Abstract

The present study evaluates the green biomass of Jerusalem artichoke (JA) as an alternative green protein. A leaf protein concentrate (LPC) was prepared from leafy shoots using biotechnological methods. Seven clones were compared to assess the importance of the genetic basis of JA, and alfalfa served as the control. The LPC content of JA was an average 39 g kg−1 of fresh biomass, while that of alfalfa was 32 g kg−1. The JA can produce up to 936 kg of protein ha−1 year−1 without fertilization under rainfed conditions. The crude protein content of the LPC varied from 24.2 to 31.4 m/m%, depending on clones and harvesting time, which was comparable to that of alfalfa LPC (~ 32.3%). The amino acid profile of the LPC of JA, particularly of the essential amino acids, was similar to alfalfa and soybean. In addition, our results confirmed that the polyunsaturated fatty acid (PUFA) content varied between 64 and 68% in the LPC fraction, regardless of the clone that was used, with linoleic acid and linolenic acid being the predominant PUFAs. In addition, unlike alfalfa, the content of arachidonic acid was 0.5% in the JA LPC. The tuber yield was significantly reduced because of the repeated harvesting of the shoot parts; however, the tubers obtained were sufficient to regenerate the plantation in the subsequent year, thus ensuring the renewable ability and sustainability of the green biomass of JA.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Together with the inevitable decline in fossil fuels and the increasing environmental problems stemming from the dramatic increase in the world’s population since the industrial revolution in the last century, securing the protein supply is one of the major problems of agriculture and civilization. Maximizing the use of natural resources, such as agricultural crops and agricultural waste in particular, is an approach that can be used to address this question. Reducing the quantity of waste produced through optimal use of resources is newly referred to as “circular economy.” In addition, the implementation of such a regenerative approach in a well-designed manner will undoubtedly contribute to, and ensure, the sustainability of environmental, social, and natural resources [1]. According to this approach, an increasing number of academic activities are focusing on protein production, particularly from agricultural waste or biomass crops.

In Europe, several studies have been launched recently with a focus on alternative sources of protein [2]. Among the agricultural crops, cereals and legumes are of great importance for protein production [3]. The main current protein sources are hindered by their negative environmental impact and several health-related concerns. Nevertheless, these protein repositories offer social and economic benefits and have a high degree of consumer acceptance. Novel or alternative protein sources require the development of new value chains and attention to issues such as production costs, food safety and ecological/environmental impact, as well as sustainability and consumer acceptance [4].

Sourcing protein from green biomass is not a new idea [5, 6]; however, it has not been as prominent in history as its value would predict. The extraction of green biomass using combined biotechnological methods is a promising tool to obtain protein and valuable phytochemicals under the green biorefinery concept [7, 8]. Generally, pressing is the first step in the green biomass extraction process to separate soluble components from the solid fibers. The obtained green juice can be further processed by different coagulation methods to isolate LPC. Sequential heating with intermediate separation step(s) or steam injection is the most frequent heat coagulation technics. Also, precipitation of soluble leaf protein can be accomplished using alkali, acids, or flocculants; in addition, the aggregated proteins can be removed by centrifugation or filtration leaving brown juice as supernatant [8]. Nevertheless, newly innovative technologies are required to further push the development in biorefineries in order to increase the trust of all the economic sectors in this approach. Consequently, positive impacts not only on the environment but also on human health can be expected with these novel protein sources [9]. Six reasons support the re-launch of leaf protein in the protein-supply chain. First, forecasts suggest an eminent lack of protein-rich products worldwide [4]. Second, the developed industrial livestock farming demands standardized and metered feeding [10]. Third, the interest in nutritional problems, particularly in developing countries, is increasing. Fourth, the member states of the Warsaw Pact wish to part from the world market and generate their own supply of food and feed protein [11]. Fifth, the rising cost of energy motivates the consideration of isolated leaf protein as an alternative to other means of green forage conservation [12]. The sixth reason pertains to the ecological impact, particularly environmental pollution that is inherent to the transportation of imported soy, mainly from the American continent. The relevance of alternative plant sources for integrated protein production in green biorefineries depends on many biological, environmental, economic, and social factors, such as nutritional profile, environmental implications, consumer acceptance, digestibility, and bioavailability [13].

There is a growing body of literature about Jerusalem artichoke (JA; Helianthus tuberosus L.) based on economic, ecological, agricultural, and industrial aspects [14,15,16,17,18]. According to Rossini et al. [19], the tubers of JA are valuable feedstock to produce different bio-based products (i.e., ethanol, biodiesel, 2, 3-butanediol, lactic acid, etc.) using the recent advances in biorefinery technology. As a fodder crop, JA possesses several desirable characteristics, such as rapid growth, high biomass, relevant total dry matter per unit of land area, high inulin content of tubers, and strong adaptability [20]. It is widely adapted to diverse and often marginal environments with harsh growth conditions, as it is tolerant to many biotic and abiotic stresses [21, 22]. This is important for avoiding competition with food production in arable soils [23]. The green biomass of JA is also valuable. The aerial part of JA can be harvested 3 to 4 times per year because of its high capacity of regeneration [24]. The leaves of JA contain protein (1.1–6.1% of the DM) together with other nutrients; therefore, they could be directed toward feeding livestock and humans [14, 15]. In addition, the green leaves of JA are a source of several phytochemicals, such as essential oils [25, 26]. Moreover, JA can substitute the alfalfa-based diet in sheep (up to 300 g kg−1 of DM), without any harmful effects on metabolisable energy and digestibility [22, 27]. Because of the desirable features of its leafy shoots, JA is potential feedstock from green bio-refinery, as it yields different valuable products, such as leaf protein concentrate (LPC) and derivatives of other fractions.

Jerusalem artichoke is highly polymorphic, which facilitates its adaptability to disparate environments. Together with its genotypic characteristics, to our knowledge, this is a neglected area of LPC production from JA. In this setting, this article compared seven different JA clones regarding LPC production. Another goal of our study was to provide new insights regarding the exploitation of the green biomass of JA as a candidate for the production of LPC and other economically important co-products under low-input conditions of fertilizers and irrigation. Soybean (Glycine max L.) is the main fodder for monogasteric animals all over the world; consequently, a huge trade is related to export and import of soybean. Europe imports yearly large amounts from the main producers of soybean, i.e., South America and USA. Nevertheless, the endogenous protein sources are unexploited [28]. Alfalfa (Medicago sativa L.) is one of the biomass crops that frequently are tested for leaf protein isolation. This is owing to the high digestibility, high protein content, and the well-balanced amino acid profile. Moreover, crude protein content in alfalfa leaf protein concentrate is comparable with this measured for soybean almost 45% [29]. Therefore, alfalfa served as a control and soybean was used as a reference feeding model.

