Abstract

Cycling time trials are characterised by riders adopting positions to lessen the impact of aerodynamic drag. Aerodynamic positions likely impact the power a rider is able to produce due to changes in oxygen consumption, blood flow, muscle activation and economy. Therefore, the gain from optimising aerodynamics must outweigh the potential physiological cost. The aim was to establish the relationship between energy expenditure and aerodynamic drag, with a secondary aim to determine the reliability of a commercially available handlebar mounted aero device for measuring aerodynamic drag. Nine trained male cyclists volunteered for the study. They completed 4 × 3200 m on an outdoor velodrome where stack height was adjusted in 1 cm integers. The drag coefficient (CdA), oxygen consumption and aerodynamic-physiological economy (APE) were determined at each stack height, with data used to model 40 km TT performance. Small to moderate effect sizes (ES) in response to stack height change were found for CdA, APE and energy cost. The change in TT time was correlated to ∆aerodynamic drag and ∆APE. Meaningful impacts of change in stack height on CdA, APE, energy cost and predicted TT performance, are apparent with highly individualised responses to positional changes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Cycling time trials (TT) are characterised by riders adopting aerodynamic positions to reduce aerodynamic drag. TTs vary in duration, ranging from approximately 25 s for a 500 m TT in a velodrome to 4–5 h on the road. It is likely that the optimal performance requirements for events of such divergent distances and durations exist on a continuum of rider aerodynamics versus physiological optimisation.

Cycling speed can be determined by several factors including a rider’s power output, aerodynamic drag coefficient, frontal area, road surface and gradient, and environmental conditions [1]. The road surface and gradient will impact both rolling and gravitational resistance respectively, which can be negated via testing on a smooth surface with no change in altitude. Aerodynamic drag is calculated using formula [2]:

where F is the total drag force (N), r is the density of air (~ 1.2 kg m−3 at sea level), V is the speed of the air relative to the rider and bike (m s−1), Cd is the drag coefficient (dimensionless) and A frontal area (m2).

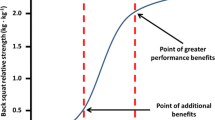

Approximately 80–95% of the resistive forces experienced during cycling occur as a consequence of the rider and their equipment [3]. Given the cubic relationship between speed and the power required to overcome aerodynamic drag, shorter faster events likely have a greater reliance on aerodynamic optimisation. Whereas longer duration TTs are more limited by rider physiology and environmental conditions [4].

Altering rider position to favour aerodynamics often results in cyclists adopting a position whereby their upper body is close to parallel to the ground which can hinder the rider’s critical power (CP) [5]. This effect is likely multifactorial and related to changes in oxygen consumption, muscle blood flow, muscle activation and economy [6,7,8,9]. Therefore, if the gain from optimising aerodynamics does not outweigh the potential physiological cost, TT performance will not improve.

Previously, we have demonstrated that a reduction in hip angle reduces aero-physiological economy (APE). We have previously suggested APE to be a way of encompassing both physiological and aerodynamic aspects of cycling economy and their interaction with performance [10]. However, our calculation of drag-area i.e. the product of drag coefficient and frontal area (CdA), was based on anthropometric measurements and frontal area [11] and not a direct measurement of CdA. Recently, several bicycle mounted pitot tubes (for example, the Notio Konect) have been developed allowing riders and coaches to measure CdA. The Notio Konect (NK) has been reported to be both highly reliable and sensitive to change for indoor velodrome use [12], and may offer a feasible and reliable way of measuring CdA during outdoor cycling, however, this is yet to be corroborated.

The aims of the present study were to (A) establish the relationship between energy expenditure, APE and aerodynamic drag and apply these data to a TT model and (B) to determine the reliability of the NK during outdoor use. It was hypothesised that increasing CdA would result in measurable physiological changes and predicted TT performance. A secondary hypothesis was that responses to positional changes would be highly individualised, owing to differing anthropometric and physiological factors impacting on form drag and oxygen consumption.

2 Methods

2.1 Participants

Nine male cyclists and triathletes who frequently raced in triathlons and/or time trial races volunteered to take part in this study (age 34 ± 13 years, performance level 4 [13]). Mean personal best time for 10 mile (16.1 km) TT was 20:48 mm:ss with a range of 19:16–22:24 mm:ss. Participants provided full written informed consent before undertaking the study. All procedures used in this investigation were given ethical approval from the University’s Ethical Review Board.

