Abstract

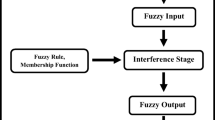

Cleaning of equipment is one of the major areas of concern in food industry. Image analysis technique was used to assess the cleaning effectiveness and optimize the CIP protocol for ohmic heating setup. Process parameters selected for optimization of cleaning were caustic concentration (1.0, 1.5, 2.0 and 2.5%), caustic temperature (70, 75, 80 and 85 °C), acid concentration (0.00, 0.25, 0.5 and 0.75%), and acid temperature (40, 50, 60 and 70 °C). Time for caustic treatment was varied from 5 to 20 min at an interval of 5 min, while time acid treatment was kept at a constant of 10 min. Taguchi orthogonal array design was used generate different combinations of acid and alkali concentration and temperature. Images of ohmic heating plates were taken before and after the cleaning procedure. MATLAB program was developed to analyze and extract Gray-Level Co-occurrence (GLCM) matrix properties from the image. Optimized combination was selected based on the highest value of desirability factor among all the experimental set of trials. Treatment with 1.5% caustic concentration at 70 °C for 5 min followed by 0.5% nitric acid concentration at 60 °C was found optimum effective CIP of the heating plates used in ohmic heating setup. GLCM properties correlation, cluster prominence, cluster shade, entropy, homogeneity and inverse difference moment normalized were found suitable for analysis of cleaning effectiveness and optimization of the CIP protocol.

Similar content being viewed by others

References

Albregtsen F (2008) Statistical texture measures computed from gray level coocurrence matrices. Image Processing Laboratory, Department of Informatics, University of Oslo, Oslo

Athreya S, Venkatesh YD (2012) Application of taguchi method for optimization of process parameters in improving the surface roughness of lathe facing operation. Int Reff J Eng Sci 1(3):13–19

Bansal B, Chen XD (2006) Effect of temperature and power frequency on milk fouling in an ohmic heater. Food Bioprod Process 84(4):286–291

Barish JA, Goddard JM (2013) Anti-fouling surface modified stainless steel for food processing. Food Bioprod Process 91:352–361

Eşme U (2009) Application of taguchi method for the optimization of resistance spot welding process. Arab J Sci Eng 34(2):519–521

Fryer PJ (2003) Electrical process heating. Encyclopaedia of food sciences and nutrition. Elsevier Science Ltd, Oxford, pp 3044–3049

Gebejes A, Huertas R (2013) Texture characterization based on grey-level co-occurrence matrix. In: Proceedings of the conference of informatics and management sciences, vol 2(1), pp 375–378

Gillham CR (1997) Enhanced cleaning of surfaces fouled by whey proteins. Ph.D. Thesis, University of Cambridge

Goshtasby AA (2012) Image registration, advances in computer vision and pattern recognition. Springer, London

Halleux DD, Piette G, Buteau ML, Dostie M (2005) Ohmic cooking of processed meats: energy evaluation and food safety considerations. Can Biosyst Eng 47(3):341–347

Kim HJ, Choi YM, Yang AAP, Yang TCS, Taub IA, Giles J, Ditusa C, Chall S, Zoltal P (1996) Microbiological and chemical investigation of ohmic heating of particulate foods using a 5 kW ohmic system. J Food Process Pres 20:41–58

Köhler H, Stoye H, Mauermann M, Weyrauch T, Majschak JP (2015) How to assess cleaning? Evaluating the cleaning performance of moving impinging jets. Food Bioprod Process 93:327–332

Kumari K, Mudgal VD, Viswasrao G, Srivastava H (2016) Studies on the effect of ohmic heating on oil recovery and quality of sesame seeds. J Food Sci Technol 53(4):2009–2016

Lanjewar PI, Minz PS (2015) Feasibility studies on ohmic heating of milk. M.Tech. Thesis, ICAR-National Dairy Research Institute, India

Manzoor MF, Zeng XA, Rahaman A, Siddeeg A, Aadil RM, Ahmed Z, Li J, Niu D (2019) Combined impact of pulsed electric field and ultrasound on bioactive compounds and FT-IR analysis of almond extract. J Food Sci Technol 56(5):2355–2364

Özkan N, Ho I, Farid M (2004) Combined ohmic and plate heating of hamburger patties: quality of cooked patties. J Food Eng 63:141–145

Parmar P, Singh AK, Meena GS, Borad S, Raju PN (2018) Application of ohmic heating for concentration of milk. J Food Sci Technol 55(12):4956–4963

Priyanka, Minz PS, Subramani P (2018) Study of heating pattern during heat treatment of milk by ohmic heating. J Pharmacogn Phytochem 7(2):3033–3036

Ran XL, Zhang M, Wang Y, Liu Y (2019) Vacuum radio frequency drying: a novel method to improve the main qualities of chicken powders. J Food Sci Technol 56(5):2355–2364

Sarkis JR, Mercali GD, Tessaro IC, Marczak LDF (2013) Evaluation of key parameters during construction and operation of an ohmic heating apparatus. Innov Food Sci Emerg Technol 18:145–154

Schöler M, Föste H, Helbig M, Gottwald A, Friedrichs J, Werner C, Augustin W, Scholl S, Majschak JP (2012) Local analysis of cleaning mechanisms in CIP processes. Food Bioprod Process 90(4):858–866

Shen L, Zhu Y, Wang L, Liu C, Liu C, Zheng X (2019) Improvement of cooking quality of germinated brown rice attributed to the fissures caused by microwave drying. J Food Sci Technol 56(5):2737–2749

Stancl J, Zitny R (2010) Milk fouling at direct ohmic heating. J Food Eng 99:437–444

Thamizhmanii S, Saparudin S, Hasan S (2007) Analyses of surface roughness by turning process using Taguchi method. J Ach Mater Manuf Eng 20:1–2

Vanga SK, Singh A, Raghavan V (2017) Review of conventional and novel food processing methods on food allergens. Crit Rev Food Sci Nutr 57(10):2077–2094

Varghese KS, Pandey MC, Radhakrishna K, Bawa AS (2014) Technology, applications and modelling of ohmic heating: a review. J Food Sci Technol 51(10):2304–2317

Wallhäuszer E, Hussein MA, Becker T (2012) Detection methods of fouling in heat exchangers in the food industry. Food Control 27:1–10

Acknowledgements

The authors acknowledge the Institute fellowship from ICAR-National Dairy Research Institute, Karnal, Haryana (India) after the course of research and special thanks to the workshop staff for fabrication of the setup.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rangi, P., Minz, P.S., Deshmukh, G.P. et al. Application of image analysis technique to determine cleaning of ohmic heating system for milk. J Food Sci Technol 56, 5405–5414 (2019). https://doi.org/10.1007/s13197-019-04011-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-04011-1