Abstract

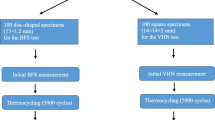

To evaluate the durability of machinable dental restorative materials, this study performed an experiment to evaluate the flexural strength and Weibull statistics of a machinable lithium disilicate glass–ceramic and a machinable composite resin after being thermocycled for certain cycles. A total of 40 bar-shape specimens of were prepared with the dimension of 20 mm × 4 mm × 2 mm, which were divided into four groups of 10 specimens. Ten specimens of machinable lithium disilicate glass–ceramic (IPS e.max CAD, Ivoclar Vivadent, Liechtenstein) and 10 specimens of machinable composite resin (Paradigm MZ 100, 3M ESPE, USA) were subjected to 3-point flexural strength test. Other 10 specimens of each material were thermocycled between water temperature of 5 and 55 °C for 10,000 cycles. After that, they were tested using 3-point flexural strength test. Statistical analysis was performed using two-way analysis of variance and Tukey multiple comparisons. Weibull analysis was performed to evaluate the reliability of the strength. Means of strength and their standard deviation were: thermocycled IPS e.max CAD 389.10 (50.75), non-thermocycled IPS e.max CAD 349.96 (38.34), thermocycled Paradigm MZ 100 157.51 (12.85), non-thermocycled Paradigm MZ 100 153.33 (19.97). Within each material group, there was no significant difference in flexural strength between thermocycled and non-thermocycled specimens. Considering the Weibull analysis, there was no statistical difference of Weibull modulus in all experimental groups. Within the limitation of this study, the results showed that there was no significant effect of themocycling on flexural strength and Weibull modulus of a machinable glass–ceramic and a machinable composite resin.

Similar content being viewed by others

References

Giordano RA (2006) Materials for chairside CAD/CAM-produced restorations. J Am Dent Assoc 137:14s–21s

Miyazaki T, Hotta Y, Kunii J, Kuriyama S, Tamaki Y (2009) A review of dental CAD/CAM: current status and future perspectives from 20 years of experience. Dent Mater J 28(1):44–56

Guess PC, Zavanelli RA, Silva NR, Bonfante EA, Coelho PG, Thompson VP (2010) Monolithic CAD/CAM lithium disilicate versus veneered Y-TZP crowns: comparison of failure modes and reliability after fatigue. Int J Prosthodont 23:434–442

Fasbinder DJ, Dennison JB, Heys D, Neiva G (2010) A clinical evaluation of chairside lithium disilicate CAD/CAM crowns: a two-year report. J Am Dent Assoc 141:10s–14s

Gonzaga CC, Yoshimura HN, Cesar PF, Miranda WG Jr (2009) Subcritical crack growth in porcelains, glass-ceramics, and glass-infiltrated alumina composite for dental restorations. J Mater Sci Mater Med 20(5):1017–1024

Guess PC, Schultheis S, Bonfante EA, Coelho PG, Ferencz JL, Silva NR (2011) All-ceramic systems: laboratory and clinical performance. Dent Clin North Am 55(2):333–352

Ornaghi BP, Meier MM, Rosa V, Cesar PF, Lohbauer U, Braga RR (2012) Subcritical crack growth and in vitro lifetime prediction of resin composites with different filler distributions. Dent Mater 28(9):985–995

Rusin RP (2001) Properties and applications of a new composite block for CAD/CAM. Compend Contin Educ Dent 22(6 Suppl):35–41

Tsitrou EA, Northeast SE, van Noort R (2007) Brittleness index of machinable dental materials and its relation to the marginal chipping factor. J Dent 35(12):897–902

Stawarczyk B, Egli R, Roos M, Ozcan M, Hämmerle CH (2011) The impact of in vitro aging on the mechanical and optical properties of indirect veneering composite resins. J Prosthet Dent 106(6):386–398

Yoshida K, Morimoto N, Tsuo Y, Atsuta M (2004) Flexural fatigue behavior of machinable and light-activated hybrid composites for esthetic restorations. J Biomed Mater Res B 70(2):218–222

