraulic fracture conductivity using nanoparticles. In: Al-Megren HA, Altamimi RH (eds) Advances in natural gas emerging technologies. s.l.:InTech, London, pp 55–74

Barati R, Liang J-T (2014) A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J Appl Polym Sci 131:40735

Batley GE, McLaughlin MJ (2010) Fate of manufactured nanomaterials in the Australian Environment. CSIRO Niche Manufacturing Flagship Report. https://www.environment.gov.au/system/files/pages/371475a0-2195-496d-91b2-0a33f9342a6d/files/manufactured-nanomaterials.pdf. Accessed 19th July 2020

Belcher CK, Seth K, Hollier R, Paternostro BP (2010) Maximising production life with the use of nanotechnology to prevent fines migration. In: International oil and gas conference and exhibition in China. SPE 132152

Bicerano J (2012) Method for the fracture stimulation of a subterranean formation having a wellbore by using impact modified thermoset polymer nanocomposite particles as proppants. United States of America, Patent No. US20120325474A1

Bose CC, Fairchild B, Jones T, Gul A, Ghahfarokhi RB (2015) Application of nanoproppants for fracture conductivity improvement by reducing fluid loss and packing of microfractures. J Nat Gas Sci Eng 27:424–431

Bustos OA, Powell AR, Olsen TN, Kordziel WR, Sobernheim DW (2007) Fiber-laden fracturing fluid improves production in the Bakken Shale Muti-lateral Play. In: Rocky Mountain oil and gas technology symposium, 16–18 April, Denver, Colorado

Cai J, Gu S, Wang F, Yang X, Yue Y, Wu X, Chixotkin VF (2016) Decreasing coalbed methane formation damage using microfoamed drilling fluid stablized by silica nanoparticles. J Nanomater 2016(10):1–11

Cleveland CJ, Morris C (2015) Dictionary of energy, 2nd edn. s.l.:Elsevier Ltd., Amsterdam

Cole DR, Striolo A (2019) The influence of nanoporosity on carbon-bearing fluids. In: Daniel I, Dasgupta R, Orcutt B (eds) Deep carbon: past to present. Cambridge University Press, New York

Crews JB, Huang T (2008) Nanotechnology applications in viscoelastic surfactant stimulation fluids. SPE Prod Oper 23:512–517

Cronshaw I, Grafton RQ (2016) A tale of two states: development and regulation of coal bed methane extraction in Queensland and New South Wales, Australia. Resour Policy 50:253–263

Cuss RJ, Wiseall AC, Hennissen JAI, Waters CN, Kemp SJ, Ougier-Simonin A, Holyoake S, Haslam RB (2015) Hydraulic fracturing: a review of theory and field experience, M4ShaleGas report D1.1, British Geological Survey, Nottingham, United Kingdom. https://ec.europa.eu/inea/en/horizon-2020/projects/h2020-energy/shale-gas/m4shalegas. Accessed 15 Jan 2021

Das A, Chauhan G, Verma A, Kalita P, Ojha K (2018) Rheological and breaking studies of novel single-phase surfactant-polymeric gel system for hydraulic fracturing application. J Petrol Sci Eng 167:559–567

Davies PJ, Gore DB, Khan SJ (2015) Managing produced water from coal seam gas projects: implications for an emerging industry in Australia. Environ Sci Pollut Res 22:10981–11000

Dingsdag DP (2016) Risks of coal seam and shale gas extraction on groundwater and aquifers in Eastern Australia. In: Maheshwari B, Singh VP, Thoradeniya B (eds) Balanced urban development: options and strategies for liveable cities. Springer International Publishing, Cham, pp 235–258

Espig M, de Rijke K (2016) Unconventional gas developments and the politics of risk and knowledge in Australia. Energy Res Soc Sci 20:82–90

Esterle JS, Williams R, Sliwa R, Malone M (2006) Variability in coal seam gas parameters that impact on fugitive gas emissions estimations for Australian Black Coals. In: The 36th Sydney Basin symposium 2006: advances in the study of the Sydney Basin, University of Woolongong, NSW, 27th–29th November, 2006

