Abstract

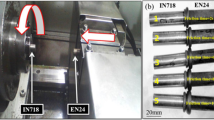

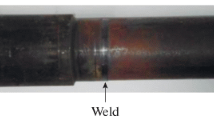

Continuous-drive rotary friction welding was performed to join cylindrical specimens of carbon steel (EN24) and nickel-based superalloy (IN718), and the microstructures of three distinct weld zones—the weld interface (WI)/thermo-mechanically affected zone (TMAZ), the heat-affected zone (HAZ), and the base metal—were examined. The joint was observed to be free of defects but featured uneven flash formation. Electron backscatter diffraction (EBSD) analysis showed substantial changes in high-angle grain boundaries, low-angle grain boundaries, and twin boundaries in the TMAZ and HAZ. Moreover, significant refinement in grain size (2–5 μm) was observed at the WI/TMAZ with reference to the base metal. The possible causes of these are discussed. The microhardness profile across the welded joint shows variation in hardness. The changes in hardness are ascribed to grain refinement, phase transformation, and the dissolution of strengthening precipitates. The tensile test results reveal that a joint efficiency of 100% can be achieved using this method.

Similar content being viewed by others

References

W. Cai, G. Daehn, A. Vivek, J.L. Li, H. Khan, R.S. Mishra, and M. Komarasamy, A state-of-the-art review on solid-state metal joining, J. Manuf. Sci. Eng., 141(2019), No. 3, art. No. 031012.

W.Y. Li, A. Vairis, M. Preuss, and T.J. Ma, Linear and rotary friction welding review, Int. Mater. Rev., 61(2016), No. 2, p. 71.

American Welding Society, American National Standard ANSI/AWS C6.1-89 (R2009), Recommended Practice for Friction Welding, American National Standards Institute, Miami, 1989.

M.J. Donachie and S.J. Donachie, Superalloys: A Technical Guide, ASM international, 2nd ed, Materials Park, 2002, p. 245.

S.V. Lalam, G.M. Reddy, T. Mohandas, M. Kamaraj, and B.S. Murty, Continuous drive friction welding of Inconel 718 and EN24 dissimilar metal combination, Mater. Sci. Technol., 25(2009), No. 7, p. 851.

H. Ma, G.L. Qin, P.H. Geng, F. Li, B.L. Fu, and X.M. Meng, Microstructure characterization and properties of carbon steel to stainless steel dissimilar metal joint made by friction welding, Mater. Des., 86(2015), p. 587.

R. Paventhan, P.R. Lakshminarayanan, and V. Balasubramanian, Fatigue behaviour of friction welded medium carbon steel and austenitic stainless steel dissimilar joints, Mater. Des., 32(2011), No. 4, p. 1888.

H. Ma, G.L. Qin, P.H. Geng, F. Li, X.G. Meng, and B.L. Fu, Effect of post-weld heat treatment on friction welded joint of carbon steel to stainless steel, J. Mater. Process. Technol., 227(2016), p. 24.

P. Wanjara, J. Gholipour, K. Watanabe, K. Nezaki, Y. Tian, and M. Brochu, Linear friction welding of IN718 to Ti6Al4V, Mater. Sci. Forum, 879(2017), p. 2072.

M. Cheepu and W.S. Che, Characterization of microstructure and interface reactions in friction welded bimetallic joints of titanium to 304 stainless steel using nickel interlayer, Trans. Indian Inst. Met., 72(2019), No. 6, p. 1597.

Z.W. Huang, H.Y. Li., M. Pruess, M. Karadge, P. Bowen, S. Bray, and G. Baxter, Inertia friction welding dissimilar nickel-based superalloys alloy 720LI to IN718, Metall. Mater. Trans. A, 38(2007), No. 7, p. 1608.

R. Damodaram, S.G.S. Raman, and K.P. Rao, Microstructure and mechanical properties of friction welded alloy 718, Mater. Sci. Eng. A, 560(2013), p. 781.

M. Sahin, H.E. Akata, and T. Gulmez, Characterization of mechanical properties in AISI 1040 parts welded by friction welding, Mater. Charact., 58(2007), No. 10, p. 1033.

P. Anitha, M.C. Majumder, V. Saravanan, and S. Rajakumar, Microstructural characterization and mechanical properties of friction-welded IN718 and SS410 dissimilar joint, Metall. Microstruct. Anal., 87(2018), No. 3, p. 277.

