Abstract

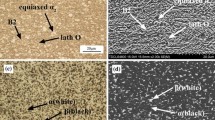

Heterogeneous welding has been investigated for three different couples of titanium alloys: α/α + β, α/β, and α + β/β. Plates of 100 × 60 mm and 1.6 or 1.8 mm thick were welded with a Yb:YAG laser. Tensile tests show that the resistance of the heterogeneous welded specimens was generally controlled by those of the weakest material except for the α + β/β where the ultimate tensile strength was approximately equal to the average value of both materials. In every case, the elongation of the welded sample was found to be smaller than that of the base metals. The rupture generally took place outside the weld metal and was found to be most of the time located in the alloy having the lowest mechanical properties. Nevertheless, a few large-size porosities detected by tomography in the α + β/β couple could explain why rupture for these samples occurred in the weld bead. For each couple, the porosities were situated at the board between the heat-affected zone and the molten zone. EBSD maps and EDX enabled the observation of different microstructures, which could be correlated to the heterogeneous composition and diffusion into the melted bath. When the stable microstructure of one of the couple alloys is the β phase, the molten zone of the bead consists of an alternative disposition of thin layers made of large equiaxed β grains and nano-martensite α′. That is explained by the weak diffusion of the alloying elements.

Similar content being viewed by others

References

Chen YC, Nakata K (2009) Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Mater Des 30(3):469–474

Dressler U, Biallas G, Mercado UA (2009) Friction stir welding of titanium alloy TiAl6V4 to aluminium alloy AA2024-T3. Mater Sci Eng A 526(1–2):113–117

Kahramana N, Gülença B, Findik F (2005) Joining of titanium/stainless steel by explosive welding and effect on interface. J Mater Process Technol 169(2):127–133

Kamachi Mudali U et al (2003) Corrosion and microstructural aspects of dissimilar joints of titanium and type 304L stainless steel. J Nucl Mater 321(1):40–48

Borrisutthekul R, Miyashita Y, Mutoh Y (2005) Dissimilar material laser welding between magnesium alloy AZ31B and aluminum alloy A5052-O. Sci Technol Adv Mater 6(2):199–204

Gao M et al (2012) Laser keyhole welding of dissimilar Ti-6Al-4V titanium alloy to AZ31B magnesium alloy. Metall Mater Trans A 43(1):163–172

Wang SQ, Liu JH, Chen DL (2013) Tensile and fatigue properties of electron beam welded dissimilar joints between Ti–6-Al–4V and BT9 titanium alloys. Mater Sci Eng A 584:47–56

Ferdinand C (2005) Mise en oeuvre et caracterisation d'assemblages soudés par procédés TIG et laser de tôles d'alliages de titane refractaire (in French), PhD thesis, INPT, France

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7(6):1564–1583

Andersson JO, Helander T, Höglund L, Shi PF, Sundman B (2002) Thermo-Calc and DICTRA, computational tools for materials science. Calphad 26(2):273–312

Weiss L et al. (2016) Microstructure and property of titanium heterogeneous laser welding. Proceedings of the 13th World Conference on Titanium, TMS, p 317–321

Huang JL et al (2012) On the mechanism of porosity formation during welding of titanium alloys. Acta Mater 60:3215–3225

Pang S, Chen W, Wang W (2014) A quantitative model of keyhole instability induced porosity in laser welding of titanium alloy. Metall Mater Trans A 45A:2808–2818

Mohandas T, Banerjee D, Kutumba Rao VV (1999) Fusion zone microstructure and porosity in electron beam welds of an α + β titanium alloy. Metall Mater Trans A 30A:789–798

Jone DW, Pessall N, McQuillan AD (1961) Correlation between magnetic susceptibility and hydrogen solubility in alloys of early transition elements. Philos Mag 6(63):455–459

Scheil E (1942) Bemerkungen zur schichtkristallbildung. Z Met 34(3):70–72

Laheurte P (2003) Contribution à l'étude du comportement pseudo-élastique d'un alliage bêta métastable. Applications aux arcs orthodontiques (in French), Thesis, Université de Metz, France

Acknowledgments

The authors would like to thank Mélanie Duband (LICB) and Patrick Moll (LEM3) for their help during the experiments.

Funding

This research has been funded by the Laboratory of Excellence for Design of Alloy Metals for Low-mass Structures (‘DAMAS’ Labex).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Weiss, L., Zollinger, J., Sallamand, P. et al. Mechanical properties and microstructural study of homogeneous and heterogeneous laser welds in α, β, and α + β titanium alloys. Weld World 63, 53–62 (2019). https://doi.org/10.1007/s40194-018-0627-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-0627-1