Abstract

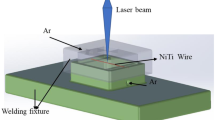

NiTi shape memory alloys are well-known due to their outstanding functional properties including superelasticity (SE) and Shape Memory Effect (SME). Laser welding is a viable technique for the joining of NiTi wires, which are employed in the design of smart structures. Joining of dissimilar wires can provide better flexibility using various alloys and, consequently, lead to multi-functional properties. However, this is really challenging due to the effect of temperature on microstructure and composition of the welded joints, since the thermal process alters the material microstructure and subsequently the transformation temperature of the heat affected area. Therefore, it is of utmost relevance to find the optimal laser operational parameters for this process. In this context, this study investigates the dissimilar laser welding of NiTi wires. The experimental investigation is based on several interconnected analyses that include optical microscopy (OM), Scanning Electron Microscopy (SEM), and Energy Dispersive X-ray Spectroscopy (EDS) analysis. Thermal analysis by Differential scanning calorimetry (DSC) is also performed to check the matching between the thermal transition of the welded joints compared to the reference materials. Highest energy delivered during welding led to welded joints of better quality. Lastly, the identification of the optimal operational parameters of the laser welding process, such as laser power and scan speed, was found to be crucial to preserve microstructural properties of the welded wires, thermal transition temperatures and therefore avoid to affect the functionality of the materials.

Similar content being viewed by others

References

Elahinia, M.: Shape Memory Alloy Actuators: Design, Fabrication and Experimental Evaluation. John Wiley & Sons (2015)

Hassan, M.M.: Review of self-healing effect on shape memory alloy (SMA) structures. Adv Mater Res. 701, 87–92 (2013)

Mehrpouya, M., Bidsorkhi, H.C.: MEMS Applications of NiTi Based Shape Memory Alloys: A Review. Micro and Nanosystems. 8(2), 79–91 (2016)

Mehrpouya, M., et al.: An investigation on the optimum machinability of NiTi based shape memory alloy. Mater Manuf Process. 1–8 (2017)

Lavvafi, H., et al.: Parametric studies on femtosecond laser cutting of Ni-Ti shape memory alloy. in MS&T 2012 Next Generation Biomaterials Symposium (2012)

Mehrpouya, M., Gisario, A., Elahinia, M.: Laser welding of NiTi shape memory alloy: a review. J Manuf Process. 2018(31), 162–186 (2018)

Mehrpouya, M., et al.: An artificial neural network model for laser transmission welding of biodegradable polyethylene terephthalate/polyethylene vinyl acetate (PET/PEVA) blends. Int J Adv Manuf Technol. 1–11 (2019)

Gisario, A., Mehrpouya, M., Pizzi, E.: Dissimilar joining of transparent poly (ethylene terephthalate) to aluminum 7075 sheets using a diode laser. Journal of Laser Applications. 29(2), 022418 (2017)

Mehrpouya, M., Lavvafi H., and Darafsheh A.: Microstructural Characterization and Mechanical Reliability of Laser-Machined Structures, in Advances in Laser Materials Processing (Second Edition). Elsevier. p. 731–761 (2018)

Panton, B., Pequegnat, A., Zhou, Y.N.: Dissimilar laser joining of NiTi SMA and MP35N wires. Metall Mater Trans A. 45(8), 3533–3544 (2014)

Zeng, Z., et al.: Dissimilar laser welding of NiTi shape memory alloy and copper. Smart Mater Struct. 24(12), 125036 (2015)

Pouquet, J., et al.: Dissimilar laser welding of NiTi to stainless steel. Int J Adv Manuf Technol. 61(1–4), 205–212 (2012)

Oliveira, J., et al.: Dissimilar laser welding of superelastic NiTi and CuAlMn shape memory alloys. Mater Des. 128, 166–175 (2017)

Zoeram, A.S., Mousavi, S.A.: Effect of interlayer thickness on microstructure and mechanical properties of as welded Ti6Al4V/Cu/NiTi joints. Mater Lett. 133, 5–8 (2014)

Oliveira, J., et al.: Laser joining of NiTi to Ti6Al4V using a niobium interlayer. Acta Mater. 105, 9–15 (2016)

