Abstract

Purpose of Review

The comprehensive assessment of timber and fuelwood harvesting operations through the consideration of the three pillars of sustainability: Economic, social, and environmental has not received much attention. The use of criteria can significantly improve impact assessment. Therefore, the objective of this review paper is to compile and analyze the most commonly used criteria and indicators for each dimension of sustainability in logging operations over the last 6 years. This review provides an overview of these criteria for different harvesting machines, geographical areas, slope classes, time periods, types of research, and silvicultural treatments.

Recent Findings

The environmental pillar was the most studied (46%), followed by the economic pillar (38%). Productivity was the most investigated criterion (15%). On the one hand, productivity is linked to the environmental and social pillars, as it is related to the level of greenhouse gas emissions, energy consumption, and the employment rate. However, productivity is mainly used as a criterion of financial interest, as it is most often studied in combination with costs. In addition to productivity, the other most frequently examined criteria were costs (10%), soil nutrients (9.5%), and soil compaction (9%). The social dimension was the least studied pillar (16%). This may be due to a lack of knowledge of social sustainability issues in this area.

Summary

Sustainability is achieved when all three dimensions are balanced. The results of this review show an imbalance, with economic and environmental aspects being weighted more heavily than social aspects. Balancing all three dimensions typically requires an assessment of trade-offs. This review provides a comprehensive summary of the criteria that have been studied to date and can be used as a checklist and guideline for future sustainability assessments of harvesting operations.

Similar content being viewed by others

Introduction

Hardly anything else has gained as much importance in the last few centuries as the concept of sustainability. However, the term sustainable has a long history. Its roots lie in forestry and are attributed to Johann “Hannß” Carl von Carlowitz (1645–1714) [1]. Since then, in forestry, the idea of sustainability has changed from a stable forest area and sustained timber yield to a wider variety of goods and ecosystem values demanded by society [2, 3]. Since the “Earth Summit” in Rio de Janeiro in 1992, the concept of Sustainable Development has been the guiding principle of International Environment and Development Policy [4]. The three-pillar model (economic, social, and environmental)—as an anthropocentric approach to sustainability—became known worldwide. It represents the consensus of various scientific definitions of sustainability [4]. The United Nations Conference on Sustainable Development (Rio+20), held in Rio de Janeiro in 2012, defined 17 overarching goals that go beyond the three dimensions of sustainable development. Today’s Sustainable Development Goals (SDGs) add peace and international cooperation to the list [5]. Often used interchangeably, the concept of sustainability and the concepts of sustainable development are distinct [6]. While sustainability is concerned with the long-term existence of an ecosystem in use [7], sustainable development is concerned with the societal process of achieving an equilibrium between environmental, economic, and social aspects. Therefore, sustainable development is an attempt to achieve sustainability as a long-term goal [6]. At the Second Ministerial Conference on the Protection of Forests in Europe (MCPFE), held in Helsinki in 1993, this trend towards sustainable forest management (SFM) was defined and adopted at the political level [8]. The United Nations Forum on Forests (2007) defines SFM “as a dynamic and evolving concept, aims to maintain and enhance the economic, social and environmental values of all types of forests, for the benefit of present and future generations” [9]. An important outcome of the MCPFE was the creation of six criteria that allow measuring the achievement of SFM goals in Europe [10]:

-

Maintenance and appropriate enhancement of forest resources and their contribution to global carbon cycles (Criterion 1)

-

Maintenance of forest ecosystem health and vitality (Criterion 2)

-

Maintenance and encouragement of productive functions of forests (wood and non-wood) (Criterion 3)

-

Maintenance, conservation, and appropriate enhancement of biological diversity in forest ecosystems (Criterion 4)

-

Maintenance and appropriate enhancement of protective functions in forest management (notably soil and water) (Criterion 5)

-

Maintenance of other socio-economic functions and conditions (Criterion 6)

The use of criteria and indicators (C &I) arose from the need to assess specific benefits and sustainability of forest management systems [11, 12]. C &I belong to a hierarchical framework and represent the levels below the principles, which are the result of a political process [12]. Criteria have the function of compliance with defined principles [12] and are used to assess their distinguishing characteristics [13]. The level below the criteria is represented by indicators. Their function is two-fold: (i) to provide criteria with quantitative or qualitative parameters [12] and (ii) to derive the state of a particular criterion [14]. Timber harvesting is a substantial part of the SFM and has multiple impacts on biodiversity conservation, renewable energy production, climate change, and carbon sequestration [15,16,17,18]. It also plays an important role in the wood-supply chain, where wood material changes location or appearance and is transformed into services and products [2]. It includes the technical processes of felling, delimbing, bucking, extraction, and debarking [19]. Forest harvesting is one of the most sensitive activities compared to other sectors [20]. For this reason, the social pillar examines the impact of the working environment on the forest worker [21,22,23,24,25,26]. The environmental pillar evaluates the high impact on the environment, such as environmental impact [27,28,29,30,31], biodiversity [32, 33], and soil impacts [34,35,36,37,38]. The economic pillar is important for forests managed for the primary purpose of wood production, as logging operations represent the largest cost center [39]. Aspects such as performance [40,41,42,43,44] and product quality [45, 46] have been studied in this context. The concept of sustainable development is rather easy to comprehend and widely accepted. The difficulties normally arise when trying to operationalize the concept, for example, by trying to measure the level of sustainability [47]. Sustainability of a single pillar, such as sustainable economic growth, might not lead to the desired results of balancing all three pillars. In fact, sustainability can only occur when all three dimensions are in balance. However, there may be conflicting objectives between the dimensions. In these cases, trade-offs must be made, which may lead to a weighting of the dimensions [48]. In their paper, Blagojevic et al. (2019) discuss how trade-offs between different criteria can be managed in a structured way with respect to multi-criteria decision analysis [49]. Little is known about a comprehensive assessment of logging operations that consider all three dimensions. As already used in the context of SFM, C &I can have a major impact on assessing the sustainability of harvesting operations. Therefore, the objective of this article is to compile and analyze the most used criteria and indicators for each dimension of sustainability in logging operations over the last 6 years (2017 to 2022). It is intended to provide an overview of the criteria used in logging operations and how they are weighted. It will also show the extent to which they have been studied in relation to the machinery used and in different regions of the world. We expect that this review will allow us to assess which sustainability dimensions are best addressed and which need further improvement. It will identify trends and show where there is currently room for improvement in assessing the sustainability of harvesting. In addition, as part of the review process, we have created a database that makes it possible to find specific studies that address a particular criterion or indicator.

Methodology

A systematic literature review was conducted to provide an overview of sustainability criteria in forest harvesting. The literature database scopus (www.scopus.com) was used to find suitable studies in the years 2017–2022. The search criteria used are listed in Table 1. Scopus returned more than 3900 studies for the period considered (Fig. 1). The following restrictions were used for study selection:

-

The studies examined the impact of harvesting machinery on economic, social, or environmental aspects.

-

The impacts had to be related to the logging technology used.

-

Articles and reports published in English language were considered.

In addition to harvesting machines, other parameters that helped analyze C &I such as slope class or silvicultural treatments were extracted from the studies (Table 2). The slope classification was developed from the classifications used in the reviewed studies [50,51,52,53]. The selected studies were assigned an ID and compiled in an Excel file with the respective parameters, i.e., one study represents one entry in the data set. Descriptive analysis identified the most important criteria (also called key criteria) across all studies by summarizing studies that addressed the same criteria. Due to the large number of criteria in the environmental dimension, we decided to present the most important 70% of the criteria for each parameter. This was done by calculating the share of each environmental criterion of the environmental pillar and sorted in descending order. Finally, the most frequently studied criteria were selected by accumulating the shares from the top down to 70%. In the social and economic pillar, where not many criteria were identified, the three most studied criteria were selected unless the following criterion had the same number of studies as the third criterion.

Results

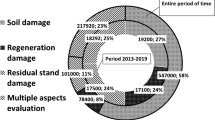

A total of 423 studies were identified for this review. One-dimensional sustainability was examined in 379 studies. Four of the studies examined all three dimensions of sustainability, whereas 40 studies considered two dimensions. Economic and environmental pillars were examined together in 31 studies, while social and economic pillars were examined in eleven studies. Environmental and social pillars were investigated in two studies.

