Abstract

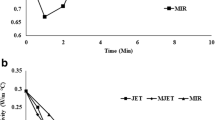

Foundry industries aim at reducing energy consumption in processing of materials. Continuous efforts are ongoing to exploit unconventional energy sources such as microwave energy to overcome drawbacks of conventional sources. In the present work, a comparative study of electrical energy consumption during melting of known quantity of metallic material in microwave oven and in conventional muffle electric furnace is carried out. The non-ferrous bulk metallic materials such as tin, zinc, aluminum and brass are used as candidate materials. A 900-W modified domestic microwave oven, operating at 2.45 GHz and a conventional muffle furnace are used for the study. The electrical energy consumed for melting of known quantity of metallic materials is presented along with the observed material wastage during melting process. The study shows that microwave oven consumes significantly lesser time than the conventional muffle electric furnace for the melting of known quantity of candidate materials. It is found that melting bulk metallic materials by microwave irradiation reduces electrical energy consumption than that of conventional melting process. In addition, material wastage is around twofold lesser by microwave melting process than the conventional melting process for the known quantity of candidate materials.

Similar content being viewed by others

References

Moore AF, Schechter DE, Morrow MS (2003) Method and apparatus for melting of metals. US Patent;20030089421

Thostenson ET, Chou TW (1999) Microwave processing: fundamentals and applications. Compos A 30(9):1055–1071

Sutton WH (1989) Microwave processing of ceramic materials. Am Ceram Soc Bull l68:376–386

Clark DE, Sutton WH (1996) Microwave processing of materials. Annu Rev Mater Sci 26:299–331

Bermúdez JM, Beneroso D, Rey-Raap N, Arenillas A, Menéndez JA (2015) Energy consumption estimation in the scaling-up of microwave heating processes. Chem Eng Process 95:1–8

Mishra RR, Sharma AK (2016) Microwave–material interaction phenomena: heating mechanisms, challenges and opportunities in material processing. Compos: Part A 81:78–97

Leonelli C, Veronesi P, Denti L, Gatto A, Iuliano L (2008) Microwave assisted sintering of green metal parts. J Mater Process Technol 205:489–496

Nishitani T (1979) Method for sintering refractories and an apparatus therefor. US patent: 4147911

Agarwal D (1997) Microwave sintering of ceramics, composites, metals and transparent materials. J Mater Edu 19(4,5&6):49–57

Zhu J, Ouyanga C, Xiao S, Gao Y (2016) Microwave sintering versus conventional sintering of NiCuZn ferrites. Part I: densification evolution. J Magn Magn Mater 407:308–313

Sharma AK, Srinath MS, Kumar P (2009) Microwave joining of metallic materials. Indian patent: 1994/Del/2009

Srinath MS, Sharma AK, Kumar P (2011) A new approach to joining of bulk copper using microwave energy. Mater Des 32:2685–2694

Badiger RI, Narendranath S, Srinath MS (2015) Joining of inconel-625 alloy through microwave hybrid heating and its characterization. J Manuf Process 18:117–123

Srinath MS, Sharma AK, Kumar P (2011) Investigation on microstructural and mechanical properties of microwave processed dissimilar joints. J Manuf Process 13(2):141–146

Gupta D, Sharma AK (2011) Development and microstructural characterization of microwave cladding on austenitic stainless steel. Surf Coat Technol 205(21):5147–5155

Hebbale AM, Srinath MS (2016) Microstructural investigation of Ni based cladding developed on austenitic SS-304 through microwave irradiation. J Mater Res Technol 5(4):293–301

Zafar S, Sharma AK (2015) On friction and wear behaviour of WC-12Co microwave clad. Tribol Trans 58(4):584–591

Arasu M, Jeffrey LR (2009) Energy consumption studies in cast iron foundries, Trans 57th Indian Foundry Congress: 331–336

Bhattacharya M, Basak T (2016) A review on the susceptor assisted microwave processing of materials. Energy 98:306–338

Chandrasekaran S, Basak T, Ramanathan S (2011) Experimental and theoretical investigation on microwave melting of metals. J Mater Process Technol 211(3):482–487

Mishra RR, Sharma AK (2016) On mechanism of in situ microwave casting of aluminium alloy 7039 and cast microstructure. Mater Des 112:97–106

Shashank LM, Srinath MS, Amarendra HJ (2017) Microstructural investigation and characterization of bulk brass melted by conventional and microwave processing methods. Mater Sci Forum 890:356–361

Shashank LM, Srinath MS, Amarendra HJ (2017) Microstructural and mechanical investigation of aluminium alloy (Al 1050) melted by microwave hybrid heating. Mater Res Exp. https://doi.org/10.1088/2053-1591/aa7aaf

Shashank LM, Srinath MS, Amarendra HJ (2017) Melting of 60Sn40Pb alloy using microwave energy and its characterization. Mater Today: Proc 4:471–476

Gouthama R, Harisha G, Manjunatha YR, Mohana Kumara SM, Srinath MS, Shashank LM (2016) Melting of tin using muffle furnace and microwave energy and its characterization. Mater Sci Eng. https://doi.org/10.1088/1757-899X/149/1/012100

Raj PP, Sudhakaran M, Raj AP (2009) Estimation of standby power consumption for typical appliances. J Eng Sci Technol Rev 2(1):71–75

Acknowledgement

This work was supported by the All India Council for Technical Education (AICTE), Govt. of India, India [Ref. No.: 8-201/RIFD/RPS/POLICY-1/2014-15].

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva.

Rights and permissions

About this article

Cite this article

Lingappa, S.M., Srinath, M.S. & Amarendra, H.J. Melting of bulk non-ferrous metallic materials by microwave hybrid heating (MHH) and conventional heating: a comparative study on energy consumption. J Braz. Soc. Mech. Sci. Eng. 40, 1 (2018). https://doi.org/10.1007/s40430-017-0921-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-017-0921-7