Abstract

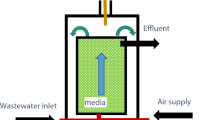

A roller bioreactor containing inert glass beads was employed to enhance naphthalene biodegradation in an aqueous solution. Mixed culture of microorganisms was isolated from sewage waste sludge and adopted for naphthalene biodegradation. The dissolution rate of naphthalene in the aqueous phase was studied at different conditions in the roller reactor. The results indicate that the best conditions for the biodegradation treatment in the roller bioreactor were 40% and 50% loads with 6 mm and 5 mm sized glass beads, respectively, at a rotation speed of 50 rpm. The biodegradation of 300 mg/L naphthalene in the bioreactor in the absence of glass beads proceeded slowly until depletion after seven days. In the presence of glass beads, the biodegradation rate was faster, depleting after only four days. At a concentration of 500 mg/L naphthalene, complete depletion was attained after nine days in the bioreactor with no glass beads and five days in the presence of glass beads. Both the biodegradation rate \(({r}_{s}\)) and the specific growth rate\(\left(\mu \right)\) increased by utilizing the glass beads bioreactor compared with the bioreactor with no glass beads, thus confirming that the presence of glass beads enhances the mass transfer of naphthalene from the solid to the aqueous phase where it becomes available for utilization. An artificial neural network was used to model naphthalene dissolution and biodegradation. Correlation coefficients of 99.2% and 98.3% were obtained between the experimental and predicted output values for dissolution and biodegradation, respectively, indicating that the ANN model can efficiently predict the experimental data.

Highlights

-

Mixed culture of microorganisms was used in a glass bead roller bioreactor.

-

Increasing the load and size of glass beads enhanced the treatment.

-

ANN was used to model the biodegradation process.

Similar content being viewed by others

Data Availability

All data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Adeola AO, Forbes PBC (2021) Advances in water treatment technologies for removal of polycyclic aromatic hydrocarbons: Existing concepts, emerging trends, and future prospects. Water Environ Res 93(3):343–359. https://doi.org/10.1002/wer.1420

Alalayah WM (2017) Simulation of the biodegradation of petroleum hydrocarbons utilizing Artificial Neural Networks. Int J Eng Sci Invention Res Dev 5(4):891–896

Al-Hawash AB, Dragh MA, Li S, Alhujaily A, Abbood HA, Zhang X et al (2018) Principles of microbial degradation of petroleum hydrocarbons in the environment. Egypt J Aquat Res 44(2):71–76. https://doi.org/10.1016/j.ejar.2018.06.001

Annadurai G, Lee JF (2007) Application of artificial neural network model for the development of optimized complex medium for phenol degradation using Pseudomonas pictorum (NICM 2074). Biodegradation 18(3):383-92. https://doi.org/10.1007/s10532-006-9072-8

Arranz A, Bordel S, Villaverde S, Zamarreno JM, Guieysse B, Munoz R (2008) Modeling photosynthetically oxygenated biodegradation processes using artificial neural networks. J Hazard Mater 155(1–2):51–57. https://doi.org/10.1016/j.jhazmat.2007.11.027

ATSDR (2005) Toxicology profile for polyaromatic hydrocarbons. ATSDR’s Toxicological Profiles on CD-ROM. CRC Press, Boca Raton

Bojes HK, Pope PG (2007) Characterization of EPA’s 16 priority pollutant polycyclic aromatic hydrocarbons (PAHs) in tank bottom solids and associated contaminated soils at oil exploration and production sites in Texas. Regul Toxicol Pharmacol 47(3):288–295. https://doi.org/10.1016/j.yrtph.2006.11.007

Dudhagara DR, Rajpara RK, Bhatt JK, Gosai HB, Dave BP (2016) Bioengineering for polycyclic aromatic hydrocarbon degradation by Mycobacterium litorale: Statistical and artificial neural network (ANN) approach. Chemometr Intell Lab Syst 159:155–163. https://doi.org/10.1016/j.chemolab.2016.10.018

Fulekar MH (2017) Microbial degradation of petrochemical waste-polycyclic aromatic hydrocarbons. Bioresour Bioprocess 4(1):28. https://doi.org/10.1186/s40643-017-0158-4

Garson GD (1991) Interpreting neural-network connection weights. AI Expert 6:47–51

