Abstract

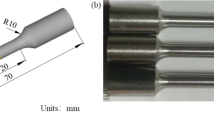

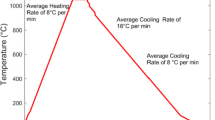

The fuel indirect precooled turbine combined cycle engine is the promising power to realise more green environmental protection intercontinental navigation and hypersonic aerospace transportation in the future. The compact, lightweight precooler arranged in the front of the inlet is a critical component of the advanced heat management system, which could improve the fuel efficiency and flight range of the turbine engine. This paper mainly focuses on the high-temperature brazing process of Inconel 718 ultrathin-walled capillary-and-plate brazed structure using the BNi-5 brazing filler metal. In this investigation, a testing method for tensile strength of ultrathin-walled structures was proposed; the effects of different brazing parameters on the mechanical properties and microstructure evolution of different types of brazed structures were studied to investigate the particularity of ultrathin-walled capillary-and-plate brazed structure. The brazed joint was mainly composed of γ-Ni solid solution, Ni5Si2, G-phase, Ni3Si, and Cr3Ni5Si2. The results showed that the higher brazing temperature and longer holding time were beneficial to improve the mechanical properties of the conventional lap brazed structure; however, the mechanical properties of the ultrathin-walled capillary-and-plate structure decrease significantly. The optimised brazing process for the ultrathin-walled structure was 1150 °C for 3 min; dissolution behaviour of the ultrathin-walled capillary and the deeper position of the precipitates induced by the acute diffusion phenomenon play an important role in the tensile strength of the ultrathin-walled structure. And the failure mechanism was analysed in detail; the result indicated that ultrathin-walled capillary-and-plate brazed structure was mainly affected by the eutectic structure of the brazing fillet; the Nb-rich precipitates in the diffusion affected zone and the dissolution behaviour of the ultrathin-walled base metal.

Similar content being viewed by others

References

Zhang G, Zhao P, Hao L, Xu Y, Cheng H (2019) A novel amine double functionalised adsorbent for carbon dioxide capture using original mesoporous silica molecular sieves as support. Sep Purif Technol 209:516–527

Siddiqui ME, Almitani KH (2018) Energy analysis of the S-CO2 Brayton cycle with improved heat regeneration. Processes 7(1):3

Li B, Sun S, Zhang L et al (2021) System modification and thermal efficiency study on the semi-closed cycle of supercritical carbon dioxide. Energy Conver Manag 241:114272

Yoro KO, Sekoai PT (2016) The potential of CO2 capture and storage technology in South Africa’s coal-fired thermal power plants. Environments 3(3):24

Mac Dowell N, Fennell PS, Shah N et al (2017) The role of CO2 capture and utilisation in mitigating climate change. Nat Clim Chang 7(4):243–249

Yoro KO, Daramola MO, Sekoai PT et al (2021) Advances and emerging techniques for energy recovery during absorptive CO2 capture: a review of process and non-process integration-based strategies. Renew Sustain Energy Rev 147:111241

Liao Z, Hu Y, Wang J et al (2019) Systematic design and optimisation of a membrane–cryogenic hybrid system for CO2 capture. ACS Sustain Chem Eng 7(20):17186–17197

Tan Y, Nookuea W, Li H et al (2019) Impacts of thermos-physical properties on plate-fin multi-stream heat exchanger design in cryogenic process for CO2 capture. Appl Therm Eng 149:1445–1453

Yu X, Yu W, Wang C et al (2019) Thermodynamic analysis of the influential mechanism of fuel properties on the performance of an indirect precooled hypersonic airbreathing engine and vehicle. Energy Convers Manage 196:1138–1152

Webber H, Feast S, Bond A (2009) Heat exchanger design in combined cycle engines. J Br Interplanet Soc 62:122–130

Varvill R, Bond A (2008) The Skylon spaceplane: progress to realisation. J Br Interplanet Soc 61(10):412–418

Varvill R (2010) Heat exchanger development at Reaction Engines Ltd. Acta Astronaut 66(9–10):1468–1474

Zou Z, Liu H, Tang H et al (2015) Precooling technology study of hypersonic aeroengine. Acta Aeronaut Astronaut Sin 36(8):2544–2562

Meng B, Wan M, Zhao R, Zou Z, Liu H (2021) Micromanufacturing technologies of compact heat exchangers for hypersonic precooled airbreathing propulsion: a review. Chinese J Aeronaut 34(2):79–103

