Abstract

Increasing energy demands are not only exploiting the fossil resources but, also depleting natural environment. Biofuels from lignocellulosic biomass is a renewable, ecofriendly, sustainable and could be a promising alternative to fossil fuels. However, pretreatment is an essential step to disarray the layers of lignocellulose prior to enzymatic hydrolysis. Among various pretreatments of lignocellulose, the biological pretreatment using microorganisms such as bacteria and fungi are gaining popularity due to its financial and environmental benefits. Careful selection of the suitable microbial consortium for efficient pretreatment of biomass is a critical step. The co-culture of bacteria and/or fungi in consolidated bioprocessing (CBP) is highly beneficial in the breakdown of complex biopolymers due to their high enzyme activity. Our selection of highly promising bacterial and/or fungal consortium has the ability to produce various extracellular enzymes including cellulase, hemicellulase, and lignases. It can be used in CBP for efficient biological pretreatment of lignocellulosic biomass following production of biofuels and bioproducts.

Similar content being viewed by others

References

Hamelinck, C.N., Van Hooijdonk, G., Faaij, A.: Ethanol from lignocellulosic biomass: techno-economic performance in short-, middle- and long-term. Biomass Bioenergy 28, 384–410 (2005). doi:10.1016/j.biombioe.2004.09.002

Millati, R., Syamsiah, S., Niklasson, C., Cahyanto, M.N., Ludquist, K., Taherzadeh, M.J.: Biological pretreatment of lignocelluloses with white-rot fungi and its applications: a review. BioResources 6, 5224–5259 (2011). doi:10.15376/BIORES.6.4.5224-5259

Horn, S., Vaaje-Kolstad, G., Westereng, B., Eijsink, V.G.: Novel enzymes for the degradation of cellulose. Biotechnol. Biofuels 5, 45 (2012). doi:10.1186/1754-6834-5-45

Zhang, Y.-H.P., Ding, S.-Y., Mielenz, J.R., Cui, J.-B., Elander, R.T., Laser, M., Himmel, M.E., McMillan, J.R., Lynd, L.R.: Fractionating recalcitrant lignocellulose at modest reaction conditions. Biotechnol. Bioeng. 97, 214–223 (2007). doi:10.1002/bit.21386

Zavrel, M., Bross, D., Funke, M., Büchs, J., Spiess, A.C.: High-throughput screening for ionic liquids dissolving (ligno-)cellulose. Bioresour. Technol. 100, 2580–2587 (2009). doi:10.1016/j.biortech.2008.11.052

Zhou, S., Ingram, L.O.: Synergistic hydrolysis of carboxymethyl cellulose and acid-swollen cellulose by two endoglucanases (CelZ and CelY) from Erwinia chrysanthemi. J. Bacteriol. 182, 5676–5682 (2000). doi:10.1128/JB.182.20.5676-5682.2000

Putro, J.N., Soetaredjo, F.E., Lin, S.-Y., Ju, Y.-H., Ismadji, S.: Pretreatment and conversion of lignocellulose biomass into valuable chemicals. RSC Adv. 6, 46834–46852 (2016). doi:10.1039/C6RA09851G

Jeffries, T.W.: Biodegradation of lignin and hemicelluloses. In: Biochemistry of Microbial Degradation, pp. 233–277. Springer, Dordrecht (1994)

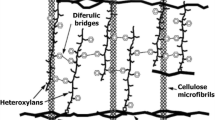

Chen, H.: Chemical composition and structure of natural lignocellulose. In: Biotechnology of Lignocellulose, pp. 25–71. Springer, Dordrecht (2014)

Sánchez, J., Cardona, C.A.: Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresour. Technol. 99, 5270–5295 (2008). doi:10.1016/j.biortech.2007.11.013

Larson, E.: Biofuel Production Technologies: Status, Prospects and Implications for Trade and Development. United Nations Conference on Trade and Development, Geneva (2008)

Saritha, M., Arora, A.: Biological pretreatment of lignocellulosic substrates for enhanced delignification and enzymatic digestibility. Indian J. Microbiol. 52, 122–130 (2012). doi:10.1007/s12088-011-0199-x

Kim, M., Day, D.F.: Composition of sugar cane, energy cane, and sweet sorghum suitable for ethanol production at Louisiana sugar mills. J. Ind. Microbiol. Biotechnol. 38, 803–807 (2011). doi:10.1007/s10295-010-0812-8

Sun, Y., Cheng, J.: Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour. Technol. 83, 1–11 (2002). doi:10.1016/S0960-8524(01)00212-7

Pérez, J., Muñoz-Dorado, J., de la Rubia, T., Martínez, J.: Biodegradation and biological treatments of cellulose, hemicellulose and lignin: an overview. Int. Microbiol. 5, 53–63 (2002). doi:10.1007/s10123-002-0062-3

Atalla, R.H., VanderHart, D.L.: Native cellulose: a composite of two distinct crystalline forms. Science. 223, 283–286 (1984)

VanderHart, D.L., Atalla, R.H.: Studies of microstructure in native celluloses using solid-state carbon-13 NMR. Macromolecules 17, 1465–1472 (1984). doi:10.1021/ma00138a009

