Abstract

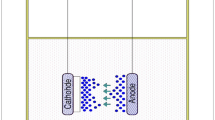

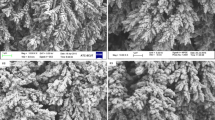

To meet the heat dissipation requirements of microelectronic devices, it is urgent to develop an efficient method to fabricate a controllable micro/nano structure for the wick in vapor chamber, which is widely investigated for its high thermal conductivity and small size. This work proposed a controllable fabrication of nano-porous copper (NPC) with high efficiency, which includes electrodeposition and dealloying. A uniform Cu–Zn alloy with single phase was prepared as the precursor for dealloying through electrodeposition. An innovative solution system for dealloying was developed for the fabrication of the bi-continuous NPC, in which the efficiency was improved ten times compared to the conventional acid solution. In addition, the effects of dealloying parameters on the NPC morphology and the process efficiency have also been studied systematically. Based on the above method, both good wettability and capillary performance were achieved by NPC with tunable pore size, which indicates its great application prospects in wicks for high-performance vapor chamber.

Graphical Abstract

Similar content being viewed by others

References

Semenov, O., Vassighi, A., Sachdev, M.: Impact of self-heating effect on long-term reliability and performance degradation in CMOS circuits. IEEE Trans. Device Mater. Reliab. 6, 17–27 (2006)

Garimella, S.V., Fleischer, A.S., Murthy, J.Y., Keshavarzi, A., Prasher, R., Patel, C., Bhavnani, S.H., Venkatasubramanian, R., Mahajan, R., Joshi, Y., Sammakia, B., Myers, B.A., Chorosinski, L., Baelmans, M., Sathyamurthy, P., Raad, P.E.: Thermal challenges in next-generation electronic systems. IEEE Trans. Compon. Packag. Technol. 31, 801–815 (2008)

Tavakkoli, F., Ebrahimi, S., Wang, S., Vafai, K.: Analysis of critical thermal issues in 3D integrated circuits. Int. J. Heat Mass Transfer 97, 337–352 (2016)

Zhang, S., Chen, J., Sun, Y., Li, J., Zeng, J., Yuan, W., Tang, Y.: Experimental study on the thermal performance of a novel ultra-thin aluminum flat heat pipe. Renew. Energy 135, 1133–1143 (2019)

Sun, Y., Wu, Y., Cai, H., Luo, J., Wang, Y., Ding, G.: A modified 360° netting vein bionic structure for enhancing thermal properties of polymer/nanofiber/nanoparticle composite. Compos. A Appl. Sci. Manuf. 14, 106276 (2021)

Tang, H., Tang, Y., Wan, Z., Li, J., Yuan, W., Lu, L., Li, Y., Tang, K.: Review of applications and developments of ultra-thin micro heat pipes for electronic cooling. Appl. Energy 223, 383–400 (2018)

Xie, D., Sun, Y., Wang, G., Chen, S., Ding, G.: Significant factors affecting heat transfer performance of vapor chamber and strategies to promote it: a critical review. Int. J. Heat Mass Transfer 175, 121132 (2021)

Lim, H.T., Kim, S.H., Im, H.D., Oh, K.H., Jeong, S.H.: Fabrication and evaluation of a copper flat micro heat pipe working under adverse-gravity orientation. J. Micromech. Microeng. 18, 105013 (2008)

Wang, M., Cui, W., Hou, Y.: Thermal spreading resistance of grooved vapor chamber heat spreader. Appl. Therm. Eng. 153, 361–368 (2019)

Li, B., Yin, X., Tang, W., Zhang, J.: Optimization design of grooved evaporator wick structures in vapor chamber heat spreaders. Appl. Therm. Eng. 166, 114657 (2020)

Li, Y., Li, Z., Zhou, W., Zeng, Z., Yan, Y., Li, B.: Experimental investigation of vapor chambers with different wick structures at various parameters. Exp. Therm. Fluid Sci. 77, 132–143 (2016)

Velardo, J., Date, A., Singh, R., Nihill, J., Date, A., Phan, T.L., Takahashi, M.: Experimental investigation of a vapour chamber heat spreader with hybrid wick structure. Int. J. Therm. Sci. 140, 28–35 (2019)