The Relevance of Sustainability Criteria

The environmental pillar was the most frequently studied (n = 182), with 114 studies examining the impact of machines on forest soils. The economic pillar was investigated in 141 studies, and the social pillar in 55 studies. According to the three pillars of sustainability, 33 criteria with their respective indicators were identified from the studies (Table 3). For the sake of clarity, we have grouped the criteria into ten categories. For example, the category termed terrain was comprised of soil rutting, soil disturbance, machine trafficability, and water erosion. The environmental pillar contained the most criteria (n = 22) and was defined by soil, biodiversity, and environmental aspects. The economic pillar was defined by the two categories for quality and performance. The social pillar included measures such as hazards and ergonomic issues and was represented by the categories exposure (e.g., vibration) and working environment. Mental workloads, such as burnout, gaze fixation duration, repetitive workload, and job satisfaction rate, were grouped together under the working conditions criterion.

As shown in Table 3, the category performance had the highest number of reported studies (n = 174), followed by soil physics (n = 112) and environmental impact (n = 85). The number of studies is not necessarily the sum of their criteria since several studies examined multiple criteria. It is often the case that a study examines several criteria at the same time. The most studied criterion was productivity (n = 159), followed by costs (n = 103), soil nutrients (n = 98), and soil compaction (n = 97). It should be noted that the values of the individual indicators were not relevant for this study. However, they will be important for practical application.

Harvesting Machines and Their Common Sustainability Criteria

Three machine types for felling and processing and seven types for extraction were examined. In some studies, more than one machine was examined at the same time. The most commonly used machine type was the forwarder (n = 144), which was closely followed by the skidder (n = 141). The most researched felling and processing machine was the harvester (n = 120), followed by the chainsaw (n = 114). Animal/manual (n = 21), tractor (trailer) extraction (n = 24), and helicopter logging (n = 3) were not evaluated further due to their relatively low frequency. The environmental pillar was most often studied in combination with the skidder (n = 95), followed by the forwarder (n = 90) and the harvester (n = 61) (Fig. 2). The economic pillar was studied most for the harvester (n = 61), followed by the forwarder (n = 59) and the chainsaw (n = 48). The social pillar had the highest number of studies for harvesting operations with the chainsaw (n = 41), followed by skidder (n = 18), whereas the harvester and the forwarder shared the same count of 16 studies each. Comparing the share of pillars among various machine types, the skidder had the highest share in the environmental pillar followed by forwarder and tractor. The economic pillar had the highest share with the cable yarder, followed by harvester and feller buncher. The social pillar had a clear peak with chainsaw accounting for a third of the data collected.

Felling and Processing Machines

With a small lead over the chainsaw, the harvester was the most studied felling and processing machine. The harvester is an articulated harvesting machine, designed to fell, delimb, and buck trees into products [54]. The most common harvester is the wheeled harvester which is limited to operate on slopes <40 %. Rugged terrain limits its range. Tracked harvesters can work on slopes up to 55%, whereas winch-assisted harvesters can be operated on slopes up to 80% [55]. The harvester is mainly used in cut-to-length (CTL) operations [55]. Compared to the chainsaw, the harvester has higher productivity [56, 57], fewer work injuries and ergonomic problems, and improved occupational safety [58]. However, harvester operation has shortcomings in terms of environmental impact (emissions and soil compaction) [59]. The environmental pillar was the most studied (Fig. 2), of which soil nutrients had the highest share (9.9%Footnote 1) followed by soil compaction (9.6%), soil moisture content (6.8%), and emissions (6.1%) (Table 4). However, the most studied criterion was productivity (19.1%), which belonged to the economic pillar, followed by costs (12.0%). The social pillar was the least studied, of which working conditions was the most studied criterion with a total share of 3.1%. The chainsaw is a machine with a wide range of applications (felling, delimbing, bucking). It is used on flat to very steep terrains. Its application is not limited by soil conditions. Especially in steep and rough terrain, there is little alternative to this method of felling [55]. Compared to fully mechanized harvesting operations, the chainsaw has a lower productivity [56, 57] and causes a higher rate of tree damage, but on the other hand produces less emissions and higher full-time equivalentsFootnote 2 [59]. In combination with helicopter extraction, there is hardly any soil compaction. In a system with a cable yarder, soil disturbance is more likely in the form of loosening of the top-soil as compared to soil compaction [59]. Most of the studies were carried out on the economic and environmental pillars (Fig. 2), of which damage to stand had the highest share across all machines and criteria (24.4%), followed by soil nutrients (23.3%) and emissions (21.2%) (Table 4). In the economic pillar, productivity was the most studied criterion (18.1%). Physical workload (5.9%) followed by exposure to vibration (5.1%) and hazards (4.6%) accounted for the largest share of the social pillar compared to all harvesting machines. The feller buncher is a harvesting machine that is designed to fell trees, collect more than one trunk (if size permits), and place them on the ground [54].

The “drive-to-tree” feller buncher is a rubber-tired machine and should be restricted to a maximum slope of 25%. On tracked machines, the felling head is mounted on a swinging boom. Combined with a self-leveling cab, they can operate on slopes up to 50% [55]. Most of the criteria were examined on the environmental pillar (Fig. 2), which is dominated by soil nutrients and soil compaction (10.5% each) (Table 4). The most studied criterion was productivity (16.1%). Exposure to noise was the dominant criterion in the social pillar with a total percentage of 2.8%. Productivity was the most studied criterion (mean = 41 studies per machine) for all three types of felling and processing machines, followed by costs (mean = 28 studies). Hazards and physical workload dominated the social pillar (mean = 7 studies per machine, respectively). It is noteworthy that the order of the criteria in the economic pillar was the same for the three felling and processing machines: productivity was the most common, followed by costs and energy consumption. The criteria of fiber loss and stem breakage were seldomly reported.

Extraction Machines

Forwarders are articulated extraction machines with usually six or eight wheels. They are designed to transport processed logs by carrying them on a log bunk [54, 55]. The operating characteristics in relation to the slope are the same as harvester. The forwarder is generally used in combination with harvesters, which are capable of producing CTL assortments [55]. The forwarder was the most studied extraction machine (n = 144). The environmental dimension was studied more frequently as compared to the economical and social dimension (Fig. 2). The highest overall percentage was productivity (13.7%), followed by soil compaction (12.1%) and costs (10.5%) (Table 5). The dominant criterion in the social pillar was exposure to vibration (1.8%).

The skidder is an extraction machine that drags the felled trees by cable, grapple, or both to the side of the road or to a landing [54, 55]. They can be wheeled or tracked when large loads need to be hauled up steep slopes. Depending on the direction of skidding (preferably downhill), these machines can typically operate on slopes of up to 45% (wheeled) or 50% (tracked) [55]. The skidder was researched in 141 studies. Compared to the other harvesting machines, the environmental pillar had the largest share for the skidder (Fig. 2). Dominant criteria on all pillars were soil compaction (12.0%) followed by soil nutrients (10.8%) (Table 5). In the economic pillar, productivity was the most studied criterion (8.5%). However, the skidder was the only extraction machine where productivity was not the most studied criterion. Work conditions had the highest share of the social criteria (1.5%). The dominant criterion in the social pillar was exposure to vibration (2.0%). Tractors are often used for small-scale harvesting operations. They can be either equipped with a winch or a grapple and used as skidders. Downhill extraction with a tractor is possible on slopes up to about 25% [60]. They can also be equipped with an attached cable winch to extract wood [61]. The environmental pillar was the most studied followed by the economic pillar (Fig. 2). The criterion with the highest overall percentage was productivity (17.0%) followed by costs (10.2%) (Table 5). Soil compaction (9.5%) and soil nutrients (7.5%) had the highest share in the environmental pillar. Physical workload and hazards dominated the social pillar. Cable yarding is described as the transportation of hanging or partially hanging trees by means of a cable system [54]. The basic components of a cable yarding system are the yarder, the carriage, and the operating crew [55]. Cable yarders are used on steep slopes where ground-based timber extraction does not allow for safe or environmentally sound operations. Inadequate ground conditions for skidding or forwarding are another typical reason for using a cable yarder [55]. The cable yarder is the only logging machine where economy is highest in all three dimensions (Fig. 2). The productivity of the cable yarder had the highest share (21.7%), followed by costs (18.5%) (Table 5). The environmental pillar was dominated by soil nutrients (8.7%) and emissions (7.8%). Hazards were the most researched criterion in the social pillar (2.6%). As with felling and processing machinery, productivity was the most studied criterion for four types of extraction machinery examined (average = 34 studies per criterion), followed by soil compaction (average = 28). The social pillar was examined with an average of at least three studies per criterion. In the social pillar, physical workload and hazards dominated with an average of four studies each. In the economic pillar, the order of the criteria was the same for each extraction machine: productivity with the most studies, followed by costs and energy consumption.