O’Sullivan, A.C.: Cellulose: the structure slowly unravels. Cellulose 4, 173–207 (1997). doi:10.1023/A:1018431705579

Joy, J., Jose, C., Mathew, P. L., Thomas, S., Khalaf, M.N.: Biological delignification of biomass. In: Khalaf, M.N. (ed.) Green Polymers and Environmental Pollution Control, p. 271. CRC Press, Boca Raton (2016)

Saha, B.C.: Hemicellulose bioconversion. J. Ind. Microbiol. Biotechnol. 30, 279–291 (2003). doi:10.1007/s10295-003-0049-x

Zhang, Z., Donaldson, A.A., Ma, X.: Advancements and future directions in enzyme technology for biomass conversion. Biotechnol. Adv. 30, 913–919 (2012). doi:10.1016/j.biotechadv.2012.01.020

Lewis, N.G., Yamamoto, E.: Lignin: occurrence, biogenesis and biodegradation. Annu. Rev. Plant Biol. 41, 455–496 (1990). doi:10.1146/annurev.pp.41.060190.002323

Cesarino, I., Araújo, P., Domingues Júnior, A.P., Mazzafera, P.: An overview of lignin metabolism and its effect on biomass recalcitrance. Braz. J. Bot. 35, 303–311 (2012). doi:10.1590/S0100-84042012000400003

Mussatto, S.I.: Biomass Fractionation Technologies for a Lignocellulosic Feedstock Based Biorefinery. Elsevier, Amsterdam (2016)

Singh Nigam, P., Singh, A.: Production of liquid biofuels from renewable resources. Prog. Energy Combust. Sci. 37, 52–68 (2011). doi:10.1016/j.pecs.2010.01.003

Renewable Fuels Association (RFA): Fueling a High Octane Future: 2016 Ethanol Industry Outlook. Renewable Fuels Association (RFA), Washington, D.C. (2016)

Gao, J., Zhang, A., Lam, S.K., Zhang, X., Thomson, A.M., Lin, E., Jiang, K., Clarke, L.E., Edmonds, J.A., Kyle, P.G., Yu, S., Zhou, Y., Zhou, S.: An integrated assessment of the potential of agricultural and forestry residues for energy production in China. GCB Bioenergy 8, 880–893 (2016). doi:10.1111/gcbb.12305

Demirbas, A.: Use of algae as biofuel sources. Energy Convers. Manag. 51, 2738–2749 (2010). doi:10.1016/j.enconman.2010.06.010

Mosier, N., Wyman, C., Dale, B., Elander, R., Lee, Y.Y., Holtzapple, M., Ladisch, M.: Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour. Technol. 96, 673–686 (2005). doi:10.1016/j.biortech.2004.06.025

Wan, C., Li, Y.: Fungal pretreatment of lignocellulosic biomass. Biotechnol. Adv. 30, 1447–1457 (2012). doi:10.1016/j.biotechadv.2012.03.003

Shi, J., Qing, Q., Zhang, T., Wyman, C., Lloyd, T.: Biofuels from cellulosic biomass via aqueous processing. In: Ginley, D.S., Cahen, D. (eds.) Fundamentals of Materials for Energy and Environmental Sustainability. Cambridge University Press, Cambridge (2011)

Harmsen, P.F.H., Huijgen, W.J.J., Bermúdez López, L.M., Bakker, R.: Literature review of physical and chemical pretreatment processes for lignocellulosic biomass. Energy Res. Cent. Netherlands. 10–13 (2010)

Taherzadeh, M.J., Karimi, K.: Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: a review. Int. J. Mol. Sci. 9, 1621–1651 (2008). doi:10.3390/ijms9091621

Conde-Mejía, C., Jiménez-Gutiérrez, A., El-Halwagi, M.: A comparison of pretreatment methods for bioethanol production from lignocellulosic materials. Process Saf. Environ. Prot. 90, 189–202 (2012). doi:10.1016/j.psep.2011.08.004

Maurya, D.P., Singla, A., Negi, S.: An overview of key pretreatment processes for biological conversion of lignocellulosic biomass to bioethanol. 3 Biotech 5, 597–609 (2015). doi:10.1007/s13205-015-0279-4

Singh, R., Shukla, A., Tiwari, S., Srivastava, M.: A review on delignification of lignocellulosic biomass for enhancement of ethanol production potential. Renew. Sustain. Energy Rev. 32, 713–728 (2014). doi:10.1016/j.rser.2014.01.051

Kim, Y., Kreke, T., Mosier, N.S., Ladisch, M.R.: Severity factor coefficients for subcritical liquid hot water pretreatment of hardwood chips. Biotechnol. Bioeng. 111, 254–263 (2014). doi:10.1002/bit.25009

Bensah, E.C., Mensah, M.: Chemical pretreatment methods for the production of cellulosic ethanol: technologies and innovations. Int. J. Chem. Eng. 2013, 1–21 (2013). doi:10.1155/2013/719607

Reguera, G., Speers, A., Young, J.: Microbial electrochemical cells and methods for producing electricity and bioproducts therein. US Patent 14/705,766, 20 Aug 2015

