Abstract

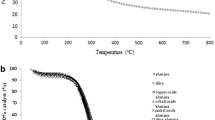

This work provides the first study about the evaluation of the bioenergy potential of lignocellulosic waste from Brazilian pine-fruit shell (Araucaria angustifolia). Physicochemical characterization, evolved gas from pyrolysis, and kinetic and thermodynamic studies were performed. A thermogravimetric analyzer was used for the pyrolysis experiments, where the runs were performed under an inert atmosphere of nitrogen at temperatures ranging from room temperature to 850 °C at different low heating rates (5, 10, 20, and 30 °C min−1). The physicochemical characterization of Brazilian pine-fruit shell showed good applicability for the gasification process due to the high fixed carbon content. Similarly, the pyrolysis experiments and FTIR-evolved gas analysis indicate its great potential for use as a solid biofuel. The kinetic study showed that the Kissinger–Akahira–Sunose method (ε = 0.07–0.11%) had a smaller relative error, when compared with the methods of Friedman (ε = 5.12–28.89%), Flynn–Wall–Ozawa (ε = 0.26–1.21%), and Starink (ε = 0.17%), and it was comparable to the Vyazovkin method (ε = 0.08–0.09%). Furthermore, the conversion rate curves obtained from kinetic parameters showed a satisfactory behavior, with a high regression coefficient (R2 ≥ 0.9165), thus demonstrating the great applicability of the parameters for the design and optimization of the thermochemical system. The endothermic and nonspontaneous process was observed, based on the positive ΔH, positive ΔG, and positive ΔS values of Brazilian pine-fruit shell. The pyrolysis of Brazilian pine-fruit shell has been identified as a viable alternative for bioenergy generation, acting as a solution for the final disposal of this agricultural waste biomass.

Similar content being viewed by others

References

IEA (2018) World energy balances: overview. IEA Publications, Paris France

Mao G, Zou H, Chen G, du H, Zuo J (2015) Past, current and future of biomass energy research: a bibliometric analysis. Renew Sust Energ Rev 52:1823–1833. https://doi.org/10.1016/j.rser.2015.07.141

Arena U, Di Gregorio F, Santonastasi M (2010) A techno-economic comparison between two design configurations for a small scale, biomass-to-energy gasification based system. Chem Eng J 162:580–590. https://doi.org/10.1016/j.cej.2010.05.067

Huang YF, Te CP, Kuan WH, Lo SL (2015) Effects of lignocellulosic composition and microwave power level on the gaseous product of microwave pyrolysis. Energy 89:974–981. https://doi.org/10.1016/j.energy.2015.06.035

Brasil JL, Ev RR, Milcharek CD et al (2006) Statistical design of experiments as a tool for optimizing the batch conditions to Cr(VI) biosorption on Araucaria angustifolia wastes. J Hazard Mater 133:143–153. https://doi.org/10.1016/j.jhazmat.2005.10.002

Lima EC, Royer B, Vaghetti JCP, Brasil JL, Simon NM, dos Santos AA Jr, Pavan FA, Dias SLP, Benvenutti EV, Silva EA (2007) Adsorption of Cu(II) on Araucaria angustifolia wastes: determination of the optimal conditions by statistic design of experiments. J Hazard Mater 140:211–220. https://doi.org/10.1016/j.jhazmat.2006.06.073

IBGE (2016) Instituto Brasileiro de Geografia e Estatística. Sistema IBGE de Recuperação Automática. Tabela 289- Quantidade produzida e valor da produção na extração vegetal, por tipo de produto (PINHÃO). <https://sidra.ibge.gov.br/tabela/289> (Accessed 02 August 2018)

Royer B, Cardoso NF, Lima EC, Vaghetti JCP, Simon NM, Calvete T, Veses RC (2009) Applications of Brazilian pine-fruit shell in natural and carbonized forms as adsorbents to removal of methylene blue from aqueous solutions—kinetic and equilibrium study. J Hazard Mater 164:1213–1222. https://doi.org/10.1016/j.jhazmat.2008.09.028

Royer B, Lima EC, Cardoso NF, Calvete T, Bruns RE (2010) Statistical design of experiments for optimization of batch adsorption conditions for removal of reactive red 194 textile dye from aqueous effluents. Chem Eng Commun 197:775–790. https://doi.org/10.1080/00986440903359004

Cardoso NF, Pinto RB, Lima EC, Calvete T, Amavisca CV, Royer B, Cunha ML, Fernandes THM, Pinto IS (2011) Removal of remazol black B textile dye from aqueous solution by adsorption. Desalination 269:92–103. https://doi.org/10.1016/j.desal.2010.10.047

