Abstract

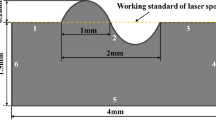

Fabricating functional metal parts using Additive Manufacturing (AM) is a leading trend. However, realizing overhanging features has been a challenge due to the lack of support mechanism for metals. Powder-bed fusion techniques like, Selective Laser Sintering (SLS) employ easily-breakable-scaffolds made of the same material to realize the overhangs. However, the same approach is not extendible to deposition processes like laser or arc based direct energy deposition processes. Although it is possible to realize small overhangs by exploiting the inherent overhanging capability of the process or by blinding some small features like holes, the same cannot be extended for more complex geometries. The current work presents a novel approach for realizing complex overhanging features without the need of support structures. This is possible by using higher order kinematics and suitably aligning the overhang with the deposition direction. Feature based non-uniform slicing and non-uniform area-filling are some vital concepts required in realizing the same and are briefly discussed here. This method can be used to fabricate and/or repair fully dense and functional components for various engineering applications. Although this approach has been implemented for weld-deposition based system, the same can be extended to any other direct energy deposition processes also.

Similar content being viewed by others

References

K.P. Karunakaran, P.V. Shanmuganathan, S.J. Jadhav, P. Bhadauria, A. Pandey, Rapid prototyping of metallic parts and moulds. J. Mater. Process. Technol. 105(3), 371–381 (2000)

K.H. Lee, K. Choi, Generating optimal slice data for layered manufacturing. Int. J. Adv. Manuf. Technol. 16(4), 277–284 (2000)

K. Mani, P. Kulkarni, D. Dutta, Region-based adaptive slicing. Comput. Aided Des. 31(5), 317–333 (1999)

F. Liou, K. Slattery, M. Kinsella, J. Newkirk, H.-N. Chou, R. Landers, Applications of a hybrid manufacturing process for fabrication of metallic structures. Rapid Prototyp. J. 13(4), 236–244 (2007)

L. Ren, T. Sparks, J. Ruan, F. Liou, Process planning strategies for solid freeform fabrication of metal parts. J. Manuf. Syst. 27(4), 158–165 (2008)

E. Sabourin, S.A. Houser, J.H. Bøhn, Adaptive slicing using stepwise uniform refinement. Rapid Prototyp. J. 2(4), 20–26 (1996)

X. Qian, D. Dutta, Feature based fabrication in layered manufacturing. J. Mech. Des. 123(3), 337–345 (1999)

I. Ilinkin, R. Janardan, J. Majhi, J. Schwerdt, M. Smid, R. Sriram, A decomposition-based approach to layered manufacturing. Comput. Geom. 23(2), 117–151 (2002)

Y. Yang, H.T. Loh, J.Y.H. Fuh, Y.S. Wong, Feature extraction and volume decomposition for orthogonal layered manufacturing. Comput. Aided Des. 35(12), 1119–1128 (2003)

P. Kazanas, P. Deherkar, P. Almeida, H. Lockett, S. Williams, Fabrication of geometrical features using wire and arc additive manufacture. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 226, 1042–1051 (2012)

K.P. Karunakaran, S. Suryakumar, V. Pushpa, S. Akula, Low cost integration of additive and subtractive processes for hybrid layered manufacturing. Robot. Comput. Integr. Manuf. 26(5), 490–499 (2010)

Y.-A. Song, S. Park, D. Choi, H. Jee, 3D welding and milling: part I-a direct approach for freeform fabrication of metallic prototypes. Int. J. Mach. Tools Manuf 45(9), 1057–1062 (2005)

S. Suryakumar, K.P. Karunakaran, A. Bernard, U. Chandrasekhar, N. Raghavender, D. Sharma, Weld bead modeling and process optimization in hybrid layered manufacturing. Comput. Aided Des. 43(4), 331–344 (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Panchagnula, J.S., Simhambhatla, S. Feature based Weld-Deposition for Additive Manufacturing of Complex Shapes. J. Inst. Eng. India Ser. C 99, 285–292 (2018). https://doi.org/10.1007/s40032-016-0339-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-016-0339-5