Zhao, X.-Q., Zi, L.-H., Bai, F.-W., Lin, H.-L., Hao, X.-M., Yue, G.-J., Ho, N.W.Y.: Bioethanol from lignocellulosic biomass. In: Biotechnology in China III: Biofuels and Bioenergy, pp. 25–51. Springer, Berlin (2011)

Faik, A.: Plant cell wall structure-pretreatment the critical relationship in biomass conversion to fermentable sugars. In: Green Biomass Pretreatment for Biofuels Production. pp. 1–30. Springer, Dordrecht (2013)

Mandels, M., Reese, E.T.: Induction of cellulase in fungi by cellobiose. J. Bacteriol. 79, 816–826 (1960)

Biswas, R., Persad, A., Bisaria, V.: Production of cellulolytic enzymes. In: Bisaria, V.S., Kondo, A. (eds.) Bioprocessing of Renewable Resources to Commodity Bioproducts. pp. 105–132. Wiley, Hoboken (2014)

Narasimha, G., Sridevi, A., Viswanath, B., Chandra, S., Reddy, R.: Nutrient effects on production of cellulolytic enzymes by Aspergillus niger. African J. Biotechnol. 5, 472 (2006)

Valaskova, V., Baldrian, P.: Degradation of cellulose and hemicelluloses by the brown rot fungus Piptoporus betulinus—production of extracellular enzymes and characterization of the major cellulases. Microbiology 152, 3613–3622 (2006). doi:10.1099/mic.0.29149-0

Hatakka, A., Hammel, K.E.: Fungal biodegradation of lignocelluloses. In: Industrial Applications, pp. 319–340. Springer, Berlin (2011)

Hespell, R.: Microbial digestion of hemicelluloses in the rumen. Mol. Microbiol. 5, 362–365 (1988)

López-Mondéjar, R., Zühlke, D., Becher, D., Riedel, K., Baldrian, P.: Cellulose and hemicellulose decomposition by forest soil bacteria proceeds by the action of structurally variable enzymatic systems. Sci. Rep. 6, 25279 (2016). doi:10.1038/srep25279

Weingartner Montibeller, V., Porto de Souza Vandenberghe, L., Amore, A., Soccol, C.R., Birolo, L., Vinciguerra, R., Salmon, Xavier, Rigon, D.N., Spier, M., Faraco, V.: Characterization of hemicellulolytic enzymes produced by Aspergillus niger NRRL 328 under solid state fermentation on soybean husks. BioResources 9, 7128–7140 (2014). doi:10.15376/biores.9.4.7128-7140

Gessesse, A., Mamo, G.: High-level xylanase production by an alkaliphilic Bacillus sp. by using solid-state fermentation. Enzyme Microb. Technol. 25, 68–72 (1999)

Zorec, M., Vodovnik, M., Marinšek-Logar, R.: Potential of selected rumen bacteria for cellulose and hemicellulose degradation. Food Technol. Biotechnol. 52, 210–221 (2014)

Dehority, B.: Degradation and utilization of isolated hemicellulose by pure cultures of cellulolytic rumen bacteria. J. Bacteriol. 89, 1515–1520 (1965)

Tangnu, S.K., Blanch, H.W., Wilke, C.R.: Enhanced production of cellulase, hemicellulase, and β-glucosidase by Trichoderma reesei (Rut C-30). Biotechnol. Bioeng. 23, 1837–1849 (1981). doi:10.1002/bit.260230811

Béguin, P., Aubert, J.-P.: The biological degradation of cellulose. FEMS Microbiol. Rev. 13, 25–58 (1994). doi:10.1111/j.1574-6976.1994.tb00033.x

Nidetzky, B., Steiner, W., Claeyssens, M.: Synergistic interaction of cellulases from Trichoderma reesei during cellulose degradation. In: Enzymatic Degradation of Insoluble Carbohydrates, pp. 90–112. American Chemical Society, Washington, D.C. (1996)

Lang, E., Eller, G., Zadrazil, F.: Lignocellulose decomposition and production of ligninolytic enzymes during interaction of white rot fungi with soil microorganisms. Microb. Ecol. 34, 1–10 (1997). doi:10.1007/s002489900029

Naraian, R., Singh, D., Verma, A., Garg, S.K.: Studies on in vitro degradability of mixed crude enzyme extracts produced from Pleurotus spp. J. Environ. Biol. 31, 945–951 (2010)

Kameshwar, A.K.S., Qin, W.: Recent developments in using advanced sequencing technologies for the genomic studies of lignin and cellulose degrading microorganisms. Int. J. Biol. Sci. 12, 156–171 (2016). doi:10.7150/ijbs.13537

Maki, M., Leung, K.T., Qin, W.: The prospects of cellulase-producing bacteria for the bioconversion of lignocellulosic biomass. Int. J. Biol. Sci. 5, 500–516 (2009). doi:10.7150/ijbs.5.500

Miron, J., Ben-Ghedalia, D., Morrison, M.: Invited review: adhesion mechanisms of rumen cellulolytic bacteria. J. Dairy Sci. 84, 1294–1309 (2001). doi:10.3168/jds.S0022-0302(01)70159-2

Duff, S.J.B., Murray, W.D.: Bioconversion of forest products industry waste cellulosics to fuel ethanol: a review. Bioresour. Technol. 55, 1–33 (1996). doi:10.1016/0960-8524(95)00122-0