Geographical regions (AF Africa, ESA East and South-East Asia, EU Europe, LA Latin America, ME Middle East, NA North America, OC Oceania, RU Russia) and their most common machine types (HV harvester, CS chainsaw, FB feller buncher, FW forwarder, SK skidder, Ts tractor (skidder), CY cable yarder, AM animal/manual, Tt tractor (trailer), HC helicopter)

Geographical Regions

Based on the results, studies were conducted in Africa, East and South-East Asia, Europe, Latin America, the Middle East, North America, Oceania, and Russia (Fig. 3). Africa (n = 5 studies, 1.2%) is represented by South Africa and Ghana. Most of the machines used in Africa were chainsaws and forwarders (Fig. 4). Productivity was studied with 27.3%, followed by stand damage with 18.2% (Table 6). For East and South-East Asia, 36 studies (8.5%) investigated the impact of harvesting machinery. Among others, 15 studies were conducted in Indonesia and six in South Korea. The chainsaw was the most studied machine (n = 19), followed by the skidder (n = 10) and the tractor (n = 9) (Fig. 4). In East and South-East Asia, the environmental criteria were the most commonly assessed at 45.2%. The largest deviation from the global trend was in the environmental impact category, which was characterized by stand damage (9.7%) (Table 6). Harvesting costs was also weighted more heavily at 15.1%. Soil compaction, on the other hand, received less attention (5.4%). The social dimension accounted for 11.9%. Exposure was not considered in these studies. However, working conditions (4.3%) and hazards (3.2%) were above the global trend. Half of the countries considered (n = 44) belong to the European region, where 193 (46%) studies were conducted. Representation of the main EU countries, 39 studies were conducted in Italy, followed by Poland (n = 24) and Germany (n = 17). In most studies, a forwarder was used (n = 80 studies), followed by a harvester (n = 65) and a chainsaw (n = 53) (Fig. 4). The percentage distribution of the examined criteria in Europe was relatively similar to that of the global distribution (Table 6). The most noticeable differences were linked with energy consumption and soil biodiversity, where the percentages were higher in Europe. Europe was also more likely than the rest of the world to examine the social pillar criteria. However, the share of the physical workload was lower. European studies showed significantly lower percentages for water erosion, cation exchange capacity, and hydraulic soil conductivity. The Latin American studies (n = 75 studies, 18%) were mainly conducted in Brazil (n = 68). Harvester and skidder were the most studied machines (30 studies each), followed by forwarder with 27 studies (Fig. 4). The environmental pillar was the most studied for Latin America (44%), which is similar to the global share. However, it had the highest share of emissions of all regions (5.3%). In turn, the other environmental criteria were less strongly represented. The economic criteria, other than costs and stem breakage, were below the global share. Within the social pillar, physical workload, exposure to vibration, and noise were strongly represented. Middle East (n = 53 studies, 13 %) is represented by Iran (n = 39) and Turkey (n = 14). Thirty-seven of the 67 machines surveyed were skidders, followed by twelve chainsaws and nine tractors (skidding/winching) (Fig. 4).

The environmental dimension accounted for 65% of the criteria studied—with 49% related to soil physical and chemical properties. Compared to Europe or North America, the Middle East had higher percentages for soil compaction, soil moisture, soil porosity, water erosion, soil pH, soil cover (humus, litter), and root regeneration (Table 6). Performance and social criteria received comparatively little or no attention. North American studies (n = 45 studies, 11%) were mainly conducted in the USA (n = 35) and ten in Canada. Priority was given to the skidder (n = 26), followed by the feller buncher (n = 23) and the forwarder (n = 18) (Fig. 4). The representation of sustainability pillars was highest for environmental (54%), followed by economic (40%), with only three studies considering social aspects. More than one-third of the studies conducted in North America (37%) included soil physics and chemistry in the environmental pillar, which is higher than the global share (28%). In the economic pillar, 90% of the studies were focused on productivity, which is again roughly in line with the global average of 88%. Eight studies (2%) were conducted in Oceania, seven of which were conducted in Australia. The most commonly studied machines were the harvester, forwarder, and skidder (n = 4 each). The studies considered performance aspects such as productivity (33.3%) and costs (27.8%). Results were well above the global average. It is worth noting that the wood quality criteria were examined at 5.6% each. This is higher than the global comparison. Very few environmental and social criteria were examined. Russia contributed to 3% of the total reported studies (n = 11). Ground-based harvesting equipment such as forwarders, skidders, tractors, and harvesters were prioritized (Fig. 4). Nearly a quarter of the studies focused on the trafficability of the machine (22.7%). Soil compaction ranked second with 18.2%, followed by soil rutting (13.6%) and productivity (9.1%).

Slope Class

The number of studies decreased with increasing slope where 53% of the studies were conducted on flat terrain and only 6% on very steep terrain. In all slope classes, productivity was the most studied criterion, ranging from 14% in flat terrain to 32% in very steep terrain (Table 7). In steep and very steep terrain, costs was the second most studied criterion (18.2, 20%). Energy consumption was also evaluated on all slopes, with the highest total percentage in very steep terrain (10%). In the environmental pillar, soil nutrients and soil compaction were studied most frequently, except on very steep terrain, where emissions had the highest share (6%). Soil compaction was studied most often on flat and moderate slopes, while it was second in the steeper slope classes. The percentage share decreased with an increasing slope (very steep = 4%). In the social pillar on steep and very steep terrain, the hazards criterion was predominant (1.4, 4%). In flat and moderate terrain, exposure to vibration and noise and physical workload were considered in the range of 1.0%.

Silvicultural Treatment

Five different silvicultural treatments were used in the studies: clear-cutting (Cc), thinning (Th), selection cutting (Sc), shelterwood cutting, and salvage logging. Clear-cut was the most studied harvesting system (n = 98 studies) followed by thinning (n = 90), and 56 group or individual selection cuts were made in uneven-aged stands. The silvicultural treatments of shelterwood cutting and salvage logging were not further considered due to their low representation. Most of the environmental criteria were investigated in clear-cutting (Table 8), of which soil nutrients had the highest share (10.7%). Soil compaction was the most studied criterion in selective cuttings (12.8%), while stand damage was most studied in thinnings (11.8%). Productivity and costs were significantly higher for thinning (22.2, 16.5%) compared to clear-cutting or selection cutting. Working conditions was investigated in all harvesting treatments, but proportionally most often in thinnings (2.4%).

Time Spans

Most studies analyzed the immediate effects of logging, within a period of less than 1 year (n = 384, 88%). The fewest were medium-term studies (n = 33), looking at a period of time from 2 to 5 years. Long-term studies had a share of 8% (n = 33) and a time period of 6–30 years. Economic criteria such as productivity and costs were more often examined in studies with a short time period (S) (Table 9). Most social criteria were examined in short-term studies: the highest proportion had exposure to vibration (2.8%), followed by physical workload (2.7%). Medium-term (M) and long-term (L) studies mainly investigated environmental criteria concerning soil aspects (M, L), root regeneration (L), and biodiversity aspects (M).

Research Types

Of the 423 included studies, 346 (82%) were case studies in which harvesting was observed in the field. Theoretical studies (6%) involved mathematical modeling without direct use of harvesting machinery. LCA studies (4%) examined the environmental impact of a harvesting system or an entire wood chain. Some experimental studies (3%) investigated harvesting processes under laboratory conditions, e.g., in workshops. Literature reviews (2%) and meta-analyses (<1%) were also included. Interviews (<1%) dealt exclusively with ergonomic and occupational safety issues. In the case studies, productivity was the most studied criterion with a total share of 15.4%. The dominant criteria in the environmental pillar were soil compaction (10.7%) and soil nutrients (9.6%). Physical workload and exposure to vibration (2.40% each) were the most studied criteria in the social pillar. In the theoretical studies, productivity and hazards were the most frequently investigated with 16.3%, while machine trafficability was the second most frequently investigated with a total of 14%. Physical workload and working conditions had the highest share (4.7% each) in the social pillar.