2.2 Experimental protocol

All testing took place on a 400 m outdoor velodrome between August 2020 and September 2021 on dry days where wind speed was below 5 m s−1. Participants arrived at the velodrome having been instructed to wear their standard race skin suit, socks and cycling shoes. Participants were first given time to familiarise themselves with the riding track. Subsequently, riders completed two efforts of 4 laps (Aero run; total distance of 4 laps ~ 1.6 km) at a target speed of ~ 40 km h−1 at one of four different stack heights. Stack height was defined as the height of the TT bike arm rests above the upper most portion of the headtube. 0 cm represents the lowest possible stack height on a given bike. The first run comprised the control condition for each participant and was completed in their own self-selected position (0 cm n = 4; 1 cm n = 3, 2 cm n = 1, 3 cm n = 0). Stack height was then adjusted to one of the four remaining stack heights (0–3 cm) and conditions were completed in a randomised order.

Participants were provided with lap splits to the nearest 0.1 s to ensure as little deviation in speed as possible between conditions. Following the Aero Run, participants had a ~ 10-min recovery before completing a 6-min steady state ride \(\dot{V}\)O2 run at the same stack height and power achieved in the corresponding Aero Run to measure oxygen consumption \(\dot{V}\)O2. Participants had 20–30 min of recovery between conditions, during which time they were encouraged to eat and hydrate as necessary to minimise the impact of glycogen depletion on performance and metabolic measurements. During this time, the bike was kept out of any direct sunlight to minimise a change in tyre pressure which would impact rolling resistance, and measurements by the NK for temperature, humidity and air density which would influence CdA.

Figure 1 shows a schematic overview of the protocol. All runs were completed on the participants’ time trial bike.

Protocol schematic. Participants completed experimental trials at four different stack heights. Riders first completed the Aero Run to determine the aerodynamic drag of that particular stack height. They rode 4 laps at a target speed of ~ 40 km h−1, followed by a 3 lap active recovery before a final block of four laps at ~ 40 km h−1. Riders then had a ~ 10 min recovery period before completing the steady state \(\dot{V}\)O2 run which was ridden at the power achieved during the preceding Aero Run. Participants had 20–30 min recovery between completing the same protocol at the remaining three stack heights

2.3 Aerodynamic measurement and analysis

Each participant used their own statically calibrated power metre and were provided with magnet-based speed and cadence sensors (Garmin, Kansas, USA) which were wirelessly connected to a Notio Konect device (Notio Technologies, Montreal, Canada). The NK was mounted on the base bar and calibrated according to the manufacturer’s instructions. Total system mass (rider, bike and clothing) was measured and recorded. All aerodynamic measurements were taken from the Aero Runs at each stack height as described above. These repeat efforts also served to allow the calculation of reliability of the NK in determining riders’ CdA. Riders were instructed to maintain a consistent position throughout the run and to maintain a constant gear. Where possible gear changes were rendered impossible via disconnection of electronic shifting motors. The NK recorded all power, speed and atmospheric data at a frequency of 4 Hz. NK data were analysed using the NK edition of Golden Cheetah (https://goldencheetah.org/) to derive CdA using the velodrome function. This function uses the inbuilt gyroscope to identify individual laps, with all altitude measurements, which provide the biggest source of variation within the measurement, set to zero.

2.4 Oxygen consumption

Oxygen consumption during the \(\dot{V}\)O2 run was recorded using a portable oxygen analyser (MetaMax 3b, Cortex, Leipzig, Germany) calibrated according to the manufacturer’s instructions. To minimise the impact of high relative wind speeds on ventilatory measures, a custom made 3-D printed baffle was mounted to the front of the turbine. The baffle did not impair the flow of inhaled or exhaled air, but minimised the direct flow of high velocity air over the turbine. \(\dot{V}\)CO2 and RER were recorded continually throughout, with data averaged over the final 60 s. The reliability of the MetaMax 3B has been reported to be less than 2.0% [14].