Dien, B.S., Cotta, M.A., Jeffries, T.W.: Bacteria engineered for fuel ethanol production: current status. Appl. Microbiol. Biotechnol. 63, 258–266 (2003). doi:10.1007/s00253-003-1444-y

Paudel, Y.P., Qin, W.: Characterization of ovel ellulase-producing bacteria isolated from rotting wood samples. Appl. Biochem. Biotechnol. 177, 1186–1198 (2015). doi:10.1007/s12010-015-1806-9

Bandounas, L., Wierckx, N.J., de Winde, J.H., Ruijssenaars, H.J.: Isolation and characterization of novel bacterial strains exhibiting ligninolytic potential. BMC Biotechnol. 11, 94 (2011). doi:10.1186/1472-6750-11-94

Palamuru, S., Dellas, N., Pearce, S.L., Warden, A.C., Oakeshott, J.G., Pandey, G.: Phylogenetic and kinetic characterization of a suite of dehydrogenases from a newly isolated bacterium, strain SG61-1L, that catalyze the turnover of guaiacylglycerol-β-guaiacyl ether stereoisomers. Appl. Environ. Microbiol. 81, 8164–8176 (2015). doi:10.1128/AEM.01573-15

De Gonzalo, G., Colpa, D.I., Habib, M.H.M., Fraaije, M.W.: Bacterial enzymes involved in lignin degradation. J. Biotechnol. 236, 110–119 (2016). doi:10.1016/j.jbiotec.2016.08.011

van Bloois, E., Torres Pazmiño, D.E., Winter, R.T., Fraaije, M.W.: A robust and extracellular heme-containing peroxidase from Thermobifida fusca as prototype of a bacterial peroxidase superfamily. Appl. Microbiol. Biotechnol. 86, 1419–1430 (2010). doi:10.1007/s00253-009-2369-x

Chandra, R., Chowdhary, P.: Properties of bacterial laccases and their application in bioremediation of industrial wastes. Environ. Sci. Process. Impacts 17, 326–342 (2015). doi:10.1039/C4EM00627E

Picart, P., de María, P.D., Schallmey, A.: From gene to biorefinery: microbial β-etherases as promising biocatalysts for lignin valorization. Front. Microbiol. 6, 916 (2015). doi:10.3389/fmicb.2015.00916

Sukumaran, R.K., Singhania, R.R., Pandey, A.: Microbial cellulases—production, applications and challenges. J. Sci. Ind. Res. 64, 832–844 (2005)

Ljungdahl, L.G.: The cellulase/hemicellulase system of the anaerobic fungus Orpinomyces PC-2 and aspects of its applied use. Ann. N. Y. Acad. Sci. 1125, 308–321 (2008). doi:10.1196/annals.1419.030

Arantes, V., Maria, A., Milagres, F.: The synergistic action of ligninolytic enzymes (MnP and laccase) and Fe3+ -reducing activity from white-rot fungi for degradation of Azure B. Enzyme Microb. Technol. 42, 17–22 (2007). doi:10.1016/j.enzmictec.2007.07.017

Shary, S., Kapich, A.N., Panisko, E.A., Magnuson, J.K., Cullen, D., Hammel, K.E.: Differential expression in Phanerochaete chrysosporium of membrane-associated proteins relevant to lignin degradation. Appl. Environ. Microbiol. 74, 7252–7257 (2008). doi:10.1128/AEM.01997-08

Dashtban, M., Schraft, H., Qin, W.: Fungal bioconversion of lignocellulosic residues; opportunities & perspectives. Int. J. Biol. Sci. 5, 578–595 (2009). doi:10.7150/ijbs.5.578

Paudel, Y.P., Qin, W.: Two bacillus species isolated from rotting wood samples are good candidates for the production of bioethanol using agave biomass. J. Microb. Biochem. Technol. 7, 218–225 (2015). doi:10.4172/1948-5948.1000210

Guillén, F., Martínez, M.J., Gutiérrez, A., Del Rio, J.C., Camarero, S., Ferreira, P., Ruiz-Dueñas, F.J., Speranza, M., Martínez, Á.T.: Biodegradation of lignocellu- losics: microbial, chemical, and enzymatic aspects of the fungal attack of lignin. Int. Microbiol. 8, 195–204 (2005)

Otjen, L., Blanchette, R., Effland, M., Leatham, G.: Assessment of 30 white rot basidiomycetes for selective lignin degradation. Holzforschung 41, 343–349 (1987). doi:10.1515/hfsg.1987.41.6.343

Sun, J., Ding, S.-Y., Doran-Peterson, J.: Biomass and its biorefinery: novel approaches from nature-inspired strategies and technology. In: Biological Converstion of Biomass for Fuels and Chemicals: Exploration from Natural Utilization System, pp. 1–13. Royal Society of Chemistry, Cambridge (2014)

Pathma, J., Sakthivel, N.: Microbial diversity of vermicompost bacteria that exhibit useful agricultural traits and waste management potential. Springerplus 1, 26 (2012). doi:10.1186/2193-1801-1-26