Discussion

This paper provides an overview of the criteria used to assess the sustainability of logging operations. The criteria of the social pillar have been less studied than those of the environmental and economic pillars. A more complex understanding of social sustainability may be one reason. The social sustainability aspects of forest operations may also be less emphasized by the wood industry. There may also be a lack of knowledge about social sustainability issues among those involved in logging operations. Social criteria were most often examined for the chainsaw. This may be due to the fact that the motor-manual work is more dangerous and causes more accidents and more exposure to various hazards [62]. Mechanized systems tend to have lower accident rates, cause less damage to the remaining stand, and result in higher efficiency than semi or non-mechanized systems [63]. Approximately 70% of the world’s annual roundwood is harvested using fully mechanized harvesting systems [64, 65]. This proportion is expected to increase. Its potential, particularly in developing regions such as Latin America, South-East Asia, and the Middle East, has yet to be reached. Newer technologies such as bogie tracks and traction winches allow expanding operations on steeper slopes [66]. This may explain why skidders, forwarders, and harvesters were the most commonly studied machines to test technological innovations. However, the proportion of studies investigating fully mechanized systems (harvester, feller buncher, forwarder) is lower (40%). Thirty-eight percent of all studies focused on the productivity of harvesting machines. On the one hand, productivity is linked to the environmental and social pillars, as it relates to the level of greenhouse gas emissions, energy consumption, and the employment rate [67, 68]. For example, less damage to the residual stand could be achieved by working more carefully at lower productivity. However, productivity is mainly used as a criterion of financial interest, as it is most often studied in combination with costs. Motor-manual harvesting systems have the lowest efficiency [63], which may explain why productivity is most studied in systems where the chainsaw is used for felling and processing. The studies that addressed the emissions criterion were mainly related to harvesting systems using a chainsaw and skidder or tractor. This may explain the relatively high number of studies dealing with chainsaw emissions. The cable yarder had the highest relative share of productivity. However, the economic criteria could have been studied even more often than the environmental criteria, as the cable yarder has little impact on the soil criteria. The skidder is the only extraction machine where productivity has not been studied the most. This is because the skidder has the highest proportion of research in the Middle East, where its impact on the soil has been a prioritized. Looking at the distribution of criteria across slope classes, soil criteria are more relevant in trafficable areas due to the machine–soil interaction as compared to steep areas where cable yarders are used. Few studies have been carried out in very steep terrain (6%). However, they have mainly focused on efficiency and economic criteria. This can be explained by the challenging accessibility of difficult terrain. Harvesting systems with manual and demanding tasks are mainly used in steep to very steep terrain, where hazards and physical workload become the main concerns. In this context, a higher proportion of studies in the working environment category would be expected compared to studies describing machine–soil interaction. Thinning is the most expensive and challenging treatment in terms of impact on residual trees. This may explain the higher scores for productivity, cost, and stand damage. Because stand density is very high and stem diameters are small, thinning must be done very carefully to minimize damage to the remaining trees. This results in lower productivity as compared to clear cut operations. It is important to carefully balance the benefits and costs of thinning to ensure that it is done in a sustainable and economically viable manner. The use of costly fully mechanized harvesting systems should be proven [69]. We assume that more heavy machinery was used for clear-cutting and selection cutting, and therefore, more emphasis was placed on soil criteria. Although not considered in this review, salvage logging may become more important in the coming years, especially in the EU, due to the high proportion of climate change-related forest disturbances. Productivity, cost, energy consumption, soil compaction, and stand damage are the criteria where the effects can be observed immediately and are therefore conducted in short-term studies. The social criteria, exposure to vibration, and physical workload can only be measured when the machine is running to analyze the effects of machine–worker interaction. For the soil criteria, there are some studies that analyze the effects immediately after harvesting, but more importantly, how long it takes for the soil to recover. The same is true, to a lesser extent, for the soil microbial biomass and root regeneration.

How Sustainable Timber and Fuelwood Harvesting Differs by Geographic Region

Technology adaptation to locally diverse and complex conditions and timber and fuelwood harvesting practices varies widely around the world. In this way, technological innovations are also created in response to a wide range of different requirements [70]. The situation in East and South-East Asia with respect to sustainable forest management is diverse and complex [71, 72]. Japan and South Korea have longstanding efforts to promote sustainable forest management [73, 74], while Indonesia and Malaysia have a history of unsustainable logging practices that have led to widespread deforestation and degradation of forest ecosystems [75, 76]. Despite regulations and policies related to forest management and certification schemes, sustainability in forest management remains a challenge [77, 78]. The framework commonly used in this region is called reduced-impact logging (RIL) and is considered a step towards sustainable forest management. RIL is a harvesting technique (selection cutting) that aims to minimize the negative impact of logging operations on the forest environment [79], while still meeting the economic needs of the forest industry [80]. However, implementation varies from country to country. For example, Indonesia and Malaysia have adopted RIL extensively by integrating it into government policies and regulations [81]. The most common method used in the region is the tree-length (TL) or whole-tree (WT) method, where trees are felled (TL and WT) and processed (only TL) with chainsaws and extracted using various systems. The relatively high share of tractors and especially skidders can be explained by the fact that many countries are currently experiencing labor shortages, leading to greater reliance on mechanization [82]. In countries with high labor costs (e.g., Japan), fully mechanized CTL systems are commonly used [83]. The implementation of RIL could be a reason for the high proportion of the environmental dimension studied. In addition, this region has unique characteristics. The high rainfall and humid conditions can lead to soil sensitivity and environmental stress. Looking at the situation in Europe, mechanized harvesting systems have been the norm for several decades, especially in Northern Europe (Sweden, Finland, Norway) [84]. In some Eastern European countries, particularly those with the most affluent populations, an increase of the CTL method can be observed [85]. This may explain the higher number of studies investigating the harvester and forwarder. Combined with the predominant use of the chainsaw in small-scale forestry and the use of the chainsaws in steep terrain, e.g., in the Alpine region, a high proportion of studies dealing with chainsaws can be explained. Europe has the highest share in the global number of studies. This explains why the percentage deviations from the global distribution of criteria are small. The forestry sector in Latin America is well represented by extensive plantations (Pinus spp. and Eucalyptus spp.). As in East and South-East Asia, RIL is used in natural tropical forests, where chainsaws are most commonly used to fell and process trees. Extraction is usually done with skidders. Until recently, the skidders used in RIL operations in Brazil, Peru, and Bolivia were showing their age. This could explain the higher share of the fuel and energy consumption criterion. In 2021, 45% of Brazil’s wood came from CTL operations [65], which is roughly in line with the study count for Latin American CTL systems in this review (39%). However, changes in average stand age and an increase in harvesting on steeper slopes could result in changes in the percentage distribution of harvesting systems. Due to pressure on land-use for agriculture and livestock, there is currently a trend in Latin America to move forest plantations to hillside locations. In addition, smaller logs are being used to reduce the rotation time of forest plantations. At the same time, new technologies are being used to produce wood products such as glued laminated timber and cross laminated timber. The differences observed in the environmental and economic pillars may be related to the high number of harvesting operations in forest plantations (68%). This requires information on their economic efficiency [86, 87] as well as their impact on the soil (soil compaction) in order to adapt silvicultural treatments against soil compaction (soil conditioning) [88, 89] for future forest conversions or forest stand reforms. The aspects of the social pillar are related to the strict certifications and labor laws that require compliance with health and safety regulations. In the Hyrcanian forests of Iran and Turkey (Middle East), the combination of large tree diameters, steep terrain, uneven-aged stands, and lack of initial investment to purchase fully mechanized harvesting systems has resulted in motor-manual tree felling being the only common system. Extraction is done with wheeled and tracked skidders, which cause the most environmental problems—namely soil compaction and degradation of forest soils, surface runoff, soil erosion, and the risk of flooding. In recent years, mechanized harvesters with advanced CTL technologies have been used only by a few private forestry companies [90]. Cable yarding techniques are not yet present in the Hyrcanian forest area, but to some extent in the mountainous regions of Turkey. Until 2010, the focus in the Middle East was on economic aspects such as productivity and costs. Subsequently, according to the sixth “Five-Year Development Plan” (FYDP), the contribution of environmental criteria to the evaluation of forestry activities should be expanded. However, attention to environmental criteria in logging operations, especially in Iran, has not resulted in minimizing environmental impacts. This is due to land-use changes, forest grazing, pest and disease invasions likely triggered by climate change, and increasing public concern [91]. The result has been a ban on timber harvesting in the Hyrcanian forests of northern Iran. Only windthrown areas and damaged trees are allowed to be harvested [91]. Hydrological problems caused by logging operations have received little attention in watershed studies because the water resources in the rivers are not very large compared to other regions. However, in recent years, the study of runoff and water erosion at plot and watershed levels has been developed [92,93,94]. A positive trend is an increase of studies on work conditions and physical workload [95,96,97,98]. Despite being only represented by two countries (Canada and the USA), North America offers broad topographic and climatic conditions that, in addition to entrepreneurial traditions and market demands, contribute to the use of multiple harvesting systems. Even within relatively short distances (\(\le \) 150 km), considerable differences in harvesting systems can be detected within federal boundaries. This is particularly the case for eastern Canada, where about 70% of the wood harvested in the province of Québec is with harvesters and forwarders as compared to only about 25% in the adjacent State of Maine. The main harvesting system used in Oceania is the harvester/forwarder (CTL). In New Zealand, manual felling is still used, particularly in steep terrain, with cable or cable-assisted machines. In Australia, manual felling and processing have been limited due to concerns about workplace accidents. In some areas, such as the Green Triangle (South Australia) and Tasmania, the industry is concerned about the amount of residue left on sites after harvesting. Where the soil is rich, whole tree harvesting is more commonly used than CTL due to lower operating costs. Its roadside residues are then recovered for bioenergy purposes [99]. This may explain the skidder operations. Economic criteria such as productivity, cost, and value recovery are highly desired by foresters and logging contractors, which is the main reason why these criteria are receiving more attention in decision-making.

