Abstract

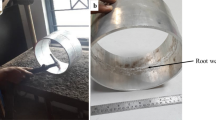

In this study, the friction-stir welding process was used to fabricate a 2-layer pipe consisting of AA5086 aluminum alloy and Cu12200 pipes. The welding was done with cylindrical and conical pin tool. The effect of rotational speed and linear velocity of the tool on the microstructure, macrostructure and mechanical properties of the joints was investigated. In this study, AA5086 aluminum alloy tube was placed upon the copper tube. Macro-studies have shown that at a rotational-travel speed ratio of 5–15 rev/mm using a conical pin tool and at a rotational-travel speed ratio of less than 10 rev/mm using a cylindrical pin tool, the tunnel defect was created in the weld cross section. The heat input is a more effective factor than the strain applied during the process, on the grain size of the stir zone. The cylindrical pin tool at rotational speed 600 rpm and travel speeds of 40 and 60 mm/min results in sound weld and a 2-layer Al/Cu pipe with monolithic interface. The effective bonding thickness and the distribution of copper particles and intermetallic compounds are important factors in achieving maximum joint strength.

Similar content being viewed by others

References

Chitkara N, Aleem A, Int J Mech Sci, 43 (2001) 2857.

Khosravifard A, Ebrahimi R, Mater Des, 31 (2010) 493.

Chen Z, Ikeda K, Murakami T, Takeda T, Xie J X, J Mater Process Technol, 137 (2003) 10.

Acarer M, Gülenç B, Findik F, Mater Des, 24 (2003) 659.

Sun X J, Jie T, Guo X Z, Trans Nonferrous Met Soc China, 21 (2011) 2175.

Bhanumurthy K, Fotedar R, Joyson D, Kale G, Pappachan A, Grover A, Krishnan J, Mater Sci Technol, 22 (2006) 321.

Zhang J, Fan Z, Wang Y, Zhou B, Mater Des, 21 (2000) 149.

Mohebbi M, Akbarzadeh A, J Mater Process Technol, 210 (2010) 510.

Wang X, Li P, Wang R, Int J Mach Tools Manuf, 45 (2005) 373.

Fan Z, Yu H, Li C, J Mater Process Technol, 229 (2016) 230.

Ding R J, Carter R W, in Google Patents (2001).

Packer S, Matsunaga M, in The Fourteenth International Offshore and Polar Engineering Conference, International Society of Offshore and Polar Engineers (2004).

Gercekcioglu E, Eren T, Yildizli K, Kahraman N, Salamci E, J Balkan Tribol Assoc, 12 (2006) 24.

Lammlein D, Gibson B, DeLapp D, Cox C, Strauss A, Cook G, Proc Inst Mech Eng Part B J Eng Manuf, 226 (2012) 383.

Jamshidi Aval H, Falahati Naghibi M, Sci Technol Weld Join, 22 (2017) 562.

Li W, Wen Q, Yang X, Wang Y, Gao D, Wang W, Mater Des, 134 (2017) 383.

Tavassolimanesh A, Nia A A, J Manuf Process, 30 (2017) 374.

Elrefaey A, Takahashi M, Ikeuchi K, Weld World, 49 (2005) 93.

Xue P, Xiao B L, Wang D, Ma Z, Sci Technol Weld Join, 16 (2011) 657.

Bisadi H, Tavakoli A, Sangsaraki M T, Sangsaraki K T, Mater Des, 43 (2013) 80.

Galvão I, Verdera D, Gesto D, Loureiro A, Rodrigues D, J Mater Process Technol, 213 (2013) 1920.

Zhang H, Liu H, Metallogr Microstruct Anal 1 (2012) 269.

Gaafer A, Mahmoud T, Mansour E, Mater Sci Eng A 527 (2010) 7424.

Humphreys F J, Prangnell P B, and Priestner R, Curr Opin Solid State Mater Sci 5 (2001) 15.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fallahati Naqibi, M., Elyasi, M., Jamshidi Aval, H. et al. Investigation of Friction-Stir Welding Parameters in the Fabrication of a 2-Layer Aluminum–Copper Pipe with Monolithic Interface. Trans Indian Inst Met 74, 285–300 (2021). https://doi.org/10.1007/s12666-020-02127-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02127-z