Mirshekari, G., et al.: Laser welding of NiTi shape memory alloy: comparison of the similar and dissimilar joints to AISI 304 stainless steel. Opt Laser Technol. 54, 151–158 (2013)

Zeng, Z., et al.: Laser welding of NiTi shape memory alloy wires and tubes for multi-functional design applications. Smart Mater Struct. 25(8), 085001 (2016)

Gugel, H., Schuermann, A., Theisen, W.: Laser welding of NiTi wires. Mater Sci Eng A. 481, 668–671 (2008)

Zoeram, A.S., Mousavi, S.A.: Laser welding of Ti–6Al–4V to nitinol. Mater Des. 61, 185–190 (2014)

Yuhua, C., et al.: Investigation of welding crack in micro laser welded NiTiNb shape memory alloy and Ti6Al4V alloy dissimilar metals joints. Opt Laser Technol. 91, 197–202 (2017)

Chen Y., et al.: Study on the cracks of NiTiNb/TC4 lap joints welded by micro laser welding, in Transactions on Intelligent Welding Manufacturing, Springer. p. 79–89 (2018)

Li, Q., Zhu, Y.: Impact butt welding of NiTi and stainless steel-an examination of impact speed effect. J Mater Process Technol. 255, 434–442 (2018)

Datta, S., et al.: Exploring the possibility of dissimilar welding of NiTi to Ti using Yb-fiber laser. Advances in Materials and Processing Technologies. 1–12 (2018)

Zhou, X., et al.: Effects of niobium addition on the microstructure and mechanical properties of laser-welded joints of NiTiNb and Ti6Al4V alloys. J Alloys Compd. 735, 2616–2624 (2018)

Gisario, A., et al.: Laser-assisted bending of titanium Grade-2 sheets: experimental analysis and numerical simulation. Opt Lasers Eng. 92, 110–119 (2017)

Gisario, A., et al.: LaserOrigami (LO) of three-dimensional (3D) components: experimental analysis and numerical modelling. J Manuf Process. 23, 242–248 (2016)

Mehrpouya, M., et al.: Laser welding of NiTi shape memory sheets using a diode laser. Opt Laser Technol. 108C, 142–149 (2018)

Chan, C., Man, H., Yue, T.: Effect of postweld heat treatment on the microstructure and cyclic deformation behavior of laser-welded NiTi-shape memory wires. Metall Mater Trans A. 43(6), 1956–1965 (2012)

Gong, W.-h., Chen, Y.-h., Ke, L.-m.: Microstructure and properties of laser micro welded joint of TiNi shape memory alloy. Trans Nonferrous Metals Soc China. 21(9), 2044–2048 (2011)

Yang, D., et al.: Microstructure and mechanical behaviors of electron beam welded NiTi shape memory alloys. Mater Des. 57, 21–25 (2014)

Bram, M., et al.: Powder metallurgical fabrication processes for NiTi shape memory alloy parts. Mater Sci Eng A. 337(1–2), 254–263 (2002)

Chatterjee, S., Abinandanan, T., Chattopadhyay, K.: Microstructure development during dissimilar welding: case of laser welding of Ti with Ni involving intermetallic phase formation. J Mater Sci. 41(3), 643–652 (2006)

Zhang, X., Sehitoglu, H.: Crystallography of the B2→ R→ B19′ phase transformations in NiTi. Mater Sci Eng A. 374(1–2), 292–302 (2004)

Frenzel, J., et al.: Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 58(9), 3444–3458 (2010)

Chan, C., Man, H., Cheng, F.: Fatigue behavior of laser-welded NiTi wires in small-strain cyclic bending. Mater Sci Eng A. 559, 407–415 (2013)

Acknowledgments

The authors would like to acknowledge Mr. Riccardo D’Amico and Mr. Attilio Panella for their contributions in the experimental tests. Prof. Silvia Vesco is acknowledged for the support in SEM analysis. Dr. Elisa Pizzi is acknowledged the support in DSC analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mehrpouya, M., Gisario, A., Barletta, M. et al. Dissimilar Laser Welding of NiTi Wires. Lasers Manuf. Mater. Process. 6, 99–112 (2019). https://doi.org/10.1007/s40516-019-00084-0

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-019-00084-0