Study Limitations

Harvesting systems are usually a combination of different felling, processing, and extraction machines. When a criterion was studied for a specific machine, it was automatically applied to all machines used in the harvesting operation. For example, if a chainsaw was used in combination with a skidder, the impact on the ground was studied only for the skidder, but for our analysis, the criterion was also applied to the chainsaw. This approach was taken because it was not always easy to link a particular impact to a respective machine. To maintain consistency, the criteria studied in a publication were assigned to all the machines studied in that publication. As a result, the number of studies that address the actual environmental impact of chainsaws is slightly less than the 90 studies assigned. Criteria may vary by region because specific working groups may have chosen to focus on certain criteria. This is particularly the case in regions where only a small number of research institutions are involved in forest technology research. For example, in the Middle East, working groups have focused on soil criteria (51% of the studies) [92,93,94]. In Russia, a working group focused on the topic of machine trafficability (46% of the studies) [100,101,102]. The decision as to whether a study falls within the scope of the research question depends, among other things, on the individual judgment of the people involved. Therefore, it was very important that all researchers involved in data collection were instructed to use the same methodology. This was ensured by cross-checking the identified papers by all involved. As mentioned in the methods section, one of the criteria for selecting studies for this review was that they had to be published in English. This may have reduced the number of studies from Asia, Europe, Latin America, the Middle East, and Russia. Due to the choice of a medium-term review period, the results may differ from a long-term trend.

Conclusion

Sustainability is achieved when all three dimensions are balanced. Our study highlights the need for a holistic and interdisciplinary approach to assessing the sustainability of timber and fuelwood harvesting practices. In this review, we compiled criteria and indicators used in recent literature that address the economic, social, and environmental impacts of logging operations. We found 33 criteria in the literature that quantify these impacts. Our results show an imbalance where economic and environmental aspects are weighted more heavily than social aspects, at least when considering the frequency of published material. Trade-offs have to be accepted when trying to balance all three dimensions. This review provides a comprehensive summary of the criteria examined within a 6-year period. Building on the findings of this paper, the criteria that have the greatest impact on sustainability issues need to be identified to ensure effective evaluation of a harvesting system with the least negative impact. Coordination of the parameters studied will be of great importance: which machines to use in which slope class and in which silvicultural method. Establishing thresholds for individual indicators to classify and label criteria will be one of the most important priorities in conducting sustainability assessments of timber and fuelwood harvesting practices. For example, the effects of different harvesting and tillage practices on soil organic carbon dynamics (CO2, CH4, and \(\delta \)13C–CO2 fluxes–soil respiration) were not often studied during the last 6 years. This criterion may become increasingly important as climate change progresses. Setting a threshold of 80 mg m-2 h-1 (efflux) would limit the negative impact on climate change caused by harvesting operations. The results could be of use in planning future researches and practices in various regions of the globe to assess the sustainability of forest operations. Care needs to be taken that preferences made by local communities, industries, and governments may vary highly among different regions which may result in different levels of sustainability in forest harvesting operations.

Availability of Data and Materials

Not applicable

Notes

The percentage refers to the sum of all criteria from the respective machine.

This indicator is used to measure employment in a comparable way, even if the number of hours worked per week differs.

References

Schulze K, editor. Wald mit Zukunft: nachhaltige Forstwirtschaft in Deutschland. Bonn: Bonn : AID; 2006.

Päivinen R, Lindner M, Rosén K, Lexer MJA. Concept for assessing sustainability impacts of forestry-wood chains. Eur J For Res. 2012;131:7–19. https://doi.org/10.1007/s10342-010-0446-4.

Farrell EP. Führer E, Ryan D, Andersson F, Hüttl R, Piussi P. European forest ecosystems: building the future on the legacy of the past, Forest ecology and management. 2000;132:5–20. https://doi.org/10.1016/S0378-1127(00)00375-3.

* Kleine A. Operationalisierung einer Nachhaltigkeitsstrategie: Ökologie, Ökonomie und Soziales integrieren,Wiesbaden,Gabler,2009. This work explains the sustainability principles on which this paper is based. It concludes that the achievement of economic, social, and environmental goals can be assessed and that an overall picture of sustainability performance is possible.

Martens J, Obenland W. Die Agenda 2030: Globale Zukunftsziele für nachhaltige Entwicklung. 2017. Global Policy Forum.

Axelsson R, Angelstam P, Elbakidze M, Stryamets N, Johansson KE. Sustainable development and sustainability: landscape approach as a practical interpretation of principles and implementation concepts. J Landsc Ecol. 2011;4(3):5–30. https://doi.org/10.2478/v10285-012-0040-1.

Reboratti C.E. Territory, scale and sustainable development, Sustainability and the social sciences. 1999; p. 207–222. https://doi.org/10.2478/v10285-012-0040-1

Wolfslehner B, Vacik H, Lexer M.J. Application of the analytic network process in multi-criteria analysis of sustainable forest management, Forest ecology and management.2005;207:157–170,https://doi.org/10.1016/j.foreco.2004.10.025

Corea G, Efimov A.N. Kaya P. Lacarte J.A. Lewis J.P. Mensah J.H. Okita S, Pajestka J, Qureshi M.L, Raj K.N, Ripert J, Salgado G, Tinbergen J. United Nations forum on forests; Report of the 7th session Economic and Social Coucil, Supplement No. 22. ,United Nations; 2007.

UNECE State of Europe’s Forests 2003 — The MCPFE Report on Sustainable Forest Management in Europe. United Nations Economic Commission for Europe. 4th Ministerial Conference on the Protection of Forests in Europe, Vienna, Austria, 28–30 April 2003.

Prabhu R, Colfer C. J. P, Venkateswarlu P, Tan L. C, Soekarmadi R, Wollenberg E, Cifor; Testing criteria and indicators for the sustainable management of forests: phase 1: final refort,1996.

** Lammerts van Bueren E, Blom E.M. Hierarchical framework for the formulation of sustainable forest management standards,Tropenbos Foundation Wageningen; 1997 Our system of criteria and indicators (C &I) is based on the hierarchical framework of the Sustainable Forest Management (SFM) Standards. This paper provides a brief but comprehensive overview of the state of the art of current C &I developments in the SFM field.