2 Materials and methods

2.1 Experimental setup

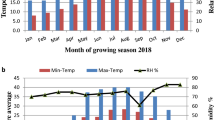

A field experiment was established in 2016 at the Horticultural Demonstration Garden of the University of Debrecen, Hungary (47° 33′ N; 21° 36′ E). Seven clones of JA (i.e., Alba, Fuseau, Kalevala, Kercaszomori, Piri, Rubik, and Tápiói sima) were compared regarding their fresh aerial biomass and yield of LPC and other co-products. Moreover, the chemical and biochemical characteristics of LPC and of the co-products (fiber and phytoserum) were assessed. Alfalfa which is a famous forage and biomass crop for LPC, served as the control species. Tubers of the JA clones were obtained from different sources, as follows: Kercaszomori, Rubik, and Tápiói sima were obtained from the Tápiószelei genebank, Hungary; Fuseau was brought from Ismailia, Egypt; Kalevala was kindly sent from Helsinki, Finland; and Alba and Piri were bought at a Hungarian market. Alfalfa seeds were bought from Magvas Vetőmag Ltd., Hungary. The experiment was set up in a randomized complete block design with six replicates. The total area of the experiment was 8 × 20 m consisting of 42 rows with a length of 3.5 m and a width of 0.8 m each. The in-row spacing was 0.6 m, which provided a planting area of 0.8 × 0.6 m2. The cultivation of the JA clones started on April 5, 2016 using size-identical tubers. After cultivation, the germinated tubers did not receive any irrigation, i.e., they were left to grow using only rain water (rain-fed plantation). Moreover, no fertilizers were added. The meteorological data recorded during the whole experimental period is presented in Fig. 1. The chemical properties of the experimental soil were as follows: total N, 555 ± 2 mg kg−1; total P, 6793 ± 17 mg kg−1; total K, 1298 ± 7 mg kg−1); and humus, 1.9% ± 0.02%).

2.2 Harvest of the green biomass of JA

The shoot parts of JA were harvested twice a year for LPC isolation. The first harvest was performed on June 27, 2016, when the height of the shoot parts reached 1.5 m from the soil surface, while the second harvest was performed on August 8, 2016, when the shoot parts reached 1.3 m in length. Alfalfa plants were cultivated using the same agronomic practices. Out of the six replicates of each cultivar, the shoot parts of three replicates were harvested as mentioned above, while the remaining three replicates were left unharvested until the end of the growing season, to study the variation in tuber yield. Germination percentage, shoot and tuber yield and leaf-to-stem ratio were measured. Germination percentage (GP, %) was calculated according to Ranal and Santana [30] as follows:

where TNG = total number of germinated tubers, TNP = total number of planted tubers.

The leaf/ stem ratio was calculated after dividing the fresh mass of separated leaves of plant by fresh mass of its stem.

2.3 Fractionation of the fresh aerial biomass of JA

To extract LPC from the fresh biomass of JA cultivars, the shoot parts were harvested at 20 cm above the soil surface in the early morning and immediately transferred to the laboratory at 4 °C using ice cubes and an ice box, to inhibit the activity of proteases (which hydrolyze cellular proteins). One kilogram of fresh shoot biomass was pressed and pulped mechanically using a twin-screw juicer (Green Star GS 3000, Anaheim, Canada), to separate the green juice from the indigestible fiber. The green juice contains chloroplastic and cytoplasmic proteins, pigments, and vitamins. Subsequently, the green juice was heated to 80 °C, to coagulate the proteins. After the thermal coagulation of the green juice, the coagulum (known as LPC) was separated from a brown-colored liquid (referred to as phytoserum) via cloth filtration. Next, all fractions (i.e., LPC, fiber, and phytoserum) were weighed to assess their fresh mass, followed by lyophilization (using an Alpha 1-4 LSCbasic lyophilizer) to get the dry mass. The method of LPC production from alfalfa green juice was conducted by microwave assisted heat coagulation (80 °C). The applied method was based on the Hungarian patent of Fári and Domokos-Szabolcsy [31]. Coagulation was followed by direct filtration through cheesecloth to separate the LPC fraction from the brown liquid. No centrifugation step was involved in the process.

2.4 Chemical characterization of the various fractions obtained from JA

2.4.1 Crude protein content

The crude protein content was measured in the different fractions (LPC, fiber, and phytoserum) obtained from the various JA clones. For ease of comparison and evaluation, a fractionated alfalfa variety and extruded soy were also used in the crude protein measurements.

To measure crude protein content, 1 g of lyophilized sample was placed into a 250-mL Kjeldahl digestion tube, followed by the addition of 15 mL of concentrated sulfuric acid (99%, VWT, Ltd) and two catalyst tablets. The Kjeldahl digestion tubes were transferred to a Tecator Digestor (VELT, VWR Ltd.) and incubated at 420 °C for 1.5 h. The total N content in the digested samples was later measured using the titration method described by Sparks et al. [32]. The total protein content of the samples was calculated using the following equation:

2.4.2 Amino acid profile

Lyophilized and grinded samples (LPC and fiber fractions) were digested with 6 M HCl at 110 °C for 23 h. As the digested samples should contain at least 25 mg of N, the weight of the samples varied. To remove the air from the samples, an inert gas and the alternated application of vacuum and a three-way valve were used. After hydrolysis, the samples were filtered into an evaporator flask. The filtrate was evaporated at 60 °C to achieve a syrup-like consistency. Subsequently, distilled water was added to the samples, which were then evaporated again using the same protocol. This procedure was repeated one more time. The evaporated samples were washed and completed with citrate buffer, pH 2.2. For the analysis of amino acid composition, an INGOS AAA500 (Ingos Ltd., Czech Republic) amino acid analyzer was used. The separation was carried out based on ionic exchange chromatography with post-column derivatization of ninhydrin. A UV/VIS detector was used at 440/570 nm.

2.4.3 Fatty acid profile

Esterification of the fatty acids contained in the LPC fraction into methyl esters was performed using the sodium methylate catalyst. Seventy milligrams of lyophilized homogeneous sample was weighed into a 20-mL tube, followed by the addition of 3 mL of n-hexane, 2 mL of dimethyl carbonate, and 1 mL of sodium methylate in methanol. The content of the test tube was shaken for 5 min (Janke and Kunkel WX2), 2 mL of distilled water was added, and the tube was shaken again. The samples were centrifuged at 3000 rpm for 2 min (Heraeus Sepatech, UK). The supernatant (2 mL; hexane phase) was transferred through a filter paper into a container that held anhydrous sodium sulfate. The prepared solution containing approximately 50–70 mg cm−3 of fatty acid methyl ester (FAME) was suitable for gas chromatography measurement. The gas chromatography analysis was performed on an Agilent 6890 N Networg Gas Chromatograph coupled with an Agilent flame ionization detector. A Supelco Omegawax capillary column (30 m, 0.32 mm i.d., 0.25-μm film thickness) was used to separate FAMEs. The oven temperature was set to 180 °C, and the total analysis time was 36 min. An Agilent 7683 automatic split/splitless injector was used at an injection temperature of 280 °C, a split ratio of 100:1, and an injection volume of 1 μL. The carrier gas (hydrogen) was provided at a flow rate of 0.6 ml min−1, whereas the makeup gas (nitrogen) was provided at a flow rate of 25.0 ml min−1. The components were identified based on retention data and the addition of standards.

