Abstract

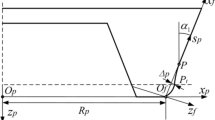

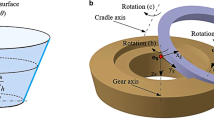

A complex geometric modeling method of a helical face gear pair with arc-tooth generated by an arc-profile cutting (APC) disc is proposed, and its tooth contact characteristics are analyzed. Firstly, the spatial coordinate system of an APC face gear pair is established based on meshing theory. Combining the coordinate transformation matrix and the tooth profile of the cutter, the equations of the curve envelope of the APC face gear pair are obtained. Then the surface equations are solved to extract the point clouds data by programming in MATLAB, which contains the work surface and the fillet surface of the APC face gear pair. And the complex geometric model of the APC face gear pair is built by fitting its point clouds. At last, through the analysis of the tooth surface contact, the sensitivity of the APC face gear to the different types of mounting errors is obtained. The results show that the APC face gear pair is the most sensitive to mounting errors in the tooth thickness direction, and it should be strictly controlled in the actual application.

摘要

本文提出了一种直升机用弧齿面齿轮副的复杂几何模型建模方法, 并对其进行了齿面接触分析. 首先, 基于啮合原理, 建立了齿轮副啮合的空间坐标系, 推导了刀具的齿面方程, 并得到了齿轮副的曲面包络族方程. 然后, 根据约束条件, 使用啮合方程求解齿轮副的工作曲面和过渡曲面的点云坐标, 并拟合点云以获得弧齿面齿轮副的复杂三维模型. 最后, 通过对弧齿面齿轮副的齿面接触分析, 研究了其在不同类型安装误差下的敏感程度. 结果表明; 弧齿面齿轮副对沿齿厚方向引入的安装误差最为敏感, 在实际应用中应当严格控制.

Similar content being viewed by others

References

LITVIN F L, ZHANG Y, WANG J C, et al. Design and geometry of face-gear drives [J]. Journal of Mechanical Design, 1992, 114(4): 642–647. DOI: https://doi.org/10.1115/1.2917055.

LITVIN F L, EGELJA A, TAN J, et al. Computerized design, generation and simulation of meshing of orthogonal offset face-gear drive with a spur involute pinion with localized bearing contact [J]. Mechanism and Machine Theory, 1998, 33(1, 2): 87–102. DOI: https://doi.org/10.1016/S0094-114X(97)00022-0.

LITVIN F L, FUENTES A. Gear geometry and applied theory [M]. Cambridge: Cambridge University Press, 2004. DOI: https://doi.org/10.1017/cbo9780511547126.

SARIBAY Z B, BILL R C, SMITH E C, et al. Geometry and kinematics of conjugate meshing face-gear pairs [J]. Journal of the American Helicopter Society, 2017, 62(3): 1–10. DOI: https://doi.org/10.4050/jahs.62.032008.

LIU Da-wei, WANG Guo-hui, REN Ting-zhi. Transmission principle and geometrical model of eccentric face gear [J]. Mechanism and Machine Theory, 2017, 109: 51–64. DOI: https://doi.org/10.1016/j.mechmachtheory.2016.10.024.

WANG Yan-zhong, CHU Xiao-meng, ZHAO Wen-jun, et al. A precision generating hobbing method for face gear with assembly spherical hob [J]. Journal of Central South University, 2019, 26(10): 2704–2716. DOI: https://doi.org/10.1007/s11771-019-4207-3.

WU Yuan-hang, ZHOU Yuan-sheng, ZHOU Zhen-yu, et al. An advanced CAD/CAE integration method for the generative design of face gears [J]. Advances in Engineering Software, 2018, 126: 90–99. DOI: https://doi.org/10.1016/j.advengsoft.2018.09.009.

ZHOU Yuan-sheng, PENG Shan-dong, LIU Xin-ru, et al. A novel method to generate the tooth surface model of face-milled generated spiral bevel gears [J]. The International Journal of Advanced Manufacturing Technology, 2019, 102(5–8): 1205–1214. DOI: https://doi.org/10.1007/s00170-018-2951-4.

