Abstract

Using the renewable energy, especially solar energy, is an environmental-friendly approach for seawater desalination. Solar evaporation is a promising freshwater harvesting strategy rich in energy, including solar and water energy. Herein, we propose a solar evaporation hybrid hydrogel including polyvinyl alcohol (PVA) and glutaraldehyde (GA) as a polymer network, semiconductor oxide nanoparticles (ZnO, CuO) and activated carbon as a photothermal material. Structural properties of hybrid hydrogel were characterized by X-ray diffraction (XRD) analysis, surface morphology by field emission scanning electron microscope (FE-SEM), chemical bonding by Fourier transform infrared spectroscopy (FTIR) and optical absorption and absorption coefficient (α) of components by UV–Vis spectroscopy. The result showed in visible region, PVA:ZnO:AC hydrogel nanocomposite has a strong absorption (55%) compare of the PVA:CuO:AC hydrogel nanocomposite (35%). In addition, by distillation measurements, the evaporator system demonstrated for PVA:CuO:AC and PVA:ZnO:AC Hydrogel an evaporation rate of 2.29 kg m−2 h−1 and 5.19 kg m−2 h−1 with the evaporation efficiency of 30.66% and 70.80%, respectively, under 0.1 sun irradiation. For PVA:CuO:AC hydrogel, the hardness of Caspian seawater decreased from 6648 to 115 ppm and ion conductance from 8641 (μS) to 244 (μS) and for the PVA:ZnO:AC Hydrogel decreased to 97 ppm and ion conductance to 206 (μS). Experiments showed that with changing type of the ZnO or CuO semiconductor oxide nanoparticles can effectively on regulate the optical properties of the evaporator. Eventually, this work begins a new point of synthesizing cost-effective photothermal absorbers based on metal oxides material and activated carbon nanocomposite.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Access to freshwater as potable water is essential for human life [1]. The scarcity of freshwater worldwide has caused the development of the water desalination and purification: Among all global of obtaining freshwater, desalination with solar steam generation systems, given that clean water can be supplied from the seas [2]. Also, for removing pollution from wastewater, surface adsorption is one of the effective methods [3]. Solar steam generation technology has been developed for water purification applications owing to its high conversion efficiency low energy, consumption, sustainability and environmental friendliness among the current technologies in the past decades [4]. Typically, the solar evaporation system consists of a hydrophilic material, in which pump water to the top surface, and the top surface is a photothermal material for sunlight absorbability and improve the efficiency of solar thermal conversion [5]. The nanostructured semiconductors [6], metallic particles [7], black materials based on carbon [8] and polymers [9] has good candidates for photothermal conversion due to its advantages of earth-abundance, nontoxicity, and stability [10]. The interaction of nanoparticles to enhancing the thermal conversion of renewable systems is one of the modern mechanism [11]. All of these depend on three conversion principles: plasma resonance, an electron–hole generation and relaxation, and thermal vibration of the molecule [12]. Most recently, numerous studies shown that some commonly used nanostructured semiconductors, especially Al2O3 [13], TiO2 [14], Ti2O3 [15], Fe3O4 [16], ZnO [17], CuO [18] have been proposed for steam water generation under solar irradiation. Compared with some other semiconductors oxide, ZnO and CuO due to small size and surface effect, good light absorption and other excellent properties, it has a wide range of applications in the fields of optics and catalysis [19, 20]. Also, considering that Hydrogels employing micro-nano pores can demonstrate enhanced light absorption, heat conversion, water and vapor transportation [21, 22]. The micro-nano structure can also improve the hydrophilic characteristics of hydrogels [23]. It is well-developed micro gaps act as numerous vapor transmission channels. Also, sunlight can be scattered and absorbed in these porous structures [24]. Therefore, hydrogels can be one of the best candidates for solar evaporation systems. Also, Hydrogels have been widely used in agriculture and biomedical areas like tissue engineering, wound dressing, drug delivery, biosensors, and sorbents for removal of dyes and heavy metals [25]. The past decade Several types of solar steam generation systems exist and use a variety of materials. Also, the researchers have investigated various heat transfer with numerical techniques the Hussain et al. studied of solitary waves in optical fibers [26]. Li et al. studied the impacts of the temperature change on the perovskite layer by modifying the structure of the perovskite to the temperature [27]. Smida et al. studied the influences of thermal radiations, nanoparticles strength, convective heat condition on the heat performance of ternary nanofluid [28]. Also, Cui et al. have prepared a DCS-PNIPAm gels with the sodium alginate (SA) and carbon nanotubes (CNTs) layer for producing clean water at hydrogel interfaces for solar-driven evaporation, that exhibit exceptional swelling capacity and reached evaporation rate up to 9.32 kg m–2 h–1 under one sun irradiation [29]. Zhao et al. reported spongy polyelectrolyte hydrogel for efficient Solar evaporation which enhances the thermal localization effect on the hydrogel surface and improves energy utilization efficiency 92.95% with evaporation rate 2.8 kg m−2h−1 in high concentration saltwater (20 wt.%) [30]. Xu et al. reported the GO/CuO film for water desalination with highest evaporation rate which reach to 1.71 kg m−2 h−1 with an efficiency of 99.2% [31]. Moreover, also reported Xu and et al. a multifunctional photothermal material based on a copper mesh with a high solar absorption of 93% and solar vapor efficiency of 84.4% under one-sun illumination [32]. In addition, for increasing the rate evaporation, recently, Xub et al. prepare the Ti4O7/PVA nanocomposite hydrogel with high evaporation rate of ∼4.45 kg m−2 h−1 with outstanding energy efficiency ~ 90.69% under one sun irradiation [33]. Zhang et al. synthesized a carbon-based material containing copper oxide (CMCC) by calcining a chitosan porous adsorption material (CPAM) with Cu2+ as the after-use adsorbent with a evaporation rate of 1.80 kg m−2 h−1 under the light intensity of 1.0 kW m−2 [21].

