Abstract

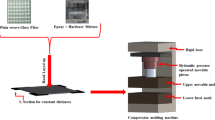

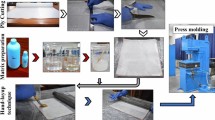

In this study, the effect of fiber angle on the tensile load-bearing performance and damage failure characteristics of glass composite laminates was investigated experimentally, analytically, and numerically. The glass fabric in the laminate was perfectly aligned along the load direction (i.e., at 0°), offset at angles of 30° and 45°, or mixed in different directions (i.e., 0°/30° or 0°/45°). The composite laminates were fabricated using vacuum-assisted resin molding. The influence of fiber orientation angle on the mechanical properties and stiffness degradation of the laminates was studied via cyclic tensile strength tests. Furthermore, simulations have been conducted using finite element analysis and analytical approaches to evaluate the influence of fiber orientation on the mechanical performance of glass laminates. Experimental testing revealed that, although the composite laminates laid along the 0° direction exhibited the highest stiffness and strength, their structural performance deteriorated rapidly. We also determined that increasing the fiber offset angle (i.e., 30°) could optimize the mechanical properties and damage failure characteristics of glass laminates. The results of the numerical and analytical approaches demonstrated their ability to capture the mechanical behavior and damage failure modes of composite laminates with different fiber orientations, which may be used to prevent the catastrophic failures that occur in composite laminates.

Similar content being viewed by others

References

Almeida J H S Jr, Ribeiro M L, Tita V, Amico S C. Stacking sequence optimization in composite tubes under internal pressure based on genetic algorithm accounting for progressive damage. Composite Structures, 2017, 178: 20–26

Bruyneel M. Composite Materials Research Progress. New York: Nova Science Pub Inc., 2008

Kathiravan R, Ganguli R. Strength design of composite beam using gradient and particle swarm optimization. Composite Structures, 2007, 81(4): 471–479

Giasin K. Machining fibre metal laminates and Al2024-T3 aluminium alloy. Dissertation for the Doctoral Degree. Sheffield: University of Sheffield, 2017

Giasin K, Dhakal H N, Featheroson C A, Pimenov D Y, Lupton C, Jiang C, Barouni A, Koklu U. Effect of fibre orientation on impact damage resistance of S2/FM94 glass fibre composites for aerospace applications: An experimental evaluation and numerical validation. Polymers, 2021, 14(1): 95

Khalid M Y, Rashid A A, Arif Z U, Akram N, Arshad H, García Márquez F P. Characterization of failure strain in fiber reinforced composites: Under on-axis and off-axis loading. Crystals, 2021, 11(2): 216

Wang L, Zhao B, Wu J, Chen C, Zhou K. Experimental and numerical investigation on mechanical behaviors of woven fabric composites under off-axial loading. International Journal of Mechanical Sciences, 2018, 141: 157–167

Megahed M, Megahed A, Agwa M. Mechanical properties of on/off-axis loading for hybrid glass fiber reinforced epoxy filled with silica and carbon black nanoparticles. Materials Technology, 2018, 33(6): 398–405

Ogi K, Takao Y. Characterization of piezoresistance behavior in a CFRP unidirectional laminate. Composites Science and Technology, 2005, 65(2): 231–239

Soliman E, Al-Haik M, Taha M R. On and off-axis tension behavior of fiber reinforced polymer composites incorporating multi-walled carbon nanotubes. Journal of Composite Materials, 2012, 46(14): 1661–1675

Zhang Y, Zhuang X. Cracking elements: A self-propagating strong discontinuity embedded approach for quasi-brittle fracture. Finite Elements in Analysis and Design, 2018, 144: 84–100

Zhang Y, Mang H A. Global cracking elements: A novel tool for Galerkin-based approaches simulating quasi-brittle fracture. International Journal for Numerical Methods in Engineering, 2020, 121(11): 2462–2480

Zhang Y, Lackner R, Zeiml M, Mang H A. Strong discontinuity embedded approach with standard SOS formulation: Element formulation, energy-based crack-tracking strategy, and validations. Computer Methods in Applied Mechanics and Engineering, 2015, 287: 335–366