Maini J.S. Sustainable development of forests: a systematic approach to defining criteria, guidelines, and indicators,1993,Forestry Canada

Prabhu R, Colfer C.J. P, Dudley R.G. Guidelines for developing, testing and selecting criteria and indicators for sustainable forest management: a C &I developer’s reference, Cifor; 1999.

Kizha AR, Han H-S. Forest residues recovered from whole-tree timber harvesting operations. Eur J For Res. 2015;1(2):46-55.

** Blanco V, Brown C, Holzhauer S, Vulturius G, Rounsevell M.D.A. The importance of socio-ecological system dynamics in understanding adaptation to global change in the forestry sector. J. Environ. Manage.2017;196:36–47. https://doi.org/10.1016/j.jenvman.2017.02.066

*Daigneault A, Johnston C, Korosuo A, Baker J.S, Forsell N, Prestemon J.P, Abt R.C. Developing detailed Shared Socioeconomic Pathway (SSP) narratives for the global forest sector, J. For. Econ.2019; 34:(1-2):7–45. This study identifies Shared Socioeconomic Pathways related to the forestry sector (FSP). It gives an overview of the methods used to develop SSPs and FSPs that could provide decision support in the further application of Sustainability C &I https://doi.org/10.1561/112.00000441

Louis L.T, Kizha A.R, Daigneault A, Han H.S, Weiskittel A. Factors affecting operational cost and productivity of ground-based timber harvesting machines: a meta-analysis,Current Forestry Reports. 2022;p. 1–17. https://doi.org/10.1007/s40725-021-00156-5

1020 OL. Holzernte - Benennungen und Definitionen. Vienna, AUT: Austrian Standards; 1997.

Landekić M, Martinić I, Mijoč D, Bakarić M, Spor čić, M. Injury patterns among forestry workers in Croatia. Forests. 2021;12(10):1356.https://doi.org/10.3390/f12101356

Marchi E, Neri F, Cambi M, Laschi A, Foderi C, Sciarra G, Fabiano F. Analysis of dust exposure during chainsaw forest operations, iForest-Biogeosciences and Forestry. 2017;10(1):341. https://doi.org/10.3832/ifor2123-009.

Kaakkurivaara N, Stampfer K. Assessment for improvement: harvesting operations in small-scale forest on Thai steep terrain. Small-Scale Forestry. 2018;17(2):259–76. https://doi.org/10.1007/s11842-017-9386-x.

Poje A, Grigolato S, Potočnik I. Operator exposure to noise and whole-body vibration in a fully mechanised CTL forest harvesting system in karst terrain. Croatian Journal of Forest Engineering: Journal for Theory and Application of Forestry Engineering. 2019;40(1):139–50.

Spinelli R, Magagnotti N, Labelle ER. The effect of new silvicultural trends on mental workload of harvester operators. Croatian Journal of Forest Engineering: Journal for Theory and Application of Forestry Engineering. 2020;41(2):1–13. https://doi.org/10.5552/crojfe.2020.747.

Cazani A. C, Miyajima R.H, Simões D, dos Santos J.E.G. Operator exposure to whole-body vibration in timber extraction with grapple skidder. J. Vib. Eng. 2021;9:177–182. https://doi.org/10.1007/s42417-020-00219-0

Oliveira NKA, Niro H, DeArmond D, Robert RCG, Eduardo AJ, Fidalgo CJP. Environmental thermal conditions related to performance, dynamics and safety of logging in the Brazilian Amazon. Croatian Journal of Forest Engineering: Journal for Theory and Application of Forestry Engineering. 2021;42(3):419–35. https://doi.org/10.5552/crojfe.2021.865.

Tuomasjukka D, Martire S, Lindner M, Athanassiadis D, Kühmaier M, Tumajer J. Sustainability impacts of increased forest biomass feedstock supply-a comparative assessment of technological solutions. International Journal of Forest Engineering. 2018;29(2):99–116. https://doi.org/10.1080/14942119.2018.1459372.

Kühmaier M, Harrill H, Ghaffariyan MR, Hofer M, Stampfer K, Brown M. Using conjoint analyses to improve cable yarder design characteristics: an Austrian yarder case study to advance cost-effective extraction. Forests. 2019;10(2):165. https://doi.org/10.3390/f10020165.

Labelle ER, Lemmer KJ. Selected environmental impacts of forest harvesting operations with varying degree of mechanization. Croatian Journal of Forest Engineering: Journal for Theory and Application of Forestry Engineering. 2019;40(2):239-257.

Britto PC, Jaeger D, Hoffmann S, Robert RCG, Vibrans AC, Fantini AC. Impact assessment of timber harvesting operations for enhancing sustainable management in a secondary Atlantic Forest. Sustainability. 2019;11(22):6272. https://doi.org/10.3390/su11226272.

Diniz CCC, de Oliveira FM, Junior RT, Robert RCG, Tramontini MP, de Brito FC. Damage caused by a wheeled harvester to the residual trees of a pinus stand in the first mechanized mixed thinning. Floresta. 2020;50(3):1547–54. https://doi.org/10.5380/rf.v50i3.64331.

Picchio R, Mercurio R, Venanzi R, Gratani L, Giallonardo T, Lo Monaco Al. Strip clear-cutting application and logging typologies for renaturalization of pine afforestation-a case study. Forests. 2018;9(6):366. https://doi.org/10.3390/f9060366

Schweier J, Blagojević B, Venanzi R, Latterini F, Picchio R. Sustainability assessment of alternative strip clear cutting operations for wood chip production in renaturalization management of pine stands. Energies. 2019;12(17):3306. https://doi.org/10.3390/en12173306.

Labelle ER, Poltorak BJ, Jaeger D. The role of brush mats in mitigating machine induced soil disturbances: an assessment using absolute and relative soil bulk density and penetration resistance. Can J For Res. 2019;49(2):164–78. https://doi.org/10.1139/cjfr-2018-0324.

Jourgholami M, Karami S, Tavankar F, Lo Monaco A, Picchio R. Effects of slope gradient on runoff and sediment yield on machine-induced compacted soil in temperate forests. Forests. 2020;12(1):49. https://doi.org/10.3390/f12010049.

Sohrabi H, Jourgholami M, Jafari M, Shabanian N, Venanzi R, Tavankar F, et al. Soil recovery assessment after timber harvesting based on the sustainable forest operation (SFO) perspective in Iranian temperate forests. Sustainability. 2020;12(7):2874. https://doi.org/10.3390/su12072874.

Schönauer M, Holzfeind T, Hoffmann S, Holzleitner F, Hinte B, Jaeger D. Effect of a traction-assist winch on wheel slippage and machine induced soil disturbance in flat terrain. Int J For Eng. 2021;32(sup1):1–11. https://doi.org/10.1080/14942119.2021.1832816.

Jourgholami M, Khoramizadeh A, Lo Monaco A, Venanzi R, Latterini F, Tavankar F. Evaluation of leaf litter mulching and incorporation on skid trails for the recovery of soil physicochemical and biological properties of mixed broadleaved forests. Land. 2021;10(6):625. https://doi.org/10.3390/land10060625.

Bürgi P, Sekot W, Ermisch N, Pauli B, Möhring B, Toscani P. Forest enterprise key figure comparison Germany-Austria-Switzerland.Schweizerische Zeitschrift für Forstwesen. 2016;167(2):73–81 Schweizerischer Forstverein, https://doi.org/10.3188/szf.2016.0073

Ghaffariyan MR, Brown M, Acuna M, Sessions J, Gallagher T, Kühmaier M, Spinelli R, Visser R, Devlin G, Eliasson L. An international review of the most productive and cost effective forest biomass recovery technologies and supply chains. Renew Sust Energ Rev. 2017;74:145–58. https://doi.org/10.1016/j.rser.2017.02.014.

Kaakkurivaara N, Kaakkurivaara T. Productivity and cost analysis of three timber extraction methods on steep terrain in Thailand. Croatian Journal of Forest Engineering: Journal for Theory and Application of Forestry Engineering. 2018;39(2):213–21.

Picchio R, Venanzi R, Di Marzio N, Tocci D, Tavankar F. A comparative analysis of two cable yarder technologies performing thinning operations on a 33 year old pine plantation: a potential source of wood for energy. Energies. 2020;13(20):5376. https://doi.org/10.3390/en13205376.

