Abstract

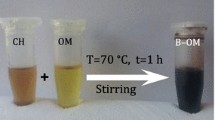

In this paper, a notable chitosan/poly(ethylene oxide) nanofiber mats containing tea tree oil liposomes (TOL-CENs) were successfully fabricated using electrospinning process. The microstructures and morphology were characterized by scanning electron microscopy. The porosity, fluid absorbability, water vapor permeability and mechanical properties of nanofiber mats were also estimated by ethanol density method, gravimetric method, dish method and tensile test, respectively. Compared to the chitosan/poly(ethylene oxide) composite freeze-dried sponges containing tea tree oil liposomes, TOL-CENs had greater porosity, water absorption, breathability and better mechanical properties. In addition, the controlled-release properties and long-term bactericidal capability of the material were also assessed. From the analysis of the release kinetics and mechanism, it was found that the significant decreased terpinen-4-ol concentration gradient from liposomal surface to the outside of material was the key to the sustained terpinen-4-ol release in virtue of liposomal encapsulation. TOL-CENs exhibited long-term and more excellent microbicidal effects against Staphylococcus aureus, Escherichia coli and Candida albicans than chitosan/poly(ethylene oxide) nanofiber mats. The combination of tea tree oil liposomes and chitosan in nanofiber mats synergistically destroyed cell membrane, prevented cell adhesion and caused the irregular aggregation of cytoplasm, resulting in cell disintegration observed by transmission electron microscope. In summary, TOL-CENs had potential application value as a long-term antimicrobial nonwoven materials.

Similar content being viewed by others

References

Y. Ren, J. Guo, Q. Lu, D. Xu, J. Qin, and F. Yan, Chemsuschem, 11, 1092 (2018).

Y. Zhu, C. Xu, N. Zhang, X. Ding, B. Yu, and F.-J. Xu, Adv. Funct. Mater., 28, 1706709 (2018).

T. V. Ivanova, R. Krumpolec, T. Homola, E. Musin, G. Baier, K. Landfester, D. C. Cameron, and M. Cernak, Plasma Processes Polym., 14, e1600231 (2017).

I. Yousefi, M. Pakravan, H. Rahimi, A. Bahador, Z. Farshadzadeh, and I. Haririan, Mat. Sci. Eng. C-Mater., 75, 433 (2017).

C. Kriegel, A. Arrechi, K. Kit, D. J. McClements, and J. Weiss, Crit. Rev. Food Sci. Nutr., 48, 775 (2008).

H. Cui, J. Wu, C. Li, and L. Lin, LWT — Food Sci. Technol., 81, 233 (2017).

L. Lin, Y. Zhu, C. Li, L. Liu, D. Surendhiran, and H. Cui, Carbohydr. Polym., 198, 225 (2018).

H. Cui, M. Bai, and L. Lin, Carbohydr. Polym., 179, 360 (2018).

M. Sadri, S. Arab-Sorkhi, H. Vatani, and A. Bagheri-Pebdeni, Fiber. Polym., 16, 1742 (2015).

S. Degoutin, M. Jimenez, F. Chai, T. Pinalie, S. Bellayer, M. Vandenbossche, C. Neut, N. Blanchemain, and B. Martel, J. Biomed. Mater. Res. A, 102, 3846 (2014).

N. Naveen, R. Kumar, S. Balaji, T. S. Uma, T. S. Natrajan, and P. K. Sehgal, Adv. Eng. Mater., 12, B380 (2010).

N. E. Zander, M. Gillan, and D. Sweetser, Materials, 9, 247 (2016).

X. Deng, A. Nikiforov, D. Vujosevic, V. Vuksanovic, B. Mugosa, U. Cvelbar, N. De Geyter, R. Morent, and C. Leys, Mater. Lett., 149, 95 (2015).