2.5 Energy expenditure

Energy expenditure (kcal min−1) was calculated using the relationship between mean \(\dot{V}\)O2 (L min−1) from the final minute of the 6 min \(\dot{V}\)O2 run and the RER. Energy cost (Ec; kcal km−1) was calculated as the sum of carbohydrate and fat oxidation derived from energy expenditure and expressed as kilocalories per kilometre [15]. Oxygen consumption (Oc; L km−1) was calculated using \(\dot{V}\)O2 data from the final minute of the \(\dot{V}\)O2 run.

2.6 Reynold’s number

The Reynold’s number (Re) is the ratio of inertial forces to viscous forces which a body is subjected to during movement in different fluid (or air velocities) and gives an indication of whether the air flow over and around a body is either laminar or turbulent. It is a non-dimensional number and relates to the type of flow and resistance that a body experiences during its movement through a fluid. Briefly, a boundary layer is a relatively thin layer of fluid around a body in which particle velocity is taken as near zero on the surface of the body and gradually matches the velocity of the free flow. A boundary layer can be of laminar or turbulent flow. The flow momentum content i.e. the product of mass and velocity, is directly related to the ability of the flow to resist adverse pressures and sustain attachment to the body’s surface. Detachment of the boundary layer creates a wake region of relatively lower pressure behind the body. The pressure difference opposes the movement of the body through the fluid. The flow momentum within the boundary layer is related to its separation from the body and therefore, the size and intensity of the wake region. Generally, a higher Reynolds number would be associated with a turbulent flow and higher flow momentum, however, the benefits in terms of flow boundary layer attachment/separation are often limited to a range of Reynolds numbers. Very high velocities may cause additional effects defeating the benefits. The Reynold’s number can be defined as:

where ρ is the fluid density (kg m−3), μ is the dynamic viscosity of the fluid (kg m−1 s−1), l is a reference length (m) and V is a reference velocity (m s−1) with the reference length calculated as the square root of the cyclist’s frontal area [16, 17]. Re was calculated for each stack height to assess airflow changes.

2.7 Aerodynamic physiological economy (APE)

Aerodynamic physiological economy (APE; W CdA L min−1) was calculated to gain insight into the combination of aerodynamic optimisation and the potential physiological implications. The W CdA−1 derived from each of the aerodynamic tests (2 × 1.6 km) was then normalised to the corresponding oxygen uptake as measured during the \(\dot{V}\)O2 run.

2.8 Prediction models

The bicycle-rider system was assumed to be on flat ground at a steady state with no changes in kinetic or potential energy or wind. The required power equation was adjusted from the literature [16, 18]. The rolling resistance coefficient, bearing and wheel related losses were taken as constant with relation to velocity:

where Pr is the required power (W) for maintaining the desired velocity, Par power corresponding to aerodynamic resistance, Prr power corresponding to rolling resistance, Ptwb power corresponding to bearing and wheel losses.

The required power difference due to the stack reconfiguration was assumed to be translatable into a corresponding achievable velocity. Wheel and bearing resistance related losses were calculated from the experimental data and were assumed to be constant. The predicted achievable velocity was calculated using the following relations:

P1r is the total required power for the control stack height at velocity V1, P2r is the total required power for manipulated stack height and for corresponding velocity V2. Correspondingly the forces (N) are F1ar is aerodynamic drag force for the control stack height, F2ar is aerodynamic drag force for the manipulated stack height, F1rr the force due to rolling resistance for the control stack height, F2rr the force due to rolling resistance for the manipulated stack height, F1wb the force resistance due to bearing and wheel losses for the control stack height, F2wb the force resistance due to bearing and wheel losses for the manipulated stack height, ∆P is the change in required power between control and manipulated stack heights for velocity V1. The above equations [4] can also be written as:

CdA2 is the product of the coefficient of drag and frontal area for the manipulated stack height, Crr is the coefficient for rolling resistance. The equation was solved for V2.

2.9 Predicted 40 km TT time saving

Time savings for each stack height were compared to the predicted time to complete a flat 40 km TT based on their velocity and CdA during the control condition. Time savings were calculated based on the relationship between CdA, ∆Pr and speed using the following equation:

where d is distance, V1 is the velocity in the control stack height and V2 is the corresponding velocity for the manipulated stack height.