2.5 Soil analysis

Total N content and its speciation (NO3−-N, NH4+-N, and organic-N) were measured using the Kjeldahl procedure [32]. Total P and K were measured by ICP-OES, as described by Yang et al. [33]. Soil humus content was determined using the method reported by Székely et al. [34].

2.6 Quality assurance of results

Glassware and plastic ware for analyses were usually new and were cleaned by soaking in 10% (v/v) HNO3 for a minimum of 24 h, followed by thorough rinsing in distilled water. All chemicals were of analytical reagent grade or equivalent analytical purity. All the used equipment was calibrated and uncertainties were calculated. Internal and external quality assurance systems were applied in the Central Laboratory of the University of Debrecen according to MSZ EN ISO 5983-1: 2005 (for Total N), MSZ EN ISO 13903:2005 (for amino acid profile) and Bunge Private Limited Company Martfű Laboratory MSZ 1905508: 1992 (for fatty acid composition).

2.7 Statistical analysis

A randomized complete block experimental design with six repeats was used here. The results of the experiments were subjected to one-way ANOVA using the “R-Studio” software, and the means were compared using Duncan’s multiple range test [35] at P < 0.05.

3 Results

3.1 Growth and fresh biomass of JA clones

Based on shoot development, we distinguished two types of cultivars. The members of the so-called generative type were characterized by multiple (4–6) thinner stems that developed parallel from the tubers, with the branches on the upper stem. Alba, Fuseau, Kalevala, and Piri were generative types of JA. An earlier flowering time was typical of generative type ones. The members of the so-called vegetative type were characterized by only one or two thick stems with branches along the stem (Kercaszomori, Tápiói sima, and Rubik). The leaf-to-stem ratio varied significantly from 0.38 (for Kercaszomori) to 0.67 (for Piri), as shown in Fig. 1a.

The fresh biomass varied significantly among JA cultivars in both harvests. In the first harvest, the fresh biomass yield was 3.75 and 5.55 kg m−2 for Kercaszomori and Kalevala, respectively. However, other clones produced more than 4.38 kg m−2 fresh biomass. Kercaszomori showed the highest fresh biomass (3.13 kg m−2) in the second harvest, while Rubik yielded 1.25 kg m−2, which was the lowest recorded yield (Fig. 2b). All JA cultivars, with the exception of Rubik, yielded a total fresh biomass > 6.25 kg m−2. Based on these results, Kalevala, Fuseau, and Tápiói sima clones were considered the most appropriate clones for fresh biomass production (Fig. 2b).

a Leaves-stem ratio of different Jerusalem artichoke (Helianthus tuberosus L.) clones and b fresh green biomass (kg m−2 FM) of Jerusalem artichoke clones harvested two times during the growing season, i.e., first harvest (27th June 2016) and second harvest (8th August 2016). Data are average of 10 plants. Different letters on the same columns show significant differences according to Duncan’s test at p < 0.05

3.2 Fresh and dry masses of LPC and other co-products

The fresh and dry masses of the different fractions (LPC, fiber, and phytoserum) generated after mechanical pressing and subsequent thermal coagulation of 1 kg of fresh biomass of the JA clones are presented in Fig. 3.

Fresh and dry masses of different fractions (fiber, phytoserum, and leaf protein concentrate, LPC) extracted from 1 kg fresh aerial biomass of different Jerusalem artichoke (Helianthus tuberosus L.) clones. a Fresh mass of the first harvest (27 June 2016). b Fresh mass of the second harvest (8 August 2016). c Dry mass of the first harvest. d Dry mass of the second harvest. Alfalfa (Medicago sativa L. var. Hunor) was used as a standard leaf protein concentrate crop. Different letters on the same columns show significant differences according to Duncan’s test at p < 0.05

3.2.1 Fresh mass

The fresh mass of LPC varied significantly among the JA clones in both harvests. In the first harvest, it changed from 63 to 121 g kg−1 of fresh JA biomass for Rubik and Piri, respectively (Fig. 3a). Similarly, in the second harvest, the fresh mass of LPC ranged from 84 to 125 g kg−1, as measured in Rubik and Piri, respectively (Fig. 3b). Moreover, these results were comparable with those obtained for alfalfa, as this species exhibited an LPC fresh mass of 112 and 109 g kg−1 in the first and second harvests, respectively (Fig. 3a, b). The fresh mass of the fiber fraction was dependant on harvesting time, as higher masses were measured in the second harvest compare with the first harvest (Fig. 3a, b). The fiber fresh mass varied between 165 and 213 g kg−1 for the Kercaszomori and Rubik clones, respectively, in the first harvest. In contrast, in the second harvest, the fresh mass of the fiber fraction varied from 184 to 230 g kg−1 for Alba and Piri, respectively (Fig. 3b). In comparison, the fiber fresh mass obtained from the alfalfa green biomass was 273 and 361 g kg−1 in the first and second harvests, respectively (Fig. 3a, b). All JA clones yielded a higher and significant fresh mass of phytoserum fraction than did alfalfa, regardless of harvesting time. The fresh mass of phytoserum was 565 and 690 g kg−1 of fresh JA biomass for Kalevala and Alba, respectively, in the first harvest (Fig. 3a). In the second harvest, the phytoserum fresh mass significantly varied from 593 (for Piri) to 653 g kg−1 (for Alba). The phytoserum fresh mass of alfalfa was higher in the second harvest (483 g kg−1) compared with the first harvest (455 g kg−1).

3.2.2 Dry mass

The clones of JA exhibited a higher but not significant LPC dry mass compared with alfalfa in the second harvest, while a similar LPC dry mass was measured in the first harvest (Fig. 2c, d). The dry mass of LPC varied significantly from 20.2 to 36.2 g kg−1 for Rubik and Tápiói sima, respectively, in the first harvest. In the second harvest, the LPC dry mass ranged from 25.8 to 36.5 g kg−1, as recorded for Rubik and Kercaszomori, respectively (Fig. 3d). However, the LPC dry mass in the second harvest was not significantly different among the JA clones. The LPC dry mass of alfalfa was 36.2 and 34.7 g kg−1 in the first and second harvests, respectively. The dry mass of the fiber fraction varied significantly from 61 to 98 g kg−1 for Keraszomori and Rubik, respectively, in the first harvest (Fig. 3c). Alba and Piri showed the lowest and highest fiber dry mass (59 and 97.5 g kg−1, respectively) in the second harvest. These values were lower than those measured for alfalfa, which yielded a fiber dry mass of 121.7 and 147.3 g kg−1 in the first and second harvests, respectively (Fig. 3c, d). Similar results were obtained for phytoserum dry mass in the first harvest; the lowest phytoserum dry mass (23.6 g kg−1) corresponded to Kercaszomori, whereas the highest dry mass (71.1 g kg−1) was recorded for Rubik. In the second harvest, the lowest and highest dry mass of phytoserum were observed for Piri and Kercaszomori (24.8 and 35.0 g kg−1, respectively), as presented in Fig. 3c, d. The phytoserum dry mass of alfalfa was almost 2. 5-fold in the second harvest (81.5 g kg−1) compared with the first harvest (34.8 g kg−1).

