Abstract

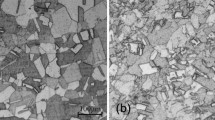

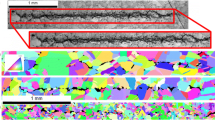

A series of sweeping detonation experiments were conducted to study the grain boundary effects during the primary spallation of high-purity copper cylinder. The free surface velocity profile of the shocked samples was measured by Doppler pins systems. The soft-recovered samples were characterized by optical and electron backscatter diffraction microscopy, and the effects of microstructures like grain boundaries, and crystal orientation on spall behavior were investigated. The results indicated that the critical stress of deformation twinning in cylindrical copper increased. The nucleation sites of spallation damage were determined by the joint influence of the grain orientation (Taylor factor) and the angle between grain boundaries and radial impact-stress direction. Voids were prone to nucleating at the grain boundaries perpendicular to the radial impact-stress direction. Nevertheless, the number of voids nucleated at boundaries was relatively different from the results obtained from the plate impact experiment and plate sweeping detonation experiment, which is a result of the curvature that existed in the cylindrical copper and the obliquity of the impact-stress direction during sweeping detonation loading.

摘要

本文通过对柱壳状高纯铜进行一系列的滑移爆轰实验, 研究了晶界对柱壳状高纯铜初期层裂过 程的影响. 利用多普勒探针系统(DPS)测量了受冲击样品的自由表面速度曲线. 通过光学显微镜和电 子背散射衍射(EBSD)技术对软回收的样品进行了表征, 具体研究了微观结构如晶界、晶体取向等对层 裂行为的影响. 结果表明, 柱壳状高纯铜在层裂过程中形变孪晶临界应力会增大; 晶粒取向(TF值)和 晶界与径向冲击应力方向的夹角共同决定了层裂损伤的形核位置; 孔洞容易在垂直于径向冲击应力方 向的晶界处形核. 与之前平板飞片冲击实验和平板滑移爆轰实验的结果相比, 本滑移爆轰实验中高纯 铜在晶界处形核的孔洞数量存在较大差异, 这是由柱壳状试样自身的几何曲率和滑移爆轰加载过程中 冲击应力方向与晶界之间的倾角引起的.

Similar content being viewed by others

References

GRAY G T III, HULL L M, LIVESCU V, et al. Influence of sweeping detonation-wave loading on shock hardening and damage evolution during spallation loading in tantalum [J]. EPJ Web of Conferences, 2012, 26: 02004. DOI: https://doi.org/10.1051/epjconf/20122602004.

KOSKELO A C, GREENFIELD S R, PAISLEY D L, et al. Dynamics of the onset of damage in metals under shock loading [J]. AIP Conference Proceedings, 2007, 955(1): 557–560. DOI: https://doi.org/10.1063/1.2833143.

FURNISH M D, CHHABILDAS L C, REINHART W D, et al. Determination and interpretation of statistics of spatially resolved waveforms in spalled tantalum from 7 to 13 GPa [J]. International Journal of Plasticity, 2009, 25(4): 587–602. DOI: https://doi.org/10.1016/j.ijplas.2008.12.007.

ESCOBEDO J P, CERRETA E K, DENNIS-KOLLER D. Effect of crystalline structure on intergranular failure during shock loading [J]. JOM, 2014, 66(1): 156–164. DOI: https://doi.org/10.1007/s11837-013-0798-6.

BROWN A D, WAYNE L, PHAM Q, et al. Microstructural effects on damage nucleation in shock-loaded polycrystalline copper [J]. Metallurgical and Materials Transactions A, 2015, 46(10): 4539–4547. DOI: https://doi.org/10.1007/s11661-014-2482-z.

YANG Yang, PENG Zhi-qiang, CHEN Xing-zhi, et al. Spall behaviors of high purity copper under sweeping detonation [J]. Materials Science and Engineering A, 2016, 651: 636–645. DOI: https://doi.org/10.1016/j.msea.2015.11.022.