2.10 Statistics

All analysis was completed using GraphPad Prism 9. Data were tested to ensure normal distribution via the Shapiro–Wilk test, where these criteria were not met, appropriate non-parametric tests were conducted. All data are presented as mean ± standard deviation unless otherwise stated.

Absolute reliability was measured using standard error and the coefficient of variation (CV), standardised typical error and interclass correlation coefficient (ICC). For typical error, results were doubled prior to interpretation [19] using the thresholds: trivial £ 0.2, small > 0.2–0.6, moderate > 0.6–1.2 and large > 1.2. Raw and typical error and ICC was determined and are presented with 95% Confidence Intervals (CI). The correlation between efforts was analysed using Spearman’s r statistic.

All performance related variables were analysed using a repeated measures one-way analysis of variance (ANOVA). The change in each variable was analysed with a mixed-method repeated measures ANOVA normalised to each rider’s control stack height. Riders were removed from the grouped analysis which represented their control stack height to avoid double counting of data. The correlation between predicted finish time and cycling economy was conducted using Pearson’s r statistic. For all other correlations, Spearman’s rho was used. The accepted level of significance was P < 0.05. Effect sizes (ES) of each stack height were calculated using Hedge’s g. Effect sizes are presented with 95% CI.

Given the expected high variability in the individual responses to alterations in stack height on aerodynamic drag and associated variables the Smallest Meaningful Change (SMC) [20] was used to determine individual responses. SMC was calculated using the relationship between the CV and an ES of 0.2 [21]. The resulting percentage was then used to calculate an absolute threshold, above which an individual was deemed to have a positive, or negative response to the intervention.

3 Results

3.1 NK reliability

All rides were completed at a mean power of 278 ± 3 W, wind speed of 0.31 ± 0.04 m s−2, ground speed of 42.2 ± 0.2 km h−1 and air speed of 42.9 ± 0.3 km h−1. The inter effort CV for CdA was 1.54% (~ 4 W) and ranged from 0.02 to 6.57% (~ 0 to 19 W). Typical error for CdA was 0.0066 (0.0054–0.0085) m2 and represents a trivial effect size. Standardised typical error was 0.2305 (0.1893–0.2950) m2, reflecting a small effect size. ICC was 0.95 (0.91–0.97) and represents high reliability and repeatability. Accordingly, effort 1 was highly correlated to effort 2 (r = 0.9328, P < 0.0001).

3.2 Aerodynamic, physiological and performance responses—group data

The modal stack height was 0 cm in the self-selected control condition (0.6 cm) with a CdA of 0.2467 ± 0.0338 m2. Aerodynamic drag was equivalent to 269 ± 24 W and APE 295 ± 69 W CdA L min−1. There was no effect for a change in stack height on the change in aerodynamic drag (Fig. 2A) or APE (Fig. 2B) when considering group mean data. However, there was an effect of stack height on Reynold’s number (P < 0.05, Fig. 2C), indicating an altered airflow around the body. The predicted time to complete a 40 km TT was 3408 ± 174 s in the riders’ control stack height. There were no differences in predicted 40 km TT time at 0 cm (3430 ± 134 s; P = 0.621), 1 cm (3307 ± 156 s; P = 0.0808), 2 cm (3414 ± 158 s; P = 0.5776) or 3 cm (3390 ± 159; P = 0.4871). However, taking the SMC of 34 s, meaningful differences in predicted performance are evident at 2 cm (84 s slower vs control) and 3 cm (60 s slower vs control).

Changes in aerodynamic parameters in response to stack height. There were no differences in group mean data following a stack height adjustment for A aerodynamic drag, or B aero-physiological economy (APE) compared to riders’ self-selected control position. C There were differences in the Reynold’s number compared to control at 0 cm, 1 cm and 2 cm. Individual participant data are reflected in differing symbols for each data point. * = P < 0.05, *** = P < 0.001

Effect sizes for each stack height ranged from trivial to large, with individual effect sizes for each condition shown in Table 1.

