Abstract

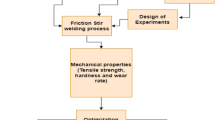

The advantages of friction stir welding (FSW) of aluminium alloys have promoted research in the area of FSW of aluminium. The recent developments in FSW are focused on optimisation of process parameters for multi-response characteristics. Experiments were conducted using the tool shoulder diameter, rotational speed, welding speed and the axial load as typical process parameters for multi-objective optimisation in FSW of AA 8011. The grey analysis was adopted to obtain grey relational grade for FSW process with multiple-characteristics, namely, tensile strength, microhardness and power consumption. Analysis of variance was used to study significance of process variables on grey relational grade which showed rotational speed and welding speed to be most significant parameters. Other than rotational speed and welding speed, tool shoulder diameter and axial load were also found to be significant. To validate the study, confirmation experiments were carried out at optimum set of parameters and predicted results were found to be in good agreement with experimental findings.

Similar content being viewed by others

References

Oosterkamp A, Oosterkamp L D, and Nordeide A, Weld J 83 (2004) 225.

Lee W B, Yeon Y M, and Jung S B, Mater Trans 45 (2004) 1700.

Rajakumar S, Muralidharan C, and Balasubramanian V, Mater Des 32 (2011) 2878.

Cavaliere P, Campanile G, Panella F, and Squillace A, J Mater Process Technol, 180 (2006) 263.

Lakshminarayanan A, and Balasubramanian V, Trans Nonferrous Met Soc China 18 (2008) 548.

Cavaliere P, Squillace A, and Panella F, J Mater Process Technol 200 (2008) 364.

Cavaliere P, Squillace A, Campanile G, and Panella F, J Mater Process Technol 108 (2006) 263.

Zhou L, Liu H J, and Liu Q W, Mater Des 31 (2010) 2631.

Karthikeyan L, and Senthil Kumar V S, Mater Des 32 (2011) 3085.

Elangovan K, and Balasubramanian V, Mater Sci Eng 459 (2007) 7.

Fujii H, Cui L, Maeda M, and Nogi K, Mater Sci Eng 419 (2006) 25.

Hirata T, Oguri T, Hagino H, Tanaka T, Chung S W, Takigawa Y, and Higashi K, Mater Sci Eng 456 (2007) 344.

Elangovan K, Balasubramanian V, and Babu S, Mater Des 30 (2009) 188.

Shanmuga Sundaram N, and Murugan N, Mater Des 31 (2010) 4184.

Okuyucu H, Kurt A, and Arcaklioglu E, Mater Des 28 (2007) 78.

Vijayan S, Raju R, and Rao S R, Mater Manuf Process 25 (2010) 1206.

Patel K M, Pandey P M, and Rao P V, Int J Adv Manuf Technol 47 (2010) 1137.

Deng J, Syst Control Lett 5 (1982) 288.

Caydas U, and Hascalik A, Opt Laser Technol 40 (2008) 987.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghetiya, N.D., Patel, K.M. & Kavar, A.J. Multi-objective Optimization of FSW Process Parameters of Aluminium Alloy Using Taguchi-Based Grey Relational Analysis. Trans Indian Inst Met 69, 917–923 (2016). https://doi.org/10.1007/s12666-015-0581-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0581-1