Calvete T, Lima EC, Cardoso NF, Dias SLP, Pavan FA (2009) Application of carbon adsorbents prepared from the Brazilian pine-fruit-shell for the removal of Procion Red MX 3B from aqueous solution—kinetic, equilibrium, and thermodynamic studies. Chem Eng J 155:627–636. https://doi.org/10.1016/j.cej.2009.08.019

Papadikis K, Gu S, Bridgwater AV, Gerhauser H (2009) Application of CFD to model fast pyrolysis of biomass. Fuel Process Technol 90:504–512. https://doi.org/10.1016/j.fuproc.2009.01.010

Ranganathan P, Gu S (2016) Computational fluid dynamics modelling of biomass fast pyrolysis in fluidised bed reactors, focusing different kinetic schemes. Bioresour Technol 213:333–341. https://doi.org/10.1016/j.biortech.2016.02.042

Liu B, Papadikis K, Gu S, Fidalgo B, Longhurst P, Li Z, Kolios A (2017) CFD modelling of particle shrinkage in a fluidized bed for biomass fast pyrolysis with quadrature method of moment. Fuel Process Technol 164:51–68. https://doi.org/10.1016/j.fuproc.2017.04.012

Xue Q, Heindel TJ, Fox RO (2011) A CFD model for biomass fast pyrolysis in fluidized-bed reactors. Chem Eng Sci 66:2440–2452. https://doi.org/10.1016/j.ces.2011.03.010

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N (2011) Thermochimica Acta ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19. https://doi.org/10.1016/j.tca.2011.03.034

Gotor FJ, Criado JM, Malek J, Koga N (2000) Kinetic analysis of solid-state reactions: the universality of master plots for analyzing isothermal and nonisothermal experiments. J Phys Chem A 104:10777–10782. https://doi.org/10.1021/jp0022205

Batistella L, Silva V, Suzin RC, Virmond E, Althoff CA, Moreira RFPM, José HJ (2015) Gaseous emissions from sewage sludge combustion in a moving bed combustor. Waste Manag 46:430–439. https://doi.org/10.1016/j.wasman.2015.08.039

Pacioni TR, Soares D, Di Domenico M et al (2016) Bio-syngas production from agro-industrial biomass residues by steam gasification. Waste Manag 58:221–229. https://doi.org/10.1016/j.wasman.2016.08.021

ASTM (2014) E1131-08: standard test method for compositional analysis by thermogravimetry. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/E1131-08R14

Alves JLF, da Silva JCG, da Silva Filho VF, Alves RF, de Araujo Galdino WV, de Sena RF (2019) Kinetics and thermodynamics parameters evaluation of pyrolysis of invasive aquatic macrophytes to determine their bioenergy potentials. Biomass Bioenergy 121:28–40. https://doi.org/10.1016/j.biombioe.2018.12.015

da Silva JCG, Alves JLF, Galdino WV de A et al (2018) Pyrolysis kinetic evaluation by single-step for waste wood from reforestation. Waste Manag 72:265–273. https://doi.org/10.1016/j.wasman.2017.11.034

ASTM (2002) D5373-08: standard test methods for instrumental determination of carbon, hydrogen, and nitrogen in laboratory samples of coal. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D5373-08

ASTM (2018) D4239-18e1: standard test method for sulfur in the analysis sample of coal and coke using high-temperature tube furnace combustion. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D4239-18E01

Channiwala SA, Parikh PP (2002) A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 81:1051–1063. https://doi.org/10.1016/S0016-2361(01)00131-4

Kan T, Strezov V, Evans TJ (2016) Lignocellulosic biomass pyrolysis: a review of product properties and effects of pyrolysis parameters. Renew Sust Energ Rev 57:1126–1140. https://doi.org/10.1016/j.rser.2015.12.185

NIST (2018) National Institute of Standards and Technology—chemistry webbook. https://webbook.nist.gov. Accessed 9 Oct 2018

Vyazovkin S (2015) Isoconversional kinetics of thermally stimulated processes, 1st edn. Springer International Publishing, Cham

Starink M (2003) The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta 404:163–176. https://doi.org/10.1016/S0040-6031(03)00144-8

Vo TK, Ly HV, Lee OK, Lee EY, Kim CH, Seo JW, Kim J, Kim SS (2017) Pyrolysis characteristics and kinetics of microalgal Aurantiochytrium sp. KRS101. Energy 118:369–376. https://doi.org/10.1016/j.energy.2016.12.040