Several physiological and aerodynamic related variables were correlated to an improvement in predicted 40 km TT time (Fig. 3). ∆TT time was correlated to ∆APE (r = − 0.493, P < 0.005), ∆W/CdA (r = − 0.490; P < 0.005) and ∆aerodynamic drag (r = 0.707; P < 0.005). ∆Ec was correlated with ∆APE (r = 0.757, P < 0.005; Fig. 4A) and ∆W CdA−1 (r = 0.374, P < 0.05, Fig. 4B). The change in oxygen consumption was negatively correlated with ∆W CdA−1 (r = − 0.4178, P < 0.05, Fig. 4C).

Aerodynamic and physiological variables and their relationship to predicted 40 km time trial time. A) aero-physiological economy (APE); B drag coefficient (CdA); C power normalised to CdA; D cycling efficiency; E cycling economy; F Reynold’s number. CdA has the closest relationship to predicted finish time, the inclusion of APE, combining physiological and aerodynamic variables, strengthens the prediction of finish time over and above physiological variables in isolation

Correlational data between aerodynamic variables and absolute energy cost. A Shows the increase in energy cost (Ec) is associated with a decline in the amount of power produced per unit of drag coefficient (W CdA−1). B Shows the relationship between aerodynamic-physiological economy (APE) and energy cost, where greater energy cost is associated with a reduction in overall efficiency. C Represents the inverse relationship between a change in oxygen consumption and W CdA−1 in response to altered stack height. Data analysed using Spearman’s rho

3.3 Aerodynamic, physiological and performance responses—individual responses

3.3.1 Drag coefficient (CdA)

The SMC for CdA was 0.002 m2. Compared to riders’ control stack height, 0 cm resulted in two individuals (25%) lowering their CdA, with two experiencing an increase in CdA. At 1 cm two (25%) experienced lower CdA, but no riders experienced an increase in CdA. Two riders (25%) showed lower CdA at 2 cm with five experiencing an increase in CdA. At 3 cm, five participants (56%) exceeded the SMC threshold for a reduction in CdA, with four showing an increase in CdA.

3.4 Aero-physiological economy (APE)

APE was sensitive to positional changes across conditions, with the SMC equivalent to 15 W CdA L min−1. At 0 cm two participants experienced a worsening of APE (− 28.1 ± 4.3 W CdA L .min−1) and one a small improvement in APE. At 1 cm, two participants showed a reduction in APE (− 26.1 ± 9.0 W CdA L min−1), with none showing an improvement. At 2 cm, three individuals showed improved APE (23.7 ± 5.2 W CdA L min−1) and four an overall reduction (− 34.8 ± 6.9 W CdA L min−1). At 3 cm only one individual showed improved APE (24.2 W CdA L min−1) and five a reduction (25.9 ± 7.4 W CdA L min−1).

3.5 Predicted 40 km TT

The SMC for defining an improvement in performance was 1.0% or 34 s. At 0 cm only one rider was predicted to improve TT performance, with none predicted to experience a worsening in performance (Fig. 5). Three riders were predicted to improve TT performance time at 1 cm (72 ± 18 s) and none a worsening. At 2 cm, two riders were predicted to improve performance time (121 ± 15 s) and one a slower time (47 s). At 3 cm, three riders were predicted to experience a faster time compared to control (81 ± 34 s) and three to be slower (51 ± 13 s).

4 Discussion

We show that the NK represents a reliable and repeatable method for detecting differences in CdA. Although the inter effort CV was greater than previously reported [12], 1.5% represents small variation in the outdoor environment where atmospheric conditions have much greater variability. These data indicate that the NK is suitable for detecting relatively small changes (> 0.0066 (0.0054–0.0085) m2) in aerodynamic drag using an outdoor velodrome. This is only slightly greater than the sensitivity of 0.002 m2 detection threshold identified by Kordi et al. [12]. Therefore, the NK is an appropriate tool to use in related research and applied investigations into rider position and aerodynamics in an outdoor environment.

Subsequent to our work validating the NK, we investigated the relationship between physiological parameters, aerodynamic drag and predicted 40 km TT performance. In line with our hypothesis, our data show small but meaningful impacts of alterations in CdA on aero-physiological efficiency, energy cost and TT performance. Importantly, when we normalise for the differences in the control position by considering the change in physiological and aerodynamic data, there is an inverse relationship between CdA and physiological cost. These data show, acutely at least, that there is a physiological cost of manipulating a rider’s position on a time trial bike which may impact on performance. Importantly, our data reflects previous work showing a large variation (− 5 to − 17%) in the change in measured power output during a 20 km TT is experienced following severe acute positional changes [22]. On an individual level, these data confirm that there is no ‘one-size fits all’ approach that can be taken for aerodynamic optimisation and performance. This reflects the multitude of individual factors that influence CdA.

