Abstract

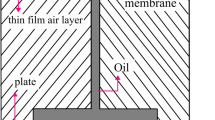

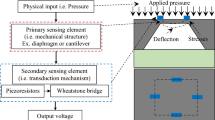

Due to the extreme importance of pressure measurement in various industrial applications, studying different types of failures possible in a pressure sensor seems to be very necessary. The presented research analyses thermally affected faults in a strain gauge type pressure sensor. The studied electro-mechanical sensor is composed of a thick plate and a very thin membrane in direct contact with the fluid whose pressure is being measured. The membrane is connected to the sensing plate via the incompressible interface fluid (silicone oil). The temperature difference between the membrane and the body of the sensor creates thermal stresses in the membrane. The equations governing the motion of the sensing plate and membrane in the presence of temperature differences have been presented and solved simultaneously. The occurrence of the buckling phenomenon is studied for the first and second deformation modes of the membrane. It has been shown that in the second deformation mode of the membrane, the existing coupling between the membrane and the plate vanishes which leads to the decrement of the equivalent stiffness of the structure. Therefore, the probability of the occurrence of the buckling phenomenon in the membrane increases significantly compared to the first deformation mode. The effect of geometrical parameters of the sensor on the measurable pressure range of the sensor is investigated in detail. The transient response of the sensor subjected to the dynamic pressure force is studied. The effect of nonlinear terms on the frequency response of the sensor has also been examined.

Similar content being viewed by others

References

Nayak, M.M.; Gunasekaran, N.; Rajanna, K.; Srinivasulu, S.; Mohan, S.: The strain gauge pressure transducers—an overview. IETE Tech Rev 9(2), 170–177 (1992)

Bakhoum, E.G.; Cheng, M.H.M.: Capacitive pressure sensor with very large dynamic range. IEEE Trans. Compon. Packag. Technol. 33(1), 79–83 (2010)

Yang, J.; Ye, Y.; Li, X.; Lü, Z.; Chen, R.: Flexible, conductive, and highly pressure-sensitive graphene-polyimide foam for pressure sensor application, composite. Sci. Technol. 164(18), 187–194 (2018)

Tandeske, D.: Pressure sensors: selection and application. Marcel Dekker, New York (1991)

Luo, S.; Yang, J.; Song, Z.; Zhou, X.; Yu, L.; Sun, T.; Yu, C.; Huang, D.; Du, C.; We, D.: Tunable-sensitivity flexible pressure sensor based on graphene transparent electrode. Solid-State Electron. 145, 29–33 (2018)

Lee, Y.; Wise, K.A.: Batch-fabricated silicon capacitive pressure transducer with low-temperature sensitivity. IEEE Trans. Electron Devices 29, 42–48 (1982)

Hierold, C.; Clasbrummel, B.; Behrend, D.; Scheiter, T.; Steger, M.; Oppermann, K.; Kapels, H.; Landgraf, E.; Wenzel, D.; Etzrodt, D.: Low power integrated pressure sensor system for medical applications. Sens. Actuators A Phys. 73, 58–67 (1999)

Palasagaram, J.N.; Ramadoss, R.: MEMS-capacitive pressure sensor fabricated using printed-circuit-processing techniques. IEEE Sens. J. 6, 1374–1375 (2006)

Van Der Heyden, F.; Blom, M.; Gardeniers, J.; Chmela, E.; Elwenspoek, M.; Tijssen, R.; Berg, A.V.D.: A low hydraulic capacitance pressure sensor for integration with a microviscosity detector. Sens. Actuators B Chem. 92, 102–109 (2003)

Xu, M.; Geiger, H.; Dakin, J.: Fiber grating pressure sensor with enhanced sensitivity using a glass-bubble housing. Electron. Lett. 32, 128 (1996)

Arkwright, J.W.; Underhill, I.D.; Maunder, S.A.; Jafari, A.; Cartwright, N.; Lemckert, C.: Fiber optic pressure sensing arrays for monitoring horizontal and vertical pressures generated by traveling water waves. IEEE Sens. J. 14, 2739–2742 (2014)