3.3 Chemical and biochemical properties of JA fractions

3.3.1 Total protein content in the LPC, fiber, and phytoserum fractions

The total protein content recorded for the LPC, fiber, and phytoserum fractions obtained from fractionated fresh biomass of the JA clones and alfalfa (as a control) are presented in Fig. 4. The LPC, as the main fraction, showed the highest total protein content among all fractions in both harvests. In the first harvest, the total protein content of the LPC ranged between 29.8 and 31.6 m/m%, with the exception of Rubik and Tápiói sima, which contained only ~ 26.9 m/m% total protein (Fig. 4a). These values were comparable with those of the two main crops used in animal feeding worldwide, as the total protein content of the alfalfa and soybean LPC was 30.9 and 44.5 m/m%, respectively. Similarly, in the second harvest, the total protein content of the LPC fraction varied from 27.5 to 31.5 m/m%, with the exception of Rubik and Kercaszomori (Fig. 4b). The alfalfa LPC exhibited a total protein content of 32.3 m/m% in the second harvest. The fiber fraction of JA clones contained between 9.3 and 13.3 m/m% total protein in the first harvest. Tápiói sima yielded the highest fiber protein content (13.3 m/m%) among all tested clones in the first harvest. These values were higher than that measured for the alfalfa fiber fraction, which displayed a total protein content of 11.2 m/m% (Fig. 4a) in the first harvest. In the second harvest, most of the JA clones showed a similar total protein content in the fiber fraction (~ 10.0 m/m%) compared with the alfalfa fiber fraction (10.5 m/m%), with the exception of Alba and Kercaszomori, which had a lower content, and Piri, which yielded the highest total protein content in the fiber fraction (12.3 m/m%), as displayed in Fig. 4b. The phytoserum fraction showed the lowest content of total protein compared with the LPC and fiber fractions. The total protein content in the phytoserum fraction of JA cultivars varied between 0.4 and 1.3 m/m% (Fig. 4) in the first harvest. Rubik had the highest phytoserum protein content (1.3 m/m%), which was higher than that recorded for the alfalfa phytoserum (1.1 m/m%), while the lowest protein content (0.4 m/m%) corresponded to Fuseau. In the second harvest, the total protein content of the phytoserum fraction ranged from 0.4 to 1.2 m/m% for Kercaszomori and Kalevala, respectively (Fig. 4b). This result was comparable to that of the alfalfa phytoserum (0.8 m/m%). Although the alfalfa LPC had a slightly higher total protein content (32.3%) than did all JA clones, the fiber and phytoserum fractions of these clones showed a higher total protein content than did the extracts of alfalfa fresh biomass (Fig. 4a, b).

Total protein content of different fractions (leaf protein concentrate LPC, fiber, and phytoserum) of different Jerusalem artichoke (Helianthus tuberosus L.) clones; a 1st harvest on 27 June 2016; b 2nd harvest on 8th August 2016. Alfalfa (Medicago sativa L. var. Hunor) was applied as a control. Different letters above columns mean significant differences according to Duncan’s multiple range test

3.3.2 Amino acid profile of LPC

The amino acid composition of the LPC fraction obtained from the fresh biomass of JA clones, as well as alfalfa and soybean (as a control), are presented in Table 1. From the forage point of view, the indispensable amino acids (i.e., lysine, histidine, isoleucine, leucine, phenylalanine, methionine, threonine, and valine) are of great importance. The amino acid profile proved the high quality of the LPC obtained from JA fresh biomass compared with alfalfa and soybean. Among the JA clones investigated here, Kalevala showed the highest content of the essential amino acids phenylalanine, histidine, isoleucine, threonine, and valine, together with aspartic acid, glycine, glutamic acid, proline and serine (Table 1). The content of lysine, as a limiting amino acid, has special importance for animal feeding. Our results showed that the lysine content of the Alba LPC (2.32%) was higher than that of the alfalfa LPC (2.21%) in the first harvest. In the second harvest, higher lysine content was measured in the LPC isolated from Fuseau (2.54%) among all JA clones, which was higher than that recorded for the alfalfa LPC (2.39%). The LPC obtained from the fresh biomass of JA clones exhibited higher values of lysine, isoleucine, methionine, threonine, alanine, proline, serine, aspartic acid, and glutamic acid than did the alfalfa LPC in the first harvest (Table 1). Generally, soy exhibited a higher content of amino acids compared with the JA and alfalfa LPCs. However, methionine, threonine and alanine were found at higher concentrations in the LPC of JA compared with extruded soy. Leucine, isoleucine and valine, which are branched-chain amino acids (BCAAs), are of special importance because of their bio-benefits. The LPC isolated from the fresh biomass of JA clones contained substantial amounts of these important amino acids, at similar or even higher levels than those detected in the alfalfa LPC and very similar to those recorded for soy (Table 1).

3.3.3 Fatty acid composition of the LPC fraction

Table 2 shows the distribution of fatty acids in the LPC fraction obtained from the fresh biomass of JA and alfalfa. In general, the LPC of JA showed a similar composition of fatty acids among JA clones; moreover, the proportion of the identified fatty acids was relatively constant. The LPC of JA and alfalfa contained both saturated and unsaturated fatty acids at different ratios. Among the saturated fatty acids (SFA), myristic acid (C14:0), palmitic acid (C16:0), and stearic acid (C18:0) were identified. Palmitic acid was the most abundant SFA and its content varied between 15% and 18% in the LPC of JA. We also found a tendency toward a lower content of palmitic acid in the alfalfa LPC, regardless of harvesting time. Similarly, the myristic acid content was significantly lower in the alfalfa LPC compared with that of JA (Table 2). The content of oleic acid (C18:1ω–9), which is a monounsaturated fatty acid (MUFA), was below 10% (6.6–9.4%) in the 1st harvest, whereas it increased to 16.8% in the 2nd harvest. This was comparable with the results of the alfalfa LPC, which contained 20.6% oleic acid. Polyunsaturated fatty acids (PUFAs), i.e., linoleic acid, (C18:2ω −6), linolenic acid (C18: 3ω −3), and arachidonic acid (C20:4ω −6), were the predominant fatty acids (64–68%) in all JA clones (Table 3). The linolenic acid content ranged between 34.7 and 43.7%, rendering this fatty acid the predominant PUFA in the JA LPC. Linoleic acid was the second most frequent PUFA, as its content varied between 21.0% and 26.9%. The Alfalfa LPC did not contain any detectable amount of arachidonic acid, while the LPC of JA, regardless of clone, contained up to 0.5% of arachidonic acid. Overall, this quantitative analysis showed significant differences between the JA clones regarding the distribution of fatty acids, but no tendentious change was found.