Huang, D., Jia, L., Wu, H., Aaker, O.: Experimental investigation on the vapor chambers with sintered copper powder wick. J. Therm. Sci. 30, 1938–1950 (2021)

Li, Y., Zhou, W., He, J., Yan, Y., Li, B., Zeng, Z.: Thermal performance of ultra-thin flattened heat pipes with composite wick structure. Appl. Therm. Eng. 102, 487–499 (2016)

Chen, L., Deng, D., Huang, Q., Xu, X., Xie, Y.: Development and thermal performance of a vapor chamber with multi-artery reentrant microchannels for high-power LED. Appl. Therm. Eng. 166, 114686 (2020)

Pepelyshev, Y.N., Tsogtsaikhan, T.: Investigation of the pulse energy noise dynamics of IBR-2M using cluster analysis. Ann. Nucl. Energy 83, 50–56 (2015)

Lu, L., Sun, J., Liu, Q., Liu, X., Tang, Y.: Influence of electrochemical deposition parameters on capillary performance of a rectangular grooved wick with a porous layer. Int. J. Heat Mass Transfer 109, 737–745 (2017)

Zhong, G., Tang, Y., Ding, X., Chen, G., Li, Z.: Experimental investigation on wettability and capillary performance of ultrasonic modified grooved aluminum wicks. Int. J. Heat Mass Transfer 179, 121642 (2021)

Zhang, Z., Wang, Y., Qi, Z., Zhang, W., Qin, J., Frenzel, J.: Generalized fabrication of nanoporous metals (Au, Pd, Pt, Ag, and Cu) through chemical dealloying. J. Phys. Chem. C 113, 12629–12636 (2009)

Qiu, H.J., Li, X., Xu, H.-T., Zhang, H.-J., Wang, Y.: Nanoporous metal as a platform for electrochemical and optical sensing. J. Mater. Chem. C 2, 9788–9799 (2014)

Chauvin, A., Delacôte, C., Molina-Luna, L., Duerrschnabel, M., Boujtita, M., Thiry, D., Du, K., Ding, J., Choi, C.-H., Tessier, P.-Y., El Mel, A.-A.: Planar arrays of nanoporous gold nanowires: when electrochemical dealloying meets nanopatterning. ACS Appl. Mater. Interfaces 8, 6611–6620 (2016)

Li, Y., Jia, W.-Z., Song, Y.-Y., Xia, X.-H.: Superhydrophobicity of 3D porous copper films prepared using the hydrogen bubble dynamic template. Chem. Mater. 19, 5758–5764 (2007)

Cheng, I.C., Hodge, A.M.: Morphology, oxidation, and mechanical behavior of nanoporous Cu foams. Adv. Eng. Mater. 14, 219–226 (2012)

Lee, Y.-S., Sun, Y.-H., Cheng, I.C.: Self-organizing Ag-decorated nanoporous Cu by dealloying process. Scr. Mater. 208, 114337 (2022)

Li, Y., Zhou, W., Li, Z., Chen, Z., Gan, Y.: Experimental analysis of thin vapor chamber with composite wick structure under different cooling conditions. Appl. Therm. Eng. 156, 471–484 (2019)

Chen, Z., Li, Y., Zhou, W., Deng, L., Yan, Y.: Design, fabrication and thermal performance of a novel ultra-thin vapour chamber for cooling electronic devices. Energy Convers. Manage. 187, 221–231 (2019)

Tang, Y., Tang, B., Qing, J., Li, Q., Lu, L.: Nanoporous metallic surface: facile fabrication and enhancement of boiling heat transfer. Appl. Surf. Sci. 258, 8747–8751 (2012)

Diao, F., Xiao, X., Luo, B., Sun, H., Ding, F., Ci, L., Si, P.: Two-step fabrication of nanoporous copper films with tunable morphology for SERS application. Appl. Surf. Sci. 427, 1271–1279 (2018)

Hayes, J.R., Hodge, A.M., Biener, J., Hamza, A.V., Sieradzki, K.: Monolithic nanoporous copper by dealloying Mn–Cu. J. Mater. Res. 21, 2611–2616 (2006)

Chen, L.-Y., Yu, J.-S., Fujita, T., Chen, M.-W.: Nanoporous copper with tunable nanoporosity for SERS applications. Adv. Funct. Mater. 19, 1221–1226 (2009)