G.I. Khidhir and S.A. Baban, Efficiency of dissimilar friction welded 1045 medium carbon steel and 316L austenitic stainless steel joints, J. Mater. Res. Technol., 8(2019), No. 2, p. 1926.

M. Kimur, K. Nakashima, M. Kusaka, K. Kaizu, Y. Nakatani, and M. Takahashi, Joining phenomena and tensile strength of joint between Ni-based superalloy and heat-resistant steel by friction welding, Int. J. Adv. Manuf. Technol., 103(2019), No. 1–4, p. 1297.

H.J. Wang, K. Ikeuchi, M. Aritoshi, M. Takahashi, and A. Ikeda, Joint strength of Inconel 718 alloy and its improvement by post-weld heat treatment-joint performance and its controlling factors in friction welding of Inconel 718 alloy, Weld. Int., 23(2009), No. 9, p. 679.

R. Damodaram, S. Ganesh Sundara Raman, and K. Prasad Rao, Effect of post-weld heat treatments on microstructure and mechanical properties of friction welded alloy 718 joints, Mater. Des., 53(2014), p. 954.

G. Madhusudhan Reddy and P. Venkata Ramana, Role of nickel as an interlayer in dissimilar metal friction welding of maraging steel to low alloy steel, J. Mater. Process. Technol., 212(2012), No. 1, p. 66.

J. Woolman and R.A. Mottram, The Mechanical and Physical Properties of the British Standard EN steels (B.S. 970–1955): En 21 to En 39, Elsevier, 1966, p. 87.

V.T. Gaikwad, V.D. Hiwarkar, V.P. Pawar, and R.K.P. Singh, Microstructure characterization and evaluation of mechanical properties for friction welded En-24 alloy steel, [in] Materials Science & Technology (MS&T)2018, Columbus, 2018, p. 822.

Y. Wang, W.Z. Shao, L. Zhen, and X.M. Zhang, Microstructure evolution during dynamic recrystallization of hot deformed superalloy 718, Mater. Sci. Eng. A, 486(2008), No. 1–2, p. 321.

Y.X. Zheng, F.N. Wang, C.R. Li, Y.L. Li, J. Cheng, and R.F. Cao, Effect of microstructure and precipitates on mechanical properties of Cr-Mo-V alloy steel with different austenitizing temperatures, ISIJ Int., 58(2018), No. 6, p. 1126.

M.K. Mishra, A.G. Rao, I. Balasundar, B.P. Kashyap, and N. Prabhu, On the microstructure evolution in friction stir processed 2507 super duplex stainless steel and its effect on tensile behaviour at ambient and elevated temperatures, Mater. Sci. Eng. A, 719(2018), p. 82.

J. Jeon, S. Mironov, Y.S. Sato, H. Kokawa, S.C.H. Park, and S. Hirano, Friction stir spot welding of single-crystal austenitic stainless steel, Acta Mater., 59(2011), No. 20, p. 7439.

V. Patel, W.Y. Li, A. Vairis, and V. Badheka, Recent development in friction stir processing as a solid - state grain refinement technique: microstructural evolution and property enhancement, Crit. Rev. Solid State Mater. Sci., 44(2019), No. 5, p. 378.

S.M. Aktarer, D.M. Sekban, T. Kucukomeroglu, and G. Purcek, Microstructure, mechanical properties and formability of friction stir welded dissimilar materials of IF-steel and 6061 Al alloy, Int. J. Miner. Metall. Mater., 26(2019), No. 6, p. 722.

Acknowledgement

The authors acknowledge Kalyani Centre for Technology & Innovation (KCTI), Bharat Forge Ltd, Pune, and Department of Scientific and Industrial Research (DSIR), goverment of India for providing financial assistance, library, and laboratory facilities. The authors are gratefulness to Review Committee of Bharat Forge Ltd, Pune to allow for publication. Also, authors are thankful to Vinayak Pawar and Santosh Dhage for their assistance in various aspects of the project. Finally, authors thank K. Chethan for valuable suggestion, guidance, and discussion.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gaikwad, V.T., Mishra, M.K., Hiwarkar, V.D. et al. Microstructure and mechanical properties of friction welded carbon steel (EN24) and nickel-based superalloy (IN718). Int J Miner Metall Mater 28, 111–119 (2021). https://doi.org/10.1007/s12613-020-2008-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2008-1