Zhou L, Zou H, Wang Y, le Z, Liu Z, Adesina AA (2017) Effect of potassium on thermogravimetric behavior and co-pyrolytic kinetics of wood biomass and low density polyethylene. Renew Energy 102:134–141. https://doi.org/10.1016/j.renene.2016.10.028

Lin Y, Liao Y, Yu Z, Fang S, Lin Y, Fan Y, Peng X, Ma X (2016) Co-pyrolysis kinetics of sewage sludge and oil shale thermal decomposition using TGA–FTIR analysis. Energy Convers Manag 118:345–352. https://doi.org/10.1016/j.enconman.2016.04.004

Vyazovkin S, Dollimore D (1996) Linear and nonlinear procedures in isoconversional computations of the activation energy of nonisothermal reactions in solids. J Chem Inf Comput Sci 36:42–45. https://doi.org/10.1021/ci950062m

Pérez-Maqueda LA, Criado JM (2000) The accuracy of Senum and Yang’s approximations to the Arrhenius integral. J Therm Anal Calorim 60:909–915. https://doi.org/10.1023/A:1010115926340

Olszak-Humienik M, Mozejko J (2000) Thermodynamic functions of activated complexes created in thermal decomposition processes of sulphates. Thermochim Acta 344:73–79. https://doi.org/10.1016/S0040-6031(99)00329-9

Kim YS, Kim YS, Kim SH (2010) Investigation of thermodynamic parameters in the thermal decomposition of plastic waste-waste lube oil compounds. Environ Sci Technol 44:5313–5317. https://doi.org/10.1021/es101163e

Pourmortazavi SM, Kohsari I, Teimouri MB, Hajimirsadeghi SS (2007) Thermal behaviour kinetic study of dihydroglyoxime and dichloroglyoxime. Mater Lett 61:4670–4673. https://doi.org/10.1016/j.matlet.2007.03.041

Straszko J, Olszak-Humienik M, Możejko J (1997) Kinetics of thermal decomposition of ZnSO4·7H2O. Thermochim Acta 292:145–150. https://doi.org/10.1016/S0040-6031(96)03114-0

Boonchom B, Puttawong S (2010) Thermodynamics and kinetics of the dehydration reaction of FePO4.2H2O. Phys B Condens Matter 405:2350–2355. https://doi.org/10.1016/j.physb.2010.02.046

Turmanova SC, Genieva SD, Dimitrova AS, Vlaev LT (2008) Non-isothermal degradation kinetics of filled with rise husk ash polypropene composites. Express Polym Lett 2:133–146. https://doi.org/10.3144/expresspolymlett.2008.18

Vlaev LT, Markovska IG, Lyubchev LA (2003) Non-isothermal kinetics of pyrolysis of rice husk. Thermochim Acta 406:1–7. https://doi.org/10.1016/S0040-6031(03)00222-3

Vassilev SV, Baxter D, Andersen LK, Vassileva CG (2010) An overview of the chemical composition of biomass. Fuel 89:913–933. https://doi.org/10.1016/j.fuel.2009.10.022

Bin YY, Ryu C, Khor A et al (2005) Effect of fuel properties on biomass combustion. Part II. Modelling approach—identification of the controlling factors. Fuel 84:2116–2130. https://doi.org/10.1016/j.fuel.2005.04.023

Domenico MD, Collazzo GC, Pacioni TR, José HJ, Moreira RFPM (2018) Gasification of Brazilian coal-chars with CO2: effect of samples’ properties on reactivity and kinetic modeling. Chem Eng Commun 0:1–11. https://doi.org/10.1080/00986445.2018.1477763

Alves JLF, Da Silva JCG, de Sena RF, et al (2018) CO2 gasification of biochars prepared from agroindustrial waste: a kinetic study. In: 26th European biomass conference and exhibition proceedings. Copenhagen, pp 769–777

Parascanu MM, Sánchez P, Soreanu G, Valverde JL, Sanchez-Silva L (2018) Environmental assessment of olive pomace valorization through two different thermochemical processes for energy production. J Clean Prod 186:771–781. https://doi.org/10.1016/j.jclepro.2018.03.169

Yu Y, Yang Y, Cheng Z, Blanco PH, Liu R, Bridgwater AV, Cai J (2016) Pyrolysis of rice husk and corn stalk in auger reactor. 1. Characterization of char and gas at various temperatures. Energy Fuel 30:10568–10574. https://doi.org/10.1021/acs.energyfuels.6b02276