Evershed N (2018) An unconventional gas boom: the rise of CSG in Australia. s.l.:The Guardian. https://www.theguardian.com/environment/datablog/ng-interactive/2018/jun/18/an-unconventional-gas-boom-the-rise-of-csg-in-australia#:~:text=Australia's%20production%20of%20coal%20seam,gas%20production%20in%202015%2D16.&text=This%20boom%20has%20been%20led,the%20east%20coast%20of%20Australia. Accessed 19 July 2020

Fakhri N, MacKintosh FC, Lounis B, Cognet L, Pasquali M (2010) Brownian motion of stiff filaments in a crowded environment. Science 330(6012):1804

Fakoyah MF, Shah SN (2013) Rheological properties of surfactant-based and polymeric nanofluids. In: SPE/ICoTA coiled tubing & well intervention conference and exhibition, 21st–22nd March 2017, Houston, Texas

Fontana C, Muruaga E, Perez DR, Cavazzoli GD, Krenz A (2007) Successful application of a high temperature viscoelastic surfactant (VES) fracturing fluids under extreme conditions in Patagonian Wells, San Jorge Basin. In: EUROPEC/EAGE conference and exhibition, 11–14 June, London, UK

FracBlack HT: Ultra-lightweight Proppant (2018) Sun speciality products. http://www.sunspecialityproducts.com/wp-content/uploads/2018/10/SUN-FracBlack-Technical-Data-Sheet-6_2018.pdf. Accessed 15 July 2020

Gandossi L (2013) An overview of hydraulic fracturing and other stimulation technologies. Publications Office of the European Union. https://op.europa.eu/en/publication-detail/-/publication/6cde6c0e-e041-11e5-8fea-01aa75ed71a1. Accessed 19th July 2020

Gandossi L, Von Estorff U (2015) An overview of hydraulic fracturing and other formation stimulation technologies for shale gas production—update 2015. Publications Office of the European Union. https://ec.europa.eu/jrc/en/publication/eur-scientific-and-technical-research-reports/overview-hydraulic-fracturing-and-other-formation-stimulation-technologies-shale-gas-0. Accessed 19th July 2020

Garneau B (2014) Oxane materials announces stronger, lighter OxThor for demanding deepwater applications. s.l.:CISION PR Newswire. https://www.prnewswire.com/news-releases/oxane-materials-announces-stronger-lighter-oxthor-for-demanding-deepwater-applications-253242821.html. Accessed 19th July 2020

Gas Resources in Australia: resources assessment and operation overview, s.l.: Upstream Petroleum Resources Working Group Report to the COAG Energy Council. COAG (2017). http://www.coagenergycouncil.gov.au/publications/report-coag-energy-council-unconventional-reserves-resources-production-forecasts-and. Accessed 15th Jan 2021

Gicheva G, Yordanov G (2013) Removal of citrate-coated silver nanoparticles from aqueous dispersions by using activated carbon. Colloids Surf A 431:51–59

GISERA, Gas Industry Social and Environmental Research Alliance (2020) Air, water and soil impacts of hydraulic fracturing, phase 2. https://gisera.csiro.au/project/air-water-and-soil-impacts-of-hydraulic-fracturing-phase-2/. Accessed 15th Jan 2021

Godec M, Koperna G, Gale J (2014) CO2-ECBM: a review of its status and global potential. Energy Procedia 63:5858–5869

Gomaa AM, Cawiezel KE, Gupta DV, Carman P, Nasr-El-Din HA (2011) Viscoelastic evaluation of a surfactant gel for hydraulic fracturing. Paper presented at the SPE European formation damage conference, Noordwijk, The Netherlands, June 2011. Paper Number: SPE-143450-MS

Gottardo S, Mech A, Gavriel M, Gaillard C, Sokull-Kluttgen B (2016) Use of nanomaterials in fluids, proppants, and downhole tools for hydraulic fracturing of unconventional hydrocarbon reservoirs, s.l.: European Comission, JRC Technical Reports. https://core.ac.uk/download/pdf/81685116.pdf