3.4 Tuber yield

Figure 5 shows the tuber yield of the JA clones after the two harvest events of their fresh biomass during the growing season. Tuber yield showed a harvest-responsive relationship, as a significant reduction in this parameter was detected after the repeated harvest of the fresh biomass of this plant. The number of tubers of control plants (left without harvesting) ranged from 72 to 193 (tuber m−2) for Kercaszomori and Fuseau, respectively. These numbers were significantly reduced to 5.8 (for Kercaszomori) and 15.8 (for Fuseau) after the harvest of fresh biomass twice a year. Consequently, a huge reduction in tuber yield was observed at the end of the experiment (October). The Alba tuber-yield reduced significantly from 16.3 (without harvest) to 0.31 (two-times harvest) kg m−2. Kercaszomori exhibited the lowest tuber yield in the absence and presence of harvesting of shoots (0.31 and 0.06 kg m−2, respectively) (Fig. 5).

Tuber yield (kg m−2) and number of tuber (per m2) of different Jerusalem artichoke (Helianthus tuberosus L.) clones harvested at the end of the growing season (October 2016). a, c Shoot part was harvested only one time at the end of the growing season in October. b, d Shoot part was harvested twice in June and August. Data are average of 10 plants. Different letters on the same columns show significant differences according to Duncan’s test at p < 0.05

3.5 Effects on soil fertility

This comparative experiment of JA was established without the use of any fertilizers during the growing season. The NPK and humus content of the soil did not decrease after the 1-year experiment; rather, an increase in these parameters was recorded (Table 3). As expected, alfalfa improved the nutritional status (i.e., total-N, organic-N, NH4+-N, NO3−-N, and humus content) of the experimental soil at the end of the experiment compared with JA. However, JA significantly increased the content of soil macronutrients, i.e., total-P and total-K, compared with alfalfa (Table 3).

4 Discussion

The interest in the isolation of protein from green leaves—known as green biorefinery—has re-surfaced as a substantial alternative in the protein supply chain. Jerusalem artichoke is among the biomass plants that have been proposed for incorporation into the green biorefinery concept. This is because of its high green biomass yielded under low-input conditions, as JA is able to grow normally on poor soils, such as marginal lands. Moreover, it does not require a special fertilization program and has low water requirements. JA is more tolerant to drought than alfalfa [15]; however, the yielded biomass can be increased with irrigation [36]. Jerusalem artichoke is a leafy plant with wide leaves, which is an advantage because chloroplast and cytoplasmic proteins are the main sources of leaf protein and are present at higher concentrations in leaf vs. stem tissues [37].

Young stems and leaves of JA are succulent and turn to be woody with the time [20]; therefore, we harvested the aerial parts twice a year when they reached a height between 1.3 and 1.5 m, approximately, in both harvests. The fresh biomass changed significantly ranged from 36 to 53 to 11–30 t per hectare in the 1st and 2nd harvests, respectively. However, the clones that were non-native to the Hungarian climate (Fuseau and Kalevala) displayed a high fresh biomass. The total fresh biomass obtained from both harvests ranged between 47 and 83 t per hectare. With an average moisture content of 47.8%, we calculated that total dry shoot biomass varied from 22.5 to 39.8 t per hectare. These results were similar to those reported by Rawate and Hill [37] (dry mass of 25 t per hectare) and comparable with those of the forage crop alfalfa, which yields around 25 t per hectare [38]. Notably, this green biomass was obtained using a rainfed plantation method; however, we expect that irrigation of the JA plants would increase this parameter, because the biomass yield of the aerial parts are sensitive to drought stress. According to Mecella et al. [39], the irrigated plots of JA had an aboveground biomass that was 98% greater than that of unirrigated plots.

Although the green shoots of JA can be used directly to feed animals, the dense trichomes of leaves and stems, as well as the high lignin and carbohydrate content and the low protein content of stems, reduce its palatability [20, 40, 41]. Therefore, the isolation of the leaf protein would increase the value of the aerial parts of JA. Here, the pressing and pulping of the fresh biomass of JA resulted in an average of 20.8%, 61.2%, and 10.2% of fresh mass of fiber, phytoserum, and LPC, respectively. Some clones, such as Piri, yielded a higher LPC content than did alfalfa (by 11.8%). The dry masses of the fiber, phytoserum, and LPC fractions obtained from JA clones were almost the same as those extracted from alfalfa; however, some clones had higher values for these parameters compared with alfalfa. These results emphasize the contention that JA is a suitable candidate for LPC production. The average protein content (based on dry mass for LPC and fiber fractions while based on fresh mass for phytoserum) of the LPC, fiber, and phytoserum fractions was 28.8, 10.5, and 0.8 m/m% in the case of JA, and 31.6, 10.8, and 1.0 m/m% for alfalfa, respectively; however, some clones of JA yielded a higher content of these parameters compared with alfalfa. It is important to note that the total protein content of 35.3 m/m% observed for the alfalfa LPC fraction is quite low; this could be attributed to the fact that the alfalfa plants were grown without irrigation. Of note, we found that the crude protein content of LPC produced from some alfalfa varieties could reach 37.7–43.9 m/m% (unpublished data). The leaves of JA represent the most important component in LPC production, because their total protein content is three times higher than that of stems [42]; our results were in agreement with these findings.

The protein content of leaves is very sensitive to the plant’s age, and old leaves have 50% less nitrogen [43]. Moreover, Seiler [44] reported a 33% reduction in crude protein content during the flowering stage of JA plants compared with the vegetative stage. In the present study, 29.6–31.4 m/m% crude protein was measured in the LPC obtained from the fresh biomass of the different JA clones. Because the harvesting of the shoot parts was carried out at a young growth stage, as mentioned above, no significant differences were detected between the two harvests. The crude protein content of the fiber fraction (~ 9.0–12.5 m/m%) was derived mainly from cellular-membrane- and cell-wall-binding proteins of the stem parts and pressed leaf fiber residue.

The content of the nine essential amino acids (i.e., valine, leucine, isoleucine, methionine, tryptophan, lysine, threonine, phenylalanine, and histidine) is a key factor in the determination of protein quality [45]. The LPC isolated from JA contained substantial amounts of lysine, isoleucine, leucine, methionine and threonine compared with the alfalfa LPC. A previous study performed by Rawate and Hill [37] reported slightly higher levels of amino acids than those detected here; however, this could be due to the different extraction techniques and different JA cultivars used in the two studies.