Rodrigues SA Jr, Ferracane JL, Della Bona A (2008) Flexural strength and Weibull analysis of a microhybrid and a nanofill composite evaluated by 3- and 4-point bending tests. Dent Mater 24(3):426–431

(2008) International Standards Organization (ISO). Dentistry-Ceramic materials, Amendment; ISO 6872

Chang KT (1982) Analysis of the Weibull distribution function. J Appl Mech 49(2):450–451

Lamon J (1990) Ceramics reliability: statistical analysis of multiaxial failure using the Weibull approach and the multiaxial elemental strength model. J Am Ceram Soc 73(8):2204–2212

Wiedhahn K (2007) From blue to white: new high-strength material for Cerec–IPS e.max CAD LT. Int J Comput Dent 10(1):79–91

Giordano RA, McLaren EA (2010) Ceramics overview: classification by microstructure and processing methods. Compend Contin Educ Dent 31(9):682–684

Höland W, Schweiger M, Watzke R, Peschke A, Kappert H (2008) Ceramics as biomaterials for dental restoration. Expert Rev Med Devices 5(6):729–745

Attia A, Abdelaziz KM, Freitag S, Kern M (2006) Fracture load of composite resin and feldspathic all-ceramic CAD/CAM crowns. J Prosthet Dent 95(2):117–123

Kassem AS, Atta O, El-Mowafy O (2012) Fatigue resistance and microleakage of CAD/CAM ceramic and composite molar crowns. J Prosthodont 21(1):28–32

Hamakubo Y, Sawase T, Yoshida K, Kamada K, Taira Y, Atsuta M (2005) The physical properties of a machinable resin composite for esthetic restorations. Dent Mater J 24(1):24–29

Vásquez V, Ozcan M, Nishioka R, Souza R, Mesquita A, Pavanelli C (2008) Mechanical and thermal cycling effects on the flexural strength of glass ceramics fused to titanium. Dent Mater J 27(1):7–15

Kang SH, Chang J, Son HH (2013) Flexural strength and microstructure of two lithium disilicate glass ceramics for CAD/CAM restoration in the dental clinic. Restor Dent Endod 38(3):134–140

Jin J, Takahashi H, Iwasaki N (2004) Effect of test method on flexural strength of recent dental ceramics. Dent Mater J 23(4):490–496

Machado AL, Puckett AD, Breeding LC, Wady AF, Vergani CE (2012) Effect of thermocycling on the flexural and impact strength of urethane-based and high-impact denture base resins. Gerodontology 29(2):e318–e323

Stewardson DA, Shortall AC, Marquis PM (2010) The effect of clinically relevant thermocycling on flexural properties of endodontic post materials. J Dent 38:437–442

Tvergaard V, Hutchinson JW (1988) Microcracking in ceramics induced by thermal expansion or elastic anisotropy. J Am Ceram Soc 71(3):157–166

Souza RO, Ozcan M, Michida SM, de Melo RM, Pavanelli CA, Bottino MA, Soares LE, Martin AA (2010) Conversion degree of indirect resin composites and effect of thermocycling on their physical properties. J Prosthodont 19(3):218–225

Danzer R, Supancic P, Pascual J, Lube T (2007) Fracture statistics of ceramics—Weibull statistics and deviation from Weibull statistics. Eng Fract Mech 74:2919–2932

McCabe JF, Carrick T (1986) A statistical approach to the mechanical testing of dental materials. Dent Mater 2(4):139–142

Quinn JB, Quinn GD (2010) A practical and systematic review of Weibull statistics for reporting strengths of dental materials. Dent Mater 26(2):135–147

Acknowledgments

The Maxillofacial Prosthodontic Research Unit and The Dental Material Research Unit, Department of Prosthetic Dentistry, Faculty of Dentistry, Prince of Songkla University, supported this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peampring, C., Sanohkan, S. Effect of Thermocycling on Flexural Strength and Weibull Statistics of Machinable Glass–Ceramic and Composite Resin. J Indian Prosthodont Soc 14, 376–380 (2014). https://doi.org/10.1007/s13191-013-0335-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13191-013-0335-x