Abstract

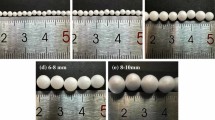

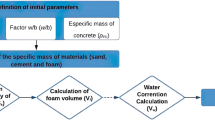

As the construction of high-rise building becomes popular, improvement and innovation are required to expand the product line of lightweight concrete. In this paper, two ways of fabricating lightweight concrete were combined to make a new kind of super lightweight concrete. Normal aggregate is replaced with expanded polystyrene (EPS) granule, while foam is introduced to facilitate fabrication process. As a result, super lightweight concrete denoted as EPS foamed concrete is fabricated, whose bulk density is less than 500 kg/m3. Compressive properties of EPS foamed concrete with bulk density 300–500 kg/m3 were investigated by stress-strain curve. It’s demonstrated that the compressive strength ranges from 0.7 to 2.5MPa, which is higher than that of similar products. Furthermore, low elastic module and high residual to ultimate strength ratio ensure its excellent deformation and energy absorption capacity. At last, numerical analysis was performed to interpret the inherent variation of elastic modulus and failure mechanism of this material. The results show that EPS foamed concrete is a kind of super lightweight, easy to fabricate material with excellent compressive property and profound utilization potential.

Similar content being viewed by others

References

Jones M R, Mccarthy A. Preliminary views on the potential of foamed concrete as a structural material [J]. Magazine of Concrete Research, 2005, 57(1): 21–32.

Narayanan N, Ramamurthy K. Structure and properties of aerated concrete: A review [J]. Cement & Concrete Composites, 2000, 22: 321–329.

Kurama H, Topcu I B, Karakurt C. Properties of the autoclaved aerated concrete produced from coal bottom ash [J]. Journal of Materials Processing Technology, 2009, 209: 767–773.

Al-Jabri K S, Hago A W, Al-Nuaimi A S, et al. Concrete blocks for thermal insulation in hot climate [J]. Cement and Concrete Research, 2005, 35: 1472–1479.

Laukaitis A, Fiks B. Acoustical properties of aerated autoclaved concrete [J]. Applied Acoustics, 2006, 67(3): 284–296.

Zollo R F, Hays C D. Engineering material properties of a fiber-reinforced cellular concrete [J]. ACI Materials Journal, 1998, 95: 631–635.

Dekelbab W. Particle packing using computational and experimental simulation [D]. Michigan, USA: Wayne State University, 2002.

Kearsley E P, Wainwright P J. Porosity and permeability of foamed concrete [J]. Cement and Concrete Research, 2001, 31: 805–812.

Lian C, Zhuge Y, Beecham S. The relationship between porosity and strength for porous concrete [J]. Construction and Building Materials, 2011, 25: 4294–4298.

Kunhanandan Nambiar E K, Ramamurthy K. Influence of filler type on the properties of foam concrete [J]. Cement and Concrete Composites, 2006, 28: 475–480.

Miled K, Sab K, le Roy R. Particle size effect on EPS lightweight concrete compressive strength: Experimental investigation and modeling [J]. Mechanics of Materials, 2007, 39(3): 222–240.

Guo Li-ying, Zhao Yun-ping, Zhang Da-wei, et al. Study on the preparation and strength influence of foamed concrete [J]. Concrete, 2011(10): 133–135 (in Chinese).

Zhou Shun-e, Lu Zhong-yuan, Jiao Lei, et al. Compression property and compression strength model of foamed concrete [J]. Journal of Wuhan University of Technology, 2010, 32(11): 9–13 (in Chinese).

Lorna J G, Michael F A. Cellular solids: Structure and properties [M]. London: Press Syndicate of the University of Cambridge, 1997.

Liu Guang-ting, Gao Zheng-guo. Random 3-D aggregate structure for concrete [J]. Journal of Tsinghua University: Science & Technology, 2003, 43(8): 1120–1123 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 50708059) and the Open Fund of Key Laboratory of Advanced Civil Engineering Materials (Tongji University), Ministry of Education (No. K201002)

Rights and permissions

About this article

Cite this article

Wu, Z., Chen, B. & Liu, N. Fabrication and compressive properties of expanded polystyrene foamed concrete: Experimental research and modeling. J. Shanghai Jiaotong Univ. (Sci.) 18, 61–69 (2013). https://doi.org/10.1007/s12204-013-1369-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-013-1369-2