In addition to its high crude protein content, the LPC of JA can also be a source of valuable biomolecules, such as fatty acids. Lipids serve two important roles in animal feed: (1) a high-density energy supply and (2) a source of essential fatty acids for special functions. The dietary source of fatty acids in farm animals improves the fatty acid profile of milk, meat and eggs by increasing the UFA:SFA ratio and decreasing the n−6:n−3 fatty acid ratio [46]. The lipid and fatty acid content of JA tubers has been documented well [20]. However, the information about the fatty acid composition of leafy shoots and derived products available in the scientific literature is scarce. Generally, chloroplasts of green tissues and the plastids of non-photosynthetic tissues are the main location of fatty acid biosynthesis in plants. Trienoic fatty acids are the most abundant (60–70%) fatty acids in photosynthetic tissues [47]. Our results showed that the LPC obtained from the green biomass of JA contains a high proportion of PUFAs. The linolenic acid content was 43.7% and 50.8% in the LPC of JA and alfalfa, respectively. Soybean, as the main seed-based protein source used in animal feeding, contains around 23%, 53%, and 8% of oleic, linoleic, and linolenic acids, respectively [48]. However, the soybean meal (after oil extraction) used in animal feeding is almost fatty acid free. Linolenic acid is a precursor of longer-chain PUFAs, i.e., eicosapentaenoic acid (EPA: C20:5ω −3) and docosahexaenoic acid (DHA: C22:6ω −3), which are not biologically synthesized by humans [49]. Hence, a linolenic acid supply is needed in the diet of humans. Greens and/or the seeds of plants or meats can serve as sources of linolenic acid. Several studies have confirmed that the composition of fodder affects the quality of meat. The presence of green grass (pasture) in fodder increases the linolenic acid and linoleic acid content of meat [50, 51]. According to anthropological and epidemiological studies, an appropriate ratio of linoleic acid to linolenic acid should also be emphasized in the human diet [52]. The trend of convergence of omega-6 to omega-3 essential fatty acids is in the range of 4:1 to 5:1. However, in the modern human diet, this ratio has shifted to 10–20:1, which is not favorable from a public health point of view. In general, the linoleic and linolenic acid ratio recorded here was 0.6–0.8:1 in the LPC of JA. Among the PUFAs, arachidonic acid was also found in the LPC of JA at a low proportion (up to 0.5%). In contrast, regardless of harvesting time, no detectable amount of arachidonic acid was observed in the alfalfa LPC. A recent study reported by Shanab et al. [52] confirmed the presence of small arachidonic acid amounts in higher plants. Palmitic acid is the most common saturated fatty acid. Humans and other animals can synthesize palmitic acid endogenously from other fatty acids, carbohydrates and/or amino acids; alternatively, it can be obtained from the diet [53]. In plants, synthesized palmitic and oleic acids are partially required for the biogenesis of cell membranes. The relatively higher proportions of palmitic (16.4–17.9%) and oleic (6.6–11.6%) acids can be explained by the fact that the LPC contains membrane debris, as it is a pressed coagulated green biomass.

JA has a high growth rate per day; it can grow up to 2.5 cm per day. Although JA can produce high tuber and forage yields, both tuber and forage cannot be obtained simultaneously [37]. The harvest of the aerial parts of JA during the growing season results in a significant reduction of tuber yield [40]. Here, the data pertaining to tuber yield showed that the harvesting of the shoot parts reduced the tuber yield drastically. For instance, the tuber yield of Alba without harvest was 16.3 kg m−2, whereas it decreased to 0.31 kg m−2 after the two harvests. However, the tuber yield recorded after the two harvests of the shoot parts was sufficient for the propagation of plants in the following year. The differences in tuber yield between the JA cultivars were assessed statistically. Several previous articles, however, reported similar differences among JA varieties [14, 20]. Dorrell and Chubey [54] reported a tuber yield of 26 Mg ha−1, whereas Chubey and Dorrell [55] documented a tuber yield ranging from 38 to 60 Mg ha−1. In the present study, harvest of the shoot parts affected not only the tuber yield but also the size of the tuber, as tuber size decreased after the harvests.

The potential effect of alfalfa on soil properties has been documented well, as it is a legume plant that fixes significant amounts of atmospheric N2 into the soil. Russelle [56] reported that alfalfa plantations fix 50 kg ha−1 of N2 is fixed into the soil. In the present study, JA had a similar effect on several soil chemical properties; it substantially increased nutrient content, i.e., total N, P and K, humus and different N species (organic, NH4+ and NO3−). Alfalfa had higher impact on N forms and humus, whereas JA exerted significantly stronger effects on P and K content. Similar findings were reported by Zhao et al. [57]. Taken together, these results led us to conclude that JA is a promising candidate for LPC production; it exhibited a high protein content and shoot biomass yield, and its amino acid and fatty acid profiles were similar to those of alfalfa and soybean. Moreover, JA required a low input of fertilizers and irrigation, combined with its considerable tolerance to biotic/abiotic stresses, such as pests, insects and drought. JA is mainly cultivated for its inulin-rich tubers, alongside this; huge useless shoot biomass is produced. Also, the direct consumption of the shoot part is not favored by animals due to the dense trichomes on leaves and stems. Therefore, converting this huge biomass into valuable-economic products, i.e., LPC, fiber, and phytoserum strongly supports the circular economy and biorefinery concepts as well as agrobiodiversity. The abovementioned results prove the high productivity of LPC derived from JA fresh biomass in addition to the co-products, i.e., fiber and phytoserum. Moreover, amino acid and fatty acid profiles demonstrate the high quality of LPC of JA compared to alfalfa LPC and soybean. However, the yield and quality of the LPC of JA seem to be dependent on cultivar and harvesting time. In summary, the current study provided deeper insights into the quality of the LPC derived from the fractionated fresh biomass of different JA cultivars. However, future studies of the anti-nutritional ingredients of LPC and the chemical composition of the other fractions (i.e., phytoserum and fiber), together with economical calculations, are needed.

5 Conclusion

In the present research paper, we provided additional information about the LPC generated from different JA cultivars compared with alfalfa and soybean. The shoot parts of JA can be harvested twice a year, thus producing huge quantities of fresh biomass using low-input conditions. The yield of LPC was the same or even higher than that of alfalfa. The distribution of total protein content in the different extraction fractions (LPC, fiber, and phytoserum) was similar between JA and alfalfa; however, the latter exhibited slightly higher values. The amino and fatty acid compositions of the LPC were similar between JA and alfalfa, and were comparable to those of soybean. The results of the present work confirm that this underestimated plant can be directed not only toward tuber production, for inulin extraction, but also for the use of its green biomass as a valuable fraction for LPC production. Thus, the high quality of the LPC of JA renders it a promising protein source for sustainable food/feed supply.