In this study, we designed a hybrid heterostructure filter with the high photothermal properties, including ZnO/CuO/polyvinyl alcohol (PVA): glutaraldehyde (GA) hydrogel. The nanocomposite hydrogels were simply prepared by repeat freezing–thawing and activated carbon by attaching glutaraldehyde (GA) as the crosslinking agent. It can more suitable for solar evaporation systems dipping on the surface of the water, as seen in Fig. 1. To design hydrogel-based-solar evaporation system, efficient light absorption at the evaporation site is crucial since the intrinsic hydrophilic polymeric network can maintain an incessant water supply. For this reason, we used the hydrophilic semiconductor oxide of zinc oxide and copper oxide nanoparticles with activated carbon as photothermal materials in the hydrogel to raise the surface temperature. In these conditions, hydrogel can pump water through capillary action to the upper surface, where localized plasmonic heat was generated upon light irradiation. In this work we distillate the Caspian Sea water with hardness 6648 ppm and ion conductance 8641 (μS) and results showed the PVA:ZnO:AC hydrogel can achieve high energy efficiency (70%) and high evaporation rates (5.19 kg m−2 h−1). In addition, the evaporator can decrease the hardness and ion conductance of Caspian seawater reduce to less than 115 ppm and 250 (μS).

Experimental detail

Materials

Polyvinyl alcohol (PVA) with the average molecular weight of 72,000, Sigma-Aldrich, Active Carbon (as-synthesized in our previous published), hydrochloric acid HCl (37%) (Merck), glutaraldehyde (GA), 50wt.% aqueous solution, distillated water and Caspian seawater, Sodium borohydride (Merck), Copper (II) sulfate (Merck), starch and Ammonia (25%) (Merck), NaOH (Merck), Zinc acetate (Scharlau).

Preparation of CuO nanoparticles

The synthesis of copper oxide nanoparticles was prepared as previously reported [8, 14], with slight modification. At first, we dissolve 1 g of CuSO4 in 10 ml of NH3 (25%) with a magnetic stirrer for 30 min. Then, HCl (37%) add dropwise to the solution until PH = 7 and 4 g of starch solved in 100 ml of 0.3 M NaOH and then add dropwise to the CuSO4 solution that deposits are formed. After the precipitation of copper oxide nanoparticles, it was separated by filtration and washed several times with water and alcohol. Then, it was dried under an IR lamp at T = 50 °C. The prepared CuO nanoparticles was placed in a furnace at 450 °C for 2 h. Finally, CuO nanoparticles is obtained.

Preparation of ZnO nanoparticle

The ZnO nanoparticles were synthesized with dissolving 2.19 gr zinc acetate in 100 ml of deionized water and 1.6 g of NaOH in 100 ml of deionized water, and stirring two solutions with a magnetic stirrer, separately [17]. NaOH solution add dropwise to the zinc acetate solution that deposit are was formed for one hour. The solution turned white, after the precipitation of zinc oxide nanoparticles, it was separated by filtration and washed several times with water and alcohol. Then it was dried under an IR lamp at 50 °C. Then it was placed in a furnace at 450 °C for 2 h. Finally, Zinc oxide nanoparticles is obtained.