Zhang, B., Li, G., Shen, T., Wang, J., Sun, Z.: Changes in microbial biomass C, N, and P and enzyme activities in soil incubated with the earthworms Metaphire guillelmi or Eisenia fetida. Soil Biol. Biochem. 32, 2055–2062 (2000). doi:10.1016/S0038-0717(00)00111-5

Vivas, A., Moreno, B., Garcia-Rodriguez, S., Benítez, E.: Assessing the impact of composting and vermicomposting on bacterial community size and structure, and microbial functional diversity of an olive-mill waste. Bioresour. Technol. 100, 1319–1326 (2009)

Siti Norfariha, M.N., Siti, A.I., Nur Farehah, Z.A., Renuka, R., Norli, I.: Second generation bioethanol from lignocellulosic biomass using worm tea as pretreatment. In: International Proceedings of Chemical, Biological and Environmental Engineering (IPCBEE), pp. 1–5. International Association of Computer Science and Information Technology Press (IACSIT), Singapore (2013)

Russell, J.B., Muck, R.E., Weimer, P.J.: Quantitative analysis of cellulose degradation and growth of cellulolytic bacteria in the rumen. FEMS Microbiol. Ecol. 67, 183–197 (2009). doi:10.1111/j.1574-6941.2008.00633.x

Fondevila, M., Dehority, B.A.: Degradation and utilization of forage hemicellulose by rumen bacteria, singly in coculture or added sequentially. J. Appl. Bacteriol. 77, 541–548 (1994). doi:10.1111/j.1365-2672.1994.tb04399.x

Weimer, P.J., Nerdahl, M., Brandl, D.J.: Production of medium-chain volatile fatty acids by mixed ruminal microorganisms is enhanced by ethanol in co-culture with Clostridium kluyveri. Bioresour. Technol. 175, 97–101 (2015). doi:10.1016/j.biortech.2014.10.054

Henrissat, B., Davies, G.: Structural and sequence-based classification of glycoside hydrolases. Curr. Opin. Struct. Biol. 7, 637–644 (1997). doi:10.1016/S0959-440X(97)80072-3

Dashtban, M., Maki, M., Leung, K.T., Mao, C., Qin, W.: Cellulase activities in biomass conversion: measurement methods and comparison. Crit. Rev. Biotechnol. 30, 302–309 (2010). doi:10.3109/07388551.2010.490938

Sweeney, M.D., Xu, F.: Biomass converting enzymes as industrial biocatalysts for fuels and chemicals: recent developments. Catalysts 2, 244–263 (2012). doi:10.3390/catal2020244

Plácido, J., Capareda, S.: Ligninolytic enzymes: a biotechnological alternative for bioethanol production. Bioresour. Bioprocess. 2, 23 (2015). doi:10.1186/s40643-015-0049-5

nee’Nigam, P.S., Gupta, N., Anthwal, A.: Pre-treatment of agro-industrial residues. In: Biotechnology for Agro-Industrial Residues Utilisation, pp. 13–33. Springer, Dordrecht (2009)

Niladevi, K.N.: Ligninolytic enzymes. In: Biotechnology for Agro-Industrial Residues Utilisation, pp. 397–414. Springer, Dordrecht (2009)

Bugg, T.D., Ahmad, M., Hardiman, E.M., Singh, R.: The emerging role for bacteria in lignin degradation and bio-product formation. Curr. Opin. Biotechnol. 22, 394–400 (2011). doi:10.1016/j.copbio.2010.10.009

Vaaje-Kolstad, G., Westereng, B., Horn, S.J., Liu, Z., Zhai, H., Sørlie, M., Eijsink, V.G.H.: An oxidative enzyme boosting the enzymatic conversion of recalcitrant polysaccharides. Science 80, 330 (2010)

Hemsworth, G.R., Taylor, E.J., Kim, R.Q., Gregory, R.C., Lewis, S.J., Turkenburg, J.P., Parkin, A., Davies, G.J., Walton, P.H.: The copper active site of CBM33 polysaccharide oxygenases. J. Am. Chem. Soc. 135, 6069–6077 (2013). doi:10.1021/ja402106e

Aachmann, F.L., Sørlie, M., Skjåk-Bræk, G., Eijsink, V.G.H., Vaaje-Kolstad, G.: NMR structure of a lytic polysaccharide monooxygenase provides insight into copper binding, protein dynamics, and substrate interactions. Proc. Natl. Acad. Sci. USA 109, 18779–18784 (2012). doi:10.1073/pnas.1208822109

Villares, A., Moreau, C., Bennati-Granier, C., Garajova, S., Foucat, L., Falourd, X., Saake, B., Berrin, J.-G., Cathala, B.: Lytic polysaccharide monooxygenases disrupt the cellulose fibers structure. Sci. Rep. 7, 40262 (2017). doi:10.1038/srep40262

Levasseur, A., Drula, E., Lombard, V., Coutinho, P.M., Henrissat, B.: Expansion of the enzymatic repertoire of the CAZy database to integrate auxiliary redox enzymes. Biotechnol. Biofuels 6, 41 (2013). doi:10.1186/1754-6834-6-41