The present data support our previous work where we developed the concept of aerodynamic-physiological economy [10]. In this work, we demonstrated that alterations to hip angle during TT cycling had an impact on APE and overall performance. A limitation of our previous work was that CdA was based on anthropometric and frontal area calculations and did not include a direct measurement of aerodynamic drag, which has been rectified in the present study. Our TT modelling also supports previous data regarding the impact of altering CdA on TT performance potential [10, 23,24,25]. However, we are able to take this further by including a CdA normalised to both individual power output (W CdA−1) and cycling economy, with reductions in both variables closely associated with impaired predicted TT performance.

To account for the difference in riders’ baseline position, we have considered the association between the change in aerodynamic related variables on the change in energy cost (Ec). The measurement and analysis of Ec over economy may offer a closer reflection of the true metabolic cost of an activity [15] and has been shown to be sensitive to postural and associated air resistance changes in cycling [26]. The association between ∆W CdA−1 and ∆Ec following acute changes to body position reported in the present study shows that there is an acute physiological effect of increasing aerodynamic drag. Such changes in Ec are likely as a consequence of altered muscle recruitment, and therefore metabolic energy expenditure, as a result of changing position [6, 27].

The relationship between aerodynamic and physiological factors should be considered when optimising a rider’s time trial position for a specific event. At speeds in excess of ~ 46 km h−1, aerodynamic drag force dominates [4] and optimisation should have a greater focus towards reducing CdA and increasing W CdA−1 [4, 8, 10]. Conversely, in events completed at lower speeds over longer durations, physiological optimisation should have greater emphasis. Carbohydrate ingestion has been shown to have little to no impact on TTs of less than 16 km [28]. Conversely, in longer TTs (~ 1 h or more) performance is more likely to be influenced by substrate availability [29, 30]. Therefore, the increased Ec associated with a change in position will likely increase the rate of carbohydrate oxidation, the onset of fatigue and altered pacing strategy. However, what remains to be determined is whether there is a reduction in muscle recruitment and Ec following a prolonged period of training in a ‘optimised’ time trial position. Such training adaptations have been reported for acute declines in power output experienced following a reduction in torso angle [31, 32]. Further work should be done to consider the impact of long-term training and adaptation to an optimised position with respect to a recovery in overall economy.

The individual responses to acute positional changes on CdA and economy reflect the expected inter-individual variability associated with aerodynamics. It is important to consider that aerodynamic drag is not solely influenced by frontal area (A component). The largest component comes from form drag and skin friction (Cd component), which represents the air flow over and around a rider. In this study we assume that by altering stack height we change A and that this also impacts Cd. However, owing to anthropometric variation it is likely that the effect on form drag could be different from one individual to the next, despite the change in A being similar. This is reflected in the present data when we consider changes in CdA at an individual level where we see occurrences of increasing stack height reducing CdA. The data show that a higher Re was linked to faster predicted TT performance and this is likely due to more turbulent air flow which helps to delay the flow separation compared to laminar flows, generally decreasing pressure drag [16, 33]. When we consider these data in our TT model, the largest performance improvements occurred at 1–2 cm, suggesting that overall form drag was reduced enough to compensate for the small increase in frontal area.

The TT model used for this study was taken from literature [16, 18]. For the purposes of this study, the required power from the rider in the control condition was assumed to be available in alternative positions. Therefore, the difference in the required power to overcome aerodynamic drag was assumed to correspond to a change in power that was translatable to a corresponding change in velocity and projected time. However, it is acknowledged that this may not be the case for all riders, and factors such as comfort and/or flexibility may impact power output [22]. The model assumed no kinetic or potential energy changes as all calculations were based on steady state riding with minimal changes to acceleration. Wind effect was also excluded, and the rolling coefficient and mechanical forces due to bearings and transmission were considered constant (3–5% of total power). Consequently our model may have some inaccuracies owing to the dynamic effects of bike movement on rolling resistance, mechanical loses at higher velocities and gravitational effects of riding up or down hill. All of these factors could have a considerable effect on TT performance depending on course profile [16].