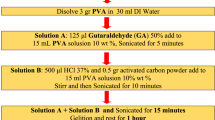

Preparation of PVA:GA:CuO/ZnO:AC nanocomposite hydrogel:

In this stage, we solved 3 g polyvinyl alcohol (PVA) powder in 30 ml deionized water at T = 85 °C for one hour. Next, 135 μl of glutaraldehyde (GA) 50% were well mixed with PVA aqueous solution (10 wt. %) through magnetic stir [9]. Then, 0.05 g metal oxide nanoparticles, 0.1 g AC was prepared, and 300 μl of HCl add to solution and mixed through bath sonication for 20 min. When the gel is formed, afterward the sample is placed in a low temperature storage box at T = − 22 °C, with freezing for 12 h. It’s thawed at T = 30 °C for 3 h, which is repeated for 5 cycles. At the end they were placed on a freeze-dryer for 24 h. Finally, hybrid hydrogel is obtained, as seen in Fig. 1.

Characterization techniques

The microstructure and pore distribution of evaporator material was studied by Field emission scanning electron microscopy (FE-SEM, MIRA3, TESCAN). The absorption spectra in the range of λ = 190–1100 nm was examined by the UV–Vis–NIR spectrometer with an integrating sphere unit (Shimadzu UV–1700). The functional groups were analyzed by an FTIR Spectrometer (Vertex 70, Bruker, Germany). The crystal structures of films were characterized by X-ray diffraction (XRD) using a Bruker D8 system with Cu Ka radiation (λ = 0.15405 nm).

Result and discussion

Structural properties

The X-ray diffraction (XRD) patterns of Activated Carbon, PVA, CuO nanoparticles, ZnO nanoparticles, PVA:CuO:AC Hydrogel nanocomposite and PVA:ZnO:AC Hydrogel nanocomposite is shown in Fig. 2a–f for diffraction angles of 5° ≤ 2θ ≤ 75° confirmed, respectively. Each chart includes the XRD patterns of nanoparticles and CuO, ZnO Hydrogels. As can be seen, X-ray diffraction clearly shows the main broad peak for the AC in amorphous state at 2θ = 24.4° as shown in Fig. 2a [9]. There is one obvious peak with the highest intensity at 2θ = 19.73° represent to pure polyvinyl alcohol corresponding to (101) crystal plane, one more peaks at 2θ = 27.85° corresponding to (201) plane indicating the semi-crystalline nature of the PVA and presence of crystalline and amorphous regions, as shown in Fig. 2b [34, 35]. The XRD pattern shows that CuO nanoparticles exhibit characteristic peaks of the monoclinic structure (Tenorite) corresponding to refection planes (110), (002), (111), (-112), (-202), (-113), (002) and (220), as shown in Fig. 2c [36, 37]. The XRD spectrum of prepared ZnO nanoparticles is shown in Fig. 2d. XRD analysis revealed that the ZnO nano particles are crystallized in hexagonal wurtzite structure corresponding to refection planes (002), (101), (102), (103), (112), and (004), respectively [38, 39]. In Fig. 2e–f, due to presence of AC and PVA, the X-ray diffraction patterns of both of hydrogels clearly shows amorphous structure, Also, from the comparison of the spectrum of AC, PVA and NPs with hydrogels, it is due to the presence of nanoparticles and AC inside the PVA matrix that caused the formation of hydrogel nanocomposite. All these changes in the XRD spectra of hydrogels are clear indications for the complexation of PVA with AC and NPs. The average crystallite size, was calculated using the Scherrer formula [40] and are presented in Table 1.

where λ is the X-ray wavelength of Cu-K radiation source (0.15418 nm), β (radiant) is the full width at half maximum (FWHM) intensity of the diffraction peak located at 2θ, and θ is the Bragg angle and K is the Scherrer constant with a value from 0.9 to 1. The average crystalline size of the CuO NPs in PVA:CuO:AC hydrogel nanocomposite is 42.14 nm and the ZnO NPs in PVA:ZnO:AC hydrogel nanocomposite is 42.35 nm.

Fourier- transform infrared spectroscopy

Fourier transform infrared (FTIR) spectra of Activated Carbon, pure PVA, CuO nanoparticles, ZnO nanoparticles, PVA:CuO:AC Hydrogel nanocomposite and PVA:ZnO:AC Hydrogel nanocomposite in the range of 4000–400 cm−1 shown in Fig. 3a–f, respectively. The peaks of Activated Carbon in Fig. 3a show wavenumber of 1720 cm−1 attributed to C=O stretching of the carbonyl functional group, 1325 cm−1 for C=C stretching of the aromatic rings [41]. The peaks of pure PVA in Fig. 3b show wavenumber at 3410 cm−1 that were assigned to the vibration and stretching of OH groups, 2940 cm−1,1710 cm−1 and 1254 cm−1 corresponding to the CH-OH bending vibration, C=O stretching vibration peak and C=C stretching peak, respectively [42]. Figure 3c shows the peak at 444 cm−1 corresponding to Cu–O stretching vibration band [43]. The peak of ZnO NPs in Fig. 3d show wavenumber at 470 cm−1 corresponding to the Zn–O bond oscillation [44]. The peaks of PVA:CuO:AC Hydrogel nanocomposite in Fig. 3e show wavenumber of 3414 cm−1 and 2934 cm−1 for OH–CH stretching, 1728 cm−1 for C=O stretching, 1100 cm−1 for C–O stretching bending and 444 cm−1 for Cu–O stretching vibration. The peaks of PVA:ZnO:AC Hydrogel nanocomposite in Fig. 3f show wavenumber 3424 cm−1 and 2934 cm−1 for OH-CH stretching, 1719 cm−1 for C=O stretching, 1254 cm−1 for C=C stretching, 1100 cm−1 for C–O stretching and 470 cm−1 for Zn–O bond oscillation. The hydroxyl and carboxyl functional groups, introduce hydrophilicity responsiveness to PVA and AC [45]. All the characteristic peaks of nanoparticles can be found in the spectrum of the both of them.

