Abstract

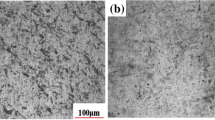

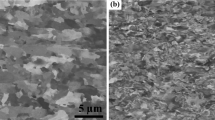

This experimental study on Al-SiC composite investigated the temperature distribution and microstructural characterization during pulsed current tungsten inert gas (PCTIG) welding. The parameters considered for PCTIG welding were peak current, base current, pulse frequency, and pulse on time. Experiments were designed and conducted using L9 orthogonal array technique. Regression model was developed to predict the ultimate tensile strength, bending load, cooling rate, and peak temperature. Statistical software was used to obtain the optimal PCTIG welding parameters, such as peak current of 160 A, base current of 60 A, pulse on time of 50 %, and pulse frequency of 5 Hz to attain desired result, including increased peak temperature of 446 °C, increased ultimate tensile strength of 138 MPa, and high cooling rate of 20 °C/s. Fine grain structures were also observed in weld region. Additionally, SEM fractography showed the difference in fracture surface between the PCTIG welding effects of different welding conditions. Statistical software was also used in identifying significant factors that caused improvement in weld strength, grain refinement in weld zone, and high cooling rate during PCTIG welding of Al-SiC composite.

Similar content being viewed by others

References

K. M. Shorowordi, T. Laoui, A. S. M. A. Haseeb, J. P. Celis and L. Froyen, Microstructure and interface characteristics of B4C, SiC and Al2O3 reinforced Al matrix composites - A comparative study, Journal of Materials Processing Technology, 142 (2003) 738–743, Doi: 10.1016/S0924-0136(03)00815-X.

A. M. El-Sabbagh, M. Soliman, M. A. Taha and H. Palkowski, Effect of rolling and heat treatment on tensile behaviour of wrought Al-SiCp composite prepared by stircasting, Journal of Materials Processing Technology, 213 (2013) 1669–1681, http:/dx.doi.org/10.1016/j.jmatprotec. 2013.04.013.

M. S. Han, H. K. Choi, J. U. Cho and C. D. Cho, Fracture property of double cantilever beam of aluminum foam bonded with spray adhesive, Journal of Mechanical Science & Technology, 29 (1) (2015) 5–10.

G. G. Sozhamannan, S. B. Prabu and V. S. K. Venkatagalapathy, Effect of processing parameters on metal matrix composites: Stir casting process, Journal of Surface Engineered Materials and Advanced Technology, 2 (2012) 11–15. Doi: 10.4236/jsemat.2012.21002.

S. Amirkhanlou, R. Jamaatri, B. Niroumand and M. R. Toroghinejad, Using ARB process as a solution for dilemma of Si and SiCp distribution in cast Al-Si/SiCp compoistes, Journal of Materials Processing Technology, 211 (2011) 1159–1165, Doi: 10.1016/j.jmatprotec.2011.01.019.

J. Hashim, L. Looney and M. S. J. Hashmi, Metal matrix composites: Production by the stir casting method, Journal of Materials Processing Technology, 92-93 (1999) 1–7, PII: S0924-0136(99)00118-1.

Y. Lei, W. Yuan, X. Chen, F. Zhu and X. Cheng, In-situ weld-alloying plasma arc welding of SiCp/Al MMC, Transactions of Nonferrous Metals Society of China, 17 (2007) 313–317.

A. Urena, M. D. Escalera and L. Gil, Influence of interface reactions on fracture mechanisms in TIG arc-welded aluminium matrix composites, Composites Science and Technology, 60 (2000) 613–622, PII: S0266-3538(99)00168-2.

X. Wang, J. Niu, S. Guan, L. Wang and D. Cheng, Investigation on TIG welding of SiCp-reinforced aluminum–matrix composite using mixed shielding gas and Al–Si filler, Materials Science and Engineering A, 499 (2009) 106–110, Doi: 10.1016/j.msea.2008.07.037.

J. Y. Lim, M. J. Yoon, S. Y. Kim, H. S. Shin and T. G. Kim, Mechanical properties of CO2/MIG welded structural rolled steel and stainless steel, Journal of Mechanical Science & Technology, 29 (1) (2015) 103–108.