References

Korhonen J, Honkasalo A, Seppälä J (2018) Circular economy: the concept and its limitations. Ecol Econ 143:37–46

Hayes M (2018) Novel proteins for food, pharmaceuticals, and agriculture: sources, applications, and advances. Wiley-Blackwell

Pojić M, Mišan A, Tiwari B (2018) Eco-innovative technologies for extraction of proteins for human consumption from renewable protein sources of plant origin. Trends Food Sci Technol 75:93–104

Henchion M, Hayes M, Mullen AM, Fenelon M, Tiwari B (2017) Future protein supply and demand: strategies and factors influencing a sustainable equilibrium. Foods 6(7):53

Ereky C (1927) New methods of preparing green vegetables for the table. Food Manuf 2:207

Pirie NW (1942) Green leaves as a source of proteins and other nutrients. Nature p251

Tamayo Tenorio A, Schreuders FKG, Zisopoulos FK, Boom RM, van der Goot AJ (2017) Processing concepts for the use of green leaves as raw materials for the food industry. J Clean Prod 64:736–748

Solati Z, Jørgensen U, Eriksen J, Søegaard K (2017) Dry matter yield, chemical composition and estimated extractable protein of legume and grass species during the spring growth. J Sci Food Agric 97(12):3958–3966

De Coratoa U, De Barib I, Violab E, Pugliesec M (2018) Assessing the main opportunities of integrated biorefining from agrobioenergy co/by-products and agroindustrial residues into high-value added products associated to some emerging markets: a review. Renew Sust Energ Rev 88:326–346

European Commission (2018) Results and deliverables of the environmental footprint pilot phase. Available online: http://ec.europa.eu/environment/eussd/smgp/PEFCR_OEFSR_en.htm (Accessed 9 Jan 2020)

Kromus S, Kamm B, Kamm M, Fowler P, Narodoslawsky M (2005) Green biorefineries: the green biorefinery concept-fundamentals and potential. In: Birgit Kamm B, Gruber PR, Kamm M (eds) Biorefineries-industrial processes and products. Wiley, London, pp 253–294

Kammes KL, Bals BD, Dale BE, Allen MS (2011) Grass leaf protein, a coproduct of cellulosic ethanol production, as a source of protein for livestock. Anim Feed Sci Technol 164(1):79–88

Shang N, Chaplot S, Wu J (2018) Food proteins for health and nutrition. In: Yada RY (ed.) Proteins in food processing, 2nd edn. Woodhead Publishing Series in Food Science, Technology and Nutrition. pp 301–336

Gunnarsson IB, Svensson S-E, Johansson E, Karakashev D, Angelidaki I (2014) Potential of Jerusalem artichoke (Helianthus tuberosus L.) as abiorefinery crop. Ind Crop Prod 56:231–240

Johansson E, Prade T, Angelidaki I, Svensson S-E, Newson WR, Gunnarsson IB, Hovmalm HP (2015) Economically viable components from Jerusalem artichoke (Helianthus tuberosus L.) in a biorefinery concept. Int J Mol Sci 16:8997–9016

Yu MN, Bao WJ, Chen FJ, Long XH, Liu L, Liu ZP (2015) Leaf protein extraction process optimization and analysis of amino acids contents of Helianthus tuberosus. Pratacult Sci 32(1):125–131 (in Chinese)

Fang YR, Liua JA, Steinberger Y, Xie GH (2018) Energy use efficiency and economic feasibility of Jerusalem artichoke production on arid and coastal saline lands. Ind Crop Prod 117:131–139

Kaszás L, Kovács Z, Nagy É, Elhawat N, Abdalla N, Domokos-Szabolcsy É (2018) Jerusalem artichoke (Helianthus Tuberosus L.) as a potential chlorophyll source for humans and animals nutrition. Env Biodiv Soil Secur 2:1–9

Rossini F, Provenzano M-E, Kuzmanovíc L, Ruggeri R (2019) Jerusalem artichoke (Helianthus tuberosus L.): a versatile and sustainable crop for renewable energy production in Europe. Agronomy 9(9):528

Kays SJ, Nottingham SF (2008) Biology and chemistry of Jerusalem artichoke: Helianthus tuberosus L. CRC Press, Taylor & Francis Group, New York

Niu L, Manxia C, Xiumei G, Xiaohua L, Hongbo S, Zhaopu L, Zed R (2016) Carbon sequestration and Jerusalem artichoke biomass under nitrogen applications in coastal saline zone in the northern region of Jiangsu. China. Sci Total Environ 568:885–890

Razmkhah M, Rezaei J, Fazaeli H (2017) Use of Jerusalem artichoke tops silage to replace corn silage in sheep diet. Anim Feed Sci Technol 228:168–177

Long X-H, Shao H-B, Liu L, Liu L-P, Liu Z-P (2016) Jerusalem artichoke: a sustainable biomass feed stock for biorefinery. Renew Sust Energ Rev 54:1382–1388

Izsáki Z, Kádi GN (2013) Biomass accumulation and nutrient uptake of Jerusalem artichoke (Helianthus tuberosus L.). Am J Plant Sci 4:1629–1640

Yuan X, Gao M, Xiao H, Tan C, Du Y (2012) Free radical scavenging activities and bioactive substances of Jerusalem artichoke (Helianthus tuberosus L.) leaves. Food Chem 133:10–14

Helmi Z, Al Azzam KM, Tsymbalista Y, Ghazleh RA, Shaibah H, Aboul-Enein H (2014) Analysis of essential oil in Jerusalem artichoke (Helianthus tuberosus L.) leaves and tubers by gas chromatography-mass spectrometry. Adv Pharm Bull 4:521–526

Fazaeli H, Nosrat-abadi N, Karkodi K, Mirhadi A (2009) In vitro and in vivo analysis of Jerusalem artichoke (Helianthus tuberosus) and alfalfa nutritive value. Sci Technol Agric Nat Resour Isfahan Univ Technol 13:163–173

Parajuli R, Dalgaard T, Jørgensen U, Adamsen APS, Knudsen MT, Birkved M, Gylling M, Schjørring JK (2015) Biorefining in the prevailing energy and materials crisis: a review of sustainable pathways for biorefinery value chains and sustainability assessment methodologies. Renew Sust Energ Rev 43:244–263

la Cour R, Schjoerring JK, Jørgensen H (2019) Enhancing protein recovery in green biorefineries by lignosulfonate-assisted precipitation. Front Sustain Food Syst 3:112. https://doi.org/10.3389/fsufs.2019.00112

Ranal MA, Santana DG (2006) How and why to measure the germination process? Rev Bras Bot 29:1–11

Fári MG, Domokos-Szabolcsy É (2019) Method for producing plant protein coagulum. Hun Patent WO/2019/150144, 8 August 2019