Optical abosorption analysis by UV–Vis spectroscopy

Figure 4a, b, shows the UV–Vis–NIR absorption spectra in a wavelength region of λ = 200–1100 nm for PVA:CuO:AC hydrogl nanocomposite and PVA:ZnO:AC hydrogel nanocomposite as form of a thickness of 1 mm in the wet gel state, respectively. According to Fig. 4a, the absorption peak was observed in the UV region around λ = 298 nm corresponding to peresence of the CuO NPs [36]. In Fig. 4b, absorption peak was about λ = 330 nm in the UV region corresponding to peresence of the ZnO NPs [46]. The solar radiation spectrum covers the light in the range from λ = 300 nm to 2500 nm. The visible light band 400–700 nm is about 48% of the total energy [47]. In visible region, PVA:ZnO:AC hydrogel nanocomposite has a strong absorption (55%), it can absorb most of the sunlight compare of the PVA:CuO:AC hydrogel nanocomposite (35%). Due to porous structures of hydrogel sunlight can be scattered and absorbed in these porous.

Optical absorption by UV–Vis spectroscopy, (a) PVA:CuO:AC hydrogel nanocomposite (b) Optical absorption coefficient (α) by UV–Vis spectroscopy, PVA:CuO:AC hydrogel nanocomposite (c) Optical absorption of PVA:ZnO:AC hydrogel nanocomposite (d) Optical absorption coefficient (α) of PVA:ZnO:AC hydrogel nanocomposite

In addition, we calculated the convert light into heat by absorption values (A) which can be measured by the device were extracted and Eq. 2.

In this regard, D is the average size of nanoparticles, which is obtained from XRD patterns. Figure 4c, d are shown the diagram of absorption coefficient (α). It can be seen that, due to presence clusters of ZnO NPs in PVA:ZnO:AC hydrogel nanocomposite, absorption coefficient (α) is more than PVA:CuO:AC hydrogel nanocomposite obtained in the range from λ = 400 nm to 800 nm.

Morphology of hydrogel nanocomposite by FE-SEM analysis

The morphology of CuO NPs, ZnO NPs, PVA:CuO:AC hydrogl nanocomposite and PVA:ZnO:AC hydrogel nanocomposite was investigated by FE-SEM images at different magnifications, as illustrated in Fig. 5a–h. The FE-SEM image of CuO NPs in Fig. 5a showed the formation of CuO nanostructure like cubic shape are clustered and the surfaces of the aggregates is rough [48]. Histogram plot for the particle size distribution of CuO NPs shown in Fig. 5b. FE-SEM image of ZnO NPs show wool Bullet-like shape of ZnO nanoparticles due to the use of the reduction method and zinc acetate as a precursor [49], and the oxide molecules grow slowly and form small spherical structures Fig. 5c, and the oxide molecules grow slowly and form small spherical structures Fig. 5c. Also, Fig. 5d shown histogram plot for the particle size distribution of ZnO NPs. It can be seen in Fig. 5e PVA:CuO:AC hydrogel nanocomposite have a three-dimensional network structure with microscale porous and irregular pores with a diameter of about (5–30) µm refer to Fig. 5f. Also, Fig. 5g shows the FE-SEM image of PVA:ZnO:AC hydrogel nanocomposite. Observed that hydrogel has two kinds of near-round pores with different sizes with a diameter of about (< 10 µm) and (> 20µm) refer to Fig. 5h, both of two different microchannels could pump water from the bottom to the top surface. In addition, the microscale porous structure of the PVA:CuO:AC hydrogel nanocomposite and PVA:ZnO:AC hydrogel nanocomposite could further benefit the evaporation due to its surface roughness, which contributed to enhanced light absorption as well as increased evaporation surface area. The EDX profile Fig. 6a–d shows CuO NPs, ZnO NPs, PVA:CuO:AC hydrogl nanocomposite and PVA:ZnO:AC hydrogel nanocomposite. The CuO nanoparticles peak obtained at 8 keV with 96.45 wt%, 12.74 at% mentioned in EDX analysis Fig. 6a. Also, EDX analysis peak of The CuO nanoparticles peak in the PVA:CuO:AC hydrogel nanocomposite obtained at 1 keV with 4.97 wt%, 1.07 at% Fig. 6b. The ZnO nanoparticles peak obtained at 1 keV with 86.41 wt%, 60.88 at% mentioned in EDX analysis Fig. 6c. Also, EDX analysis peak of the CuO nanoparticles peak in the PVA:ZnO:AC hydrogel nanocomposite obtained at 1.2 keV with 0.39 wt%, 0.08 at% Fig. 6d.