Guo P, Cheng Y (2013) Permeability prediction in deep coal seam: a case study on the No. 3 coal seam of the Southern Qinshui Basin in China. Sci World J 2013:161457

Guo T, Zhang SC, Xiao B, Liu GQ, Wang F, Zhang JC, Bian XB (2012) Evaluation and optimisation of new nanocomposite fiber for fracturing technology based on new equipment. Transp Porous Media 94:243–257

Gurluk MR, Nasr-El-Din HA, Crews JB (2013) Enhancing the performance of viscoelastic surfactant fluids using nanoparticles. SPE 94:164900

Habibi A, Ahmadi M, Pourafshary P, Ayatollahi Sh, Al-Wahaibi Y (2012) Reduction of fines migration by nanofluids injection: an experimental study. SPE J 18(2):309–318

Hamawand I, Yusaf T, Hamawand SG (2013) Coal seam gas and associated water: a review paper. Renew Sustain Energy Rev 22:550–560

Hanafy A, Najem F, Nasr-El-Din HA (2018) Impact of nanoparticles shape on the VES performance for high temperature applications. Paper presented at the SPE Western regional meeting, Garden Grove, California, USA, April 2018. Paper Number: SPE-190099-MS

Huang T, Crews JB, Willingham JR (2008) Nanoparticles for formation fines fixation and improving performance of surfactant structure fluids. Paper presented at the International petroleum technology conference, Kuala Lumpur, Malaysia, December 2008. Paper Number: IPTC-12414-MS

Huang T, Crews JB, Agrawal G (2010) Nanoparticle pseudocrosslinked micellar fluids: optimal solution for fluid-loss control with internal breaking. Paper presented at the SPE international symposium and exhibition on formation damage control, Lafayette, Louisiana, USA, February 2010. Paper Number: SPE-128067-MS

Huang B, Huang CM, Cheng QY, Huang CH (2012) Hydraulic fracturing technology for improving permeability in gas-bearing coal seams in underground coal mines. Int J S Afr Inst Min Metall 112(6):485–495

Hydraulic Fracture Stimulation (2015) APLNG Australian Pacific LNG, n.d.. s.l.:Austalia Pacific LNG. https://www.aplng.com.au/content/dam/aplng/documents/Factsheet_Fraccing-APLNG.pdf

IESC (2014) Coal seam gas extraction and co-produced water. Independent Expert Scientific Committee on Coal Seam Gas and Large Coal Mining Development. https://iesc.environment.gov.au/system/files/resources/3b6a1b5a-dde5-4c24-9b16-5520321c2765/files/fact-sheet-coal-seam-gas-extraction-co-produced-water.pdf. Accessed 15th Jan 2021

Islam R (2015) Chapter 2—world gas reserve and the role of unconventional gas. In: Unconventional gas reservoirs, pp 9–69

Jackson RB, Vengosh A, Darrah TH, Warner NR, Down A, Poreda RJ, Osborn SG, Zhao K, Karr JD (2013) Increased stray gas abundance in a subset of drinking water wells near Marcellus shale gas extraction. PNAS 110(28):11250–11255

Janas D (2020) From bio to nano: a review of sustainable methods of synthesis of carbon nanotubes. Sustainability 12(10):4115

Jawed A, Vashsith V, Sharma B (2017) Effect of high temperature on fly ash concrete. SSRG Int J Civ Eng 4(6):48–51

Jenkins CD, Boyer C (2008) Coalbed and shale-gas reservoirs. J Petrol Technol 60(2):92–99

Jing Z, Balucan RD, Underschultz JR, Pan S, Steel KM (2020) Chemical Stimulation for enchancing coal seam permeability: laboratory study into permeability variation and coal structure examination. Int J Coal Geol 219:103375

Johnson K (2010) Advances in nanotechnology hold huge potential promise in upstream applications. s.l.:The American Oil & Gas Reporter. https://www.aogr.com/magazine/cover-story/advances-in-nanotechnology-hold-huge-potential-promise-in-upstream-applicat