H. Rokbani, F. Daigle, and A. Ajji, Nanomaterials, 8, 129 (2018).

C. F. Carson, K. A. Hammer, and T. V. Riley, Clin. Microbiol. Rev., 19, 50 (2006).

M. Sherry, C. Charcosset, H. Fessi, and H. Greige-Gerges, J. Liposome Res., 23, 268 (2013).

B. M. Hausen, Dermatitis, 15, 213 (2004).

B. M. Hausen, J. Reichling, and M. Harkenthal, Am. J. Contact Dermat., 10, 68 (1999).

Y. Ge and M. Q. Ge, J. Liposome Res., 25, 222 (2015).

A. M. Abdelgawad, S. M. Hudson, and O. J. Rojas, Carbohydr. Polym., 100, 166 (2014).

J. S. Choi, K. W. Leong, and H. S. Yoo, Biomaterials, 29, 587 (2008).

K. Ohkawa, D. I. Cha, H. Kim, A. Nishida, and H. Yamamoto, Macromol. Rapid Commun., 25, 1600 (2004).

X. Y. Geng, O. H. Kwon, and J. H. Jang, Biomaterials, 26, 5427 (2005).

B. M. Min, S. W. Lee, J. N. Lim, Y. You, T. S. Lee, P. H. Kang, and W. H. Park, Polymer, 45, 7137 (2004).

B. Duan, C. H. Dong, X. Y. Yuan, and K. D. Yao, J. Biomaterials Sci-polym. E., 15, 797 (2004).

L. Deng, M. Taxipalati, A. Zhang, F. Que, H. Wei, F. Feng, and H. Zhang, J. Agr. Food Chem., 66, 6219 (2018).

D. Wang, Q. Lu, M. Wei, and E. Guo, J. Appl. Polym. Sci., 135, 46504 (2018).

R. X. Wu, G. F. Zheng, W. W. Li, L. B. Zhong, and Y. M. Zheng, J. Nanosci. Nanotechnol., 18, 5624 (2018).

Y. Ge and M. Q. Ge, J. Exp. Nanosci., 11, 345 (2015).

R. Bnyan, I. Khan, T. Ehtezazi, I. Saleem, S. Gordon, F. O’Neill, and M. Roberts, J. Pharm. Sci., 107, 1237 (2018).

K. B. Johnsen, J. M. Gudbergsson, M. Duroux, T. Moos, T. L. Andresen, and J. B. Simonsen, J. Control. Release, 269, 10 (2018).

C. Liolios, O. Gortzi, S. Lalas, J. Tsaknis, and I. Chinou, Food Chem., 112, 77 (2009).

C. Sinico, A. De Logu, F. Lai, D. Valenti, M. Manconi, G. Loy, L. Bonsignore, and A. M. Fadda, Eur. J. Pharm. Biopharm., 59, 161 (2005).

E. Moghimipour, N. Aghel, A. Zarei Mahmoudabadi, Z. Ramezani, and S. Handali, Jundishapur J. Nat. Pharm. Prod., 7, 117 (2012).

H. Cui, L. Yuan, W. Li, and L. Lin, Int. J. Food Sci. Tech., 52, 687 (2017).

H. Cui, M. Bai, M. M. A. Rashed, and L. Lin, Int. J. Food Microbiol., 266, 69 (2018).

L. Lin, Y. Dai, and H. Cui, Carbohydr. Polym., 178, 131 (2017).

L. Lin, Y. Zhu, and H. Cui, Lwt-Food Sci. Technol., 97, 711 (2018).

H. Cui, M. Bai, C. Li, R. Liu, and L. Lin, LWT — Food Sci. Technol., 96, 671 (2018).

Y. Ge and J. P. Tang, Fiber. Polym., 17, 862 (2016).

J. P. Tang and Y. Ge, Fiber. Polym., 18, 424 (2017).

J. L. Ford, K. Mitchell, P. Rowe, D. J. Armstrong, P. N. Elliott, C. Rostron, and J. E. Hogan, Int. J. Pharm., 71, 95 (1991).

H. Kim and R. Fassihi, J. Pharm. Sci., 86, 316 (1997).

H. Kim and R. Fassihi, J. Pharm. Sci., 86, 323 (1997).

C. Y. Gao, D. Y. Wang, and J. C. Shen, Polym. Adv. Technol., 14, 373 (2003).

G. Chen, T. Ushida, and T. Tateishi, Mat. Sci. Eng. C-Mater., 17, 63 (2001).

G. Dogan, F. Ozyildiz, G. Basal, and A. Uzel, Int. Polym. Process, 28, 143 (2013).

A. J. Bavariya, A. Norowski, Jr., K. M. Anderson, P. C. Adatrow, F. Garcia-Godoy, S. H. Stein, and J. D. Bumgardner, J. Biomed. Mater. Res. B, 102, 1084 (2014).

M. E. Frohbergh, A. Katsman, G. R. Botta, P. Lazarovici, C. L. Schauer, U. G. K. Wegst, and P. I. Lelkes, Biomaterials, 33, 9167 (2012).

K. Jalaja, D. Naskar, S. C. Kundu, and N. R. James, Carbohydr. Polym., 136, 1098 (2016).

I. M. Helander, E. L. Nurmiaho-Lassila, R. Ahvenainen, J. Rhoades, and S. Roller, Int. J. Food Microbiol., 71, 235 (2001).

L. G. Silva Garcia, G. M. de Melo Guedes, M. L. Queiroz da Silva, D. S. Collares Maia Castelo-Branco, J. J. Costa Sidrim, R. D. A. Cordeiro, M. F. Gadelha Rocha, R. S. Vieira and R. S. Nogueira Brilhante, Carbohydr. Polym., 195, 662 (2018).

Acknowledgements

This work was supported by National Natural Science Foundation of China (grant no. 51803095), Natural Science Research of Jiangsu Higher Education Institutions of China (grant no. 17KJB540002).

Author information

Authors and Affiliations

Corresponding author

Supplementary materials

12221_2019_1092_MOESM1_ESM.pdf

Characteristics, Controlled-release and Antimicrobial Properties of Tea Tree Oil Liposomes-incorporated Chitosan-based Electrospun Nanofiber Mats

Rights and permissions

About this article

Cite this article

Ge, Y., Tang, J., Fu, H. et al. Characteristics, Controlled-release and Antimicrobial Properties of Tea Tree Oil Liposomes-incorporated Chitosan-based Electrospun Nanofiber Mats. Fibers Polym 20, 698–708 (2019). https://doi.org/10.1007/s12221-019-1092-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-019-1092-1