Abstract

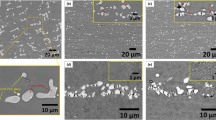

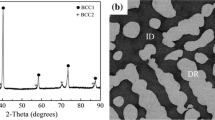

CoCrFeNiNb0.25 hypoeutectic high-entropy alloy (HEA) has shown good mechanical properties. However, due to interdendritic eutectics, it is challenging to further optimize the microstructure through cold rolling and annealing. The current study showed that hot deformation effectively tailored the hypoeutectic microstructure. We investigated the hot deformation behavior and microstructure evolution of the dual-phase CoCrFeNiNb0.25 HEA at different temperatures from 800 to 1000 °C and different strain rates from 0.01 to 10.00 s−1. The systematic investigation showed the deformation activation energy around 500 kJ·mol−1. Microstructure with refined grains and uniformly distributed Laves phases can be obtained after 70% compression at 900 °C with a strain rate of 0.01 s−1.

Graphical abstract

摘要

CoCrFeNiNb0.25 亚共晶高熵合金 (HEA) 显示出了良好的力学性能。然而, 枝晶间共晶的存在使通过冷轧和退火进一步优化微观组织困难。本研究发现热变形能有效地调控亚共晶微观组织。本文研究了双相CoCrFeNiNb0.25 HEA在温度800 oC至1000 oC和应变速率0.01 s−1至10.00 s−1下的热变形行为和微观组织演化。研究表明CoCrFeNiNb0.25 HEA的变形激活能量为 ~ 500 kJ·mol−1。在900 oC, 应变速率为 0.01 s−1时, 压缩 70% 后, 获得的微观组织具有细小晶粒和均匀分布的 Laves 相。

Similar content being viewed by others

References

Cantor B, Chang ITH, Knight P, Vincent AJB. Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A. 2004;375–377:213.

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater. 2004;6(5):299.

Miracle DB, Senkov ON. A critical review of high entropy alloys and related concepts. Acta Mater. 2017;122:448.

Chang HT, Huo XF, Li WP, Yang T, Huang JC, Wu BL, Duan GS, Du XH. Research development of strengthening mechanism of high entropy alloy. Rare Metal Mater Eng. 2020;49(10):3633.

Sharma P, Dwivedi VK, Dwivedi SP. Development of high entropy alloys: a review. Mater Today Proc. 2021;43:502.

Baker I, Wu M, Wang ZW. Eutectic/eutectoid multi-principle component alloys: a review. Mater Charact. 2019;147:545.

Gludovatz B, Hohenwarter A, Catoor D, Chang EH, George EP, Ritchie RO. A fracture-resistant high-entropy alloy for cryogenic applications. Science. 2014;345(6201):1153.

Zhang Z, Mao MM, Wang J, Gludovatz B, Zhang Z, Mao SX, George EP, Yu Q, Ritchie RO. Nanoscale origins of the damage tolerance of the high-entropy alloy CrMnFeCoNi. Nat Commun. 2015;6:10143.

Santodonato LJ, Zhang Y, Feygenson M, Parish CM, Gao MC, Weber RJK, Neuefeind JC, Tang Z, Liaw PK. Deviation from high-entropy configurations in the atomic distributions of a multi-principal-element alloy. Nat Commun. 2015;6:5964.

Senkov ON, Miller JD, Miracle DB, Woodward C. Accelerated exploration of multi-principal element alloys with solid solution phases. Nat Commun. 2015;6:6529.

Li Z, Pradeep KG, Deng Y, Raabe D, Tasan CC. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature. 2016;534(7606):227.

Koželj P, Vrtnik S, Jelen A, Jazbec S, Jagličić Z, Maiti S, Feuerbacher M, Steurer W, Dolinšek J. Discovery of a superconducting high-entropy alloy. Phys Rev Lett. 2014;113(10):107001

Zou Y, Maiti S, Steurer W, Spolenak R. Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy. Acta Mater. 2014;65:85.

Senkov O, Wilks G, Scott J, Miracle D. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics. 2011;19(5):698.

Wang JB, Li JJ, Wang Q, Wang JC, Wang ZJ, Liu CT. The incredible excess entropy in high entropy alloys. Scripta Mater. 2019;168:19.

Lee DH, Seok MY, Zhao Y, Choi IC, He J, Lu Z, Suh JY, Ramamurty U, Kawasaki M, Langdon TG, Jang JI. Spherical nanoindentation creep behavior of nanocrystalline and coarse-grained CoCrFeMnNi high-entropy alloys. Acta Mater. 2016;109:314.

Otto F, Dlouhý A, Somsen C, Bei H, Eggeler G, George EP. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013;61(15):5743.

Schuh B, Mendez-Martin F, Völker B, George EP, Clemens H, Pippan R, Hohenwarter A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 2015;96:258.

Wu Z, Bei H, Pharr GM, George EP. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014;81:428.

Xian X, Zhong LJ, Zhu ZX, Chen C, Wu YC. Tailoring strength and ductility of high-entropy CrMnFeCoNi alloy by adding. Al Rare Metals. 2022. https://doi.org/10.1007/s12598-018-1161-4.