Keshavarz A, Badalyan A, Carageorgos T, Bedrikovetsky P (2015) Stimulation of coal seam permeability by micro-sized graded proppant placement using selective fluid properties. Fuel 144:228–236

Kim J, Worthen AJ, Johnston KP, DiCarlo DA, Huh C (2016) Size-dependent properties of silica nanoparticles for Pickering stabilization of emulsions and foams. J Nanopart Res 18:82

Laxminarayana C, Crosdale PJ (1999) Role of coal type and rank on methane sorption characteristics of Bowen Basin, Australia coals. Int J Coal Geol 40:309–325

Le T, Striolo A, Cole DR (2015) CO2/C4H10 mixtures simulated in silica slit pores: relation between structure and dynamics. J Phys Chem C 119:15274–15284

Li H, Xiao H-g, Yuan J, Ou J (2004) Microstructure of Cement mortar with nano-particles. Compos B Eng 35(2):185–189

Li Q, Xing H, Liu J, Liu X (2015a) A review of hydraulic fracturing of unconventional reservoir. Petroleum 1(1):8–15

Li Y, DiCarlo D, Li X, Zang J, Li Z (2015b) An experimental study on application of nanoparticles in unconventional gas reservoir CO2 fracturing. J Petrol Sci Eng 133:238–244

Liang F, Al-Muntasheri G, Ow H, Cox J (2015) Reduced polymer loading, high temperature fracturing fluids using nano-crosslinkers. SPE J 22(02):622–631

Liu D, Yan Y, Bai G, Yuan Y, Zhu T, Zhang F, Shao M, Tian X (2018) Mechanisms for stablising and supporting shale fractures with nanoparticles in Pickering emulsion. J Petrol Sci Eng 164:103–109

Lock the Gate (2020) Lock the Gate Alliance. https://lockthegate.org.au. Accessed 17 June 2020

Lu M, Connell LD (2020) Coal seam failure during primary/enhanced gas prodution: how failure develops in fields. Int J Coal Geol 221:103432

Mallants D, Jeffrey R, Zhang X, Wu B, Kear J, Chen Z, Wu B, Bekele E, Raiber M, Apte S, Gray B (2018) Review of plausible chemical migration pathways in Australian coal seam gas basins. Int J Coal Geol 195:280–303

Marcos-Martinez R, Measham TG, Fleming-Muñoz DA (2019) Economic impacts of early unconventional gas mining: lessons from the coal seam gas industry in New South Wales, Australia. Energy Policy 125:338–346

Maxey J, Crews J, Huang T (2008) Nanoparticle associated surfactant micellar fluids. AIP Conf Proc 1027:857

Moghadasi R, Rostami A, Hemmati-Sarapardeh A (2019) Application of nanofluids for treating fines migration during hydraulic fracturing: experimental study and mechanistic undertanding. Adv Geo-Energy Res 3(2):198–206

Mohamed AR (2012) New method for continuous production of carbon nanotubes. Scientific Malaysian. https://www.scientificmalaysian.com/2012/04/23/continuous-production-carbon-nanotubes-usm/

Montaño MD, Badiei HR, Bazargan S, Ranville J (2014) Improvements in the detection and characterization of engineered nanoparticles using spICP-MS with microsecond dwell times. Environ Sci Nano 1:338–346

Montgomery C (2013) Fracturing fluids. Paper presented at the ISRM international conference for effective and sustainable hydraulic fracturing. Brisbane, Australia. Paper Number: ISRM-ICHF-2013-035

Moore TA (2012) Coalbed methane: a review. Int J Coal Geol 101:36–81

Morrow L, Potter DK, Barron AR (2014) Detection of magnetic nanoparticles against proppant and shale reservoir rocks. J Exp Nanosci 10(13):1028–1041

National Partnership Agreement on Coal Seam Gas and Large Coal Mining Development (2012) Australian Government, Department of Agriculture, Water and the Environment. DAWE. https://www.environment.gov.au/water/coal-and-coal-seam-gas/office-of-water-science/npa. Accessed 15th Jan 2021

Natural Gas Explained (2019) U.S. Energy Information Administration. EIA. https://www.eia.gov/energyexplained/natural-gas/. Accessed 19th July 2020