Xu, J.; Wang, X.; Cooper, K.L.; Wang, A.: Miniature all-silica fiber optic pressure and acoustic sensors. Opt. Lett. 30, 3269–3271 (2005)

Sabry, Y.M.; Khalil, D.; Bourouina, T.: Monolithic silicon-micromachined free-space optical interferometers on-chip. Laser Photonics Rev. 9, 1–24 (2015)

Zhang, D.; Wang, M.; Yang, Z.: Facile fabrication of graphene oxide/Nafion/indium oxide for humidity sensing with highly sensitive capacitance response. Sens. Actuators B Chem. 292, 187–195 (2019)

Zhang, S.; Zhang, L.; Wang, L.; Wang, F.; Pan, G.A.: Flexible e-skin based on micro-structured PZT thin films prepared via a low-temperature PLD method. J. Mater. Chem. 7, 4760–4769 (2019)

Akiyama, M.; Morofuji, Y.; Kamohara, T.; Nishikubo, K.; Tsubai, M.; Fukuda, O.; Ueno, N.: Flexible piezoelectric pressure sensors using oriented aluminum nitride thin films prepared on polyethylene terephthalate films. J. Appl. Phys. 100, 114318 (2006)

Toprak, A.; Tigli, O.: Piezoelectric energy harvesting: State-of-the-art and challenges. Appl. Phys. Rev. 1, 31104 (2014)

Wei, H.; Wang, H.; Xia, Y.; Cui, D.; Shi, Y.; Dong, M.; Liu, C.; Ding, T.; Zhan, J.-X.; Ma, Y., et al.: An overview of lead-free piezoelectric materials and devices. J. Mater. Chem. 6, 12446–12467 (2018)

Santosh Kumar, S.; Pant, B.D.: Design principles and considerations for the ‘ideal’ silicon piezoresistive pressure sensor: a focused review. Microsyst. Technol. 20, 1213–1247 (2014)

Tsai, H.H.; Hsieh, C.C.; Fan, C.W.; Chen, Y.C.; Wu, W.T.: Design and characterization of temperature-robust piezoresistive micropressure sensor with double wheatstone-bridge structure. Symposium on Design, Test, Integration & Packaging of MEMS/MOEMS, Rome, Italy (2009)

Burg, B.R.; Helbling, R.; Hierold, C.; Poulikakos, D.: Piezoresistive pressure sensors with parallel integration of individual single-walled carbon nanotube. J. Appl. Phys. 109(6), 064310 (2011)

Zhang, Y.H.; Yang, C.; Zhang, Z.H.; Hw, L.; Liu, L.T.; Ren, T.L.: A novel pressure microsensor with 30-μm-thick diaphragm and meander-shaped piezoresistors partially distributed on high stress bulk silicon region. IEEE Sens. J. 7(12), 1742–1748 (2007)

Chen, S.; Zhu, M.Q.; Ma, B.H.; Yuan, W. Z.: Design and optimization of micro piezoresistive pressure sensor. 2008 3rd IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Sanya, China (2008)

Song, P.; Ma, Z.; Ma, J.; Yang, L., et al.: Recent progress of miniature MEMS sensors. Micromachines 11, 56 (2020)

Ghanbari, M.; Hossainpour, S.; Rezazadeh, G.: On the modeling of a piezoelectrically actuated microsensor for measurement of micro-scale fluid physical properties. Appl. Phys. A 121(2), 651–663 (2015)

Rezazadeh, G.; Ghanbari, M.: On the mathematical modeling of a MEMS-based sensor for simultaneous measurement of fluids viscosity and density. Sens. Imaging (2018). https://doi.org/10.1007/s11220-018-0213-z

Ghanbari, M.; Rezazadeh, G.: An electrostatically actuated microsensor for determination of micropolar fluid physical properties. Meccanica (2020). https://doi.org/10.1007/s11012-020-01242-x

Ghanbari, M.; Rezazadeh, G.: A liquid-state high sensitive accelerometer based on a micro-scale liquid marble. Microsyst. Technol. 26, 617–623 (2020)

Paliwal, S.; Yenuganti, S.: Design and simulation of digital output MEMS pressure sensor. Arab. J. Sci. Eng. 45, 6661–6673 (2020)