A. Kumar, P. Shailesh and S. Sundarrajan, Optimization of magnetic arc oscillation process parameters on mechanical properties of AA5456 Aluminum alloy weldments, Materials and Design, 29 (2008) 1904–1913, Doi: 10.1016/j.matdes. 2008.04.044.

S. R. K. Rao, G. M. Reddy, M. Kamaraj and K. P. Rao, Grain refinement through arc manipulation techniques in Al- Cu alloy GTA welds, Materials Science and Engineering A, 404 (2005) 227–234, Doi: 10.1016/j.msea.2005.05.080.

T. S. Kumar, V. Balasubramanian and M. Y. Sanavullah, Influences of pulsed current tungsten inert gas welding parameter on the tensile properties of AA6061 aluminium alloy, Materials and Design, 28 (2007) 2080–2092, Doi: 10.1016/ j.matdes.2006.05.027.

V. Balasubramanian, V. Ravisankar and G. M. Reddy, Influences of pulsed current welding and post weld aging treatment on fatigue crack growth behaviour of AA7075 aluminium alloy joints, International Journal of Fatigue, 30 (2008) 405–416, Doi: 10.1016/j.ijfatigue.2007.04.012.

S. Kannan, S. S. Kumaran and L. A. Kumaraswamidhas, Optimization of friction welding by taguchi and ANOVA method on commercial aluminium tube to Al 2025 tube plate with backing block using an external tool, Journal of Mechanical Science & Technology, 30 (5) (2016) 2225–2235.

K. Karunakaran and V. Balasubramanian, Effect of pulsed current on temperature distribution, weld bead profiles and characteristics of gas tungsten arc welded aluminum alloy joints, Transactions of Nonferrous Metals Society of China, 21 (2011) 278–286, Doi: 10.1016/S1003-6326(11)60710-3.

V. Balasubramanian, V. Ravisankar and G. M. Reddy, Effect of pulsed current welding on fatigue behaviour of high strength aluminium alloy joints, Materials and Design, 19 (2008) 492–500, Doi: 10.1016/j.matdes.2006.12.015.

V. Balasubramanian, V. Ravisankar and G. M. Reddy, Effect of pulsed current welding on mechanical properties of high strength aluminum alloy, International Journal of Advanced Manufacturing Technology, 36 (2008) 254–262, Doi: 10.1007/s00170-006-0848-0.

G. Padmanaban and V. Balasubramanian, Optimization of pulsed current gas tungsten arc welding process parameters to attain maximum tensile strength in AZ31B magnesium alloy, Transaction of Nonferrous Metals Society of China, 21 (2011) 467–476, Doi: 10.1016/S1003-6326(11)60738-3.

K. S. Prasad, C. S. Rao and D. N. Rao, Optimizing pulsed current micro plasma arc welding parameters to maximize ultimate tensile strength of Inconel625 Nickel alloy using response surface method, International Journal of Engineering, Science and Technology, 6 (6) (2011) 226–236, Doi: http://dx.doi.org/10.4314/ijest.v3i6.18.

S. Babu, T. S. Kumar and V. Balasubramanian, Optimizing pulsed current gas tungsten arc welding parameters of AA6061 aluminium alloy using Hooke and Jeeves algorithm, Transactions of Nonferrous Metals Society of China, 18 (2008) 1028–1036.

A. R. Rose, K. Manisekar, V. Balasubramanian and S. Rajakumar, Predication and optimization of pulsed current tungsten inert gas welding parameter to attain maximum tensile strength in AZ61A magnesium alloy, Materials and Design, 37 (2012) 334–348, Doi: 10.1016/j.matdes.2012.01.007

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Young Whan Park

P. Sivachidambaram is a doctoral student in the School of Mechanical Engineering, SASTRA Deemed University. Past 7 years he is working on the field of composite material & welding and to evaluate the mechanical properties and material characteristics of the welded & casted material. He is having field of interest in Powder metallurgy, Material processing technology & Additive Manufacturing. He is broadening his research interest in Nuclear Materials, Reverse Engineering & Automation in Manufacturing.

Rights and permissions

About this article

Cite this article

Pichumani, S., Srinivasan, R. & Ramamoorthi, V. Mechanical properties, thermal profiles, and microstructural characteristics of Al-8 %SiC composite welded using pulsed current TIG welding. J Mech Sci Technol 32, 1713–1723 (2018). https://doi.org/10.1007/s12206-018-0130-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-018-0130-4