Nur Agista M, Guo K, Yu Z (2018) A state-of-the-art review of nanoparticles application in petroleum with a focus on enhanced oil recovery. Appl Sci 8:871

Omurlu C, Pham H, Nguyen QP (2016) Interaction of surface-modified silica nanoparticles with clay minerals. Appl Nanosci 6:1167–1173

Ottestad E (2014) Nano-porous proppants for shale oil and gas production. Masters thesis. Norwegian University of Science and Technology, Department of Materials Science and Engineering. https://core.ac.uk/download/pdf/52104027.pdf

Packham R, Connell L, Cinar Y, Moreby R (2012) Observations from an enhanced gas recovery field trial for coal mine gas management. Int J Coal Geol 100:82–92

Palmer I (2010) Coalbed methane completions: a world view. Int J Coal Geol 82:184–195

Pan J, Zhang Z, Li M, Wu Y, Wang K (2019) Characteristics of multi-scale pore structure of coal and its influence on permeability. Nat Gas Ind B 6(4):357–365

Peduzzi P, Harding RRR (2013) Gas fracking: can we safely squeeze the rocks? Environ Dev 6:86–89

Petroleum and Gas (Production and Safety) Act 2004. https://www.legislation.qld.gov.au/view/pdf/inforce/current/act-2004-025. Accessed 6th Feb 2022

Phan A, Striolo A (2019) Methane transport through hierarchical silica micro-mesoporous materials: from non-equilibrium atomistic simulations to phenomenological correlations. Microporous Mesoporous Mater 288:109559

Queenland Government, Open Data Portal. https://www.data.qld.gov.au/dataset/petroleum-and-gas-production-and-reserve-statistics-historical-data/resource/3f70f964-94d2-4cf0-a2dc-695eed6ad093. Accessed 4th Feb 2022

Ren J, Zhang L, Ren S, Lin J, Meng S, Ren G, Gentzis T (2014) Multi-branched horizontal wells for coalbed methane production: field perfomance and well structure analysis. Int J Coal Geol 131:52–64

Roarty M (2011) The development of Australias's coal seam gas resources. s.l.:Parliament of Australia. https://www.aph.gov.au/About_Parliament/Parliamentary_Departments/Parliamentary_Library/pubs/BN/2011-2012/CoalSeamGas

Rodvelt G (2014) Chapter 6—vertical well construction and hydraulic fracturing for CBM completions. In: Thakur P, Schatzel S, Aminian K (eds) Coal bed methane: from prospect to pipeline. s.I.:Elsevier Inc., Amsterdam, pp 101–135

Saha A, Ghosh S, Behabtu N, Pasquali M, Marti AA (2011) Single-walled carbon nanotubes shell decorating porous silicate materials: a general platform for studying the interaction of carbon nanotubes with photoactive molecules. Chem Sci 2:1682–1687

Salmachi A, Yarmohammadtooski Z (2015) Production data analysis of coalbed methane wells to estimate time required to reach peak of gas production. Int J Coal Geol 141:33–41

Sampath KHSM, Perera MSA, Elsworth D, Ranjith PG, Matthai SK, Rathnaweera T, Zhang G (2019) Effect of coal maturity on CO2-based hydraulic fracturing process in coal seam gas reservoirs. Fuel 236:179–189

Seidle J (2011) Fundamentals of coalbed methane reservoir engineering. s.l.:PennWell Books, Tulsa

Sengul H, Theis TL, Ghosh S (2008) Towards sustainable nanoparticles: an overview of nanomaufacturing methods. J Ind Ecol 12(3):329–359

SEPA, Scottish Environment Protection Agency. Regulatory guidance: coal bed methane and shale gas. Version 121119. https://www.sepa.org.uk/media/139706/unconventional_gas_guidance.pdf

Shibaev AV, Osiptsov AA, Philippova OE (2021) Novel trends in the development of surfactant-based hydraulic fracturing fluids: a review. Gels 7:258