Rabczuk T, Zi G, Bordas S, Nguyen-Xuan H. A simple and robust three-dimensional cracking-particle method without enrichment. Computer Methods in Applied Mechanics and Engineering, 2010, 199(37–40): 2437–2455

Callens M, Gorbatikh L, Verpoest I. Ductile steel fibre composites with brittle and ductile matrices. Composites. Part A, Applied Science and Manufacturing, 2014, 61: 235–244

Schmeer S, Steeg M, Maier M, Mitschang P. Metal fibre reinforced composite-potentialities and tasks. Advanced Composites Letters, 2009, 18(2): 096369350901800202

Katnam K, Dalfi H, Potluri P. Towards balancing in-plane mechanical properties and impact damage tolerance of composite laminates using quasi-UD woven fabrics with hybrid warp yarns. Composite Structures, 2019, 225: 111083

Dalfi H, Babu-Katnum K, Potluri P, Selver E. The role of hybridisation and fibre architecture on the post-impact flexural behaviour of composite laminates. Journal of Composite Materials, 2021, 55(11): 1499–1515

Dalfi H. Improving the mechanical performance and impact damage tolerance of glass composite laminates via multi-scales of hybridization. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 2022, 236(12): 2339–2356

Kretsis G. A review of the tensile, compressive, flexural and shear properties of hybrid fibre-reinforced plastics. Composites, 1987, 18(1): 13–23

Swolfs Y, Gorbatikh L, Verpoest I. Fibre hybridisation in polymer composites: A review. Composites. Part A, Applied Science and Manufacturing, 2014, 67: 181–200

You Y J, Park Y H, Kim H Y, Park J S. Hybrid effect on tensile properties of FRP rods with various material compositions. Composite Structures, 2007, 80(1): 117–122

Hwang S F, Mao C P. Failure of delaminated interply hybrid composite plates under compression. Composites Science and Technology, 2001, 61(11): 1513–1527

Yerramalli C S, Waas A. Compressive behavior of hybrid composites. In: The 44th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Norfolk, VI: American Institute of Aeronautics and Astronautics Inc., 2003

Wisnom M R, Czél G, Swolfs Y, Jalalvand M, Gorbatikh L, Verpoest I. Hybrid effects in thin ply carbon/glass unidirectional laminates: Accurate experimental determination and prediction. Composites. Part A, Applied Science and Manufacturing, 2016, 88: 131–139

Hayashi T. On the improvement of mechanical properties of composites by hybrid composition. In: Proceedings of the 8th International Reinforced Plastics Congress. London: British Plastics Federation, 1972, 149–152

Czél G, Jalalvand M, Wisnom M R. Design and characterisation of advanced pseudo-ductile unidirectional thin-ply carbon/epoxy-glass/epoxy hybrid composites. Composite Structures, 2016, 143: 362–370

Selver E, Dalfi H, Yousaf Z. Investigation of the impact and postimpact behaviour of glass and glass/natural fibre hybrid composites made with various stacking sequences: Experimental and theoretical analysis. Journal of Industrial Textiles, 2022, 51(8): 1264–1294

Dalfi H, Al-Obaidi A J, Razaq H. The influence of the inter-ply hybridisation on the mechanical performance of composite laminates: Experimental and numerical analysis. Science Progress, 2021, 104(2): 1–29

Sezgin H, Berkalp O B. The effect of hybridization on significant characteristics of jute/glass and jute/carbon-reinforced composites. Journal of Industrial Textiles, 2017, 47(3): 283–296

Mariatti M, Nasir M, Ismail H. Effect of stacking sequence on the properties of plain-satin hybrid laminate composites. Polymer-Plastics Technology and Engineering, 2003, 42(1): 65–79

Park R, Jang J. Stacking sequence effect of aramid-UHMPE hybrid composites by flexural test method: Material properties. Polymer Testing, 1998, 16(6): 549–562

Zhang J, Chaisombat K, He S, Wang C H. Hybrid composite laminates reinforced with glass/carbon woven fabrics for lightweight load bearing structures. Materials & Design, 2012, 36: 75–80

Jesthi D K, Nayak R K. Improvement of mechanical properties of hybrid composites through interply rearrangement of glass and carbon woven fabrics for marine application. Composites. Part B, Engineering, 2019, 168: 467–475

