Abstract

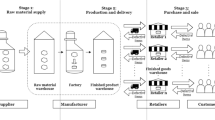

This paper addresses the economic lot-sizing and manpower planning in a two-stage manufacturing system. We refer to the first and second stages as the vendor and the manufacturer, respectively. Both the vendor and the manufacturer can operate at different production rates by varying the levels of their manpower. In Economics and Econometrics, the rate of production is usually modelled using the production function, a model which links company productivity to the level of existing resources, such as labour and capital. Namely, we utilize the Cobb–Douglas production function to represent the relationship between the production inputs (labour and capital) and the productivity. The impact of manpower planning decisions on the proposed supply chain system is studied. An efficient solution technique is proposed; then, sensitivity analysis and fractional factorial design were conducted to assess the performance of the proposed model. Our results suggest that the variable production rates may lead to substantial savings to the supply chain, especially in the case of low-profit margins. Furthermore, considering the vendor as a leader and the manufacturer as a follower in a Stackelberg sequential game, we present two contracts to share the resulting savings between the vendor and the manufacturer.

Similar content being viewed by others

References

Taleizadeh, A.A.; Kalantari, S.S.; Cárdenas-Barrón, L.E.: Determining optimal price, replenishment lot size and number of shipments for an EPQ model with rework and multiple shipments. J. Ind. Manag. Optim. 11(4), 1059–1071 (2015)

Ben-Daya, M.; Hariga, M.: Integrated single vendor single buyer model with stochastic demand and variable lead time. Int. J. Prod. Econ. 92(1), 75–80 (2004)

Gallego, G.: Reduced production rates in the economic lot scheduling problem. Int. J. Prod. Res. 31, 1035–1036 (1993)

Utama, D.M.; Maulana, S.K.D.B.; Baroto, T.; Dewi, S.K.: Optimizing vendor-buyer inventory model with exponential quality degradation for food product using grey wolf optimizer. Int. J. Food Syst. Dyn. 13(2), 225–246 (2022)

Zeng, Y.-R.; Peng, L.; Zhang, J.; Wang, L.: An effective hybrid differential evolution algorithm incorporating simulated annealing for joint replenishment and delivery problem with trade credit. Int. J. Comput. Intell. Syst. 9(6), 1001–1015 (2016)

Wang, L.; Peng, L.; Wang, S.; Liu, S.: Advanced backtracking search optimization algorithm for a new joint replenishment problem under trade credit with grouping constraint. Appl. Soft Comput. 86, 105953 (2020)

Jauhari, W.A., Pujawan, I.N., Suef, M.: Sustainable inventory management with hybrid production system and investment to reduce defects. Ann. Oper. Res. pp. 1–30 (2022)

Alfares, H.K.: An EPQ model with variable holding cost. Int. J. Ind. Eng. Theory Appl. Pract. 19(5), 232–240 (2012)

Glock, C.H.; Grosse, E.H.; Ries, J.M.: The lot sizing problem: A tertiary study. Int. J. Prod. Econ. 155, 39–51 (2014)

Zoller, K.; Robrade, A.: Dynamic lot sizing techniques: Survey and comparison. J. Oper. Manag. 7(3–4), 125–148 (1988)

Glock, C.H.; Grosse, E.H.: The impact of controllable production rates on the performance of inventory systems: A systematic review of the literature. Eur. J. Oper. Res. 288(3), 703–720 (2021)

Glock, C.H.: Batch sizing with controllable production rates. Int. J. Prod. Res. 48(20), 5925–5942 (2010)

AlDurgam, M.; Duffuaa, S.: Optimal joint maintenance and operation policies to maximize overall systems effectiveness. Int. J. Prod. Res. 51(5), 1319–1330 (2013)

Liu, X.; Zhao, F.: Using a random coefficient regression model to jointly determine the optimal critical level and lot sizing. IEEE Access 8, 66003–66012 (2020)

Khouja, M.: The economic production lot size model under volume flexibility. Comput. Oper. Res. 22(5), 515–523 (1995)

Eiamkanchanalai, S.; Banerjee, A.: Production lot sizing with variable production rate and explicit idle capacity cost. Int. J. Prod. Econ. 59, 1 (1999)

Glock, C.H.: Batch sizing with controllable production rates in multi-stage production systems. Int. J. Prod. Res. 49(20), 6017–6039 (2011)

Wysk, R.A.; Davis, R.P.; Tanchoco, J.M.A.: Machining parameter optimization with lot size considerations. AIIE Trans. 12(1), 59–63 (1980)

