Abstract

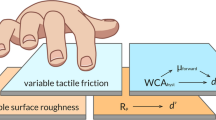

Polymer-based furniture with wood-like visual printing is widely used in domestic and office applications. Although polymers could fulfil the high quality requirements of strength and appearance, they cannot mimic the feel of wood during touch. In this study, polymers with textured surfaces were designed to mimic the tactile friction and naturalness of wood. The influence of a series of factors on tactile friction was assessed. Textured polypropylene surfaces showed a 14.8% reduction in friction, and were more similar to wood compared to un-textured rough polypropylene surface, indicating the significant influence of surface texture on tactile friction. The touch perception test further proved that polymer samples were perceived as more natural with a rough or textured surface than with a smooth surface. This study suggests that, with a detailed design of the surface texture parameter, it is possible to mimic the tactile friction and naturalness of wood by using textured polymers.

Similar content being viewed by others

References

X. Zhou, J. Mo, Y. Li, J. Xu, X. Zhang, S. Cai, and Z. Jin, X. Zhou, J. Mo, Y. Li, J. Xu, X. Zhang, S. Cai, and Z. Jin, Tribol. Int. 123, 286 (2018).

S. Derler, and L.C. Gerhardt, S. Derler, and L.C. Gerhardt, Tribol. Lett. 45, 1 (2012).

X. Zeng, and E. van der Heide, X. Zeng, and E. van der Heide, Skin Care Suppl. H&PC Today 10(2), 14 (2015).

S.A. Jadhav, A.V. Rane, K. Kanny, S.S. Mulge, V.K. Abitha, and S. Thomas, S.A. Jadhav, A.V. Rane, K. Kanny, S.S. Mulge, V.K. Abitha, and S. Thomas, Application of blends and polyurethane interpenetrating polymer networks, in Polyurethane Polymers: Blends and Interpenetrating Polymer Networks. ed. by S. Thomas, J. Datta, J.T. Haponiuk, and A. Reghunadhan (Elsevier, Amsterdam, 2017), pp. 359–375.

H. Dahy, H. Dahy, Sensors 19, 738 (2019).

K.E. Overvliet, and S. Soto-Faraco, K.E. Overvliet, and S. Soto-Faraco, Acta Psychol. 136, 92 (2011).

W. Yin, Z. Liu, P. Tian, D. Tao, Y. Meng, Z. Han, and Y. Tian, W. Yin, Z. Liu, P. Tian, D. Tao, Y. Meng, Z. Han, and Y. Tian, Biotribology 5, 67 (2016).

M. Xu, L. Li, M. Wang, and B. Luo, M. Xu, L. Li, M. Wang, and B. Luo, Tribol. Trans. 57, 87 (2014).

B.A. Svensson, S. Nystrom, P.A. Gradin, and H. Hoglund, B.A. Svensson, S. Nystrom, P.A. Gradin, and H. Hoglund, Tribol. Int. 42, 190 (2009).

M.A. Darden, and C.J. Schwartz, M.A. Darden, and C.J. Schwartz, Wear 267, 1289 (2009).

S. Schreiner, M. Rechberger, and J. Bertling, S. Schreiner, M. Rechberger, and J. Bertling, Tribol. Int. 63, 21 (2013).

S.P. Tay, X. Hu, P. Fleming, and S. Forrester, S.P. Tay, X. Hu, P. Fleming, and S. Forrester, Mater. Des. 89, 177 (2016).

J.D. Ndengue, I. Cesini, J. Faucheu, E. Chatelet, H. Zahouani, D. Delafosse, and F. Massi, J.D. Ndengue, I. Cesini, J. Faucheu, E. Chatelet, H. Zahouani, D. Delafosse, and F. Massi, IEEE T. Haptics 10(3), 409 (2017).

S. Zhang, A. Rodriguez Urribarri, M. Morales Hurtado, X. Zeng, and E. van der Heide, S. Zhang, A. Rodriguez Urribarri, M. Morales Hurtado, X. Zeng, and E. van der Heide, Int. J. Solids Struct. 56–57, 53 (2015).