Shilova T, Rybalkin L (2018) A lightweight proppant influence on the coal specimen permeability. s.l.: Proceedings of 18th international multidisciplinary scientific GeoConference SGEM 2018, 2nd–8th July, 2018, 18, Book number: 1.3, pp 27–32

Simshauser P, Nelson T (2015) Australia’s coal seam gas boom and the LNG entry result. Austral J Agric Resour Econ 59(4):602–623

Smith RJ, Loscutova JR, Coker CHE, Barron AR, Skala RD, Whitsitt EA, Weisner M, Costantino SA, Bordia R (2011) Composition and methods for making a proppant. United States of America, Patent No. US2011/0077176A1

St John A (2017) The coal seam gas debate. s.l.:Parliament of Australia. https://www.aph.gov.au/About_Parliament/Parliamentary_Departments/Parliamentary_Library/pubs/BriefingBook44p/GasDebate

Stilwell F, Troy P (2000) Multilevel governance and urban development in Australia. Urban Stud 37(5–6):909–930

Striolo A (2019) Studying surfactants adsorption on heterogeneous substrates. Curr Opin Chem Eng 23:115–122

Tosco T, Sethi R (2018) Human health risk assessment for nanoparticle-contaminated aquifir systems. Environ Pollut 239:242–252

Unconventional Gas Mining Submission 121 (2014) Submitter: Australian Petroleum Production & Exploration Association (APPEA)

Underschultz JR, Vink S, Garnett A (2018) Coal seam gas associated water production in Queensland: actual versus predicted. J Nat Gas Sci Eng 52:410–414

Urena-Benavides EE et al (2016) Low adsorption of magnetite nanoparticles with uniform polyelectrolyte coatings in concentrated brine on model silica and sandstone. Ind Eng Chem Res 55(6):1522–1532

Vengosh A, Jackson RB, Warner N, Darrah TH, Kondash A (2014) A critical review of the risks to water resources from unconventional shale gas development and hydraulic fracturing in the United States. Environ Sci Technol 48(15):8334–8348

Vipulanandan C, Mohammed A, Qu Q (2014) Characterizing the hydraulic fracturing fluid modified with nano silica proppant. American Association of Drilling Engineers. AADE-15-NTCE-38

Wang K, Wang Y, Ren J, Dai C (2017) Highly efficient nano boron crosslinker for low-polymer loading fracturing fluid system. Paper presented at the SPE/IATMI Asia Pacific oil and gas conference and exhibition, Jakarta, Indonesia, October 2017. Paper Number: SPE-186943-MS

Wang T, Zhang Y, Li L, Liu Y, Fang J, Dai C, You Q (2018) Experimental study on pressure-decreasing performance and mechanism of nanoparticles in low permeability reservoir. J Petrol Sci Eng 166:693–703

Wang X, Cheng H, Chai P, Bian J, Wang X, Liu Y, Yi X, Pan S, Pan Z (2020) Pore characterization of different clay minerals and its impact on methane adsorption capacity. Energy Fuels 34(10):12204–12214

Wang G, Li Y, Wang E, Huang Q, Wang S, Li H (2022) Experimental study on preparation of nanoparticle-surfactant nanofluids and their effects on cola surface wettability. Int J Min Sci Technol. (In press)

Wanniarachchi WAM, Ranjith PG, Perera MSA (2017) Shale gas fracturing using foam-based fracturing fluid: a review. Environ Earth Sci 76:76–91

Warheit DB, Sayes CM, Reed KL, Swain KA (2008) Health effects related to nanoparticle exposures: environmental, health and safety considerations for assessing hazards and risks. Pharmacol Ther 120(1):35–42

Water trigger 2013. EPBC Act amendment (2013) Independent review of the 2013 EPBC Act amendment—water trigger. Australian Government, Department of Agriculture, Water and the Environment. https://www.environment.gov.au/epbc/what-is-protected/water-resources/review

Worthen AJ, Tran V, Cornell KA, Truskett TM, Johnston KP (2016) Steric stabilization of nanoparticles with grafted low molecular weight ligands in highly concentrated bribes including divalent ions. Soft Matter 12:2025–2039

