Abstract

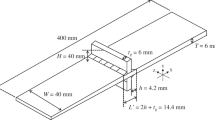

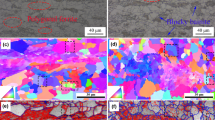

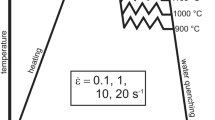

Structural elements of steel frame experience very high strain rates in the progressive collapse, and hence their constitutive properties do not remain constant but change significantly with time. Quasi-static and dynamic tensile tests of Q345 steel were performed to study the dynamic tensile behavior within the range of 0.001 to 330/s strain rates by INSTRON and Zwick/Roell HTM5020 testing machine. A three dimensional finite element model is developed using LS-DYNA to extrapolate the true stress-strain relationship after necking of Q345 steel. The hardening behavior of Q345 steel after the onset of necking is predicted with the Ludwik constitutive equation at quasi-static strain rates and with the Voce constitutive equation at higher strain rates, in which the strain hardening parameters are obtained by trial and error until the numerical results agree well with the experimental results. The linear combination of Hollomon and Voce (H/V-R) model is proved to be capable of predicting the transition of hardening rate with the increasing strain rate for Q345 steel although there is a little deviation between the experimental and fitting results. In this study, an empirical constitutive model is developed by introducing the Wagoner rate law into the H/V-R model to improve its precision in predicting the dynamic behavior of Q345 steel.

Similar content being viewed by others

References

Abed, F., and Makarem, F. (2012). “Comparisons of Constitutive Models for Steel over a Wide Range of Temperatures and Strain Rates.” J. Eng. Mater. Technol., 134(2), 021001.

Boyce, B. L., and Dilmore, M. F. (2009). “The dynamic tensile behavior of tough, ultrahigh-strength steels at strain-rates from 0.0002 s−1 to 200 s−1.” Int. J. Impact Eng., 36(2), pp. 263–271.

Bridgman, P. W. (1952). Studies in large plastic flow and fracture, McGraw-Hill, New York, U.S.

CEN (European Committee for Standardization). (2009). “Metallic materials-tensile testing-Part 1: method of test at ambient temperature.” EN ISO 6892-1, Brussels.

Chen, J. L., Peng, W. B., Ma, R. L., and He, M. J. (2012). “Strengthening of Horizontal Bracing on Progressive Collapse Resistance of Multistory Steel Moment Frame.” J. Perform. Constr. Facil., 10.1061/(ASCE)CF.1943-5509.0000261, 26(5), pp. 720–724

Choung, J., Nam, W., and Lee, J.Y. (2013). “Dynamic hardening behaviors of various marine structural steels considering dependencies on strain rate and temperature.” Mar. Struct., 32, pp. 49–67.

Cowper, G. R., and Symonds, P. S. (1957). Strain-hardening and strain-rate effects in the impact loading of cantilever beams. Brown University, Providence RI.

Dunand, M., and Mohr, D. (2010). “Hybrid experimentalnumerical analysis of basic ductile fracture experiments for sheet metals.” Int. J. Solids Struct., 47(9), pp. 1130–1143.

Hollomon, J. H. (1945). “Tensile deformation.” Trans. Metall. Soc. AIME., 162, pp. 268–290.

Huh, H., Lee, H. J., and Song, J. H. (2012). “Dynamic hardening equation of the auto-body steel sheet with the variation of temperature.” Int. J. Automot. Techn., 13(1), pp. 43–60.

ISO (The International Organization for Standardization). (2011). “Metallic material-tensile testing at high strain rates-part2: servo-hydraulic and other test systems.” ISO 26203-2, Switzerland.

Johnson, G. R., and Cook, W. H. (1983). “A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures.” Proc. 7th Int. Symp. on Ballistics, International Ballistics Committee, The Hague, Netherlands, 21, pp. 541–547.

Joun, M. S., Eom, J. G., and Lee, M. C. (2008). “A new method for acquiring true stress-strain curves over a large range of strains using a tensile test and finite element method.” Mech. Mater., 40(7), pp. 586–593.

Khan, A. S., and Liang, R. Q. (1999). “Behaviors of three BCC metal over a wide range of strain rates and temperatures: experiments and modeling.” Int. J. Plast., 15(10), pp. 1089–1109.

Khan, A. S., Baig, M., Choi, S. H., Yang, H. S., and Sun, X. (2012). “Quasi-static and dynamic responses of advanced high strength steels: experiments and modeling.” Int. J. Plast., 30-31, pp. 1–17.

Khandelwal, K., El-Tawil, S., and Sadek, F. (2009). “Progressive collapse analysis of seismically designed steel braced frames.” J. Constr. Steel Res., 65(3), pp. 699–708.

Kim, J. H., Kim, D., Han, H. N., Barlatc, F., and Lee, M. G. (2013). “Strain rate dependent tensile behavior of advanced high strength steels: Experiment and constitutive modeling.” Mat. Sci. Eng., 559, pp. 222–231.

Ludwik, P. (1909). Elemente der technologischen Mechanik. Springer Berlin Heidelberg, Berlin.

Sato, K., Yu, Q., Hiramoto, J., Urabe, T., and Yoshitake, A. (2015). “A method to investigate strain rate effects on necking and fracture behaviors of advanced high-strength steels using digital imaging strain analysis.” Int. J. Impact Eng., 75, pp. 11–26.

Sung, J. H., Kim, J. H., and Wagoner, R. H. (2010). “A plastic constitutive equation incorporating strain, strainrate, and temperature.” Int. J. Plast., 26(12), pp. 1746–1771.

Voce, E. (1948). “The relationship between stress and strain for homogeneous deformation.” J. Inst. Metals, 74, pp. 537–562.

Wagoner, R. H. (1981). “A new description of strain-rate sensitivity.” Scripta Metal., 15(10), pp. 1135–1137.

Wood, K. C., Schley, C. A., Williams, M., Beaumont, R., Rusinek, A., Mayer, U., and Pearce, A. (2009). “A method to calibrate a specimen with strain gauges to measure force over the full-force range in high rate testing.” Proc. 9th Int. Conf. on Mechanical and Physical Behavior of Materials under Dynamic Loading, EDP Sciences, Paris, FRA, pp. 265–273.

Yu, W., Zhao, J., and Shi, J. (2010). “Dynamic mechanical behaviour of Q345 steel at elevated temperatures: experimental study.” Mater. High Temp., 27(4), pp. 285–293.

Zhang, Z. L., Hauge, M., Ødegård, J., and Thaulow, C. (1999). “Determining material true stress-strain curve from tensile specimens with rectangular cross-section.” Int. J. Solids Struct., 36(23), pp. 3497–3516.

Zhu, J. E., Zeng, L., Ma, L. C, Xia, Y., Zhou, Q., Wang, X. S., Cao, G. X., Zhuang, H. Y., and Zhang, Y. H. (2013). “A Hybrid Experimental-numerical Converse Method for the Necking Behavior Study of High Strength Steel Sheets.” Proc. 16th Chn. Conf. of Automotive Safety Technology, Society of Automotive Engineers of China, Beijing, CHN, pp. 282–293.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, J., Shu, W. & Li, J. Constitutive model of Q345 steel at different intermediate strain rates. Int J Steel Struct 17, 127–137 (2017). https://doi.org/10.1007/s13296-016-0122-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13296-016-0122-8