Abstract

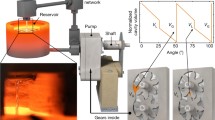

In this paper, a novel liquid metal-based minichannel heat dissipation method was developed for cooling electric devices with high heat flux. A high-performance electromagnetic induction pump driven by rotating permanent magnets is designed to achieve a pressure head of 160 kPa and a flow rate of 3.24 L/min, which could enable the liquid metal to remove the waste heat quickly. The liquid metal-based minichannel thermal management system was established and tested experimentally to investigate the pumping capacity and cooling performance. The results show that the liquid metal cooling system can dissipate heat flux up to 242 W/cm2 with keeping the temperature rise of the heat source below 50°C. It could remarkably enhance the cooling performance by increasing the rotating speed of permanent magnets. Moreover, thermal contact resistance has a critical importance for the heat dissipation capacity. The liquid metal thermal grease is introduced to efficiently reduce the thermal contact resistance (a decrease of about 7.77 × 10−3 °C/W). This paper provides a powerful cooling strategy for thermal management of electric devices with large heat power and high heat flux.

Similar content being viewed by others

References

Yang X H, Liu J. Advances in liquid metal science and technology in chip cooling and thermal management. Advances in Heat Transfer, 2018, 50: 187–300

Hamidnia M, Luo Y, Wang X D. Application of micro/nano technology for thermal management of high power LED packaging—a review. Applied Thermal Engineering, 2018, 145: 637–651

Habibi Khalaj A, Halgamuge S K A Review on efficient thermal management of air-and liquid-cooled data centers: from chip to the cooling system. Applied Energy, 2017, 205: 1165–1188

Qian Z, Li Y, Rao Z. Thermal performance of lithium-ion battery thermal management system by using mini-channel cooling. Energy Conversion and Management, 2016, 126: 622–631

Lee J, Ki S, Seo D, et al. Liquid cooling module incorporating a metal foam and fin hybrid structure for high power insulated gate bipolar transistors (IGBTs). Applied Thermal Engineering, 2020, 173: 115230

Liu D, Zhao F Y, Yang H X, et al. Thermoelectric mini cooler coupled with micro thermosiphon for CPU cooling system. Energy, 2015, 83: 29–36

Yeh L T. Review of heat transfer technologies in electronic equipment. Journal of Electronic Packaging, 1995, 117(4): 333–339

Tuckerman D B, Pease R F W. High-performance heat sinking for VLSI. IEEE Electron Device Letters, 1981, 2(5): 126–129

Feng Z, Li P. Fast thermal analysis on GPU for 3D ICs with integrated microchannel cooling. IEEE Transactions on Very Large Scale Integration Systems, 2012, 21(8): 1526–1539

Chein R, Chuang J. Experimental microchannel heat sink performance studies using nanofluids. International Journal of Thermal Sciences, 2007, 46(1): 57–66

Dixit T, Ghosh I. Review of micro-and mini-channel heat sinks and heat exchangers for single phase fluids. Renewable & Sustainable Energy Reviews, 2015, 41: 1298–1311

Mahalingam M. Thermal management in semiconductor device packaging. Proceedings of the IEEE, 1985, 73(9): 1396–1404

Mehendale S S, Jacobi A M, Shah R K. Fluid flow and heat transfer at micro-and meso-scales with application to heat exchanger design. Applied Mechanics Reviews, 2000, 53(7): 175–193

Muhammad A, Selvakumar D, Wu J. Numerical investigation of laminar flow and heat transfer in a liquid metal cooled mini-channel heat sink. International Journal of Heat and Mass Transfer, 2020, 150: 119265

Xie X L, Liu Z J, He Y L, et al. Numerical study of laminar heat transfer and pressure drop characteristics in a water-cooled minichannel heat sink. Applied Thermal Engineering, 2009, 29(1): 64–74

Sohel M R, Khaleduzzaman S S, Saidur R, et al. An experimental investigation of heat transfer enhancement of a minichannel heat sink using Al2O3-H2O nanofluid. International Journal of Heat and Mass Transfer, 2014, 74: 164–172

Ijam A, Saidur R, Ganesan P. Cooling of minichannel heat sink using nanofluids. International Communications in Heat and Mass Transfer, 2012, 39(8): 1188–1194

Liu X, Yu J. Numerical study on performances of mini-channel heat sinks with non-uniform inlets. Applied Thermal Engineering, 2016, 93: 856–864

Hung T C, Yan W M, Li W P. Analysis of heat transfer characteristics of double-layered microchannel heat sink. International Journal of Heat and Mass Transfer, 2012, 55(11–12): 3090–3099

Yang X H, Tan S C, Ding Y J, et al. Flow and thermal modeling and optimization of micro/mini-channel heat sink. Applied Thermal Engineering, 2017, 117: 289–296