Niu SZ, Kou HC, Wang J, Li JS. Improved tensile properties of Al0.5CoCrFeNi high-entropy alloy by tailoring microstructures. Rare Metals. 2021;40(9):2508.

Lin YC, Huang J, He DG, Zhang XY, Wu Q, Wang LH, Chen C, Zhou KC. Phase transformation and dynamic recrystallization behaviors in a Ti55511 titanium alloy during hot compression. J Alloy Compd. 2019;795:471.

Lin YC, Wu XY, Chen XM, Chen J, Wen DX, Zhang JL, Li LT. EBSD study of a hot deformed nickel-based superalloy. J Alloy Compd. 2015;640:101.

Chen XM, Lin YC, Wen DX, Zhang JL, He M. Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation. Mater Des. 2014;57:568.

Stepanov N, Tikhonovsky M, Yurchenko N, Zyabkin D, Klimova M, Zherebtsov S, Efimov A, Salishchev G. Effect of cryo-deformation on structure and properties of CoCrFeNiMn high-entropy alloy. Intermetallics. 2015;59:8.

Wang H, Guo KK, Liu XQ, Hong CF, Wang WG, Dai PQ, Tang Q. Effect of two-step thermomechanical processing on grain boundary character distribution of CoCrFeMnNi high-entropy alloy. Mater Charact. 2019;149:105.

Sathiaraj GD, Skrotzki W, Pukenas A, Schaarschuch R, Immanuel RJ, Panigrahi SK, Chelvane JA, Kumar SSS. Effect of annealing on the microstructure and texture of cold rolled CrCoNi medium-entropy alloy. Intermetallics. 2018;101:87.

Stepanov ND, Shaysultanov DG, Yurchenko NY, Zherebtsov SV, Ladygin AN, Salishchev GA, Tikhonovsky MA. High temperature deformation behavior and dynamic recrystallization in CoCrFeNiMn high entropy alloy. Mater Sci Eng, A. 2015;636:188.

Nayan N, Singh G, Murty SVSN, Jha AK, Pant B, George KM, Ramamurty U. Hot deformation behaviour and microstructure control in AlCrCuNiFeCo high entropy alloy. Intermetallics. 2014;55:145.

Eleti RR, Bhattacharjee T, Zhao LJ, Bhattacharjee PP, Tsuji N. Hot deformation behavior of CoCrFeMnNi FCC high entropy alloy. Mater Chem Phys. 2018;210:176.

Sunkari U Reddy SR, Rathod BDS, Kumar D, Saha R, Chatterjee S, Bhattacharjee PP, Tuning nanostructure using thermo-mechanical processing for enhancing mechanical properties of complex intermetallic containing CoCrFeNi2.1Nbx high entropy alloys. Mater Sci Eng Struct Mater Prop Microstruct Process 2020; 769:138489.

He F, Wang Z, Cheng P, Wang Q, Li J, Dang Y, Wang J, Liu CT. Designing eutectic high entropy alloys of CoCrFeNiNbx. J Alloy Compd. 2016;656:284.

He F, Wang Z, Niu S, Wu Q, Li J, Wang J, Liu CT, Dang Y. Strengthening the CoCrFeNiNb0.25 high entropy alloy by FCC precipitate. J Alloys Comp. 2016; 667:53.

Liu W, He J, Huang H, Wang H, Lu Z, Liu C. Effects of Nb additions on the microstructure and mechanical property of CoCrFeNi high-entropy alloys. Intermetallics. 2015;60:1.

Prusa F, Cabibbo M, Senkova A, Kucera V, Veselka Z, Skolakova A, Vojtech D, Cibulkova J, Capek J, High-strength ultrafine-grained CoCrFeNiNb high-entropy alloy prepared by mechanical alloying: properties and strengthening mechanism. J Alloys Comp. 2020; 835:155308.

Zhao JF, Wang HP, Wei B. A new thermodynamically stable Nb2Ni intermetallic compound phase revealed by peritectoid transition within binary Nb-Ni alloy system. J Mater Sci Technol. 2022;100:246.

Thomas A, El-Wahabi M, Cabrera JM, Prado JM. High temperature deformation of Inconel 718. J Mater Process Technol. 2006;177(1–3):469.

Yuan H, Liu WC. Effect of the δ phase on the hot deformation behavior of Inconel 718. Mater Sci Eng A. 2005;408(1–2):281.

Zaddach AJ, Niu C, Koch CC, Irving DL. mechanical properties and stacking fault energies of NiFeCrCoMn high-entropy alloy. JOM. 2013;65(12):1780.

He F, Wang Z, Shang X, Leng C, Li J, Wang J. Stability of lamellar structures in CoCrFeNiNbx eutectic high entropy alloys at elevated temperatures. Mater Des. 2016;104:259.

Acknowledgements

This work was financially supported by the National Key R&D Program of China (No. 2018YFC0310400) and the Research Fund of the State Key Laboratory of Solidification Processing, China (Nos. 2020-TS-06 and 2021-TS-02).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Liu, XR., He, F., Li, JJ. et al. Tailoring microstructures of CoCrFeNiNb0.25 hypoeutectic high-entropy alloy by hot deformation. Rare Met. 41, 2028–2037 (2022). https://doi.org/10.1007/s12598-021-01932-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-021-01932-9