Eibinger, M., Ganner, T., Bubner, P., Rošker, S., Kracher, D., Haltrich, D., Ludwig, R., Plank, H., Nidetzky, B.: Cellulose surface degradation by a lytic polysaccharide monooxygenase and its effect on cellulase hydrolytic efficiency. J. Biol. Chem. 289, 35929–35938 (2014). doi:10.1074/jbc.M114.602227

Patel, I., Kracher, D., Ma, S., Garajova, S., Haon, M., Faulds, C., Berrin, J., Ludwig, R., Record, E.: Salt-responsive lytic polysaccharide monooxygenases from the mangrove fungus Pestalotiopsis sp. NCi6. Biotechnol. Biofuels 9, 108 (2016)

Dix, N.J., Webster, J.: Fungi of extreme environments. In: Fungal Ecology, pp. 322–340. Springer, Dordrecht (1995)

Sindhu, R., Binod, P., Pandey, A.: Biological pretreatment of lignocellulosic biomass—an overview. Bioresour. Technol. 199, 76–82 (2016). doi:10.1016/j.biortech.2015.08.030

Raimbault, M.: General and microbiological aspects of solid substrate fermentation. Electron. J. Biotechnol. 1, 26–27 (1998). doi:10.4067/s0717-34581998000300007

Raghavarao, K.S.M.., Ranganathan, T., Karanth, N.: Some engineering aspects of solid-state fermentation. Biochem. Eng. J. 13, 127–135 (2003). doi:10.1016/S1369-703X(02)00125-0

Meehnian, H., Jana, A.K., Jana, M.M.: Effect of particle size, moisture content, and supplements on selective pretreatment of cotton stalks by Daedalea flavida and enzymatic saccharification. 3 Biotech 6, 235 (2016). doi:10.1007/s13205-016-0548-x

Saha, B.C., Kennedy, G.J., Qureshi, N., Cotta, M.A.: Biological pretreatment of corn stover with Phlebia brevispora NRRL-13108 for enhanced enzymatic hydrolysis and efficient ethanol production. Biotechnol. Prog. 33, 365–374 (2017). doi:10.1002/btpr.2420

Zhong, W., Yu, H., Song, L., Zhang, X.: Combined pretreatment with white-rot fungus and alkali at near room-temperature for improving saccharification of corn stalks. BioResources 6, 3440–3451 (2011). doi:10.2307/302397

Liong, Y.Y., Halis, R., Lai, O.M., Mohamed, R.: Conversion of lignocellulosic biomass from grass to bioethanol using materials pretreated with alkali and the white rot fungus Phanerochaete chrysosporium. BioResources 7, 5500–5513 (2012). doi:10.15376/biores.7.4.5500-5513

Bhargav, S., Panda, B., Ali, M., Javed, S.: Solid-state fermentation: an overview. Chem. Biochem. Eng. Q. 22, 49–70 (2008)

Marra, L.M., de Oliveira-Longatti, S.M., Soares, C.R., de Lima, J.M., Olivares, F.L., Moreira, F.: Initial pH of medium affects organic acids production but do not affect phosphate solubilization. Braz. J. Microbiol. 46, 367–375 (2015). doi:10.1590/S1517-838246246220131102

Reid, I.D.: Solid-state fermentations for biological delignification. Enzyme Microb. Technol. 11, 786–803 (1989). doi:10.1016/0141-0229(89)90052-5

Agosin, E., Odier, E.: Solid-state fermentation, lignin degradation and resulting digestibility of wheat straw fermented by selected white-rot fungi. Appl. Microbiol. Biotechnol. 21, 397–403 (1985). doi:10.1007/BF00249988

Geiger, G., Brandl, H., Furrer, G., Schulin, R.: The effect of copper on the activity of cellulase and β-glucosidase in the presence of montmorillonite or Al-montmorillonite. Soil Biol. Biochem. 30, 1537–1544 (1998)

Himmel, M.E., Ding, S.-Y., Johnson, D.K., Adney, W.S., Nimlos, M.R., Brady, J.W., Foust, T.D.: Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 315, 804–807 (2007). doi:10.1126/science.1137016

Pu, Y., Hu, F., Huang, F., Davison, B.H., Ragauskas, A.J., Huang, C., Sherman, D., Tucker, M., Sun, L., Çetinkol, Ö., Dixon, R., Wang, Z.-Y., Templer, R., Tschaplinski, T.: Assessing the molecular structure basis for biomass recalcitrance during dilute acid and hydrothermal pretreatments. Biotechnol. Biofuels 6, 15 (2013). doi:10.1186/1754-6834-6-15

Kondo, T., Sawatari, C., Manley, R.S.J., Gray, D.G.: Characterization of hydrogen bonding in cellulose-synthetic polymer blend systems with regioselectively substituted methylcellulose. Macromolecules 27, 210–215 (1994). doi:10.1021/ma00079a031

Mansfield, S., Mooney, C., Saddler, J.: Substrate and enzyme characteristics that limit cellulose hydrolysis. Biotechnol. Prog. 15, 804–816 (1999). doi:10.1021/bp9900864

Rahikainen, J.: Cellulase-lignin interactions in the enzymatic hydrolysis of lignocellulose. (2013)

