Abstract

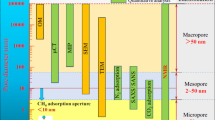

Permeability is a major indicator of concrete durability, and depends primarily on the microstructure characteristics of concrete, including its porosity and pore size distribution. In this study, a variety of concrete samples were prepared to investigate their microstructure characteristics via nuclear magnetic resonance (NMR), mercury intrusion porosimetry (MIP), and X-ray computed tomography (X-CT). Furthermore, the chloride diffusion coefficient of concrete was measured to explore its correlation with the microstructure of the concrete samples. Results show that the proportion of pores with diameters < 1000 nm obtained by NMR exceeds that obtained by MIP, although the difference in the total porosity determined by both methods is minimal. X-CT measurements obtained a relatively small porosity; however, this likely reflects the distribution of large pores more accurately. A strong correlation is observed between the chloride diffusion coefficient and the porosity or contributive porosity of pores with sizes < 1000 nm. Moreover, microstructure parameters measured via NMR reveal a lower correlation coefficient R2 versus the chloride diffusion coefficient relative to the parameters determined via MIP, as NMR can measure non-connected as well as connected pores. In addition, when analyzing pores with sizes > 50 µm, X-CT obtains the maximal contributive porosity, followed by MIP and NMR.

Similar content being viewed by others

References

Alexander M G, Magee B J. Durability performance of concrete containing condensed silica fume. Cement and Concrete Research, 1999, 29(6): 917–922

Yang L F, Cai R, Yu B. Investigation of computational model for surface chloride concentration of concrete in marine atmosphere zone. Ocean Engineering, 2017, 138: 105–111

Isgor O B, Razaqpur A G. Modelling steel corrosion in concrete structures. Materials and Structures, 2007, 39(3): 291–302

Wu L J, Li W, Yu X N. Time-dependent chloride penetration in concrete in marine environments. Construction & Building Materials, 2017, 152: 406–113

Aldea C M, Shah S P, Karr A. Effect of cracking on water and chloride permeability of concrete. Journal of Materials in Civil Engineering, 1999, 11(3): 181–187

Yu Y N, Yu J S, Ge Y. Water and chloride permeability research on ordinary cement mortar and concrete with compound admixture and fly ash. Construction & Building Materials, 2016, 127: 556–564

Yang Y, Wang M. Pore-scale modeling of chloride ion diffusion in cement microstructures. Cement and Concrete Composites, 2018, 85: 92–104

Bágel’ L’, Živica V. Relationship between pore structure and permeability of hardened cement mortars: On the choice of effective pore structure parameter. Cement and Concrete Research, 1997, 27(8): 1225–1235

Das B B, Kondraivendhan B. Implication of pore size distribution parameters on compressive strength, permeability and hydraulic diffusivity of concrete. Construction & Building Materials, 2012, 28(1): 382–386

Zhang Z Q, Zhang B, Yan P Y. Hydration and microstructures of concrete containing raw or densified silica fume at different curing temperatures. Construction & Building Materials, 2016, 121: 483–490

Mun K J, So S Y, Soh Y S. The effect of slaked lime, anhydrous gypsum and limestone powder on properties of blast furnace slag cement mortar and concrete. Construction & Building Materials, 2007, 21(7): 1576–1582

Powers T C, Brownyard T L. Studies of the physical properties of hardened Portland cement paste. Concrete International, 2003, 41: 1–6

Mehta P K, Paulo J M. Concrete: Microstructure, Properties, Materials. 4th ed. New York: McGraw-Hill Press, 2006

Zhang M H, Li H. Pore structure and chloride permeability of concrete containing nano-particles for pavement. Construction & Building Materials, 2011, 25(2): 608–616

Pipilikaki P, Beazi-Katsioti M. The assessment of porosity and pore size distribution of limestone Portland cement pastes. Construction & Building Materials, 2009, 23(5): 1966–1970

Zhou J, Ye G, van Breugel K. Cement hydration and microstructure in concrete repairs with cementitious repair materials. Construction & Building Materials, 2016, 112: 765–772

Tanaka K, Kurumisawa K. Development of technique for observing pores in hardened cement paste. Cement and Concrete Research, 2002, 32(9): 1435–1441

Liu J, Ou G F, Qiu Q W, Chen X C, Hong J, Xing F. Chloride transport and microstructure of concrete with/without fly ash under atmospheric chloride condition. Construction & Building Materials, 2017, 146: 493–501

Stark J. Recent advances in the field of cement hydration and microstructure analysis. Cement and Concrete Research, 2011, 41(7): 666–678

Brue F, Davy C A, Skoczylas F, Burlion N, Bourbon X. Effect of temperature on the water retention properties of two high performance concretes. Cement and Concrete Research, 2012, 42(2): 384–396

Liu J, Xing F, Dong B Q, Ma H Y, Pan D. Study on water sorptivity of the surface layer of concrete. Materials and Structures, 2014, 47(11): 1941–1951

Kong D L Y, Sanjayan J G, Sagoe-Crentsil K. Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cement and Concrete Research, 2007, 37(12): 1583–1589

Tian H H, Wei C F, Wei H Z, Yan R T, Chen P. An NMR-based analysis of soil-water characteristics. Applied Magnetic Resonance, 2014, 45(1): 49–61