Wang H, Chen Z, Gao J. Influence of geometric parameters on flow and heat transfer performance of micro-channel heat sinks. Applied Thermal Engineering, 2016, 107: 870–879

Lee J, Mudawar I. Assessment of the effectiveness of nanofluids for single-phase and two-phase heat transfer in micro-channels. International Journal of Heat and Mass Transfer, 2007, 50(3–4): 452–463

Wang Q, Yu Y, Liu J. Preparations, characteristics and applications of the functional liquid metal materials. Advanced Engineering Materials, 2018, 20(5): 1700781

Cao L X, Yin T, Jin M X, et al. Flexible circulated-cooling liquid metal coil for induction heating. Applied Thermal Engineering, 2019, 162: 114260

de Castro I A, Chrimes A F, Zavabeti A, et al. A gallium-based magnetocaloric liquid metal ferrofluid. Nano Letters, 2017, 17(12): 7831–7838

Gu J, She J, Yue Y. Micro/nanoscale thermal characterization based on spectroscopy techniques. ES Energy & Environment, 2020, 9(2): 15–27

Zhang X D, Zhou Y X, Liu J. A novel layered stack electromagnetic pump towards circulating metal fluid: design, fabrication and test. Applied Thermal Engineering, 2020, 179: 115610

Tawk M, Avenas Y, Kedous-Lebouc A, et al. Numerical and experimental investigations of the thermal management of power electronics with liquid metal mini-channel coolers. IEEE Transactions on Industry Applications, 2013, 49(3): 1421–1429

Sun P, Zhang H, Jiang F C, et al. Self-driven liquid metal cooling connector for direct current high power charging to electric vehicle. eTransportation, 2021, 10: 100132

Zhang X D, Yang X H, Zhou Y X, et al. Experimental investigation of galinstan based minichannel cooling for high heat flux and large heat power thermal management. Energy Conversion and Management, 2019, 185: 248–258

Zhou X, Gao M, Gui L. A liquid-metal based spiral magnetohydrodynamic micropump. Micromachines, 2017, 8(12): 365

Wang Y, Zhang P, Tan S, et al. Experimental and numerical analysis on a compact liquid metal blade heat dissipator with twin stage electromagnetic pumps. International Communications in Heat and Mass Transfer, 2019, 104: 15–22

Bucenieks I E. Perspectives of using rotating permanent magnets in the design of electromagnetic induction pumps. Magnetohydrodynamics, 2000, 151–156

Wang X, Kolesnikov Y. A numerical visualization of physical fields in an electromagnetic pump with rotating permanent magnets. Magnetohydrodynamics, 2014, 50(2): 139–156

Koroteeva E, Scepanskis M, Bucenieks I, et al. Numerical modeling and design of a disk-type rotating permanent magnet induction pump. Fusion Engineering and Design, 2016, 106: 85–92

Bucenieks I E. High pressure and high flowrate induction pumps with permanent magnets. Magnetohydrodynamics, 2003, 39(4): 411–418

Hvasta M G, Nollet W K, Anderson M H. Designing moving magnet pumps for high-temperature, liquid-metal systems. Nuclear Engineering and Design, 2018, 327: 228–237

Mirhoseini S M H, Diaz-Pacheco R R, Volpe F A. Passive and active electromagnetic stabilization of free-surface liquid metal flows. Magnetohydrodynamics, 2017, 53(1): 45–54

Bojarevics A, Beinerts T, Gelfgat Y, et al. Permanent magnet centrifugal pump for liquid aluminium stirring. International Journal of Cast Metals Research, 2016, 29(3): 154–157

Miner A, Ghoshal U. Cooling of high-power-density microdevices using liquid metal coolants. Applied Physics Letters, 2004, 85(3): 506–508

Bergman T L, Incropera F P, DeWitt D P, et al. Fundamentals of Heat and Mass Transfer. New York: John Wiley & Sons, 2011

Liu D, Garimella S V. Analysis and optimization of the thermal performance of microchannel heat sinks. International Journal of Numerical Methods for Heat & Fluid Flow, 2005, 15(1): 7–26

Harms T M, Kazmierczak M J, Gerner F M. Developing convective heat transfer in deep rectangular microchannels. International Journal of Heat and Fluid Flow, 1999, 20(2): 149–157

Holman J P, Gajda W J. Experimental Methods for Engineers. 5th ed. New York: McGraw-Hill, 1989

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 52076213) and the 2115 Talent Development Program of China Agricultural University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, C., He, Z. High heat flux thermal management through liquid metal driven with electromagnetic induction pump. Front. Energy 16, 460–470 (2022). https://doi.org/10.1007/s11708-022-0825-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-022-0825-9