García R, Pizarro C, Lavín AG, Bueno JL (2012) Characterization of Spanish biomass wastes for energy use. Bioresour Technol 103:249–258. https://doi.org/10.1016/j.biortech.2011.10.004

Haykiri-Acma H, Turan AZ, Yaman S, Kucukbayrak S (2010) Controlling the excess heat from oxy-combustion of coal by blending with biomass. Fuel Process Technol 91:1569–1575. https://doi.org/10.1016/j.fuproc.2010.06.004

García R, Pizarro C, Lavín AG, Bueno JL (2014) Spanish biofuels heating value estimation. Part I: ultimate analysis data. Fuel 117:1130–1138. https://doi.org/10.1016/j.fuel.2013.08.048

Sanchez-Silva L, López-González D, Garcia-Minguillan AM, Valverde JL (2013) Pyrolysis, combustion and gasification characteristics of Nannochloropsis gaditana microalgae. Bioresour Technol 130:321–331. https://doi.org/10.1016/j.biortech.2012.12.002

Werner K, Pommer L, Broström M (2014) Thermal decomposition of hemicelluloses. J Anal Appl Pyrolysis 110:130–137. https://doi.org/10.1016/j.jaap.2014.08.013

Collard F-X, Blin J (2014) A review on pyrolysis of biomass constituents: mechanisms and composition of the products obtained from the conversion of cellulose, hemicelluloses and lignin. Renew Sust Energ Rev 38:594–608. https://doi.org/10.1016/j.rser.2014.06.013

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788. https://doi.org/10.1016/j.fuel.2006.12.013

Liu C, Hu J, Zhang H, Xiao R (2016) Thermal conversion of lignin to phenols: relevance between chemical structure and pyrolysis behaviors. Fuel 182:864–870. https://doi.org/10.1016/j.fuel.2016.05.104

Sahoo S, Seydibeyoğlu MÖ, Mohanty AK, Misra M (2011) Characterization of industrial lignins for their utilization in future value added applications. Biomass Bioenergy 35:4230–4237. https://doi.org/10.1016/j.biombioe.2011.07.009

Silverstein RM, Webster FX, Kiemle DJ (2005) Spectrometric identification of organic compounds, 7th edn. Wiley, New York

Shen DK, Gu S, Bridgwater AV (2010) Study on the pyrolytic behaviour of xylan-based hemicellulose using TG–FTIR and Py–GC–FTIR. J Anal Appl Pyrolysis 87:199–206. https://doi.org/10.1016/j.jaap.2009.12.001

Chen D, Liu D, Zhang H, Chen Y, Li Q (2015) Bamboo pyrolysis using TG–FTIR and a lab-scale reactor: analysis of pyrolysis behavior, product properties, and carbon and energy yields. Fuel 148:79–86. https://doi.org/10.1016/j.fuel.2015.01.092

Zhao J, Xiuwen W, Hu J, Liu Q, Shen D, Xiao R (2014) Thermal degradation of softwood lignin and hardwood lignin by TG-FTIR and Py-GC/MS. Polym Degrad Stab 108:133–138. https://doi.org/10.1016/j.polymdegradstab.2014.06.006

Zhou H, Long Y, Meng A, Chen S, Li Q, Zhang Y (2015) A novel method for kinetics analysis of pyrolysis of hemicellulose, cellulose, and lignin in TGA and macro-TGA. RSC Adv 5:26509–26516. https://doi.org/10.1039/C5RA02715B

Burnham AK, Zhou X, Broadbelt LJ (2015) Critical review of the global chemical kinetics of cellulose thermal decomposition. Energy Fuel 29:2906–2918. https://doi.org/10.1021/acs.energyfuels.5b00350

Yeo JY, Chin BLF, Tan JK, Loh YS (2017) Comparative studies on the pyrolysis of cellulose, hemicellulose, and lignin based on combined kinetics. J Energy Inst 92:27–37. https://doi.org/10.1016/j.joei.2017.12.003

Wang S, Ru B, Dai G, Shi Z, Zhou J, Luo Z, Ni M, Cen K (2017) Mechanism study on the pyrolysis of a synthetic β-O-4 dimer as lignin model compound. Proc Combust Inst 36:2225–2233. https://doi.org/10.1016/j.proci.2016.07.129

Alves JLF, Da Silva JCG, Costa RL et al (2018) Investigation of the bioenergy potential of microalgae Scenedesmus acuminatus by physicochemical characterization and kinetic analysis of pyrolysis. J Therm Anal Calorim. https://doi.org/10.1007/s10973-018-7506-2

