Abstract

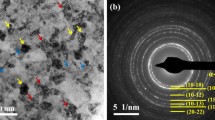

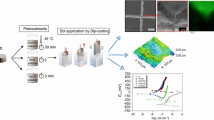

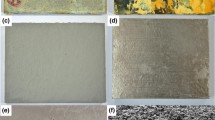

In this research, TiAl3 layers with different thicknesses were deposited on a titanium sheet by immersion of titanium in molten aluminum for different times. The oxidation behavior of the coated titanium at 850 °C was investigated and the comparison of the results was made with the oxidation behavior of the uncoated titanium sheet. The results showed that the produced TiAl3 layer could protect the titanium substrate against the oxidation if it contains an appropriate quality and morphology, otherwise not only it cannot withstand the oxidation, but also it accelerates the oxidation process of the titanium substrate. The protection mechanisms of the layers were probed into, performing the XRD analysis. It was found that the TiAl3 layer morphology affects oxidation mechanism and oxidation products.

Similar content being viewed by others

References

S. Djanarthany, J.C. Viala, J. Bouix, Mater. Chem. Phys. 72, 301–319 (2001)

D.M. Dimiduk, Mater. Sci. Eng., A 26, 3281–3288 (1999)

E.A. Loria, Intermetallics 8, 1339–1345 (2000)

C. Leyens, Oxidation and Protection of Titanium Alloys and Titanium Aluminides, Titanium and Titanium Alloys (Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, 2005), pp. 187–230

R. Khoshhal, M. Soltanieh, M. Mirjalili, Iran. J. Mater. Sci. Eng. 7, 24–31 (2010)

P. Kofstad, J. Less Common Metals 12, 449–464 (1967)

E. Gemelli, N.H.A. Camargo, Matéria (Rio de Janeiro) 12, 525–531 (2007)

G. Ottaviani, F. Nava, G. Queirolo, G. Iannuzzi, G. de Santi, K.N. Tu, Thin Solid Films 146, 201–207 (1987)

I. Takayama, Nippon steel technical report, 1994

V.A. Lavrenko, A.D. Panasyuk, S.A. Firstov, Powder Metall. Met. Ceram. 42, 291–296 (2003)

D.E. Mencer, T.R. Hess, T. Mebrahtu, D.L. Cocke, D.G. Naugle, J. Vac. Sci. Technol. A Vac. Surf. Films 9, 1610–1615 (1991)

R.G. Reddy, X. Wen, I.C.I. Okafor, Metall. Mater. Trans. A 31, 3023–3028 (2000)

Outokumpu Research, Finland, 2002

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khoshhal, R. Effect of TiAl3 Coating Thickness and Morphology, Formed Using the Immersion of Titanium Sheets in Molten Aluminum, on Titanium Oxidation Behavior. Met. Mater. Int. 25, 449–455 (2019). https://doi.org/10.1007/s12540-018-0183-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0183-7