Abstract

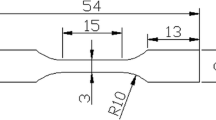

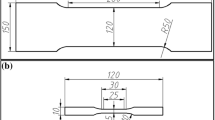

The gradient mechanical properties, variation of stress with strain and surface cracking behavior of expanded austenite developed on 316L austenitic stainless steel were investigated by nanoindentation tests, X-ray residual stress analysis and scanning electron microscope observation in four-point bending tests. The results show that the plastic properties of the carburizing layer including true initial yield strengths and strain hardening exponents increase significantly from substrate to surface, while the true elastic modulus just improves slightly. Due to the onset of plastic flow, the residual stresses are almost equivalent to the true initial yield strengths from surface to the depth of ~ 10 μm. The results of four-point bending tests show that surface stress increases linearly with the increase in strain until the strain reaches ~ 1.0%, after that the plastic yield happens. The expanded austenite surface layer is brittle, and the cracks will be created at the strain of ~ 1.4%. The cracking stress is about ~ 2.4 GPa.

Similar content being viewed by others

References

N. Agarwal, H. Kahn, A. Avishai, G. Michal, F. Ernst, A.H. Heuer, Acta Mater. 55, 5572 (2007)

K. Tokaji, K. Kohyama, M. Akita, Int. J. Fatigue 26, 543 (2004)

L. Ceschini, G. Minak, Surf. Coat. Technol. 202, 1778 (2008)

Y. Sun, T. Bell, Wear 253, 689 (2002)

J. Qu, P.J. Blau, L. Zhang, H. Xu, Wear 265, 1909 (2008)

M. Faccoli, G. Cornacchia, R. Roberti, V. Bordiga, Metall. Ital. 4, 13 (2013)

R.H. Van Der Jagt, Heat Treat. Met. 27, 62 (2000)

D.S. Rong, Y. Jiang, J.M. Gong, Acta Metall. Sin. 51, 1516 (2015)

F. Ernst, Y. Cao, G.M. Michal, Acta Mater. 52, 1469 (2004)

T.L. Christiansen, M.A.J. Somers, Metall. Mater. Trans. A 40, 1791 (2009)

T.L. Christiansen, T.S. Hummelshøj, M.A.J. Somers, Surf. Eng. 26, 242 (2010)

Y. Sun, L.Y. Chin, Surf. Eng. 18, 443 (2002)

R.M. Souza, M. Ignat, C.E. Pinedo, A.P. Tschiptschin, Surf. Coat. Technol. 204, 1102 (2009)

J.C. Stinville, J. Cormier, C. Templier, P. Villechaise, Mater. Sci. Eng. A 605, 51 (2014)

Z.S. Ma, Y.C. Zhou, S.G. Long, C.S. Lu, J. Mater. Sci. Technol. 28, 626 (2012)

Y.W. Peng, J.M. Gong, D.S. Rong, Y. Jiang, M.H. Fu, G. Yu, Acta Metall. Sin. 51, 1500 (2015). (in Chinese)

Y.W. Peng, J.M. Gong, Y. Jiang, M.H. Fu, D.S. Rong, Appl. Mech. Mater. 853, 178 (2017)

G.M. Michal, F. Ernst, H. Kahn, Y. Cao, F. Oba, N. Agarwal, A.H. Heuer, Acta Mater. 54, 1597 (2006)

M. Sadiq, J.S. Lecomte, M. Cherkaoui, J. Electron. Packag. 137, 031005 (2015)

W.C. Oliver, G.M. Pharr, J. Mater. Res. 7, 1564 (1992)

W.D. Nix, H. Gao, J. Mech. Phys. Solids 46, 411 (1998)

X. Xiao, D. Terentyev, Q.Y. Chen, L.R. Chen, L.R. Chen, A. Bakaev, H.L. Duan, Int. J. Plasticity 7(90), 212 (2017)

M.X. Gu, C.Q. Sun, Z. Chen, T.C.A. Yeung, S. Li, C.M. Tan, Phys. Rev. B 75, 125403 (2007)

Y.T. Cheng, C.M. Cheng, Philos. Mag. Lett. 78, 115 (1998)

J.W. Li, X.J. Liu, L.W. Yang, X.D. Gao, D.S. Shang, X.J. Lin, Appl. Phys. Lett. 95, 031906 (2009)

C.Q. Sun, B.K. Tay, S.P. Lau, X.W. Sun, J. Appl. Phys. 90, 2615 (2001)

A. Leyland, A. Matthews, Wear 246, 1 (2000)

D. Hoeft, B.A. Latella, K.T. Short, J. Phys. Condens. Mater. 17, 3547 (2005)

D.R.G. Mitchell, D.J. Attard, G.A. Collins, K.T. Short, Surf. Coat. Technol. 165, 107 (2003)

Y.T. Cheng, C.M. Cheng, Mater. Sci. Eng. R 44, 91 (2004)

A. Bolshakov, G.M. Pharr, J. Mater. Res. 13, 1049 (1998)

W. Li, X. Li, H. Dong, Acta Mater. 59, 5765 (2011)

Acknowledgements

The work is supported financially by the National Natural Science Foundation of China (Nos. 51475224 and 51605164) and the Natural Science Foundation of Jiangsu Higher Education Institutions of China (No. 14KJA470002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Jiang, Y., Li, Y., Jia, YF. et al. Gradient Elastic–Plastic Properties of Expanded Austenite Layer in 316L Stainless Steel. Acta Metall. Sin. (Engl. Lett.) 31, 831–841 (2018). https://doi.org/10.1007/s40195-018-0710-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-018-0710-z