ZHOU Yuan-sheng, WU Yuan-hang, WANG Li-ming, et al. A new closed-form calculation of envelope surface for modeling face gears [J]. Mechanism and Machine Theory, 2019, 137: 211–226. DOI: https://doi.org/10.1016/j.mechmachtheory.2019.03.024.

SHEN Yun-bo, LIU Xuan. Computer-integrated shaving processing for spiroid face gear on a five-axis CNC machine [J]. The International Journal of Advanced Manufacturing Technology, 2018, 97(1–4): 1061–1070. DOI: https://doi.org/10.1007/s00170-018-1988-8.

ZHOU Yuan-sheng, WANG Sheng-hui, WANG Li-ming, et al. CNC milling of face gears with a novel geometric analysis [J]. Mechanism and Machine Theory, 2019, 139: 46–65. DOI: https://doi.org/10.1016/j.mechmachtheory.2019.04.009.

WANG Yan-zhong, HOU Liang-wei, LAN Zhou, et al. Precision milling method for face-gear by disk cutter [J]. The International Journal of Advanced Manufacturing Technology, 2017, 89(5–8): 1545–1558. DOI: https://doi.org/10.1007/s00170-016-9189-9.

WANG Sheng-hui, ZHOU Yuan-sheng, LIU Xin-ru, et al. An advanced comprehensive approach to accurately modeling the face-milled generated spiral bevel gears [J]. Journal of Computing and Information Science in Engineering, 2021, 21(4): 041008. DOI: https://doi.org/10.1115/1.4049152.

WANG Yan-zhong, HOU Liang-wei, LAN Zhou, et al. Precision grinding technology for complex surface of aero face-gear [J]. The International Journal of Advanced Manufacturing Technology, 2016, 86(5–8): 1263–1272. DOI: https://doi.org/10.1007/s00170-015-8241-5.

TANG Jin-yuan, YIN Feng, CHEN Xing-ming. The principle of profile modified face-gear grinding based on disk wheel [J]. Mechanism and Machine Theory, 2013, 70: 1–15. DOI: https://doi.org/10.1016/j.mechmachtheory.2013.06.013.

PENG Xian-long, NIU Qin-yu, GUO Wei, et al. A new method of motion rule synthesis for face gear manufacturing by plane-cutter [J]. Journal of Mechanical Design, 2018, 140(2): 023302. DOI: https://doi.org/10.1115/1.4037762.

KOLIVAND M, KAHRAMAN A. An ease-off based method for loaded tooth contact analysis of hypoid gears having local and global surface deviations [J]. Journal of Mechanical Design, 2010, 132(7): 071004. DOI: https://doi.org/10.1115/1.4001722.

SIMON V. Computer simulation of tooth contact analysis of mismatched spiral bevel gears [J]. Mechanism and Machine Theory, 2007, 42(3): 365–381. DOI: https://doi.org/10.1016/j.mechmachtheory.2006.02.010.

SIMON V V. Influence of tooth modifications on tooth contact in face-hobbed spiral bevel gears [J]. Mechanism and Machine Theory, 2011, 46(12): 1980–1998. DOI: https://doi.org/10.1016/j.mechmachtheory.2011.05.002.

TANG Jin-yuan, CUI Wei, ZHOU heng, et al. Integrity of grinding face-gear with worm wheel [J]. Journal of Central South University, 2016, 23(1): 77–85. DOI: https://doi.org/10.1007/s11771-016-3051-y.

LIN Chao, WEI Yan-qun, CAI Zhi-qin. Study on the compound transmission mechanism of the curve-face gear based on screw theory [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2018, 232(17): 3115–3124. DOI: https://doi.org/10.1177/0954406217730092.

TANG Jin-yuan, LIU Yan-ping. Loaded multi-tooth contact analysis and calculation for contact stress of face-gear drive with spur involute pinion [J]. Journal of Central South University, 2013, 20(2): 354–362. DOI: https://doi.org/10.1007/s11771-013-1495-x.