5 Conclusion

The NK device represents a reliable tool for measuring changes in aerodynamic drag during outdoor cycling for athletes and coaches and could be widely employed to assist in positional optimisation of time trial riding. We also demonstrate that there are meaningful impacts of change in stack height on CdA, APE, energy cost and predicted TT performance, however, these responses are highly individualised with regard to stack height changes. Positional optimisation for TTs should be completed on an individual basis as there does not appear to be one approach that works for all riders.

Data availability

Data collected and analysed as part of this investigation is freely available on request to the authors.

References

Martin JC, Gardner AS, Barras M, Martin DT (2006) Modeling sprint cycling using field-derived parameters and forward integration. Med Sci Sports Exerc 38:592–597. https://doi.org/10.1249/01.mss.0000193560.34022.04

Froncioni A (2017) Cycling Science. In: Cheung SS, Zabala M (eds) Cycling science: the ultimate nexus of knowledge and performance, 1st edn. Human Kinetics, Champaign, pp 92–109

di Prampero PE, Cortili G, Mognoni P, Saibene F (2017) Equation of motion of a cyclist. J Appl Physiol 47:201–206. https://doi.org/10.1152/jappl.1979.47.1.201

Fintelman DM, Sterling M, Hemida H, Li FX (2014) Optimal cycling time trial position models: aerodynamics versus power output and metabolic energy. J Biomech 47:1894–1898. https://doi.org/10.1016/j.jbiomech.2014.02.029

Kordi M, Fullerton C, Passfield L, Parker Simpson L (2019) Influence of upright versus time trial cycling position on determination of critical power and W′ in trained cyclists. Eur J Sport Sci 19:192–198. https://doi.org/10.1080/17461391.2018.1495768

Verma R, Hansen EA, de Zee M, Madeleine P (2016) Effect of seat positions on discomfort, muscle activation, pressure distribution and pedal force during cycling. J Electromyogr Kinesiol 27:78–86. https://doi.org/10.1016/j.jelekin.2016.02.003

de Moura BM, Moro VL, Rossato M et al (2017) Effects of saddle height on performance and muscular activity during the Wingate test. J Phys Educ 28:156. https://doi.org/10.4025/jphyseduc.v28i1.2838

Fintelman DM, Sterling M, Hemida H, Li FX (2016) Effect of different aerodynamic time trial cycling positions on muscle activation and crank torque. Scand J Med Sci Sports 26:528–534. https://doi.org/10.1111/sms.12479

Elmer SJ, Barratt PR, Korff T, Martin JC (2011) Joint-specific power production during submaximal and maximal cycling. Med Sci Sports Exerc 43:1940–1947. https://doi.org/10.1249/MSS.0b013e31821b00c5

Faulkner SH, Jobling P (2020) The effect of upper-body positioning on the aerodynamic-physiological economy of time-trial cycling. Int J Sports Physiol Perform 16:51–58. https://doi.org/10.1123/ijspp.2019-0547

Kyle C (1991) The effects of crosswinds upon time trials. Cycl Sci 3:51–56

Kordi M, Galis G, van Erp T, Terra W (2021) Reliability and sensitivity of the Notio Konect to quantify coefficient of drag area in elite track cyclists. Eur J Sport Sci 2021:1–6. https://doi.org/10.1080/17461391.2021.1891296

De PK, Roelands B, De GB, Meeusen R (2013) Guidelines to classify subject groups in sport- science research. Int J Sports Physiol Perform 8:111–122. https://doi.org/10.1123/ijspp.8.2.111

Vogler AJ, Rice AJ, Gore CJ (2010) Validity and reliability of the Cortex MetaMax3B portable metabolic system. J Sports Sci 28:456. https://doi.org/10.1080/02640410903582776

Shaw AJ, Ingham SA, Folland JP (2014) The valid measurement of running economy in runners. Med Sci Sports Exerc 46:1968–1973. https://doi.org/10.1249/MSS.0000000000000311