YANG Yang, JIANG Zhi, CHEN Ji-xiong, et al. The characteristics of void distribution in spalled high purity copper cylinder under sweeping detonation [J]. Philosophical Magazine, 2018, 98(9): 752–765. DOI: https://doi.org/10.1080/14786435.2017.1417649.

YANG Yang, PENG Zhi-qiang, GUO Zhao-liang, et al. Multidimensional study on spall behavior of high-purity copper under sliding detonation [J]. Metallurgical and Materials Transactions A, 2015, 46(9): 4070–4077. DOI: https://doi.org/10.1007/s11661-015-3027-9.

YANG Yang, CHEN Ji-xiong, PENG Zhi-qiang, et al. X-ray quantitative analysis on spallation response in high purity copper under sweeping detonation [J]. Materials Science and Engineering A, 2016, 667: 54–60. DOI: https://doi.org/10.1016/j.msea.2016.04.090.

YANG Yang, CHEN Ji-xiong, GUO Zhao-liang, et al. 3-D characterization of incipient spallation response in cylindrical copper under sweeping detonation [J]. Journal of Materials Research, 2017, 32(8): 1499–1505. DOI: https://doi.org/10.1557/jmr.2017.25.

YANG Yang, WANG Can, CHEN Xing-zhi, et al. Effects of the phase interface on spallation damage nucleation and evolution in multiphase alloy [J]. Journal of Alloys and Compounds, 2018, 740: 321–329. DOI: https://doi.org/10.1016/j.jallcom.2018.01.031.

YANG Yang, WANG Can, CHEN Xing-zhi, et al. The void nucleation mechanism within lead phase during spallation of leaded brass [J]. Philosophical Magazine, 2018, 98(21): 1975–1990. DOI: https://doi.org/10.1080/14786435.2018.1468942.

YANG Y, JIANG Z, WANG C, et al. Effects of the phase interface on initial spallation damage nucleation and evolution in dual phase titanium alloy [J]. Materials Science and Engineering A, 2018, 731: 385–393. DOI: https://doi.org/10.1016/j.msea.2018.06.066.

YANG Yang, YANG Shuang-jun, WANG Hai-min. Effects of the phase content on dynamic damage evolution in Fe50Mn30Co10Cr10 high entropy alloy [J]. Journal of Alloys and Compounds, 2021, 851: 156883. DOI: https://doi.org/10.1016/j.jallcom.2020.156883.

YANG Yang, WANG Hai-min, WANG Can, et al. Effects of the phase interface on spallation damage nucleation and evolution in dual-phase steel [J]. Steel Research International, 2020, 91(6): 1900583. DOI: https://doi.org/10.1002/srin.201900583.

TEN K A, PRUUEL E R, KASHKAROV A O, et al. Detection of particle ejection from shock-loaded metals by synchrotron radiation methods [J]. Combustion, Explosion, and Shock Waves, 2018, 54(5): 606–613. DOI: https://doi.org/10.1134/s0010508218050143.

ANTIPOV M V, YURTOV I V, UTENKOV A A, et al. Piezoelectric method for measuring the parameters of shock-induced ejecta [J]. Combustion, Explosion, and Shock Waves, 2018, 54(5): 599–605. DOI: https://doi.org/10.1134/s0010508218050131.

CHUDAKOV E A, FEDOROV A V, FINYUSHIN S A, et al. Determining the velocity and specific weight of a particle flow discharged from surfaces of metals under a shock-wave load [J]. Combustion, Explosion, and Shock Waves, 2018, 54(5): 593–598. DOI: https://doi.org/10.1134/s001050821805012x.

DRENNOV O B, MIKHAILOV A L. Initial stage in the acceleration of thin plates in the grazing detonation mode of a high explosive charge [J]. Combustion, Explosion and Shock Waves, 1979, 15(4): 539–542. DOI: https://doi.org/10.1007/BF00743138.

MEYERS M. Dynamic behavior of materials [M]. New York: Wiley, 1994.

KANEL G I. Distortion of the wave profiles in an elastoplastic body upon spalling [J]. Journal of Applied Mechanics and Technical Physics, 2001, 42(2): 358–362. DOI: https://doi.org/10.1023/A:1018804709273.