Wu H, Zhou Q, Sun R, Zhang P, Bai B, Kang W (2018) SiO2 nanoparticle-assisted low-concentration viscoelastic cationic surfactant fracturing fluid. J Mol Liq 266:864–869

Xiao B, Jiang T, Zhang S (2017) Novel nanocomposite fiber-laden viscoelastic fracturing fluid fo coal bed methane reservoir stimulation. J Energy Resour Technol 139(2):022906. Paper No: JERT-16-1148

Yan Z, Dai C, Zhao., M., Sun, Y. & Zhao, G., (2016) Development, formation mechanism and performance evaluation of a reusable viscoelastic surfactant fracturing fluid. J Ind Eng Chem 37:115–122

Yang Z, Liu ZW, Allaker RP, Reip P, Oxford J, Ahmad Z, Ren G (2010) A review of nanoparticle functionality and toxicity on the central nervous system. J R Soc Interface 7(4):411–422

Yekeen N, Padmanabhan E, Idris AK, Chauhan PS (2019) Nanoparticles applications for hydraulic fracturing of unconventional reservoirs: a comprehensive review of recent advances and prospects. J Petrol Sci Eng 178:41–73

Yethiraj A, Striolo A (2013) Fracking: what can physical chemistry offer? J Phys Chem Lett 4(4):687–690

Zhang XL, Wu GJ, Yao TD, Zhang CL, Yue YH (2011) Characterization of individual fly ash particles in surface snow at Urumqi Glacier No. 1, Eastern Tianshan. Chin Sci Bull 56:3464–3473

Zhang Z, Pan H, Liu P, Zhao M, Li X, Zhang Z (2017) Boric acid incorporated onto the surface of reactive nanosilica providing a nano-crosslinker with potential in guar gum fracturing fluid. J Appl Polym Sci 134(27):45037

Zhang Z, Wang H, Deng B, Li M, Zhang D (2018) Field investigation of hydraulic fracturing in coal seams and its enhancement for methane extraction in the Southest Sichuan Basin, China. Energies 11(12):3451

Zhang H, Li D, Wurz P, Cheng Y (2019) Residual gas adsorption and desorption in the field emission of titanium-coated carbon nanotubes. Materials 12(18):2937

Zheng X, Perreault F, Jang J (2018) Fines adsorption on nanoparticle-coated surface. Acta Geotech 13:219–226

Zheng L, Rücker M, Bultreys T, Georgiadis A, Mooijer-van den Heuvel MM, Bresme F, Trusler JPM, Müller EA (2020) Surrogate models for studying the wettability of nanoscale natural rough surfaces using molecular dynamics. Energies 13(11):2770

Zhi S, Elsworth D (2020) Proppant embedment in coal and shale: impacts of stress hardening and sorption. Int J Coal Geol 227:103545

Zhou H, Chen M, Zhu L, Li L, Zhu R (2017) Molecular simulation study on the interaction of nanoparticles with clay minerals: C60 on surfaces of pyrophyllite and kaolinite. Clays Clay Miner 65:398–409

Zou Q, Lin B, Liu T, Hu X, Zheng C (2017) Variations in coalbed gas content, initial gas desorption property and coal strength after drilling–slotting integration technique and gas drainage: insight into pore characteristics. Int J Oil Gas Coal Technol 15:235–266

Acknowledgements

This work was supported, in part, by the Department of Chemical Engineering, University College London, and by the Futures Industries Institute of the University of South Australia. AS gratefully acknowledges financial support from the Horizon 2020 project ‘Science 4 Clean Energy’, supported by grant number 764810 from the European Commission, and from the US Department of Energy, Office of Basic Energy Sciences, Division of Chemical Sciences, Geosciences and Biosciences, under grant number DE-SC0006878. MM gratefully acknowledges financial support from the Australian research council, FT200100301.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Marsden, H., Basu, S., Striolo, A. et al. Advances of nanotechnologies for hydraulic fracturing of coal seam gas reservoirs: potential applications and some limitations in Australia. Int J Coal Sci Technol 9, 27 (2022). https://doi.org/10.1007/s40789-022-00497-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-022-00497-x