Gupta S, Pathak B (2019) Biodegradation of naphthalene using bacterial consortium. AIJRFANS1:19–22. ISSN (CD-ROM) : 2328–3793.25. Available online at http://www.iasir.net

Haleyur N, Shahsavari E, Jain SS, Koshlaf E, Ravindran VB, Morrison PD, Osborn AM, Ball AS (2019) Influence of bioaugmentation and biostimulation on PAH degradation in aged contaminated soils: response and dynamics of the bacterial community. J Environ Manage 238:49–58. https://doi.org/10.1016/j.jenvman.2019.02.115

Hamzaoui YE, Hernández JA, Silva-Martínez S, Bassam A, Álvarez A, Lizama-Bahena C (2011) Optimal performance of COD removal during aqueous treatment of alazine and gesaprim commercial herbicides by direct and inverse neural network. Desalination 277(1–3):325–337. https://doi.org/10.1016/j.desal.2011.04.060

Hill GA, Robinson CW (1975) Substrate inhibition kinetics: phenol degradation by Pseudomonas putida. Biotechnol Bioeng 17:1599–1615. https://doi.org/10.1002/bit.260171105

Hussar E, Richards S, Lin ZQ, Dixon RP, Johnson KA (2012) Human health risk assessment of 16 priority polycyclic aromatic hydrocarbons in soils of Chattanooga, Tennessee, USA. Water Air Soil Pollut 223(9):5535–5548. https://doi.org/10.1007/s11270-012-1265-7

Ishak WMFW, Jamek S, Jalanni NA, Jamaludin NFM (2011) Isolation and identification of bacteria from activated sludge and compost for municipal solid waste treatment system. Int Conf Biol Environ Chem 24:450–454

Jamal Sisi A, Khataee A, Fathinia M, Vahid B, Orooji Y (2020) Comparative study of sonocatalytic process using MOF-5 and peroxydisulfate by central composite design and artificial neural network. J Mol Liq 316. https://doi.org/10.1016/j.molliq.2020.113801

Janbandhu A, Fulekar MH (2011) Biodegradation of phenanthrene using adapted microbial consortium isolated from petrochemical contaminated environment. J Hazard Mater 187(1–3):333–340. https://doi.org/10.1016/j.jhazmat.2011.01.034

Jimoh AA, Lin J (2019) Biosurfactant: A new frontier for greener technology and environmental sustainability. Ecotoxicol Environ Saf 184:109607. https://doi.org/10.1016/j.ecoenv.2019.109607

Khataee AR, Kasiri MB (2011) Modeling of biological water and wastewater treatment processes using artificial neural networks. Clean Soil Air Water 39(8):742–749. https://doi.org/10.1002/clen.201000234

Kristanti RA, Hadibarata T, Al Farraj DA, Elshikh MS, Alkufeidy RM (2018) Biodegradation mechanism of phenanthrene by halophilic hortaea sp. B15. Water Air Soil Pollut 229(10). https://doi.org/10.1007/s11270-018-3969-9

Lee Y, Lee Y, Jeon CO (2019) Biodegradation of naphthalene, BTEX, and aliphatic hydrocarbons by Paraburkholderia aromaticivorans BN5 isolated from petroleum-contaminated soil. Sci Rep 9(1):860. https://doi.org/10.1038/s41598-018-36165-x

Lin C, Gan L, Chen ZL (2010) Biodegradation of naphthalene by strain Bacillus fusiformis (BFN). J Hazard Mater 182(1–3):771–777. https://doi.org/10.1016/j.jhazmat.2010.06.101

Maeda M, Itoh A, Kawase Y (2005) Kinetics for aerobic biological treatment of o-cresol containing wastewaters in a slurry bioreactor: biodegradation by utilizing waste activated sludge. Biochem Eng J 22(2):97–103. https://doi.org/10.1016/j.bej.2004.09.005

Mojiri A, Zhou JL, Ohashi A, Ozaki N, Kindaichi T (2019) Comprehensive review of polycyclic aromatic hydrocarbons in water sources, their effects and treatments. Sci Total Environ 696:133971. https://doi.org/10.1016/j.scitotenv.2019.133971