Sathyanarayanan, S.; Juliet, A.V.: Modeling and Analyses of thin film PolySi diaphragm pressure sensor. Arab. J. Sci. Eng. 38, 679–683 (2013)

Chau, H.L.; Wise, K.D.: An ultraminiature solid-state pressure sensor for a cardiovascular catheter. IEEE Trans. Electron Devices 35, 2355 (1998)

Kalvesten, E.; Smith, L.; Tenerz, L.; Stemme, G.: The first surface micromachined pressure sensor for cardiovascular pressure measurements. In Proceedings of the Eleventh Annual International Workshop on Micro Electro Mechanical Systems, An Investigation of Micro Structures, Sensors, Actuators, Machines and Systems (Cat. No.98CH36176), Heidelberg, Germany, 25–29 January :574–579 (1998)

Allen, H.; Ramzan, K.; Withers, S.; Knutti, J.: A Novel Ultra-miniature catheter tip pressure sensor fabricated using silicon and glass thinning techniques. MRS Proc, 681 (2001)

Melvås, P.; Kälvesten, E.; Stemme, G.A.: temperature compensated dual beam pressure sensor. Sens. Actuators A Phys. 100, 46–53 (2002)

Melvås, P.; Kälvesten, E.; Enoksson, P.; Stemme G.: Miniaturized pressure sensor using a free hanging strain-gauge with leverage effect for increased sensitivity. In Transducers ’01 Eurosensors XV: The 11th International Conference on Solid-State Sensors and Actuators, 10–14 June 2001, Munich, Germany; Springer: Berlin/Heidelberg, Germany: 494–497 (2001)

Eswaran, P.; Malarvizhi, S.: Design analysis of MEMS capacitive differential pressure sensor for aircraft altimeter. Int. J. Appl. Phys. Math. 2, 14–20 (2012)

Eswaran, P.; Malarvizhi, S.: Simulation analysis of MEMS based capacitive differential pressure sensor for aircraft application. Adv. Mater. Res. 403, 4152–4156 (2011)

Chen, H.; Buric, M.; Ohodnicki, P.R.; Nakano, J.; Liu, B.; Chorpening, B.T.: Review and perspective: Sapphire optical fiber cladding development for harsh environment sensing. Appl. Phys. Rev. 5, 11102 (2018)

Corradetti, A.; Leoni, R.; Carluccio, R.; Fortunato, G.; Reita, C.; Plais, F.; Pribat, D.: Evidence of carrier number fluctuation as origin of 1/f noise in polycrystalline silicon thin film transistors. Appl. Phys. Lett. 67, 1730–1732 (1995)

DelRio, F.W.; Cook, R.F.; Boyce, B.L.: Fracture strength of micro- and nano-scale silicon components. Appl. Phys. Rev. 2, 021303 (2015)

Bhat, K.; Nayak, M.: MEMS pressure sensors-an overview of challenges in technology and packaging. Smart Struct. Syst. 2, 1–10 (2013)

Soltani, K.; Bushuev, O.Y.; Tugova, E.; Ghanbari, M.; Henry, M.P.; Rezazadeh, G.: Modelling Fluid Loss Faults in an Industrial Pressure Sensor, IEE Global Smart Industry Conference, Chelyabinsk, Russia (2020)

Lin, L.; Chu, H.C.; Lu, Y.W.: A simulation program for the sensitivity and linearity of piezoresistive pressure sensors. J. Microelectromech. Syst. 8(4), 514–522 (1999)

Rao, S.S.: Vibration of continuous systems, p. 14. Wiley, NY (2007)

Velzen, D.V.; Cardozo, R.L.; Langenkamp, H.: A liquid viscosity-temperature-chemical constitution relation for organic components. Ind. Eng. Chem. Fundam. 11(1), 20–25 (1972)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interests to declare.

Rights and permissions

About this article

Cite this article

Ghanbari, M., Rezazadeh, G. Investigating Static and Dynamic Behavior of the Strain Gauge Type Pressure Sensor in Exposure to Thermal Stresses. Arab J Sci Eng 47, 8931–8944 (2022). https://doi.org/10.1007/s13369-021-06443-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06443-4