Tuan, N.T., Park, J., Lee, J., Gwak, J., Lee, D.: Synthesis of nanoporous Cu films by dealloying of electrochemically deposited Cu–Zn alloy films. Corros. Sci. 80, 7–11 (2014)

Erlebacher, J.: An atomistic description of dealloying. J. Electrochem. Soc. 151, C614 (2004)

Mao, R., Liang, S., Wang, X., Yang, Q., Han, B.: Effect of preparation conditions on morphology and thermal stability of nanoporous copper. Corros. Sci. 60, 231–237 (2012)

Sun, Y., Ren, Y., Yang, K.: New preparation method of micron porous copper through physical vacuum dealloying of Cu–Zn alloys. Mater. Lett. 165, 1–4 (2016)

Yue, H., Zhang, C.C., Yang, Z.Q., Wang, H., Ding, G.F., Zhao, X.L.: A preparation method of patterned nanoporous copper. Adv. Mater. Res. 663, 322–325 (2013)

Vivegnis, S., Krid, M., Delhalle, J., Mekhalif, Z., Renner, F.U.: Use of pyrophosphate and boric acid additives in the copper-zinc alloy electrodeposition and chemical dealloying. J. Electroanal. Chem. 848, 113310 (2019)

Lu, H.-B., Li, Y., Wang, F.-H.: Synthesis of porous copper from nanocrystalline two-phase Cu–Zr film by dealloying. Scr. Mater. 56, 165–168 (2007)

Yang, Q., Liang, S., Han, B., Wang, J., Mao, R.: Preparation and properties of enhanced bulk nanoporous coppers. Mater. Lett. 73, 136–138 (2012)

Erlebacher, J., Aziz, M.J., Karma, A., Dimitrov, N., Sieradzki, K.: Evolution of nanoporosity in dealloying. Nature 410, 450–453 (2001)

Qi, Z., Weissmüller, J.: Hierarchical nested-network nanostructure by dealloying. ACS Nano 7, 5948–5954 (2013)

Liu, K., Li, Y., Zhang, H., Liu, Y.: Synthesis of the polypyrrole encapsulated copper nanowires with excellent oxidation resistance and temporal stability. Appl. Surf. Sci. 439, 226–231 (2018)

Li, Y., Zheng, W., Zhang, H., Wang, H., Cai, H., Zhang, Y., Yang, Z.: Electron transfer mechanism of graphene/Cu heterostructure for improving the stability of triboelectric nanogenerators. Nano Energy 70, 104540 (2020)

Wenzel, R.N.: Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 28, 988–994 (1936)

Wenzel, R.N.: Surface roughness and contact angle. J. Phys. Colloid Chem. 53, 1466–1467 (1949)

Cassie, A.B.D., Baxter, S.: Wettability of porous surfaces. Trans. Faraday Soc. 40, 546–551 (1944)

Li, Q., Lan, Z., Chun, J., Lian, S., Wen, R., Ma, X.: Fabrication and capillary characterization of multi-scale micro-grooved wicks with sintered copper powder. Int. Commun. Heat Mass Transfer 121, 105123 (2021)

Tang, Y., Tang, H., Li, J., Zhang, S., Zhuang, B., Sun, Y.: Experimental investigation of capillary force in a novel sintered copper mesh wick for ultra-thin heat pipes. Appl. Therm. Eng. 115, 1020–1030 (2017)

Huang, S., Wan, Z., Zhang, X., Yang, X., Tang, Y.: Evaluation of capillary performance of a stainless steel fiber–powder composite wick for stainless steel heat pipe. Appl. Therm. Eng. 148, 1224–1232 (2019)

Acknowledgements

The authors would like to thank supports from the Shanghai Professional Technical Service Platform for Non-Silicon Micro-Nano Integrated Manufacturing. This work is supported by the National Key Research and Development Program of China (No. 2021YFB2011800) and the National Natural Science Foundation of China (No. 62104141).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chen, S., Cai, H., Li, Y. et al. Development of an Efficient and Controllable Nano-porous Copper with Good Wettability and Capillary Performance for Wicks of Vapor Chamber. Electron. Mater. Lett. 18, 465–474 (2022). https://doi.org/10.1007/s13391-022-00357-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-022-00357-5