FE-SEM image (a) CuO nanoparticle, (b) The histogram of the grain size distribution from FE-SEM images for CuO nanoparticle. (c) ZnO nanoparticle, (d) The histogram of the grain size distribution from FE-SEM images for ZnO nanoparticle (e) PVA:CuO:AC hydrogel nanocomposite, (f) Pore size diagram of PVA:CuO:AC hydrogel nanocomposite (g) PVA:ZnO:AC hydrogel nanocomposite, (h) Pore size diagram of PVA:ZnO:AC hydrogel nanocomposite

Water-absorbing test

To calculate water absorption, at first, the hydrogels nanocomposites with a certain weight (wt) were freeze-dried and then hydrogel samples immersed in distilled water at room temperature for 6 h, weighed wet hydrogel samples.

Swelling ratio (Q%) in equilibrium state was determined as follows [50]:

Here, M and Md are the weights of the water in the swollen and the corresponding dried hydrogel state, respectively. The results based on Eq. (3) Show that the swelling rate in Table (2).

Solar vapor rate measurement

The solar evaporation performances were estimated with a homemade real-time monitoring device under stable and constant solar radiation (0.1sun). Simulated sunlight was provided by two IR lamps (250 W, 2300 K). The light intensity was measured by a Lux meter (9 \(\times\) 105 LUX). The metal oxide hydrogel evaporator (d = 40 mm) was floated on water and Catton wipe in a beaker at an ambient temperature of T = 25 °C. For measuring the evaporation rate under the solar radiation of two IR lamps, the mass change of the water was recorded with an electronic scale is used to record the evaporation system’s mass changes in the real time with a resolution of 0.01g. Figure 7a showed the histograms of mass losses. The weight change of system is recorded within one hour under 0.1 sun, which was used to further calculate the evaporation rate (Veva) by Eq. (4) and reported in Table 2, where Wloss corresponds to the weight losses of the evaporated water, D represents the diameter of hydrogel (40 mm), and t indicates the irradiation time period [51].

During the experiment, a digital thermometer is used to record the sample’s heating process under light, and the maximum temperature of the surface sample is studied. The initial surface temperature of PVA:CuO:AC hydrogl nanocomposite is set at room temperature (T = 25 °C), while after one hour, the temperature was rised around T = 50 °C. Also, the surface temperature of PVA:ZnO:AC hydrogl nanocomposite after one hour, rised around 56 °C. From this, for the PVA:CuO:AC hydrogl nanocomposite an evaporation rate of 2.29 kg m−2 h−1 is determined and evaporation rate of the PVA:ZnO:AC hydrogl nanocomposite is 5.19 kg m−2 h−1. The solar evaporation efficiency (η) in the process can be calculated according to Eq. (5) [52].

where Veva is the net evaporation rate, △H is the total enthalpy for the liquid to vapor phase change of water, C is the specific heat of water (4.2 kJ kg−1 K−1), T1 is the temperature of water/ hydrogel interface, T0 is the initial temperature of bulk water at T = 20 °C, and qsolar is the simulated solar intensity (100 Wm−2). Under 60 min of irradiation, the solar evaporation efficiency (η) for PVA:CuO:AC Hydrogel nanocomposite is 30.66% and for PVA:ZnO:AC Hydrogel nanocomposite is 70.80% obtained (refer to Fig. 7b). The seawater sample and clean water samples produced from both systems are collected and tested for the quality of the water. For PVA:CuO:AC hydrogel nanocomposite and PVA:ZnO:AC hydrogel nanocomposite, the hardness of Caspian seawater sample decreased from 6648 to 115 ppm, 97 ppm respectively. Also, ion conductance for the Caspian Seawater is 8651 μS (micro Siemens) and after distillation for PVA:CuO:AC hydrogel nanocomposite sample is 244 μS, and for the PVA:ZnO:AC hydrogel nanocomposite sample is 206 μS. The outcomes of the water quality tests are presented in Table 2. Figure 8a, b shows hydrogels composite before distillate and after for 1h, 6h, 12 h of continuous testing, it can be seen salts crystallized on top of the hydrogels, the PVA:ZnO:AC hydrogel nanocomposite sample which can influence the hydrogels for water purifications. The results of the literature comparison by others are shown in Table 3.