Nalbant M, Altın A, Gökkaya H (2007) The effect of coating material and geometry of cutting tool and cutting speed on machinability properties of Inconel 718 super alloys. Mater Des 28(5):1719–1724

Ghahferokhi AI, Kasiri-Asgarani M, Amini K et al (2021) Evolution of microstructure and mechanical properties on on dissimilar transient liquid phase (TLP) bonding of GTD-111 and IN-718 by BNi-9 (AWS A5. 8/A5. 8M) interlayer. Weld World 65(2):329–343

Bridges D, Ma C, Palmer Z et al (2017) Laser brazing of Inconel® 718 using Ag and Cu-Ag nano-pastes as brazing materials. J Mater Process Technol 249:313–324

Khorram A, Fakhraei O, Torkamany MJ (2017) Laser brazing of Inconel 718 and Inconel 600 with BNi-2 nickel-based filler metal. Int J Adv Manuf Technol 88(5–8):2075–2084

Pouranvari M, Ekrami A, Kokabi AH (2014) Aging response of transient liquid phase bonded wrought IN718 superalloy: influence of post-bond heat treatment. Sci Technol Weld Joining 19(2):105–110

Pouranvari M, Ekrami A, Kokabi AH (2013) TLP bonding of cast IN718 nickel based superalloy: process–microstructure–strength characteristics. Mater Sci Eng, A 568:76–82

Pouranvari M, Ekrami A, Kokabi AH (2013) Solidification and solid state phenomena during TLP bonding of IN718 superalloy using Ni–Si–B ternary filler alloy. J Alloy Compd 563:143–149

Pouranvari M, Ekrami A, Kokabi AH (2013) Transient liquid phase bonding of wrought IN718 nickel based superalloy using standard heat treatment cycles: microstructure and mechanical properties. Mater Des 50:694–701

Han W, Wan M, Zhao R et al (2021) Microstructural evolution and mechanical properties of brazed IN718 ultrathin-walled capillary structure using different particulate reinforced filler alloy[J]. Chinese Journal of Aeronautics 2021(10)

Han WP, Wan M, Zhao R et al (2019) Vacuum brazing of the ultrathin-walled structure using particulate-reinforced composite filler metal: microstructural evolution and mechanical properties. J Alloy Compd 805:638–647

Schuster JC, Du Y (2000) Experimental investigation and thermodynamic modeling of the Cr-Ni-Si system. Metall and Mater Trans A 31(7):1795–1803

Han WP, Wan M, Zhao R et al (2019) Effect of post-bond heat treatment on microstructural evolution and mechanical properties of brazed ultrathin-walled structure. Mater Sci Eng, A 742:680–691

Grushko B, Weiss BZ (1984) Structure of vacuum brazed BNi-5 joint of Inconel 718. Metall Trans A 15(4):609–620

Gupta KP (2006) The Cr-Ni-Si (chromium-nickel-silicon) system. J Phase Equilib Diffus 27(5):523

Massalski TB, Okamoto H, Subramanian PR et al (1990) Binary alloy phase diagrams. ASM. Int 2:2104

Nash P (1991) Phase diagrams of binary nickel alloys. ASM Int 1991:394

Chen Y, Zhang Y, Yao S et al (2008) Scanning electron beam brazing of thin-wall capillary tube–sheet structure. J Mater Process Technol 203(1–3):301–304

Jiang W, Gong JM, Tu ST (2010) Effect of holding time on vacuum brazing for a stainless steel plate-fin structure. Mater Des 31(4):2157–2162

Jiang W, Gong J, Tu ST (2010) A study of the effect of filler metal thickness on tensile strength for a stainless steel plate-fin structure by experiment and finite element method. Mater Design 31(5):2387–2396

Funding

This author would like to acknowledge the financial support by the project (Grant numbers JCKY2017601B013, JCKY2018601C207) from the Defense Industrial Technology Development Program and the Jiangxi Research Institute of Beihang University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XVII - Brazing, Soldering and Diffusion Bonding

Rights and permissions

About this article

Cite this article

Han, W.P., Wan, M., Tan, J.F. et al. Study on mechanical properties and microstructure development of Inconel 718 ultrathin-walled capillary-and-plate brazed structure using BNi-5 filler metal. Weld World 66, 541–555 (2022). https://doi.org/10.1007/s40194-021-01219-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01219-8