Narayanaswamy, N., Dheeran, P., Verma, S., Kumar, S.: Biological pretreatment of lignocellulosic biomass for enzymatic saccharification. In: Fang, Z. (ed.) Pretreatment Techniques for Biofuels and Biorefineries, pp. 3–34. Springer, Berlin (2013)

Brenner, K., You, L., Arnold, F.H.: Engineering microbial consortia: a new frontier in synthetic biology. Trends Biotechnol. 26, 483–489 (2008). doi:10.1016/j.tibtech.2008.05.004

Chandra, R., Raj, A., Purohit, H., Kapley, A.: Characterisation and optimisation of three potential aerobic bacterial strains for kraft lignin degradation from pulp paper waste. Chemosphere 67, 839–846 (2007). doi:10.1016/j.chemosphere.2006.10.011

Kato, S., Haruta, S., Cui, Z.J., Ishii, M., Igarashi, Y.: Effective cellulose degradation by a mixed-culture system composed of a cellulolytic Clostridium and aerobic non-cellulolytic bacteria. FEMS Microbiol. Ecol. 51, 133–142 (2004). doi:10.1016/j.femsec.2004.07.015

Kato, S., Haruta, S., Cui, Z.J., Ishii, M., Igarashi, Y.: Stable coexistence of five bacterial strains as a cellulose-degrading community. Appl. Environ. Microbiol. 71, 7099–7106 (2005). doi:10.1128/AEM.71.11.7099-7106.2005

Kato, S., Haruta, S., Cui, Z.J., Ishii, M., Igarashi, Y.: Network relationships of bacteria in a stable mixed culture. Microb. Ecol. 56, 403–411 (2008). doi:10.1007/s00248-007-9357-4

Salimi, F., Mahadevan, R.: Characterizing metabolic interactions in a clostridial co-culture for consolidated bioprocessing. BMC Biotechnol. 13, 95 (2013). doi:10.1186/1472-6750-13-95

Wen, Z., Liao, W., Chen, S.: Production of cellulase/β-glucosidase by the mixed fungi culture Trichoderma reesei and Aspergillus phoenicis on dairy manure. Process Biochem. 40, 3087–3094 (2005). doi:10.1016/j.procbio.2005.03.044

Madamwar, D., Patel, S.: Formation of cellulases by co-culturing of Trichoderma reesei and Aspergillus niger on cellulosic waste. World J. Microbiol. Biotechnol. 8, 183–186 (1992). doi:10.1007/BF01195843

Maheshwari, D.K., Gohade, S., Paul, J., Varma, A.: Paper mill sludge as a potential source for cellulase production by Trichoderma reesei QM 9123 and Aspergillus niger using mixed cultivation. Carbohydr. Polym. 23, 161–163 (1994). doi:10.1016/0144-8617(94)90098-1

Ahamed, A., Vermette, P.: Enhanced enzyme production from mixed cultures of Trichoderma reesei RUT-C30 and Aspergillus niger LMA grown as fed batch in a stirred tank bioreactor. Biochem. Eng. J. 42, 41–46 (2008). doi:10.1016/j.bej.2008.05.007

Duenas, R., Tengerdy, R.P., Gutierrez-Correa, M.: Cellulase production by mixed fungi in solid-substrate fermentation of bagasse. World J. Microbiol. Biotechnol. 11, 333–337 (1995). doi:10.1007/BF00367112

Chi, Y., Hatakka, A., Maijala, P.: Can co-culturing of two white-rot fungi increase lignin degradation and the production of lignin-degrading enzymes? Int. Biodeterior. Biodegrad. 59, 32–39 (2007). doi:10.1016/j.ibiod.2006.06.025

Mikesková, H., Novotný, Č., Svobodová, K.: Interspecific interactions in mixed microbial cultures in a biodegradation perspective. Appl. Microbiol. Biotechnol. 95, 861–870 (2012). doi:10.1007/s00253-012-4234-6

Minty, J.J., Singer, M.E., Scholz, S.A., Bae, C.-H., Ahn, J.-H., Foster, C.E., Liao, J.C., Lin, X.N.: Design and characterization of synthetic fungal-bacterial consortia for direct production of isobutanol from cellulosic biomass. Proc. Natl. Acad. Sci. USA 110, 14592–14597 (2013). doi:10.1073/pnas.1218447110

Fu, N., Peiris, P., Markham, J., Bavor, J.: A novel co-culture process with Zymomonas mobilis and Pichia stipitis for efficient ethanol production on glucose/xylose mixtures. Enzyme Microb. Technol. 45, 210–217 (2009). doi:10.1016/j.enzmictec.2009.04.006

Golias, H., Dumsday, G., Stanley, G.: Evaluation of a recombinant Klebsiella oxytoca strain for ethanol production from cellulose by simultaneous saccharification and fermentation: comparison with native cellobiose-utilising yeast strains and performance in co-culture with thermotolerant yeast and Zymomonas mobilis. J. Biotechnol. 96, 155–168 (2002)

Kamsani, N., Salleh, M.M., Yahya, A., Chong, C.S.: Production of lignocellulolytic enzymes by microorganisms isolated from Bulbitermes sp. termite gut in solid-state fermentation. Waste Biomass Valoriz. 7, 357–371 (2016). doi:10.1007/s12649-015-9453-5

