Abstract

An experimental program was undertaken to study the effect of inclusion of pond ash and randomly distributed polypropylene fibres on the strength behaviour of cement-stabilized clayey soil. In the present investigation, 19 combinations of fibre-reinforced cement-stabilized clayey soil-pond ash mixes at three different percentages of pond ash (i.e. 10, 20 and 30%) and two different percentages of polypropylene fibres (i.e. 0.5 and 1%) of length 6 and 12 mm with 5% cement content were prepared. The combinations of clayey soil-cement-pond ash-fibres were subjected to a series of standard proctor test, unconfined compressive strength and split tensile strength tests. Based on favourable test results obtained, it can be concluded that partial replacement of cement-stabilized clayey soil by pond ash with the inclusion of polypropylene fibres causes a significant increase in strength, decrease in the stiffness, and rate of loss of post-peak strength. The fibre inclusion changed the brittle behaviour of the composite to ductile. The inclusion of 1% fibres of 6 mm length or 0.5% fibre of 12 mm length has the same impact on the unconfined compressive strength and split tensile strength of the mixtures. The study demonstrates that pond ash can be used successfully as partial replacement of the clayey soil by using reinforcement and cement.

Similar content being viewed by others

Abbreviations

- PPF:

-

Polypropylene fibres

- OMC:

-

Optimum moisture content

- MDD:

-

Maximum dry density

- UCS:

-

Unconfined compressive strength

- STS:

-

Split tensile strength

- CBR:

-

California bearing ratio

- SEM:

-

Scanning electron microscopy

References

Gray, D.H., Al-Refeai, T.: Behavior of fabric- versus fiber-reinforced sand. J. Geotech. Eng. 112, 804–820 (1987)

Ranjan, G., Vasan, R.M., Charan, H.D.: Probabilistic analysis of randomly distributed fiber-reinforced soil. J. Geotech. Eng. 122, 419–426 (1994)

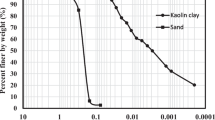

Maher, M.H., Ho, Y.C.: Mechanical properties of kaolinite/fiber soil composite. J. Geotech. Eng. 120, 1381–1393 (1995)

Kaniraj, B.S.R., Havanagi, V.G.: Behavior of cement -stabilized fiber-reinforced fly ash-soil mixtures. J. Geotech. Geoenviron. Eng. 127, 574–584 (2001)

Tang, C., Shi, B., Gao, W., Chen, F., Cai, Y.: Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 25, 194–202 (2007). https://doi.org/10.1016/j.geotexmem.2006.11.002

Kumar, A., Walia, B.S., Bajaj, A.: Influence of fly ash, lime, and polyester fibers on compaction and strength properties of expansive soil. J. Mater. Civ. Eng. 19, 242–248 (2007). https://doi.org/10.1061/(ASCE)0899-1561(2007)19:3(242)

Fatahi, B., Khabbaz, H., Fatahi, B.: Mechanical characteristics of soft clay treated with fibre and cement. Geosynth. Int. 19, 252–262 (2012). https://doi.org/10.1680/gein.12.00012

Yadav, J.S., Tiwari, S.K.: Behaviour of cement stabilized treated coir fibre-reinforced clay-pond ash mixtures. J. Build. Eng. 8, 131–140 (2016). https://doi.org/10.1016/j.jobe.2016.10.006

Kathari, P.M.: Rheological properties of polypropylene reinforced asphalt binder. Transp. Infrastruct. Geotechnol. 3, 109–126 (2016). https://doi.org/10.1007/s40515-016-0033-3

Setty, K.R.N.S., Rao, S.V.G.: Characteristics of fiber reinforced lateritic soils. In: Proc. Indian Geotech. Conf. Bangalore, India. pp 329–333(1987)

Wasti, Y.: Behaviour of model footings on sand reinforced with discrete inclusions. Geotext. Geomembr. 14, 575–584 (1997)

Ranjan, G., Bhupal, S., HD, C.: Experimental study of soft clay reinforced with sand–fiber. Indian. Geotech. J. 29, 281–291 (1999)

Santoni, R.L., Webster, S.L.: Airfields and roads construction using fiber stabilization of sands. J. Transp. Eng. 127, 96–104 (2001)

Kumar, A., Walia, B.S., Mohan, J.: Compressive strength of fiber reinforced highly compressible clay. Constr. Build. Mater. 20, 1063–1068 (2006). https://doi.org/10.1016/j.conbuildmat.2005.02.027

Pradhan, P.K., Kar, R.K., Naik, A.: Effect of random inclusion of polypropylene fibers on strength characteristics of cohesive soil. Geotech. Geol. Eng. 30, 15–25 (2012). https://doi.org/10.1007/s10706-011-9445-6

Mclaren, R.J., Digioia, A.M.: The typical engineering properties of fly ash. In: Geotech. Pract. Waste Dispos. ‘87. p 872 (1987)

Central Electricity Authority: Report on fly ash generation at coal/lignite based thermal power stations and its utilization in the country for the year 2014–15 (2015)

Gray, D.H., Lin, Y.K.: Engineering properties of compacted fly ash. J. Soil Mech. Found Div. 98, 361–380 (1972)

Bera, A.K., Ghosh, A., Ghosh, A.: Shear strength response of reinforced pond ash. Constr. Build. Mater. 23, 2386–2393 (2009). https://doi.org/10.1016/j.conbuildmat.2008.10.008

Jakka, R.S., Ramana, G.V., Datta, M.: Shear behaviour of loose and compacted pond ash. Geotech. Geol. Eng. 28, 763–778 (2010). https://doi.org/10.1007/s10706-010-9337-1

Priyadarshee, A., Gupta, D., Kumar, V., Sharma, V.: Comparative study on performance of tire crumbles with fly ash and kaolin clay. Int. J. Geosynth. Ground Eng. 1, 1–7 (2015). https://doi.org/10.1007/s40891-015-0033-3

Ghosh, A.: Compaction characteristics and bearing ratio of pond ash stabilized with lime and phosphogypsum. J. Mater. Civ. Eng. 22, 343–351 (2010). https://doi.org/10.1061/(ASCE)MT.1943-5533.0000028

IS: Classification and identification of soils for general engineering purposes, Bureau of Indian Standards, New Delhi (1498-1970)

IS: (Part VII-1980), Methods of test for soils, determination of water content-dry density relation using light compaction. Bureau of Indian Standards, New Delhi (2720)

IS: (Part X-1991), Methods of test for soils, determination of unconfined compression test. Bureau of Indian Standards, New Delhi (2720)

ASTM, C496-96, Standard test method for splitting tensile strength of cylindrical concrete specimens

Kaniraj, S.R., Gayathri, V.: Geotechnical behavior of fly ash mixed with randomly oriented fiber inclusions. Geotext. Geomembr. 21, 123–149 (2003). https://doi.org/10.1016/S0266-1144(03)00005-0

Yadav, J.S., Tiwari, S.K.: E ff ect of waste rubber fi bres on the geotechnical properties of clay stabilized with cement. (2017) doi: https://doi.org/10.1016/j.clay.2017.07.037

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yadav, J.S., Tiwari, S.K. & Shekhwat, P. Strength Behaviour of Clayey Soil Mixed with Pond Ash, Cement and Randomly Distributed Fibres. Transp. Infrastruct. Geotech. 5, 191–209 (2018). https://doi.org/10.1007/s40515-018-0056-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40515-018-0056-z