Sparks DL, Page AL, Helmke PA, Loppert RH, Soltanpour PN, Tabatabai MA, Johnston CT, Summner ME (1996) Methods of soil analysis: chemical methods, part 3. ASA and SSSA, Madison

Yang J, Bai J, Liu M, Chen Y, Wang S, Yang Q (2018) Determination of phosphorus in soil by ICP-OES using an improved standard addition method. Journal of Analytical Methods in Chemistry, vol. 2018, Article ID 1324751, 8 pages, 2018. https://doi.org/10.1155/2018/1324751

Székely Á, B-né S, T-né S (1960) On the photometric and colorimetric determination of organic carbon. Agrokém Talajt 9:111–120 (In Hungarian)

Duncan DB (1955) Multiple range and multiple F-tests. Biometric 11:1–42

Monti A, Amaducci MT, Venturi G (2005) Growth response, leaf gas exchange and fructans accumulation of Jerusalem artichoke (Helianthus tuberosus L.) as affected by different water regimes. Eur J Agron 23:136–145

Rawate PD, Hill RM (1985) Extraction of a high-protein isolate from Jerusalem artichoke (Helianthus tuberosus) tops and evaluation of its nutrition potential. J Agric Food Chem 33:29–31

Stavarache M, Samuil C, Popovici CI, Tarcau D, Vintu V (2015) The productivity and quality of alfalfa (Medicago sativa L.) in Romanian forest steppe. Not Bot Horti Agrobo 43(1):179–185

Mecella G, Scandella P, Neri U, Di Blasi N, Moretti R, Troisi A, Lauciano R, Alterio M, Di Carlo V (1996) The productive and chemical evolution of the Jerusalem artichoke (Helianthus tuberosus L.) under various conditions of irrigation. Agric Med 126:233–239

Boswell VR, Steinbauer CE, Babb MF, Burlison WL, Alderman WH, Schoth HA (1936) Studies of the culture and certain varieties of the Jerusalem artichoke, USDA Technical Bulletin 415. U.S. Department of Agriculture, Washington, DC

Hay RKM, Offer NW (1992) Helianthus tuberosus as an alternative forage crop for cool maritime regions: a preliminary study of the yield and nutritional quality of shoot tissues from perennial stands. J Sci Food Agric 60:213–221

Malmberg A, Theander O (1986) Differences in chemical composition of leaves and stem in Jerusalem artichoke and changes in low-molecular sugar and fructan content with time of harvest. Swed J Agric Res 16:7–12

Rashchenko IN (1959) Biochemical investigations of the aerial parts of Jerusalem artichoke. Trudy Kazakh Sel’skokhoz Inst 6:40–52

Seiler GJ (1988) Nitrogen and mineral content of selected wild and cultivated genotypes of Jerusalem artichoke. Agron J 80:681–687

Boisen S, Hvelplund T, Weisbjerg MR (2000) Ideal amino acid profiles as a basis for feed protein evaluation. Livest Prod Sci 64:239–251

Woods VB, Fearon AM (2009) Dietary sources of unsaturated fatty acids for animals and their transfer into meat, milk and eggs: a review. Livest Sci 126(1–3):1–20

Aid F (2019) Plant lipid metabolism [online first]. IntechOpen. https://doi.org/10.5772/intechopen.81355

Çetingül IS, Yardımcı M (2008) The importance of fats in farm animal nutrition. Kocatepe Vet J 1:77–81

Sultan SM, Dikshit N, Vaidya UJ (2015) Oil content and fatty acid composition of soybean (Glysine max L.) genotypes evaluated under rainfed conditions of Kashmir Himalayas in India. J Appl Nat Sci 7(2):910–915

Díaz MT, Velasco S, Cañeque V, Lauzurica S, Huidobro FR, Pérez C, González J, Manzanares C (2002) Use of concentrate or pasture for fattening lambs and its effect on carcass and meat quality. Small Rumin Res 43:257–268

Morel PCH, Mc Intoshi JC, Janz JAM (2006) Alteration of the fatty acid profile of pork by dietary manipulation. J Anim Sci 19(3):431–437

Shanab SMM, Hafez RM, Fouad AS (2018) A review on algae and plants as potential source of arachidonic acid. J Adv Res 11:3–13

Carta G, Murru E, Banni S, Manca C (2017) Palmitic acid: physiological role, metabolism and nutritional implications. Front Physiol 8:902. https://doi.org/10.3389/fphys.2017.00902

Dorrell DG, Chubey BB (1977) Irrigation, fertilizer, harvest dates and storage effects on the reducing sugar and fructose concentrations of Jerusalem artichoke tuber. Can J Plant Sci 57:591–596

Chubey BB, Dorrell DG (1982) Columbia Jerusalem artichoke. Can J Plant Sci 62:537–539

Russelle M (2004) The environmental impacts of N2 fixation by alfalfa. In: Proceedings, National Alfalfa Symposium, 13–15 December 2004, San Diego, CA, UC

Zhao GM, Liu ZP, Chen MD, Guo SW (2008) Soil properties and yield of Jerusalem artichoke (Helianthus tuberosus L.) with seawater irrigation in north China plain. Pedosphere. 18(2):195–202

Acknowledgements

This paper was also supported by the János Bolyai Research Scholarship of the Hungarian Academy of Sciences. The authors thank Prof. Mohamed E. Ragab (Horticulture Department, Faculty of Agriculture, Ain Shams University, Egypt) for providing them with tubers of Fuseau.

Availability of data and material (data transparency)

All data and materials are original and have not been published before.

Code availability

(software application or custom code)

No software application or custom code.

Funding

Open access funding provided by University of Debrecen (DE). The research was financed by the Higher Education Institutional Excellence Programme (NKFIH-1150-6/2019) of the Ministry of Innovation and Technology in Hungary, within the framework of the Biotechnology thematic programme of the University of Debrecen. This research was financed also by the “Complex Rural Economic and Sustainable Development, Elaboration of its Service Networks in the Carpathian Basin (Project ID: EFOP-3.6.2-16-2017-00001, Hungary)” research project.

Author information

Authors and Affiliations

Contributions

László Kaszás, Éva Domokos-Szabolcsy: conceptualization. Zoltán Kovács, László Kaszás: methodology, software. Nevien Elhawat, Hassan El-Ramady: data curation, writing-original draft preparation. Judit Koroknai: visualization, investigation. Miklós Fári: supervision. Zoltán Kovács: software, validation. Éva Domokos-Szabolcsy, Tarek Alshaal: writing-reviewing and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kaszás, L., Alshaal, T., Kovács, Z. et al. Refining high-quality leaf protein and valuable co-products from green biomass of Jerusalem artichoke (Helianthus tuberosus L.) for sustainable protein supply. Biomass Conv. Bioref. 12, 2149–2164 (2022). https://doi.org/10.1007/s13399-020-00696-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00696-z