Das S C, Paul D, Grammatikos S A, Siddiquee M A, Papatzani S, Koralli P, Islam J M M, Khan M A, Shauddin S M, Khan R A, Vidakis N, Petousis M. Effect of stacking sequence on the performance of hybrid natural/synthetic fiber reinforced polymer composite laminates. Composite Structures, 2021, 276: 114525

Petrucci R, Santulli C, Puglia D, Sarasini F, Torre L, Kenny J. Mechanical characterisation of hybrid composite laminates based on basalt fibres in combination with flax, hemp and glass fibres manufactured by vacuum infusion. Materials & Design, 2013, 49: 728–735

Murugan R, Ramesh R, Padmanabhan K. Investigation on static and dynamic mechanical properties of epoxy based woven fabric glass/carbon hybrid composite laminates. Procedia Engineering, 2014, 97: 459–468

Ganguli R. Optimal design of composite structures: A historical review. Journal of the Indian Institute of Science, 2013, 93: 557–570

Tarfaoui M, Choukri S, Nême A. Effect of fibre orientation on mechanical properties of the laminated polymer composites subjected to out-of-plane high strain rate compressive loadings. Composites Science and Technology, 2008, 68(2): 477–485

Hosur M, Alexander J, Vaidya U, Jeelani S, Mayer A. Studies on the off-axis high strain rate compression loading of satin weave carbon/epoxy composites. Composite Structures, 2004, 63(1): 75–85

Chen D, Luo Q, Meng M, Li Q, Sun G. Low velocity impact behavior of interlayer hybrid composite laminates with carbon/glass/basalt fibres. Composites. Part B, Engineering, 2019, 176: 107191

Hossain R, Islam A, Van Vuure A, Ignaas V. Effect of fiber orientation on the tensile properties of jute epoxy laminated composite. Journal of scientific research, 2013, 5: 43–54

Jackson P, Cratchley D. The effect of fibre orientation on the tensile strength of fibre-reinforced metals. Journal of the Mechanics and Physics of Solids, 1966, 14(1): 49–64

Degrieck J and Van Paepegem W. Fatigue damage modeling of fibre-reinforced composite materials. Applied Mechanics Reviews, 2001, 54(4): 279–300

Van Paepegem W, Degrieck J. A new coupled approach of residual stiffness and strength for fatigue of fibre-reinforced composites. International Journal of Fatigue, 2002, 24(7): 747–762

Herakovich C T. Mechanics of composites: A historical review. Mechanics Research Communications, 2012, 41: 1–20

Nurhaniza M, Ariffin M, Ali A, Mustapha F, Noraini A. Finite element analysis of composites materials for aerospace applications. In: IOP Conference Series: Materials Science and Engineering. Putrajaya: IOP Publishing Ltd., 2010, 012010

Sadeghian P, Rahai A R, Ehsani M R. Effect of fiber orientation on nonlinear behavior of CFRP composites. Journal of Reinforced Plastics and Composites, 2009, 28(18): 2261–2272

Lupěşteanu V, Ţǎranu N, Popoaei S. Theoretical strength properties of unidirectional reinforced fiber reinforced polymer composites. The Bulletin of the Polytechnic Institute of Jassy, Construction. Architecture Section, 2013, 59(6): 83

Kaw A K. Mechanics of Composite Materials. Boca Raton, FL: CRC press, 2005

Dalfi H. Effect of intra-yarn hybridisation and fibre architecture on the impact response of composite laminates: Experimental and numerical analysis. Proceedings of the Institution of Mechanical Engineers. Part C, Journal of Mechanical Engineering Science, 2022, 236(6): 3004–3026

Moreno M S, Muñoz S H. Pseudo-ductile effects in ±45° angle-ply CFRP laminates under uniaxial loading: Compression and cyclic tensile test. Composites. Part B, Engineering, 2022, 233: 109631

Morioka K, Tomita Y. Effect of lay-up sequences on mechanical properties and fracture behavior of CFRP laminate composites. Materials Characterization, 2000, 45(2): 125–136

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Dalfi, H., Al-Obaidi, A., Tariq, A. et al. Optimization of the mechanical performance and damage failure characteristics of laminated composites based on fiber orientation. Front. Struct. Civ. Eng. 17, 1357–1369 (2023). https://doi.org/10.1007/s11709-023-0996-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-023-0996-4