Abstract

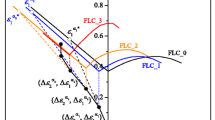

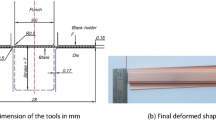

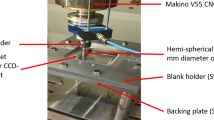

The investigation of bendability of sheet metal alloys is of great importance for the evaluation of process robustness in production of hemmed sheet metal assemblies. Furthermore, material cracks due to bending can also occur at deep drawing operations. This contribution focuses on the experimental determination of material’s formability at deep drawing, the characterisation of bendability especially for hemming operations and the determination of formability under combined deep drawing and bending loads, respectively.

Similar content being viewed by others

Abbreviations

- BLC:

-

bending limit diagram

- FLC:

-

forming limit curve

- FLD:

-

forming limit diagram

- M:

-

correlation function for combined load conditions

- r i :

-

inner bending radius

- α :

-

strain path orientation

- β :

-

bending indicator

- ϕ 1 :

-

major strain

- ϕ 1,1 :

-

major strain of pre-strain

- ϕ 1,res :

-

major strain of pre-strain inclusive subsequent bending

- ϕ2 :

-

minor strain

- ϕb :

-

bending strain (outer fiber)

- ϕ 1,planar :

-

major strain component of planar forming limit description

- ϕ M :

-

major forming limit strain component for combined load conditions

- \(\overline{\overline {\varphi _b }} \) :

-

strain tensor for bending operations

- \(\overline{\overline {\varphi _d }} \) :

-

strain tensor for deep drawing operations

- \(\overline{\overline \varphi } \) :

-

strain tensor for all possible states of strain

References

Liewald M, Schleich R (2007) Robust processes in sheet metal forming in car body manufacturing with regard to production volume. In: Keynote-Beitrag IDDRG-Konferenz Györ

Feldmann P, Schatz M (2006) Effective evaluation of FLC—tests with the optical in-process strain analysis system AutoGrid. In: Proceedings of the 15th FLC Zurich

Schleich R, Jud F, Sindel M, Liewald M (2007) Prozesssicherheit beim Biegen von Aluminiumblechen, Blech, Rohre, Profile. Meisenbach, Bamberg

Schleich R, Sindel M, Liewald M (2008) Material characterisation for aluminium sheet forming processes in automotive industry. In: Proceedings International Conference New Developments in Sheet Metal Forming Technology, Stuttgart

Schleich R, Sindel M, Liewald M (2007) Potentiale der differenzierten Betrachtungsweise prozessabhängiger Grenzformänderungskurven in der Umformsimulation. In: ANSYS Conference & CADFEM Users’ Meeting, Dresden

NN (2004) ISO 12004-1, Metallic materials—determination of forming limit curves. International Organization for Standardization, Geneva

NN (2001) DIN EN ISO 10002, Prüfung von metallischen Werkstoffen, Zugversuch, Teil 1: Prüfverfahren bei Raumtemperatur. Deutsches Institut für Normung, Berlin

Emmens WC, van den Boogaard AH (2008) Extended tensile testing with simultaneous bending. In: IDDRG 2008 International Conference, Olofström, Sweden

Schleich R, Held C, Sindel M, Liewald M (2008) Beitrag zur Qualifizierung von Falzprozessen im Automobilbau, UTF-Science. Meisenbach, Bamberg

Till E, Berger E, Larour P (2008) On an exceptional forming behaviour aspects of AHSS sheets. In: IDDRG 2008 International Conference, Olofström, Sweden

Shi MF, Gerdeen JC (1991) Effect of strain gradient and curvature on forming limit diagrams for anisotropic sheets. Int J Mater Shaping Technol 9:253–268

Benedyk JC, Mostovoy S, Janota R (2002) The continuous bending under tension (CBT) test method for evaluating formability of sheet metal. Light Met Age 60:6–8

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schleich, R., Sindel, M. & Liewald, M. Investigation on the effect of curvature on forming limit prediction for aluminium sheet alloys. Int J Mater Form 2, 69–74 (2009). https://doi.org/10.1007/s12289-009-0394-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-009-0394-z