Ghaffariyan MR. General productivity predicting model for skidder working in eucalypt plantations.Eur J For Res. 2020;6(1):1–6.https://doi.org/10.33904/ejfe.618344

Varch T, Erber G, Spinelli R, Magagnotti N, Stampfer K. Productivity, fuel consumption and cost in whole tree cable yarding: conventional diesel carriage versus electrical energy-recuperating carriage. Int J For Eng. 2021;32(sup1):20–30. https://doi.org/10.1080/14942119.2020.1848178.

Williams C, Ackerman P. South African pine cut-to-length harvesting: an analysis of fibre loss and productivity. Croatian Journal of Forest Engineering: Journal for Theory and Application of Forestry Engineering. 2019;40(1):55–63.

Oliveira GS, Soares PRC, Sampietro JA. Quality function deployment (QFD) applied to the variables that influence quality costs in mechanized forest harvest operations. Floresta. 2020;50(4):1717–24. https://doi.org/10.5380/rf.v50i4.60137.

Azapagic A, Perdan S. Indicators of sustainable development for industry: a general framework. Process Safety and Environmental Protection. 2000;78(4):243–61. https://doi.org/10.1205/095758200530763.

Grunwald A, Kopfmüller J. Nachhaltigkeit: 3. Campus Verlag; 2022.

** Blagojevic B, Jonsson R, Björheden R, Nordström E.M, Lindroos O. Multi-Criteria Decision Analysis (MCDA) in forest operations-an introductional review. Croatian Journal of Forest Engineering: Journal for Theory and Application of Forestry Engineering. 2019;40(1):191–2015.This paper discusses how trade-offs between different criteria can be managed in a structured way with respect to multi-criteria decision analysis. A comparison is made between different methods.

Lopes ES, Oliveira FM, Droog A. Damage to residual trees following commercial thinning by harvester and forwarder in a Pinus taeda stand in Southern Brazil. Scientia Forestalis. 2018;118:167–175. https://doi.org/10.18671/scifor.v46n118.03

Sohrabi H, Jourgholami M, Tavankar F, Venanzi R, Picchio R. Post-harvest evaluation of soil physical properties and natural regeneration growth in steep-slope terrains. Forests. 2019;10(11):1034. https://doi.org/10.3390/f10111034.

Etehadi Abari M, Majnounian B, Malekian A, Jourgholami M. Effects of forest harvesting on runoff and sediment characteristics in the Hyrcanian forests, Northern Iran. Eur J For Res. 2017;136(2):375–86. https://doi.org/10.1007/s10342-017-1038-3.

Dembure TP, McEwan A, Spinelli R, Magagnotti N, Ramantswana M. A comparison between two alternative harvesting systems in the thinning of fast-growing pine plantations under the conditions of low labour cost. Eur J For Res. 2019;138(1):43–52. https://doi.org/10.1007/s10342-018-1152-x.

ISO 6814. Machinery for forestry - Mobile and self-propelled machinery - Terms, definitions and classification. ISO, Geneva, Switzerland; 2009. Norm: ISO 6814:2009.

USDA. Forest Operations Equipment Catalog. U.S. Department of Agriculture, Forest Service; 2022. [Accessed 9th November 2022]. Available from: https://www.fs.usda.gov/forestmanagement/equipment-catalog/index.shtml

Cataldo MF, Proto AR, Macri G, Zimbalatti G. Evaluation of different wood harvesting systems in typical Mediterranean small-scale forests: a Southern Italian case study. Ann. Silvic. Res. 2020;45(1):1–11. https://doi.org/10.12899/asr-1883

Mederski PS, Schweier J, DJuka A, Tsioras P, Bont LG, Bembenek M. Mechanised harvesting of broadleaved tree species in Europe. Current Forestry Reports. 2022;p. 1–19. https://doi.org/10.1007/s40725-021-00154-7

Gerasimov Y, Sokolov A. Ergonomic evaluation and comparison of wood harvesting systems in Northwest Russia. Applied ergonomics. 2014;45(2):318–38. https://doi.org/10.1016/j.apergo.2013.04.018.

** Schweier J, Spinelli R, Magagnotti N, Wolfslehner B, Lexer MJ. Sustainability assessment of alternative thinning operations in Mediterranean softwood plantations. Forests. 2018;9(7):375. The results of the study allow quantification of potential sustainability impacts and thus support management decisions. This could be supported by our C &I paper—the study of the holistic sustainability of timber and fuelwood harvesting. https://doi.org/10.3390/f9070375

Heinrich RH. Appropriate wood harvesting operations in plantation forests in developing countries. FAO; 1986.

Akay AE. Using farm tractors in small-scale forest harvesting operations. J appl sci res. 2005;1(2):196–9.

Axelsson S. The mechanization of logging operations in Sweden and its effect on occupational safety and health. J For Eng. 1998;9(2):25–31.

Enache A, Kühmaier M, Visser R, Stampfer K. Forestry operations in the European mountains: a study of current practices and efficiency gaps. Scand J For Res. 2016;31(4):412–27. https://doi.org/10.1080/02827581.2015.1130849.

Nordfjell T, Öhman E, Lindroos O, Ager B. The technical development of forwarders in Sweden between 1962 and 2012 and of sales between 1975 and 2017. Int J For Eng. 2019;30(1):1–13. https://doi.org/10.1080/14942119.2019.1591074.

* Lundbäck M, Häggström C, Nordfjell T. Worldwide trends in methods for harvesting and extracting industrial roundwood. Int. J. For. Eng. 2021;32(3):202–215. The study identified the explanatory variables that influence the differences between countries in the level of mechanization and harvesting methods. It was used as a basis for discussion in the geographical regions chapter to verify the level of mechanization of harvesting identified within regions. https://doi.org/10.1080/14942119.2021.1906617

Schaare R, Harrill H, Visser R. Tension monitoring of cable-assisted felling machines. New Zealand Forest Research Institute Limited (Scion): Rotorua, New Zealand; 2016. Report No. H028.

Whittaker C, Mortimer N, Murphy R, Matthews R. Energy and greenhouse gas balance of the use of forest residues for bioenergy production in the UK. Biomass and Bioenergy. 2011;35(11):4581–94. https://doi.org/10.1016/j.biombioe.2011.07.001.

Berg S, Fischbach J, Brüchert F, Poissonnet M, Pizzirani S, Varet A, Sauter UH. Towards assessing the sustainability of European logging operations. Eur J For Res. 2012;131:81–94. https://doi.org/10.1007/s10342-011-0561-x.

Mederski PS, Venanzi R, Bembenek M, Karaszewski Z, Rosinska M, Pilarek Z. Designing thinning operations in 2nd age class pine stands-economic and environmental implications. Forests. 2018;9(6):335.https://doi.org/10.3390/f9060335

Lindroos O, La Hera P, Häggström C. Drivers of advances in mechanized timber harvesting-a selective review of technological innovation. Croatian Journal of Forest Engineering: Journal for Theory and Application of Forestry Engineering. 2017;38(2):243–58.

Rametsteiner E, Simula M. Forest certification-an instrument to promote sustainable forest management? J Environ Manage. 2003;67(1):87–98. https://doi.org/10.1016/S0301-4797(02)00191-3.

Cashore B, Gale F, Meidinger E, Newsom D. Confronting sustainability: forest certification in developing and transitioning countries. Forestry & Environmental Studies Publications Series; 2006. [Accessed 3rd January 2023]. Available from: https://elischolar.library.yale.edu/fes-pubs/28

Korean Forest Service. National report on sustainable forest management in Korea 2014. Korea Forest Service; 2015. [Accessed 3rd January 2023]. Available from: https://montreal-process.org/documents/publications/general/2014/KoreaNationalReportForSFM2014.pdf

Forestry Agency. State of Japan’s forests and forest management. Ministry of Agriculture, Forestry and Fisheries, Japan; 2019. [Accessed 1st February 2023]. Available from:https://www.maff.go.jp/e/policies/forestry/attach/pdf/index-8.pdf

Tsujino R, Yumoto T, Kitamura S, Djamaluddin I, Darnaedi D. History of forest loss and degradation in Indonesia. Land use policy. 2016;57:335–47. https://doi.org/10.1016/j.landusepol.2016.05.034.

