Abstract

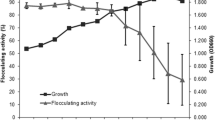

The effect of the type of carbohydrate (glucose, fructose, sucrose or galactose) used as the carbon source in the substrate on weissellin A production by Weissella paramesenteroides DX was evaluated on a solid-state cultivation procedure and conventional batch fermentations. Solid-state cultivation was done on M17-based medium over 3- and 6-h incubation periods. Experimental data showed that glucose supports the highest production levels on a per cell basis. Stirred tank bioreactor fermentations carried out at 50 % dissolved oxygen tension revealed the superiority of glucose over the other carbohydrates. Glucose supports growth-associated production and increased production rates and productivities (1,120 AU/ml). Growth-associated production was maintained with fructose but with lower fermentation rates and productivities. Sucrose cannot support this type of production. Fermentations with sucrose were characterized of lower sugar uptake rates, and lower specific growth and production rates, with bacteriocin titres not exceeding 630 AU/ml, while product formation kinetics were of the intermediate type.

Similar content being viewed by others

Abbreviations

- Symbols:

-

Units

- AU, Arbitrary units of activity:

-

AU/ml

- CFU, Colony forming units:

-

CFU/ml

- k s, Saturation constant:

-

–

- q p, Specific production rate:

-

AU/g/l

- r s, Substrate consumption rate :

-

g/l/h

- r x, Growth rate:

-

g/l/h

- r p, Product formation rate:

-

AU/ml/h

- x v, Biomass:

-

g/l

- α,Product formation parameter:

-

–

- β, Product formation parameter:

-

–

- μ, Specific growth rate :

-

h−1

- μ max, Maximum specific growth rate:

-

h−1

References

Papagianni, M. (2003). Biotechnology Advances, 79, 465–499.

Biswas, S. R., Ray, P., Johnson, M. C., & Ray, B. (1991). Applied and Environmental Micriobiology, 57, 1265–1267.

Jimenez-Diaz, R., Rios-Sanchez, R. M., Desmazeaud, M., Ruiz-Barba, J. L., & Piard, J. C. (1993). Applied and Environmental Micriobiology, 59, 1416–1424.

Papagianni, M., & Papamichael, E. M. (2011). Bioresource Technology, 102, 6730–6734.

Wu, C. W., Yin, L. J., & Jiang, S. T. (2004). Journal of Agricultural and Food Chemistry, 52, 1146–1151.

Cabo, M. L., Murado, M. A., Gonzalez, M. P., & Pastoriza, L. (2001). Enzyme and Microbial Technology, 29, 264–273.

De Vuyst, L. (1995). Journal of Applied Bacteriology, 78, 28–33.

Papagianni, M., Avramidis, N., & Filiousis, G. (2007). Enzyme and Microbial Technology, 40, 1557–1563.

Ray, B. (1992). In B. Ray & M. Daeschel (Eds.), Food biopreservatives of microbial origin (pp. 265–322). New York: CRC Press.

Ray, B., & Miller, K. W. (2000). In A. S. Naidu (Ed.), Natural food antimicrobial systems (pp. 525–566). Boca Raton: CRC Press.

Desjardins, P., Meghrous, J., & Lacroix, C. (2001). International Dairy Journal, 11, 943–951.

GenBank. http://www.ncbi.nlm.nih.gov/genbank/. Accessed 2012.

UniProt KB. http://www.ebi.ac.uk/swissprot; http://www.uniprot.org. Accessed 2012.

Fimland, G., Sletten, K., & Nissen-Meyer, J. (2002). Biochemical and Biophysical Research Communications, 295, 826–827.

Papagianni, M. (2012). Bioprocess and Biosystems Engineering. doi:10.1007/s00449-012-0689-1.

Kandler, O. (1983). Antonie Van Leeuwenhoek, 49, 209–224.

Chandrapati, S., & O’Sullivan, D. J. (1998). Journal of Biotechnology, 63, 229–233.

Luedeking, R., & Piret, E. L. (1959). Journal of Biochemistry, Microbiology and Technological Engineering, 1, 393–412.

Terzaghi, B., & Sandine, W. E. (1975). Applied Microbiology, 29, 807–813.

Wolf, C. E., & Gibbons, W. R. (1996). Journal of Applied Bacteriology, 80, 453–457.

Kunst, A., Draeger, B., & Ziegenhom, J. (1986). Methods of Enzymatic Analysis, 6, 178–185.

Sinclair, C. G., & Kristiansen, B. (1987). Fermentation Kinetics and Modelling. New York: Taylor and Francis.

Papagianni, M., Avramidis, N., Filiousis, G., Dasiou, D., & Ambrosiadis, I. (2006). Microbial Cell Factories, 5, 30.

Tramer, J., & Fowler, G. G. (1964). Journal of the Science of Food and Agriculture, 15, 522–528.

Guerra, N. P., Luisa Rua, M., & Pastrana, L. (2001). International Journal of Food Microbiology, 70, 267–281.

Neysens, P., Messens, W., Gevers, D., Swings, J., & De Vuyst, L. (2003). Microbiology, 149, 1073–1082.

Hemme, D., & Foucaud-Scheunemann, C. H. (2004). International Dairy Journal, 14, 467–494.

Benomar, N., Abriouel, H., Lee, H., Cho, G. S., Huch, M., Pulido, R. P., et al. (2011). Journal of Bacteriology, 193, 5868–5869.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Papagianni, M., Papamichael, E.M. Production of the Antimicrobial Protein Weisselin A by Weissella paramesenteroides DX in Batch Fermentations: the Type of Carbohydrate Used as the C-Source in the Substrate Affects the Association of Production with Growth. Appl Biochem Biotechnol 168, 1212–1222 (2012). https://doi.org/10.1007/s12010-012-9851-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-012-9851-0