Abstract

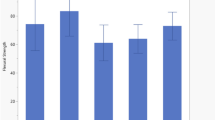

Aims and objective of the study was to evaluate the flow property of seven commercially available zinc oxide eugenol impression materials at various time intervals, after mixing 49 samples (seven groups) were fabricated for flow property of the material. The sample were fabricated as equal length of base and accelerator paste of the test materials was taken on the glass slab and mixed with a rigid stainless steel spatula as per manufacturers recommendation till the homogenous mix was obtained. The mix material was loaded in glass syringe and 0.5 ml material was injected on a cellophane sheet placed on marked glass plate. A cellophane sheet and glass plate 70 and 500 g weight was carefully placed on freshly dispensed zinc oxide eugenol impression paste sequentially. The diameter of the mix was noted after 30 s and 1 min of load application and also after the final set of material. The diameter gives the flow of material. The samples were stored at the room temperature. The data of the flow property was analyzed with analysis of variance, Post hoc test and t test. The flow of the zinc oxide eugenol impression paste after 30 s, 1 min and final set of load application for Group A to Group G was noted. Maximum flow was seen for Group G zinc oxide eugenol impression material followed by Group F, D, E, B, C and A in descending order respectively after 30 s, where as the flow property changed after 1 min in the sequence of maximum for Group G followed by Group E, D, B, A, C, and F. Lastly after final set of the impression material the flow maximum for Group G followed by Group E, D, C, F, A and B in descending order. Based on statistical analysis of the results and within in the limitations of this in-vitro study, the following conclusions were drawn that; the flow of zinc oxide eugenol impression material after 30 s, 1 min and that after the final set was maximum for P.S.P. (Group G) and the flow for PYREX (Group A) was minimum.

Similar content being viewed by others

References

Frank RP (1969) Analysis of pressure produced during maxillary edentulous impression procedure. J Prosthet Dent 22:400–412

Frank RP (1970) Controlling pressure during complete denture impressions. Dent Clinic North Am 14:453–469

Robert J (1957) Clark, Phillips R.W. Flow studies of certain dental impression materials. J Pros Dent 7:259–266

Reinitz R.J. From plaster to polyvinyls. A reviews of dental impression materials

Balthazar Y, Sandrik JL, Malone WFP, Mazur B, Hart T (1981) Accuracy and dimensional stability of four interocclusal recording materials. J Prosthet Dent 45:586–591

Michalakis KX, Pissiotis A, Anastasiadou V, Kapari D (2004) An experimental study on particular physical properties of several interocclusal recording media. J Prosthodont 13:42–46

Al-ahmar AO, Lynch CD, Locke M, Youngson CC (2008) Quality of master impressions and related materials for fabrication of complete dentures in the UK. J Oral Rehabil 35:111–115

Pratten DH, Novetsky M (1991) Detail reproduction of soft tissue. J Prosthet Dent 65:188–191

Koran A (1980) Impression procedure for recording the denture bearing mucosa. Dent Clinic North Am 24:97–111

Chai J, Dennis K, Leong Pang IC (1994) An investigation of the rhelogical properties of several interocclusal registration materials. J Prosthdont 3:134–137

Asgarzadeh K, Peyton FA (1954) Physical properties of the corrective impression paste. J Prosthet Dent 4:555–567

Myers GE, Peyton FA (1961) Physical properties of the zinc oxide eugenol impression pastes. J Dent Res 40:39–48

Tyas MJ, Wilson HJ (1970) Properties of zinc oxide eugenol impression pastes. Brit Dent J 129:461–465

Kumagai K, Tamiya N, Lwamoto K, Taniguchi Y, Takeda H, Kikuzuki K (1989) Factors affecting the setting time of zinc oxide eugenol impression materials-the influence of humidity and temperature to the reaction velocity. Nihon Hotetsu Shika Gakkai Zasshi 1:127–132

Gomes WL, Santos JF, Muench A (1990) Consistency of zinc oxide eugenol impression materials. Rev Odontol Univ Sao Paulo 3:197–199

American Dental Association (1964) No. 16 for dental impression paste-zinc oxide-eugenol type. Guide to dental material, 2nd edn. American Dental Association, Chicago

Acknowledgments

Authors would like to thanks to Late Dr. H. R. Dayaker, Ex Principal, Proffessor and Head of the Department, Department of Prosthodontics, Darshan Dental College and Hospital, Udaipur, Rajasthan. Its because of his constant support and motivation I was able to finish my dissertation work. Sir though you are no more between us but your words of guidance are still with me. Thanks for everything.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Katna, V., Suresh, S., Vivek, S. et al. To Study the Flow Property of Seven Commercially Available Zinc Oxide Eugenol Impression Material at Various Time Intervals After Mixing. J Indian Prosthodont Soc 14, 393–399 (2014). https://doi.org/10.1007/s13191-013-0338-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13191-013-0338-7