Bryan JE, Shearman PL, Asner GP, Knapp DE, Aoro G, Lokes B. Extreme differences in forest degradation in Borneo: comparing practices in Sarawak, Sabah, and Brunei. PloS one. 2013;8(7):e69679. https://doi.org/10.1371/journal.pone.0069679.

Putz FE, Sist P, Fredericksen T, Dykstra D. Reduced-impact logging: challenges and opportunities. Forest ecology and management. 2008;256(7):1427–33. https://doi.org/10.1016/j.foreco.2008.03.036.

Lewin A, Mo K, Scheyvens H, Gabai S. Forest certification: more than a market-based tool, experiences from the Asia Pacific region. Sustainability. 2019;11(9):2600. https://doi.org/10.3390/su11092600.

FAO. Reduced impact logging in tropical forests: literature synthesis, analysis and prototype statistical framework. Food and Agriculture Organization of the United Nations; 2004. Forest harvesting and engineering working paper no.1.

Sist P. Reduced-impact logging in the tropics : objectives, principles and impacts. vol. 2. Commonwealth Forestry Association; 2000. [Accessed 20th February 2023].

Holmes TP. Financial and economic analysis of reduced impact logging. Tropical forestry handbook Springer-Verlag, Berlin, Heidelberg. 2015;https://doi.org/10.1007/978-3-642-41554-8_223-1

Kamarudin N, Ismail MH, Jusoff K, Sood AM. Evolution and development of forest harvesting in Peninsular Malaysia. The Malaysian Forester. 2011;74(2):79–102.

Akaguma E, Aruga K, Okuyama T. Analysis on economic balances of clear cutting and regeneration operations in the northern area of Tochigi prefecture. Bulletin of Utsunomiya University Forest. 2017;53:69–77.

Karjalainen T, Zimmer B, Berg S,Welling J, Schwaiger H, Finer L. Energy, carbon and other material flows in the Life Cycle Assessment of forestry and forest products. Joensuu: European Forest Institute Discussion Paper. 2001;10:1–67.

Moskalik T, Borz SA, Dvořák J, Ferencik M, Glushkov S, Muiste P, Lazdiņš A, Styranivsky O. Timber harvesting methods in Eastern European countries: a review. Croatian Journal of Forest Engineering: Journal for Theory and Application of Forestry Engineering. 2017;38(2):231–41.

Britto PC, Jaeger D, Hoffmann S, Robert RCG, Fantini AC, Vibrans AC. Productivity assessment of timber harvesting techniques for supporting sustainable forest management of secondary Atlantic Forests in southern Brazil. Ann. For. Res. 2017;60(2):203–215. https://doi.org/10.15287/afr.2017.898

Brown RO, Oliveira-Nascimento KA, Robert RCG, DeArmond D. Wood extraction performance with a farm tractor in a mountainous region of Brazil: cycle time, productivity and costs of two different work crews. Southern Forests: a Journal of Forest Science. 2022;84(2):136–47. https://doi.org/10.2989/20702620.2022.2078251.

de Melo R.O, da Fonseca A.A, de Barros N.F, Fernandes R.B.A,Teixeira RdS, Melo IN, Martins R, Previdente NF, Fernandes RBA, Teixeira RdS, Melo IN. Retention of eucalyptus harvest residues reduces soil compaction caused by deep subsoiling. J. For. Res. 2022;33(2):643–651.

Rodrigues MF, Rodrigues D, Pellegrini A, Pocojeski E. Gradual increase in the intensityof machine traffic in timber harvesting: effects on soil composition and functionality. Southern Forests: a J For Sci. 2022;84(2):148–63.

Bilici E, Akay AE. Forestry and forest operations in Turkey: challenges and developments. Revista Padurilor. 2021;136(1):37–52.

Goushehgir Z, Feghhi J, Innes JL. Challenges facing the improvement of forest management in the Hyrcanian Forests of Iran. Forests. 2022;13(12):2180. https://doi.org/10.3390/f13122180.

Jourgholami M, Labelle ER, Feghhi J. Response of runoff and sediment on skid trails of varying gradient and traffic intensity over a two-year period. Forests. 2017;8:472. https://doi.org/10.3390/f8120472.

Jourgholami M, Fathi K, Labelle ER. Effects of foliage and traffic intensity on runoff and sediment in skid trails after trafficking in a deciduous forest. Eur J For Res. 2018;137:223–35. https://doi.org/10.1007/s10342-018-1102-7.

Jourgholami M, Labelle ER, Feghhi J. Efficacy of leaf litter mulch to mitigate runoff and sediment yield following mechanized operations in the Hyrcanian mixed forests. J Soils Sediments. 2019;19:2076–88. https://doi.org/10.1007/s11368-018-2194-x.

Lotfalian M, Sheikhmoonesi F, Sabzi M, Abaspour M, Peyrov S. Prevalence of burnout among forest workers in Mazandaran, Iran. J. For. Sci. 2017;63(2):70–74. https://doi.org/10.17221/111/2015-JFS

Enez K, Nalbantoğlu SS. Comparison of ergonomic risk assessment outputs from OWAS and REBA in forestry timber harvesting. Int J Ind Ergon. 2019;70:51–7. https://doi.org/10.1016/j.ergon.2019.01.009.

Unver S, Ergenc I. Safety risk identification and prioritize of forest logging activities using analytic hierarchy process (AHP). Alexandria Engineering Journal. 2021;60(1):1591–9. https://doi.org/10.1016/j.aej.2020.11.012.

Arman Z, Nikooy M, Tsioras PA, Heidari M, Majnounian B. Physiological workload evaluation by means of heart rate monitoring during motor-manual clearcutting operations. Int J For Eng. 2021;32(2):91–102. https://doi.org/10.1080/14942119.2021.1868238.

Ghaffariyan MR, Brown M. Selecting the efficient harvesting method using multiplecriteria analysis: a case study in south-west Western Australia. J For Sci. 2013;59(12):479–86.

Grigorev GV, Dmitrieva IN, Kotenev EV. Permissible ground pressure of wheeled forestry vehicles depending on the ground conditions. IOP Conference Series: Materials Science and Engineering. 2020;817. https://doi.org/10.1088/1757-899X/817/1/012011

Grigorev G, Dmitrieva I, Khitrov E. Theoretical evaluation of rut depth components caused by forest soil shear and compaction. 20th International Multidisciplinary Scientific GeoConference SGEM 2020. 2020;p. 763–768. https://doi.org/10.5593/sgem2020/3.1/s14.098

Khitrov E, Grigorev G, Dmitrieva I. Theoretical estimation of soil resistance to forestry vehicles turning. International Multidisciplinary Scientific GeoConference: SGEM. 2020;20(3.1):757-762. https://doi.org/10.5593/sgem2020/3T/s14.097

Acknowledgements

We would like to thank Franz Holzleitner, Stefano Grigolato, Elizabeth Dodson, Benjamin Kromoser, and Klaus Katzensteiner for their constructive advice.

Funding

Open access funding provided by University of Natural Resources and Life Sciences Vienna (BOKU). This research was funded by the Austrian Federal Ministry of Agriculture, Forestry, Regions, and Water Management, grant numbers 101677 and 101724.

Author information

Authors and Affiliations

Contributions

Conceptualization and methodology by J. Grünberg and M. Kühmaier. J. Grünberg carried out the literature search and data collection, wrote the main text of the manuscript, and created the figures and tables. Contributions to the “Geographical Regions” chapter, M.R. Ghaffariyan (Oceania), M. Jourgholami (Middle East), E.R. Labelle (North America), N. Kaakkurivaara (East & South East Asia), R.C.G. Robert (South America), J. Grünberg, and M. Kühmaier (Europe). Supervision, project administration, fundraising, and correspondence, M. Kühmaier. All authors reviewed the manuscript and agreed to the published version.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Human and Animal Rights and Informed Consent

This article does not contain any studies with human or animal subjects performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Grünberg, J., Ghaffariyan, M.R., Jourgholami, M. et al. Criteria for Assessing the Sustainability of Logging Operations—A Systematic Review. Curr. For. Rep. 9, 350–369 (2023). https://doi.org/10.1007/s40725-023-00198-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40725-023-00198-x