J. Chen, H. Yang, J. Li, J. Chen, Y. Zhang, and X. Zeng, J. Chen, H. Yang, J. Li, J. Chen, Y. Zhang, and X. Zeng, J. Mech. Behav. Biomed 94, 308 (2019).

U. Heinrich, U. Koop, M.C. Leneven-Duchemin, K. Osterrieder, S. Bielfeldt, C. Chkarnat, J. Deggwert, D. Hantschel, S. Jaspers, H.P. Nissen, M. Rohr, G. Schneider, and H. Tronnier, U. Heinrich, U. Koop, M.C. Leneven-Duchemin, K. Osterrieder, S. Bielfeldt, C. Chkarnat, J. Deggwert, D. Hantschel, S. Jaspers, H.P. Nissen, M. Rohr, G. Schneider, and H. Tronnier, Int. J. Cosmet. Sci. 25(1–2), 45 (2003).

S. Comaish, and E. Bottoms, S. Comaish, and E. Bottoms, Br. J. Dermatol. 84(1), 37 (1971).

S.E. Tomlinson, R. Lewis, and M.J. Carre, S.E. Tomlinson, R. Lewis, and M.J. Carre, Wear 267, 1311 (2009).

A. C. Rodriguez Urribarri, The role of tactile friction on the differentiation of surface textures. PhD thesis, University of Twente, ISBN 978-90-365-4222-7 (2016).

S. Zhang, X. Zeng, D.T.A. Matthews, A. Igartua, E. Rodriguez-Vidal, J. Contrearas Fortes, and E. van der Heide, S. Zhang, X. Zeng, D.T.A. Matthews, A. Igartua, E. Rodriguez-Vidal, J. Contrearas Fortes, and E. van der Heide, Friction 5(2), 207 (2017).

S. Ding, Y. Pan, M. Tong, and X. Zhao, S. Ding, Y. Pan, M. Tong, and X. Zhao, Sensors 17, 2748 (2017).

D. Gueorguiev, E. Vezzoli, A. Mouraux, B. Lemaire-Semail, and J.-L. Thonnard, D. Gueorguiev, E. Vezzoli, A. Mouraux, B. Lemaire-Semail, and J.-L. Thonnard, J. R. Soc. Interface 14, 2017641 (2017).

I. Cesini, J.D. Ndengue, E. CHatelet, J. Faucheu, and F. Massi, I. Cesini, J.D. Ndengue, E. CHatelet, J. Faucheu, and F. Massi, Tribol. Int. 120, 330 (2018).

W. Tang, R. Liu, Y. Shi, C. Hu, S. Bai, and H. Zhu, W. Tang, R. Liu, Y. Shi, C. Hu, S. Bai, and H. Zhu, J. Adv. Res. 21, 129–139 (2020).

W. Tang, X. Lu, S. Chen, S. Ge, X. Jing, X. Wang, R. Liu, and H. Zhu, W. Tang, X. Lu, S. Chen, S. Ge, X. Jing, X. Wang, R. Liu, and H. Zhu, J. Text. I. 111, 623 (2020).

M.K. Saleen, C. Yilmaz, and C. Basdogan, M.K. Saleen, C. Yilmaz, and C. Basdogan, IEEE T. Haptics 4(11), 599 (2018).

Acknowledgement

This work was supported by the Natural Science Foundation of Shanghai (17ZR1442100), FP7 Marie Curie CIG (PCIG10-GA-2011-303922), and European Fund for Regional Development GO EFRO 209-18331.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all the authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, L., Rodríguez Urribarrí, A.C., Wang, H. et al. Textured Polymer Surfaces Mimicking the Tactile Friction Between Wood and Skin. JOM 73, 515–523 (2021). https://doi.org/10.1007/s11837-020-04513-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04513-w