Koulamas, C.P.: Lot sizing and machining economics: The multi-item, multi-stage cost minimization case. Int. J. Prod. Res. 30(10), 2265–2280 (1992)

Koulamas, C.P.: Simultaneous determination of the cutting speed and lot size values in machining systems. Eur. J. Oper. Res. 84(2), 356–370 (1995)

AlDurgam, M.; Selim, S.; Alshehabi, S.; Al-Durgham, L.: Economic production quantity model with variable machining rates and product quality. Int. J. Eng. Bus. Manag. 11, 1–9 (2019)

Alfares, H.K., Ghaithan, A.M., A generalized production-inventory model with variable production, demand, and cost rates. Arab. J. Sci. Eng. pp. 1–16 (2022)

AlDurgam, M.; Adegbola, K.; Glock, C.H.: A single-vendor single-manufacturer integrated inventory model with stochastic demand and variable production rate. Int. J. Prod. Econ. 191, 335–350 (2017)

Malik, A.I.; Kim, B.S.: A multi-constrained supply chain model with optimal production rate in relation to quality of products under stochastic fuzzy demand. Comput. Ind. Eng. 149, 106814 (2020)

Khalifehzadeh, S.; Fakhrzad, M.B.: A modified firefly algorithm for optimizing a multi stage supply chain network with stochastic demand and fuzzy production capacity. Comput. Ind. Eng. 133, 42–56 (2019)

Malik, A.I.; Sarkar, B.: Coordination supply chain management under flexible manufacturing, stochastic leadtime demand, and mixture of inventory. Mathematics 8(6), 911 (2020)

Lee, C.-Y.: Most productive scale size versus demand fulfillment: A solution to the capacity dilemma. Eur. J. Oper. Res. 248(3), 954–962 (2016)

Merhi, A.; Zervos, M.: A model for reversible investment capacity expansion. SIAM J. Control. Optim. 46(3), 839–876 (2007)

Lee, C.-Y.; Charles, V.: A robust capacity expansion integrating the perspectives of marginal productivity and capacity regret. Eur. J. Oper. Res. 296(2), 557–569 (2022)

Cobb, C.W.; Douglas, P.H.: A theory of production. Am. Econ. Rev. 18(1), 139–165 (1928)

Arrow, K.J., Chenery, H.B., Minhas, B.S., Solow, R.M.: Capital-labor substitution and economic efficiency. Rev. Econ. Stat. pp. 225–250 (1961)

Christensen, L.R., Jorgenson, D.W., Lau, L.J.: Transcendental logarithmic production frontiers. Rev. Econ. Stat. pp. 28–45 (1973)

Ishikawa, A., Fujimoto, S., Mizuno, T.: Why does production function take the cobb–douglas form?. Evolut. Inst. Econ. Rev. pp. 1–24 (2020)

Darwish, M.A.; Abdulmalek, F.; Alkhedher, M.: Optimal selection of process mean for a stochastic inventory model. Eur. J. Oper. Res. 226(3), 481–490 (2013)

Khouja, M.; Mehrez, A.: Economic production lot size model with variable production rate and imperfect quality. J. Oper. Res. Soc. 45(12), 1405–1417 (1994)

Roul, J.; Maity, K.; Kar, S.; Maiti, M.: Multi-item reliability dependent imperfect production inventory optimal control models with dynamic demand under uncertain resource constraint. Int. J. Prod. Res. 53(16), 4993–5016 (2015)

Buzacott, J.A.; Ozkarahan, I.: One-and two-stage scheduling of two products with distributed inserted idle time: The benefits of a controllable production rate. Naval Res. Logist. Quart. 30(4), 675–696 (1983)

Ben-Daya, M.; Hariga, M.: Integrated single vendor single buyer model with stochastic demand and variable lead time. Int. J. Prod. Econ. 92(1), 75–80 (2004)

Hadley, G.W.; Whitten, T.T.M.: Analysis of inventory systems, p. 1963. Englewood Cliffs, (1963)

Jaber, M.Y.; Zanoni, S.; Zavanella, L.E.: Economic order quantity models for imperfect items with buy and repair options. Int. J. Prod. Econ. 155, 126–131 (2014)

Acknowledgements

The authors would like to acknowledge the support provided by the deanship of scientific research-KFUPM (project number SB191034).

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the deanship of scientific research at KFUPM, Grant SB191034.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

AlDurgam, M., Hanbali, A.A., Saeed, T. et al. An Integrated Two-Stage Inventory and Workforce Planning Model with Variable Production Rates. Arab J Sci Eng 48, 7127–7144 (2023). https://doi.org/10.1007/s13369-022-07458-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07458-1