Conclusions

In conclusion, PVA:CuO:AC hydrogel nanocomposite and PVA:ZnO:AC hydrogel nanocomposite was used as light-absorbing material for efficient solar steam generation device.

-

(1)

Both of hydrogels prepared by simply repeat freezing–thawing the mixture of the nanocomposite metal oxide by loading (CuO and ZnO) nanoparticles into PVA:CuO:AC hydrogel nanocomposite and PVA:ZnO:AC hydrogel nanocomposite, respectively. In these systems due to rough surface, porous structure and plasma resonance effect (metal oxide NPs) can adjust light absorption, balance water transportation and evaporation, thus achieving efficient solar photothermal conversion.

-

(2)

FE-SEM images of AC showed that both of hydrogels have microscale porous structure, that could pump water from the bottom to the top surface.

-

(3)

The absorbance spectrum of hydrogels showed that absorption and absorption coefficient coefficient (α) for the PVA:ZnO:AC hydrogel nanocomposite (55%) is higher than PVA:CuO:AC hydrogel nanocomposite (35%).

-

(4)

The PVA:CuO:AC hydrogel nanocomposite exhibits an evaporation efficiency of 30.66% with an evaporation rate of 2.29 kg m−2 h−1 and efficiency of PVA:ZnO:AC hydrogel nanocomposite is 70.80% with an evaporation rate of 5.19 kg m−2 h−1 under 0.1 sun illumination.

-

(5)

The results of seawater purification in both of samples showed low TDS and EC so that the hardness decreased. result for the PVA:ZnO:AC hydrogel nanocomposite is better than PVA:CuO:AC hydrogel nanocomposite. It can be that the hardness of Caspian seawater sample decreased from 6648 to 97 ppm. Also, ion conductance reduced from 8651 μS (micro Siemens) to 206 μS.

-

(6)

Swelling ratio of the PVA:ZnO:AC hydrogel nanocomposite (30%) is farther than PVA:CnO:AC hydrogel nanocomposite (21%).

-

(7)

Both of samples is Cost-effective hydrogels for solar vapor generation system because of that are material for synthesis readily available, durability, easy to produce, and have good thermal stability and absorb salt due to 3D structure.

-

(8)

In the future work, it is possible to design and optimize the creation of an energy-efficient hybrid system that uses more than one energy source from the environment and facilitates efficient energy conversion. Produced more efficient and affordable water treatment systems.

To sum up, these hydrogels provide a new route for improving the performance of semiconductor materials. It is foreseeable that if a solar-clean water production technology with high efficiency and excellent purification of sea water and decontamination ability is developed, it will be extremely attractive to remote water scarce areas. It is hoped that the construction strategy of composite photothermal devices could provide new solutions for environmental protection.

Data availability statements

All data generated or analyzed during this study are included in this published article.

References

Fillet, R., et al.: A review of natural materials for solar evaporation. Sol. Energy Mater. Sol. Cells 219, 110814 (2021)

Zhao, Z., et al.: Condensation device design represents a critical step for solar-driven water evaporation toward practical applications. Cell Rep. Phys. Sci. 20, 24 (2024)

Le, Q.H., et al.: Removal of heavy metals by polymers from wastewater in the industry: a molecular dynamics approach. Eng. Anal. Boundary Elem. 155, 1035–1042 (2023)

Fan, Y., et al.: The assembly of a polymer and metal nanoparticle coated glass capillary array for efficient solar desalination. J. Mater. Chem. A 8(48), 25904–25912 (2020)

Shen, C., et al.: Economical salt-resistant superhydrophobic photothermal membrane for highly efficient and stable solar desalination. ACS Appl. Mater. Interfaces 12(31), 35142–35151 (2020)

Zhu, Q., et al.: A hydrogenated metal oxide with full solar spectrum absorption for highly efficient photothermal water evaporation. J. Phys. Chem. Lett. 11(7), 2502–2509 (2020)

Aldabesh, A.D., Tlili, I.: Thermal enhancement and bioconvective analysis due to chemical reactive flow viscoelastic nanomaterial with modified heat theories: bio-fuels cell applications. Case Stud. Thermal Eng. 52, 103768 (2023)

Liang, C., et al.: Carbon foam directly synthesized from industrial lignin powder as featured material for high efficiency solar evaporation. Chem. Eng. J. 481, 148375 (2024)

Fargharazi, M., Bagheri-Mohagheghi, M.: PVA: GA polymer hydrogel/activated carbon (AC) nanocomposite as solar photothermal materials: study of structural, optical absorption and water purification properties. J. Mater. Sci. Mater. Electron. 35(6), 449 (2024)

