Abstract

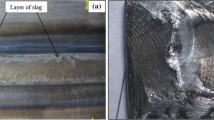

18 Ni maraging steels (250 grade), due to their high strength and excellent fracture toughness, are candidate materials for pressure vessel applications such as rocket motor, since these steels are easily weldable over a wide range of thicknesses. These rocket motor segments with a diameter of 3,200 mm and length of 8,400 mm are fabricated with maraging steel plates of 8 mm thick and rolled rings. During the fabrication of one such segment, unacceptable fluorescent dye penetrant indications were observed after proof pressure testing in the weld joints which were further confirmed by ultrasonic testing (UT) and x-ray radiography. None of these indications were detected in previous stages of UT conducted prior to proof pressure testing. In order to understand the reasons for cracking and assess the suitability of the segment for repair, non-destructive, on-site, in situ metallography has been employed. Extensive in situ metallographic analysis was carried out on these segments at several locations where cracks were found, and this work describes the details of the work carried out on these segments with the goal of understanding the mechanism of cracking and recommending measures to avoid recurrence of such defects. Weld tensile specimens fabricated along with motor segment were also analysed to study the behaviour of welded joints. Two types of cracks were noticed on the rocket motor segments namely longitudinal cracks at the weld fusion boundary and cracks at HAZ–parent metal interface. Based on detailed analysis, the reasons for cracking of the segment are attributed to (a) stress corrosion cracking (for longitudinal cracks) and (b) HAZ–parent material interface cracking (for transverse cracks).

Similar content being viewed by others

References

INCO Data Book, 18 Percent Nickel Maraging Steels-Engineering Properties, Publication No. 4419, (Inco Europe Limited, 1976), pp. 1–29

F.H. Lang, N. Kenyon, Welding of Maraging Steels, Welding Research Council Bulletin No. 159 (1971), pp. 1–40

J.J. Pepe, W.F. Savage, Effects of constitutional liquation in 18-Ni maraging steel weldments. Weld. Res. Suppl. 46, 411S–422S (1967)

J.J. Pepe, W.F. Savage, The heat affected zone of the 18-Ni maraging steels. Weld. Res. Suppl. 49, 545S–558S (1970)

A. Goldberg, Influence of repeated thermal cycling under various conditions on the hardness of maraging steel. Weld. Res. Suppl. 47, 199s–202s (1968)

B.C. Syrett, Stress corrosion cracking in 18% Ni (250) maraging steel. Corros. NACE 27(7), 151–161 (1971)

A. Luxmoore, D.K.Y. Can, G.R. Egan, in Welded Maraging Steel Sheet, vol. 2. Residual Stresses in Welded Maraging Steel Sheet METAL Construction and British Welding Journal (1970), pp. 229–234

N. Kenyon, Design of base metals for weldability-maraging steels. Weld. J. Res. Suppl. 48, 105s (1969)

R.N. Parkins, E.G. Haney, Stress corrosion cracking of 18% Ni maraging steel in acidified sodium chloride solution. Trans. Metall. Soc. AIME 242, 162–172 (1968)

T. Boniszewski, Hydrogen induced delayed cracking in maraging steel, British Welding Journal, November 1965, in Source Book on Maraging Steels, ed. by R.F. Decker (ASM, Metals Park, 1979), pp. 193–202

K.G. Reddy, S. Arumugham, T.S. Lakshmanan, Hydrogen embrittlement of maraging steel. J. Mater. Sci. 27, 5159–5162 (1992)

P. Rameshnarayanan, K. Sreekumar, A. Natarajan, P.P. Sinha, Metallographic investigations of heat affected zone II/parent metal interface cracking in 18Ni maraging steel welded structures. J. Mater. Sci. 25, 4587–4591 (1990)

Acknowledgments

Authors wish to acknowledge Dr. S. Biju, Manager (SHFS), S/Shri. A.K. Mishra, DGM, RMFA, Roy M Cherian, GM, EFA, S.K. Jain, Resident Manager, Anurag Shukla, Resident Quality Surveyor, Shri. Chidanand Magadum, Resident Engineer of Mumbai Work Centre of ISRO, Mumbai for all the kind support rendered during the execution of this work. The support of engineers from L&T, Mumbai during in situ metallography on the segments is also gratefully acknowledged. The authors are indebted to Director, VSSC for his permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Narayana Murty, S.V.S., Sudarsana Rao, G., Venugopal, A. et al. Metallurgical Analysis of Defects in the Weld Joints of Large-Sized Maraging Steel Rocket Motor Casing. Metallogr. Microstruct. Anal. 3, 433–447 (2014). https://doi.org/10.1007/s13632-014-0161-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-014-0161-5