Malizia F, Blocken B (2020) Bicycle aerodynamics: history, state-of-the-art and future perspectives. J Wind Eng Ind Aerodyn 200:104134. https://doi.org/10.1016/j.jweia.2020.104134

Crouch TN, Burton D, LaBry ZA, Blair KB (2017) Riding against the wind: a review of competition cycling aerodynamics. Sports Eng 20:81–110. https://doi.org/10.1007/s12283-017-0234-1

Martin JC, Milliken DL, Cobb JE et al (1998) Validation of a mathematical model for road cycling power. J Appl Biomech 14:276–291. https://doi.org/10.1123/jab.14.3.276

Smith TB, Hopkins WG (2011) Variability and predictability of finals times of elite rowers. Med Sci Sports Exerc 43:2155–2160. https://doi.org/10.1249/MSS.0b013e31821d3f8e

Buchheit M (2016) The numbers will love you back in return—i promise. Int J Sports Physiol Perform 11:551–554. https://doi.org/10.1123/IJSPP.2016-0214

Cohen JW (1988) Statistical power analysis for the behavioural sciences, 2nd edn. Lawrence Erlbaum Associates, Hillside

Polanco AP, Muñoz LE, Doria A, Suarez DR (2020) Selection of posture for time-trial cycling events. Appl Sci (Switzerl) 10:563. https://doi.org/10.3390/APP10186546

Defraeye T, Blocken B, Koninckx E et al (2010) Aerodynamic study of different cyclist positions: CFD analysis and full-scale wind-tunnel tests. J Biomech 43:1262–1268. https://doi.org/10.1016/j.jbiomech.2010.01.025

Blocken B, Defraeye T, Koninckx E et al (2013) CFD simulations of the aerodynamic drag of two drafting cyclists. Comput Fluids 71:435–445. https://doi.org/10.1016/j.compfluid.2012.11.012

Fintelman DM, Sterling M, Hemida H, Li F-X (2015) The effect of time trial cycling position on physiological and aerodynamic variables. J Sports Sci 33:1730–1737. https://doi.org/10.1080/02640414.2015.1009936

Ryschon TW, James S-G (1991) The effect of body position on the energy cost of cycling. Med Sci Sports Exerc 23:146

Bini RR, Daly L, Kingsley M et al (2019) Muscle force adaptation to changes in upper body position during seated sprint cycling. J Sports Sci 37:2270–2278. https://doi.org/10.1080/02640414.2019.1627983

Jeukendrup AE, Hopkins S, Aragón-Vargas LF, Hulston C (2008) No effect of carbohydrate feeding on 16 km cycling time trial performance. Eur J Appl Physiol 104:831–837. https://doi.org/10.1007/s00421-008-0838-z

Jeukendrup A, Brouns F, Wagenmakers AJM, Saris WHM (1997) Carbohydrate-electrolyte feedings improve 1 h time trial cycling performance. Int J Sports Med 18:125–129. https://doi.org/10.1055/s-2007-972607

Jeukendrup AE, Craig NP, Hawley JA (2000) The bioenergetics of world class cycling. J Sci Med Sport 3:414–433. https://doi.org/10.1016/S1440-2440(00)80008-0

Peveler W, Bishop P, Smith J, Richardson M (2005) Effects of training in an aero position on anaerobic power output. J Exerc Physiol Online 7:52–56

Jeukendrup AE, Martin J (2001) How should we spend our time and money. Sports Med 31:559–569

Anderson JD (1984) Fundamentals of aerodynamics, 6th edn. McGraw Hill HIgher Education, New York

Acknowledgements

The authors would like to acknowledge the important contribution of all of the participants who agreed to volunteer for this study, their questioning throughout provided interesting insight into perceptions about aerodynamic optimisation. They also thank Dr Jamie Pringle for his discussion and insight into data analysis and interpretation. No potential competing interest was reported by the authors.

Funding

This research was supported by funding from Nottingham Trent University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors report that there are no competing interests to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Faulkner, S.H., Jobling, P., Griggs, K.E. et al. Individual aerodynamic and physiological data are critical to optimise cycling time trial performance: one size does not fit all. Sports Eng 27, 4 (2024). https://doi.org/10.1007/s12283-023-00446-0

Accepted:

Published:

DOI: https://doi.org/10.1007/s12283-023-00446-0