Preston, G.M., Haubold, B., Rainey, P.B.: Bacterial genomics and adaptation to life on plants: implications for the evolution of pathogenicity and symbiosis. Curr. Opin. Microbiol. 1, 589–597 (1998). doi:10.1016/S1369-5274(98)80094-5

Cohan, F.M., Koeppel, A.F.: The origins of ecological diversity in prokaryotes. Curr. Biol. 18, R1024–R1034 (2008). doi:10.1016/j.cub.2008.09.014

Grice, E.A., Kong, H.H., Conlan, S., Deming, C.B., Davis, J., Young, A.C., Bouffard, G.G., Blakesley, R.W., Murray, P.R., Green, E.D., Turner, M.L., Segre, J.A.: Topographical and temporal diversity of the human skin microbiome. Science 324, 80- (2009). doi:10.1126/science.1171700 1190–1192 ).

Bader, J., Mast-Gerlach, E., Popović, M.K., Bajpai, R., Stahl, U.: Relevance of microbial coculture fermentations in biotechnology. J. Appl. Microbiol. 109, 371–387 (2010). doi:10.1111/j.1365-2672.2009.04659.x

Kumar, D., Murthy, G.S.: Impact of pretreatment and downstream processing technologies on economics and energy in cellulosic ethanol production. Biotechnol. Biofuels 4, 27 (2011). doi:10.1186/1754-6834-4-27

van Zyl, W.H., Lynd, L.R., den Haan, R., McBride, J.E.: Consolidated bioprocessing for bioethanol production using Saccharomyces cerevisiae. In: Biofuels, pp. 205–235. Springer, Berlin (2007)

Singh, N., Mathur, A.S., Tuli, D.K., Gupta, R.P., Barrow, C.J., Puri, M.: Cellulosic ethanol production via consolidated bioprocessing by a novel thermophilic anaerobic bacterium isolated from a Himalayan hot spring. Biotechnol. Biofuels 10, 73 (2017). doi:10.1186/s13068-017-0756-6

Demain, A.L., Newcomb, M., Wu, J.H.D.: Cellulase, clostridia, and ethanol. Microbiol. Mol. Biol. Rev. 69, 124–154 (2005). doi:10.1128/MMBR.69.1.124-154.2005

Taylor, M.P., Eley, K.L., Martin, S., Tuffin, M.I., Burton, S.G., Cowan, D.A.: Thermophilic ethanologenesis: future prospects for second-generation bioethanol production. Trends Biotechnol. 27, 398–405 (2009). doi:10.1016/j.tibtech.2009.03.006

Akinosho, H., Yee, K., Close, D., Ragauskas, A.: The emergence of Clostridium thermocellum as a high utility candidate for consolidated bioprocessing applications. Front. Chem. 2, 66 (2014). doi:10.3389/fchem.2014.00066

Jin, M., Balan, V., Gunawan, C., Dale, B.E.: Consolidated bioprocessing (CBP) performance of Clostridium phytofermentans on AFEX-treated corn stover for ethanol production. Biotechnol. Bioeng. 108, 1290–1297 (2011). doi:10.1002/bit.23059

Jain, A., Morlok, C.K., Henson, J.M.: Comparison of solid-state and submerged-state fermentation for the bioprocessing of switchgrass to ethanol and acetate by Clostridium phytofermentans. Appl. Microbiol. Biotechnol. 97, 905–917 (2013). doi:10.1007/s00253-012-4511-4

Weimer, P.: The ruminant animal as a natural biomass-conversion platform and a source of bioconversion agents. In: Biological Conversion of Biomass for Fuels and Chemicals, pp. 248–281. Royal Society of Chemistry, Cambridge (2013)

He, Q., Hemme, C.L., Jiang, H., He, Z., Zhou, J.: Mechanisms of enhanced cellulosic bioethanol fermentation by co-cultivation of Clostridium and Thermoanaerobacter spp. Bioresour. Technol. 102, 9586–9592 (2011). doi:10.1016/j.biortech.2011.07.098

Svetlitchnyi, V.A., Kensch, O., Falkenhan, D.A., Korseska, S.G., Lippert, N., Prinz, M., Sassi, J., Schickor, A., Curvers, S.: Single-step ethanol production from lignocellulose using novel extremely thermophilic bacteria. Biotechnol. Biofuels 6, 31 (2013). doi:10.1186/1754-6834-6-31

Chung, D., Cha, M., Guss, A.M., Westpheling, J.: Direct conversion of plant biomass to ethanol by engineered Caldicellulosiruptor bescii. Proc. Natl. Acad. Sci. USA 111, 8931–8936 (2014). doi:10.1073/pnas.1402210111

Lynd, L.R., Weimer, P.J., van Zyl, W.H., Pretorius, I.S.: Microbial cellulose utilization: fundamentals and biotechnology. Microbiol. Mol. Biol. Rev. 66, 506–577 (2002). doi:10.1128/MMBR.66.3.506-577.2002. table of contents

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, H.K., Xu, C. & Qin, W. Biological Pretreatment of Lignocellulosic Biomass for Biofuels and Bioproducts: An Overview. Waste Biomass Valor 10, 235–251 (2019). https://doi.org/10.1007/s12649-017-0059-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-0059-y