SANCHEZ J C, MURR L E, STAUDHAMMER K P. Effect of grain size and pressure on twinning and microbanding in oblique shock loading of copper rods [J]. Acta Materialia, 1997, 45(8): 3223–3235. DOI: https://doi.org/10.1016/S1359-6454(97)00018-9.

RICE J R, TRACEY D M. On the ductile enlargement of voids in triaxial stress fields [J]. Journal of the Mechanics and Physics of Solids, 1969, 17(3): 201–217. DOI: https://doi.org/10.1016/0022-5096(69)90033-7.

PERALTA P, DIGIACOMO S, HASHEMIAN S, et al. Characterization of incipient spall damage in shocked copper multicrystals [J]. International Journal of Damage Mechanics, 2009, 18(4): 393–413. DOI: https://doi.org/10.1177/1056789508097550.

WAYNE L, KRISHNAN K, DIGIACOMO S, et al. Statistics of weak grain boundaries for spall damage in polycrystalline copper [J]. Scripta Materialia, 2010, 63(11): 1065–1068. DOI: https://doi.org/10.1016/j.scriptamat.2010.08.003.

WATANABE T, TSUREKAWA S. Prediction and control of grain boundary fracture in brittle materials on the basis of the strongest-link theory [J]. Materials Science Forum, 2005, 482: 55–62. DOI: https://doi.org/10.4028/www.scientific.net/msf.482.55.

CAO Fang, BEYERLEIN I J, ADDESSIO F L, et al. Orientation dependence of shock-induced twinning and substructures in a copper bicrystal [J]. Acta Materialia, 2010, 58(2): 549–559. DOI: https://doi.org/10.1016/j.actamat.2009.09.033.

CERRETA E K, ESCOBEDO J P, PEREZ-BERGQUIST A, et al. Early stage dynamic damage and the role of grain boundary type [J]. Scripta Materialia, 2012, 66(9): 638–641. DOI: https://doi.org/10.1016/j.scriptamat.2012.01.051.

FENSIN S J, CERRETA E K, III G T G, et al. Why are some interfaces in materials stronger than others? [J]. Scientific Reports, 2014, 4: 5461. DOI: https://doi.org/10.1038/srep05461.

FENSIN S J, ESCOBEDO-DIAZ J P, BRANDL C, et al. Effect of loading direction on grain boundary failure under shock loading [J]. Acta Materialia, 2014, 64: 113–122. DOI: https://doi.org/10.1016/j.actamat.2013.11.026.

KRISHNAN K, BROWN A, WAYNE L, et al. Three-dimensional characterization and modeling of microstructural weak links for spall damage in FCC metals [J]. Metallurgical and Materials Transactions A, 2015, 46(10): 4527–4538. DOI: https://doi.org/10.1007/s11661-014-2667-5.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Projects(51871243, 51574290) supported by the National Natural Science Foundation of China; Project(2019JJ40381) supported by the Natural Science Foundation of Hunan Province, China; Project supported by the Guangdong-Hong Kong-Macao Joint Laboratory for Neutron Scattering Science and Technology, China

Contributors

YANG Yang provided the concept and edited the draft of the manuscript. HUANG Jun-yi and WANG Hai-min conducted the literature review and wrote the first draft of the manuscript. HUANG Jun-yi, WANG Hai-min, and CHEN Ji-xiong analyzed the measured data. GUO Zhao-liang edited the draft of the manuscript. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

YANG Yang, HUANG Jun-yi, WANG Hai-min, CHEN Ji-xiong, and GUO Zhao-liang declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Yang, Y., Huang, Jy., Wang, Hm. et al. Grain boundary effects on spall behavior of high purity copper cylinder under sweeping detonation. J. Cent. South Univ. 29, 1107–1117 (2022). https://doi.org/10.1007/s11771-022-4980-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4980-2

Key words

- sweeping detonation

- high purity copper cylinder

- spallation

- microstructure

- electron backscatter diffraction