Moscoso F, Deive FJ, Longo MA, Sanroman MA (2012) Technoeconomic assessment of phenanthrene degradation by Pseudomonas stutzeri CECT 930 in a batch bioreactor. Bioresour Technol 104:81–89. https://doi.org/10.1016/j.biortech.2011.10.053

Mulder H, Breure AM, Van Andel JG, Grotenhuis JTC, Rulkens WH (1998) Influence of hydrodynamic conditions on naphthalene dissolution and subsequent biodegradation. Biotechnol Bioeng 57:145–154. https://doi.org/10.1002/(SICI)1097-0290(19980120)57:2<145::AID-BIT3>3.0.CO;2-N

Mustafa YA, Abdul-Hameed HM, Razak ZA (2015) Biodegradation of 2,4-dichlorophenoxyacetic acid contaminated soil in a roller slurry bioreactor. Clean Soil Air Water 43(8):1241–1247. https://doi.org/10.1002/clen.201400623

Nikakhtari H, Kumar P, Nemati M, Hill GA (2008) Mass transfer and bioremediation of aromatics from NAPL in a baffled roller bioreactor. Process Saf Environ Prot 86(4):252–258. https://doi.org/10.1016/j.psep.2008.04.007

Nikakhtari H, Kumar P, Nemati M, Hill GA (2009) Biodegradation of diesel oil in a baffled roller bioreactor. J Chem Technol Biotechnol 84(4):525–532. https://doi.org/10.1002/jctb.2074

Nikakhtari H, Song W, Nemati M, Hill GA (2014) Oxygen mass transfer and scale-up studies in baffled roller bioreactors. Bioprocess Biosyst Eng 37(2):193–203. https://doi.org/10.1007/s00449-013-0985-4

Ofori SA, Cobbina SJ, Doke DA (2020) The occurrence and levels of polycyclic aromatic hydrocarbons (PAHs) in African environments-a systematic review. Environ Sci Pollut Res 27(26):32389–32431. https://doi.org/10.1007/s11356-020-09428-2

Ofori SA, Cobbina SJ, Imoro AZ, Doke DA, Gaiser T (2021) Polycyclic aromatic hydrocarbon (PAH) pollution and its associated human health risks in the niger delta region of Nigeria: a systematic review. Environ Process 8(2):455–482. https://doi.org/10.1007/s40710-021-00507-1

Olawoyin R (2016) Application of backpropagation artificial neural network prediction model for the PAH bioremediation of polluted soil. Chemosphere 161:145–150. https://doi.org/10.1016/j.chemosphere.2016.07.003

Pareek VK, Brungs MP, Adesina AA, Sharma R (2002) Artificial neural network modeling of a multiphase photodegradation system. J Photochem Photobiol A: Chem 149(1–3):139–146. https://doi.org/10.1016/S1010-6030(01)00640-2

Patel AB, Mahala K, Jain K, Madamwar D (2018) Development of mixed bacterial cultures DAK11 capable for degrading mixture of polycyclic aromatic hydrocarbons (PAHs). Bioresour Technol 253:288–296. https://doi.org/10.1016/j.biortech.2018.01.049

Patel AB, Shaikh S, Jain KR, Desai C, Madamwar D (2020) Polycyclic aromatic hydrocarbons: sources, toxicity, and remediation approaches. Front Microbiol 11:562813. https://doi.org/10.3389/fmicb.2020.562813

Patel AB, Singh S, Patel A, Jain K, Amin S, Madamwar D (2019) Synergistic biodegradation of phenanthrene and fluoranthene by mixed bacterial cultures. Bioresour Technol 284:115–120. https://doi.org/10.1016/j.biortech.2019.03.097

Patel V, Jain S, Madamwar D (2012) Naphthalene degradation by bacterial consortium (DV-AL) developed from Alang-Sosiya ship breaking yard, Gujarat, India. Bioresour Technol: 107:122–130. https://doi.org/10.1016/j.biortech.2011.12.056

Peng X, Xu PF, Du H, Tang Y, Meng Y, Yuan L et al (2018) Degradation of polycyclic aromatic hydrocarbons: a review. Appl Ecol Environ Res 16(5):6419-6440. https://doi.org/10.15666/aeer/1605_64196440

Perpetuo EA, Silva DN, Avanzi IR, Gracioso LH, Baltazar MP, Nascimento CA (2012) Phenol biodegradation by a microbial consortium: application of artificial neural network (ANN) modelling. Environ Technol 33(13–15):1739–1745. https://doi.org/10.1080/09593330.2011.644585