CUI Wei, TANG Jin-yuan. New method for calculating face gear tooth surface involving worm wheel installation errors [J]. Journal of Central South University, 2017, 24(8): 1767–1778. DOI: https://doi.org/10.1007/s11771-017-3585-7.

MING Xing-zu, GAO Qin, YAN Hong-zhi, et al. Mathematical modeling and machining parameter optimization for the surface roughness of face gear grinding [J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(9–12): 2453–2460. DOI: https://doi.org/10.1007/s00170-016-9576-2.

MO Shuai, ZHANG Yi-du. Spiral bevel gear true tooth surface precise modeling and experiments studies based on machining adjustment parameters [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2015, 229(14): 2524–2533. DOI: https://doi.org/10.1177/0954406214562632.

MO Shuai, ZHANG Yi-du, WU Qiong. Research on multiple-split load sharing of two-stage star gearing system in consideration of displacement compatibility [J]. Mechanism and Machine Theory, 2015, 88: 1–15. DOI: https://doi.org/10.1016/j.mechmachtheory.2015.01.005.

MO Shuai, ZHANG Ting, JIN Guo-guang, et al. Analytical investigation on load sharing characteristics of herringbone planetary gear train with flexible support and floating sun gear [J]. Mechanism and Machine Theory, 2020, 144: 103670. DOI: https://doi.org/10.1016/j.mechmachtheory.2019.103670.

MO Shuai, ZHANG Ting, JIN Guo-guang, et al. Influence mechanism of multi-coupling error on the load sharing characteristics of herringbone gear planetary transmission system [J]. Proceedings of the Institution of Mechanical Engineers, Part K: Journal of Multi-Body Dynamics, 2019, 233(4): 792–816. DOI: https://doi.org/10.1177/1464419319848175.

LI Zheng-min-qing, WANG Jing, ZHU Ru-peng. Influence comparisons of two version tooth profile modifications on face gear dynamic behaviors [J]. Journal of Vibroengineering, 2016, 18(6): 3499–3511. DOI: https://doi.org/10.21595/jve.2016.17025.

TANG Jin-yuan, HU Ze-hua, CHEN Si-yu, et al. Effects of directional rotation radius and transmission error on the dynamic characteristics of face gear transmission system [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2014, 228(7): 1108–1118. DOI: https://doi.org/10.1177/0954406213500745.

CHEN C K, YANG S C. Geometric modelling for cylindrical and helical gear pumps with circular arc teeth [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2000, 214(4): 599–607. DOI: https://doi.org/10.1243/0954406001523939.

CUI Yan-mei, FANG Zong-de, SU Jin-zhan, et al. Precise modeling of arc tooth face-gear with transition curve [J]. Chinese Journal of Aeronautics, 2013, 26(5): 1346–1351. DOI: https://doi.org/10.1016/j.cja.2013.04.006.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Project(51805368) supported by the National Natural Science Foundation of China; Project(2018QNRC001) supported by the Young Elite Scientists Sponsorship Program, China; Project(DMETKF2021017) supported by the Fund of State Key Laboratory of Digital Manufacturing Equipment and Technology, Huazhong University of Science and Technology, China; Project(HTL-0-21G07) supported by the National key Laboratory of Science and Technology on Heicopter Transmission, China

Contributors

MO Shuai provided the concept, designed the project and performed data analysis. SONG Wen-hao wrote the paper, and carried out data processing. ZHU Sheng-ping performed data analysis, and contributed to the paper writing. TANG Wen-jie contributed to the data analysis. FENG Zhi-you and GAO Han-jun contributed to the paper revising.

Conflict of interest

MO Shuai, SONG Wen-hao, ZHU Sheng-ping, FENG Zhi-you, TANG Wen-jie, and GAO Han-jun declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Mo, S., Song, Wh., Zhu, Sp. et al. Complex geometric modeling and tooth contact analysis of a helical face gear pair with arc-tooth. J. Cent. South Univ. 29, 1213–1225 (2022). https://doi.org/10.1007/s11771-022-4988-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4988-7