Zuo, S., et al.: Dual-functional CuO/CN for highly efficient solar evaporation and water purification. Sep. Purif. Technol. 254, 117611 (2021)

Tlili, I., et al.: Nanofluid bioconvective transport for non-Newtonian material in bidirectional oscillating regime with nonlinear radiation and external heat source: applications to storage and renewable energy. J. Energy Storage 68, 107839 (2023)

Fuzil, N.S., et al.: A review on photothermal material and its usage in the development of photothermal membrane for sustainable clean water production. Desalination 517, 115259 (2021)

Sajjad, R., et al.: CFD analysis for different nanofluids in fin waste heat recovery prolonged heat exchanger for waste heat recovery. S. Afr. J. Chem. Eng. 47(1), 9–14 (2024)

Chen, X., et al.: Laser-synthesized rutile TiO2 with abundant oxygen vacancies for enhanced solar water evaporation. ACS Sustain. Chem. Eng. 8(2), 1095–1101 (2020)

Li, W., et al.: Highly efficient solar vapour generation via self-floating three-dimensional Ti2O3-based aerogels. Colloids Surf. A 634, 128031 (2022)

Wang, Q., et al.: Recyclable Fe3O4@ Polydopamine (PDA) nanofluids for highly efficient solar evaporation. Green Energy Environ. 7(1), 35–42 (2022)

Zhang, K., et al.: Hierarchical CuO/ZnO heterojunction with improved spectrum absorption for interfacial solar steam generation. Ind. Eng. Chem. Res. 62(36), 14557–14567 (2023)

Moghaieb, H.S., et al.: Efficient solar-thermal energy conversion with surfactant-free Cu-oxide nanofluids. Nano Energy 108, 108112 (2023)

Xu, J., et al.: Hierarchical CuO colloidosomes and their structure enhanced photothermal catalytic activity. J. Phys. Chem. C 120(23), 12666–12672 (2016)

Liu, J., et al.: Photo-thermal synergistically catalytic conversion of glycerol and carbon dioxide to glycerol carbonate over Au/ZnWO4-ZnO catalysts. Appl. Catal. B 244, 836–843 (2019)

Zhang, T., et al.: Solar water evaporation using porous cellulose polyacrylamide hydrogel with carbon-based material containing copper oxide prepared from after-use adsorbent. Desalination 527, 115576 (2022)

An, N., et al.: Efficient water purification and desalination using hydrogel and aerogel solar evaporators based on different carbon materials. Sep. Purif. Technol. 301, 122003 (2022)

Sidorenko, A., Krupenkin, T., Aizenberg, J.: Controlled switching of the wetting behavior of biomimetic surfaces with hydrogel-supported nanostructures. J. Mater. Chem. 18(32), 3841–3846 (2008)

Nandakumar, D.K., et al.: A super hygroscopic hydrogel for harnessing ambient humidity for energy conservation and harvesting. Energy Environ. Sci. 11(8), 2179–2187 (2018)

Yin, B., et al.: Engineering multifunctional dynamic hydrogel for biomedical and tissue regenerative applications. Chem. Eng. J. 2, 150403 (2024)

Hussain, Z., et al.: Analysis of bifurcation and chaos in the traveling wave solution in optical fibers using the Radhakrishnan–Kundu–Lakshmanan equation. Results Phys. 55, 107145 (2023)

Li, C., Tlili, I.: Novel study of perovskite materials and the use of biomaterials to further solar cell application in the built environment: a molecular dynamic study. Eng. Anal. Boundary Elem. 155, 425–431 (2023)

Smida, K., et al.: Numerical thermal study of ternary nanofluid influenced by thermal radiation towards convectively heated sinusoidal cylinder. Heliyon 9, 9 (2023)

Cui, L., et al.: Robust and elastic thermoresponsive hydrogels with high swelling properties for efficient solar water purification. ACS Appl. Polymer Mater. 2, 2 (2024)

Zhao, J., et al.: Spongy polyelectolyte hydrogel for efficient Solar-Driven interfacial evaporation with high salt resistance and compression resistance. Chem. Eng. J. 2, 150118 (2024)

Xu, C., Li, H.: Enhancing solar absorbance using a 2D graphene oxide/CuO composite film for efficient solar desalination. Environ. Sci.: Water Res. Technol. 9(2), 523–532 (2023)

Xu, Y., et al.: Multifunctional CuO nanowire mesh for highly efficient solar evaporation and water purification. ACS Sustain. Chem. Eng. 7(5), 5476–5485 (2019)

Xu, X., et al.: Full-spectrum-responsive Ti4O7-PVA nanocomposite hydrogel with ultrahigh evaporation rate for efficient solar steam generation. Desalination 2, 117400 (2024)