Purwaningsih IS, Hill GA, Headley JV (2002) Air stripping and dissolution rates of aromatic hydrocarbon particles in a bioreactor. Chem Eng Commun 189(2):268–283. https://doi.org/10.1080/00986440211842

Rabani MS, Sharma R, Singh R, Gupta MK (2020) Characterization and identification of naphthalene degrading bacteria isolated from petroleum contaminated sites and their possible use in bioremediation. Polycycl Aromat Compd 1–12. https://doi.org/10.1080/10406638.2020.1759663

Riess R, Nemati M, Headley J, Hill G (2005) Improved mass transfer and biodegradation rates of naphthalene particles using a novel bead mill bioreactor. J Chem Technol Biotechno 80(6):662–668. https://doi.org/10.1002/jctb.1247

Salari D, Niaei A, Khataee A, Zarei M (2009) Electrochemical treatment of dye solution containing C.I. Basic Yellow 2 by the peroxi-coagulation method and modeling of experimental results by artificial neural net works. J Electroanal Chem 629(1–2):117–125. https://doi.org/10.1016/j.jelechem.2009.02.002

Thomas S, Veettil NT, Subbiah K (2021) Isolation, characterization and optimization of chrysene degradation using bacteria isolated from oil-contaminated water. Water Sci Technol. https://doi.org/10.2166/wst.2021.227

Tirkey SR, Ram S, Mishra S (2021) Naphthalene degradation studies using Pseudomonas sp. strain SA3 from Alang-Sosiya ship breaking yard. Gujarat Heliyon 7(3):e06334. https://doi.org/10.1016/j.heliyon.2021.e06334

Yang W, Cao Z, Lang Y (2021) Pollution status of polycyclic aromatic hydrocarbons (PAHs) in northeastern china: a review and metanalysis. Environ Process 8(2):429–454. https://doi.org/10.1007/s40710-020-00489-6

Yu R, Nemati M, Hill G, Headley J (2006) Mass transfer and bioremediation of naphthalene and methyl naphthalenes in baffled and bead mill bioreactors. Can J Chem Eng 84(3):349–355. https://doi.org/10.1002/cjce.5450840311

Vaidya S, Devpura N, Jain K, Madamwar D (2018) Degradation of chrysene by enriched bacterial consortium. Front Microbiol 9:1333. https://doi.org/10.3389/fmicb.2018.01333

Wang W, Wang L, Shao Z (2018) Polycyclic aromatic hydrocarbon (PAH) degradation pathways of the obligate marine PAH degrader cycloclasticus sp. strain P1. Appl Environ Microbiol 84(21). https://doi.org/10.1128/AEM.01261-18

Wang Y, Riess R, Nemati M, Hill G, Headley J (2008) Scale-up impacts on mass transfer and bioremediation of suspended naphthalene particles in bead mill bioreactors. Bioresour Technol 99(17):8143–8150. https://doi.org/10.1016/j.biortech.2008.03.070

Zenati B, Chebbi A, Badis A, Eddouaouda K, Boutoumi H, El Hattab M, Hentati D, Chelbi M, Sayadi S, Chamkha M, Franzetti A (2018) A non-toxic microbial surfactant from Marinobacter hydrocarbonoclasticus SdK644 for crude oil solubilization enhancement. Ecotoxicol Environ Saf 154:100–107. https://doi.org/10.1016/j.ecoenv.2018.02.032

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Material preparation and data collection were performed by Sinan J. Mohammed and Yasmen A. Mustafa. Data analysis and validation were made by Sinan J. Mohammed, Yasmen A. Mustafa, and Mohanad S. Jabbar. The first draft of the manuscript was written by Yasmen A. Mustafa and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

All the authors associated with this work declare that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

ESM 1

(XLSX 20.3 KB)

Rights and permissions

About this article

Cite this article

Mohammed, S.J., Mustafa, Y.A. & Jabbar, M.S. Biodegradation of Naphthalene Using Glass Beads Roller Bioreactor: Application of Artificial Neural Network Modeling. Environ. Process. 9, 16 (2022). https://doi.org/10.1007/s40710-022-00559-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40710-022-00559-x