Tian H H, Wei C F, Wei H Z, Zhou J Z. Freezing and thawing characteristics of frozen soils: Bound water content and hysteresis phenomenon. Cold Regions Science and Technology, 2014, 103: 74–81

Wang X X, Shen X D, Wang H L, Zhao H X. Nuclear magnetic resonance analysis of air entraining natural pumice concrete freeze-thaw damage. Advanced Materials Research, 2014, 919–921: 1939–1943

Yao Y B, Liu D M. Comparison of low-field NMR and mercury intrusion porosimetry in characterizing pore size distributions of coals. Fuel, 2012, 95: 152–158

du Plessis A, Olawuyi B J, Boshoff W P, le Roux S G. Simple and fast porosity analysis of concrete using X-ray computed tomography. Materials and Structures, 2016, 49(1–2): 553–562

Huang Y J, Yang Z J, Ren W Y, Liu G H, Zhang C. 3D meso-scale fracture modelling and validation of concrete based on in-situ X-ray computed tomography images using damage plasticity model. International Journal of Solids and Structures, 2015, 67–68: 340–352

Qin X, Xu Q. Statistical analysis of initial defects between concrete layers of dam using X-ray computed tomography. Construction & Building Materials, 2016, 125: 1101–1113

Zhang J Z, Guo J, Li D H, Zhang Y R, Bian F, Fang Z F. The influence of admixture on chloride time-varying diffusivity and microstructure of concrete by low-field NMR. Ocean Engineering, 2017, 142: 94–101

Zhang J Z, Bian F, Zhang Y R, Fang Z F, Fu C Q, Guo J. Effect of pore structures on gas permeability and chloride diffusivity of concrete. Construction & Building Materials, 2018, 163: 402–413

Feng N Q, Xing F. High performance concrete technology. Beijing: Atomic Energy Press, 2000

Feng N Q, Feng X X, Hao T Y, Xing F. Effect of ultrafine mineral powder on the charge passed of the concrete. Cement and Concrete Research, 2002, 32(4): 623–627

Ye G. Percolation of capillary pores in hardening cement pastes. Cement and Concrete Research, 2005, 35(1): 167–176

Kumar R, Bhattacharjee B. Study on some factors affecting the results in the use of MIP method in concrete research. Cement and Concrete Research, 2003, 33(3): 417–424

Diamond S. Mercury porosimetry: An inappropriate method for the measurement of pore size distributions in cement-based materials. Cement and Concrete Research, 2000, 30(10): 1517–1525

Li B, Mao J Z, Nawa T, Han T Y. Mesoscopic damage model of concrete subjected to freeze-thaw cycles using mercury intrusion porosimetry and differential scanning calorimetry (MIP-DSC). Construction & Building Materials, 2017, 147: 79–90

Zhang Y, Verwaal W, van de Ven MFC, Molenaar AAA, Wu S P. Using high-resolution industrial CT scan to detect the distribution of rejuvenation products in porous asphalt concrete. Construction & Building Materials, 2015, 100: 1–10

Huang Y J, Yan D M, Yang Z J, Liu G H. 2D and 3D homogenization and fracture analysis of concrete based on in-situ X-ray computed tomography images and monte carlo simulations. Engineering Fracture Mechanics, 2016, 163: 37–54

Zhou J, Ye G, van Breugel K. Characterization of pore structure in cement-based materials using pressurization-depressurization cycling mercury intrusion porosimetry (PDC-MIP). Cement and Concrete Research, 2010, 40(7): 1120–1128

Wang Y, Yuan Q, Deng D H, Ye T, Fang L. Measuring the pore structure of cement asphalt mortar by nuclear magnetic resonance. Construction & Building Materials, 2017, 137: 450–458

Zhou Y, Hou D S, Jiang J Y, Wang P G. Chloride ions transport and adsorption in the nano-pores of silicate calcium hydrate: Experimental and molecular dynamics studies. Construction & Building Materials, 2016, 126: 991–1001

Sun C, Bai B. Diffusion of gas molecules on multilayer graphene surfaces: Dependence on the number of graphene layers. Applied Thermal Engineering, 2017, 116: 724–730

Sun W G, Sun W, Wang C H. Relationship between the transport behavior of modern concrete and its microstructures: Research methods and progress. Materials Review, 2018, 32: 3010–3022

Zhang P, Wittmann F H, Zhao T J, Lehmann E H, Vontobel P. Neutron radiography, a powerful method to determine time-dependent moisture distributions in concrete. Nuclear Engineering and Design, 2011, 241(12): 4758–4766

Korat L, Ducman V, Legat A, Mirtic B. Characterisation of the pore-forming process in lightweight aggregate based on silica sludge by means of X-ray micro-tomography (micro-CT) and mercury intrusion porosimetry (MIP). Ceramics International, 2013, 39(6): 6997–7005

Acknowledgements

Thanks to the financial supports provided by the Natural Science Foundation of Zhejiang Province (LY17E090007, LQ18G010007, and LY19E90006) and the National Natural Science Foundation of China (Grant No. 51279181). Moreover, thanks are due to Wang J D, Feng X X, Shao X J and Wang M for assistance with the experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Xu, S., Gao, Y. et al. Correlation of chloride diffusion coefficient and microstructure parameters in concrete: A comparative analysis using NMR, MIP, and X-CT. Front. Struct. Civ. Eng. 14, 1509–1519 (2020). https://doi.org/10.1007/s11709-020-0681-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-020-0681-9