Chen C, Miao W, Zhou C, Wu H (2017) Thermogravimetric pyrolysis kinetics of bamboo waste via asymmetric double sigmoidal (Asym2sig) function deconvolution. Bioresour Technol 225:48–57. https://doi.org/10.1016/j.biortech.2016.11.013

Yuan X, He T, Cao H, Yuan Q (2017) Cattle manure pyrolysis process: kinetic and thermodynamic analysis with isoconversional methods. Renew Energy 107:489–496. https://doi.org/10.1016/j.renene.2017.02.026

Müsellim E, Tahir MH, Ahmad MS, Ceylan S (2018) Thermokinetic and TG/DSC-FTIR study of pea waste biomass pyrolysis. Appl Therm Eng 137:54–61. https://doi.org/10.1016/j.applthermaleng.2018.03.050

Ye G, Luo H, Ren Z, Ahmad MS, Liu CG, Tawab A, al-Ghafari AB, Omar U, Gull M, Mehmood MA (2018) Evaluating the bioenergy potential of Chinese liquor-industry waste through pyrolysis, thermogravimetric, kinetics and evolved gas analyses. Energy Convers Manag 163:13–21. https://doi.org/10.1016/j.enconman.2018.02.049

Kaur R, Gera P, Jha MK, Bhaskar T (2018) Pyrolysis kinetics and thermodynamic parameters of castor (Ricinus communis) residue using thermogravimetric analysis. Bioresour Technol 250:422–428. https://doi.org/10.1016/j.biortech.2017.11.077

Huang L, Liu J, He Y, Sun S, Chen J, Sun J, Chang KL, Kuo J, Ning X’ (2016) Thermodynamics and kinetics parameters of co-combustion between sewage sludge and water hyacinth in CO2/O2 atmosphere as biomass to solid biofuel. Bioresour Technol 218:631–642. https://doi.org/10.1016/j.biortech.2016.06.133

Ahmad MS, Mehmood MA, Liu C-G, Tawab A, Bai FW, Sakdaronnarong C, Xu J, Rahimuddin SA, Gull M (2018) Bioenergy potential of Wolffia arrhiza appraised through pyrolysis, kinetics, thermodynamics parameters and TG-FTIR-MS study of the evolved gases. Bioresour Technol 253:297–303. https://doi.org/10.1016/j.biortech.2018.01.033

Mehmood MA, Ye G, Luo H, Liu C, Malik S, Afzal I, Xu J, Ahmad MS (2017) Pyrolysis and kinetic analyses of camel grass (Cymbopogon schoenanthus) for bioenergy. Bioresour Technol 228:18–24. https://doi.org/10.1016/j.biortech.2016.12.096

Ahmad MS, Mehmood MA, Al Ayed OS et al (2017) Kinetic analyses and pyrolytic behavior of Para grass (Urochloa mutica) for its bioenergy potential. Bioresour Technol 224:708–713. https://doi.org/10.1016/j.biortech.2016.10.090

Fournel S, Marcos B, Godbout S, Heitz M (2015) Predicting gaseous emissions from small-scale combustion of agricultural biomass fuels. Bioresour Technol 179:165–172. https://doi.org/10.1016/j.biortech.2014.11.100

Acknowledgments

We are also thankful to LCA/UFPB and LACOM/UFPB for the permission to use their facilities.

Funding

The authors are grateful to the financial support given by the Brazilian Council for Scientific and Technological Development (CNPq/Brazil process 423869/2016-7) and Brazilian Coordination for the Improvement of Higher Education Personnel (CAPES/Brazil finance code 001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• This is the first study that provides parameters for the initial application of Brazilian pine-fruit shell for bioenergy production.

• Typical compounds released from Brazilian pine-fruit are identified through TG-FTIR.

• Kinetics, thermodynamic parameters, and reaction mechanism were investigated.

• Simulation using the kinetic parameter of pyrolysis showed good adjustment with experimental data.

• The Brazilian pine-fruit shell has bioenergy potential comparable to established bioenergy feedstocks.

Electronic Supplementary Material

ESM 1

(DOCX 18 kb)

Rights and permissions

About this article

Cite this article

Alves, J.L.F., Da Silva, J.C.G., da Silva Filho, V.F. et al. Determination of the Bioenergy Potential of Brazilian Pine-Fruit Shell via Pyrolysis Kinetics, Thermodynamic Study, and Evolved Gas Analysis. Bioenerg. Res. 12, 168–183 (2019). https://doi.org/10.1007/s12155-019-9964-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-019-9964-1