Soliman, T., Vshivkov, S.: Effect of Fe nanoparticles on the structure and optical properties of polyvinyl alcohol nanocomposite films. J. Non-Cryst. Solids 519, 119452 (2019)

Sau, S., Pandit, S., Kundu, S.: Crosslinked poly (vinyl alcohol): structural, optical and mechanical properties. Surfaces Interfaces 25, 101198 (2021)

Khalaji, A., et al.: CuO nanoparticles: preparation, characterization, optical properties, and antibacterial activities. J. Mater. Sci. Mater. Electron. 31, 11949–11954 (2020)

Welegergs, G., et al.: Structural and optical properties of copper oxide (CuO) nanocoatings as selective solar absorber. Mater. Today: Proc. 36, 509–513 (2021)

Agarwal, S., et al.: Morphology-dependent structural and optical properties of ZnO nanostructures. Appl. Phys. A 125(8), 553 (2019)

Chand, P., Gaur, A., Kumar, A.: Structural and optical properties of ZnO nanoparticles synthesized at different pH values. J. Alloy. Compd. 539, 174–178 (2012)

Sedaghati-Jamalabad, G., Bagheri-Mohagheghi, M.: Influence of synthesis route on structural properties of SnFe2O4 spinel phase via methods of co-precipitation, sol–gel and solvothermal: morphology, phase analysis, crystallite size and lattice strain. Discover Applied Sciences 6(4), 202 (2024)

Ali, R., et al.: BET, FTIR, and RAMAN characterizations of activated carbon from waste oil fly ash. Turk. J. Chem. 44(2), 279–295 (2020)

Feng, X., et al.: Mechanical and antibacterial properties of tannic acid-encapsulated carboxymethyl chitosan/polyvinyl alcohol hydrogels. Eng. Regen. 2, 57–62 (2021)

Yaseen, M., et al.: Fabrication and characterization of CuO–SiO2/PVA polymer nanocomposite for effective wastewater treatment and prospective biological applications. Green Chem. Lett. Rev. 17(1), 2321251 (2024)

Gharoy Ahangar, E., et al.: Preparation and characterization of PVA/ZnO nanocomposite. J. Food Process. Preserv. 39(6), 1442–1451 (2015)

Le, Q.H., et al.: pH-responsive anticancer drug delivery systems: Insights into the enhanced adsorption and release of DOX drugs using graphene oxide as a nanocarrier. Eng. Anal. Boundary Elem. 157, 157–165 (2023)

Srinivasan, N., Rangasami, C., Kannan, J.: Synthesis structure and optical properties of zinc oxide nanoparticles. Int. J. Appl. Eng. Res. 10, 343–345 (2015)

Gao, M., et al.: Solar absorber material and system designs for photothermal water vaporization towards clean water and energy production. Energy Environ. Sci. 12(3), 841–864 (2019)

Bhosale, M.A., Karekar, S.C., Bhanage, B.M.: Room temperature synthesis of copper oxide nanoparticles: morphological evaluation and their catalytic applications for degradation of dyes and C-N bond formation reaction. ChemistrySelect 1(19), 6297–6307 (2016)

Fakhari, S., Jamzad, M., Kabiri Fard, H.: Green synthesis of zinc oxide nanoparticles: a comparison. Green Chem. Lett. Rev. 12(1), 19–24 (2019)

Sharma, G., et al.: Applications of nanocomposite hydrogels for biomedical engineering and environmental protection. Environ. Chem. Lett. 16, 113–146 (2018)

Tao, F., et al.: CuS nanoflowers/semipermeable collodion membrane composite for high-efficiency solar vapor generation. Mater. Today Energy 9, 285–294 (2018)

Zhu, L., et al.: Recent progress in solar-driven interfacial water evaporation: Advanced designs and applications. Nano Energy 57, 507–518 (2019)

Zhao, F., et al.: Highly efficient solar vapour generation via hierarchically nanostructured gels. Nat. Nanotechnol. 13(6), 489–495 (2018)

Indriyati, D., et al.: Flexible photothermal membrane based on PVA/carbon dot hydrogel films for high-performance interfacial solar evaporation. ACS Appl. Polymer Mater. 2, 5 (2024)

Zhou, X., et al.: A hydrogel-based antifouling solar evaporator for highly efficient water desalination. Energy Environ. Sci. 11(8), 1985–1992 (2018)

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by M. Fargharazi, M. M. Bagheri—Mohagheghi. The first draft of the manuscript was written by M. Fargharazi and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fargharazi, M., Bagheri-Mohagheghi, M.M. The photothermal properties of hydrogel nanocomposite embedded with ZnO/CuO based on PVA/GA/activated carbon for solar-driven interfacial evaporation. Mater Renew Sustain Energy (2024). https://doi.org/10.1007/s40243-024-00271-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-024-00271-w