Abstract

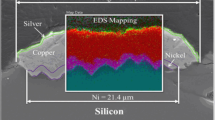

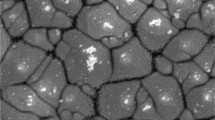

The improvement of adhesion strength and durability of plated contacts is required for cell manufacturers to gain confidence for large-scale manufacturing. To overcome weak adhesion at the metal/Si interface, new approaches were developed. These involve the formation of laser-ablated anchor points, or grooves in the extreme case of overlapping anchor points, in the heavily doped silicon surface. When plated, these features greatly strengthen the mechanical adhesion strength of the metal. A stylus-based adhesion tester was developed specifically for evaluating the effectiveness of plated contacts to smooth silicon surfaces. The use of such a tester was also extended in this work to textured and roughened surfaces to allow evaluation of different metal contacting approaches. The adhesion strengths for various metal contacting schemes were evaluated, including screenprinted silver contacts, nickel/copper (Ni/Cu) lightinduced plated (LIP) contacts for laser-doped selective emitter (LDSE) cells, buried-contact solar cells (BCSCs), and Ni/Cu LIP contacts formed with laser-ablated anchoring points in selective emitter (LAASE) cells. The latter has superior adhesion strength. The standard “peel test” of the industry was compared to the stylus-based adhesion testing, with the latter shown value for testing metal contacts on smooth surfaces but with caution needed for use with textured or roughened surfaces.

Similar content being viewed by others

References

ITRPV Working Group. International technology roadmap for photovoltaics (ITRPV): Results, 2015. 2016-05, http://www.itrpv.net/Reports/Downloads/

Kray D, McIntosh K R. Analysis of selective phosphorous laser doping in high-efficiency solar cells. IEEE Transactions on Electron Devices, 2009, 56(8): 1645–1650

Wenham S. Laser grooved silicon solar cells. Dissertation for the Doctoral Degree. Sydney: The University of New South Wales, 1986

Shi Z, Wenham S, Ji J. Mass production of the innovative PLUTO solar cell technology (Invited Plenary Session Paper). In: 34th IEEE PV Specialists Conference. Philadelphia, USA, 2009

Alonso-Abella M, Chenlo M, Alonso A, Gonzalez D. Toledo PV plant 1 MWp—20 years of operation. In: European Photovoltaic Solar Energy Conference. Amsterdam, NL, 2014

Lennon A, Yao Y, Wenham S. Evolution of metal plating for silicon solar cell metallisation. Progress in Photovoltaics: Research and Applications, 2013, 21(7): 1454–1468

Chong C M, Wenham A, Chen R, Wang S, Ji J, Shi Z, Wenham S. Improved adhesion for plated Solar cell metallisation. In: 42nd IEEE Photovoltaic Specialist Conference (PVSC), 2015

Wenham A, Chong C M, Wang S, Chen R, Ji J, Shi Z, Mai L, Sugianto A, Wenham S R, Barnett A, Green MA. Overcoming issues with copper plated contacts for large-scale manufacturing. In: 30th European Photovoltaic Solar Energy Conference. Hamburg, Germany, 2015

Wenham A. High efficiency solar cells. Dissertation for the Master’s Degree. Sydney: The University of New South Wales, 2009

Hallam B, Wenham S, Lee H, Lee E, Lee H, Kim J, Shin J, Cho K, Kim J. Record efficiency on large area p-type Czochralski silicon substrates. Japanese Journal of Applied Physics, 2012, 51(10S): 10NA08–10NA08-4

Kim M, Kyeong D, Lee K, Lee W J, Cho E C. Copper metallization of silicon PERL solar cells. In: European Photovoltaic Solar Energy Conference. Amsterdam, NL, 2014

Jacobsson R. Measurement of the adhesion of thin films. Thin Solid Films, 1976, 34(2): 191–199

Young T L, Hee K, Lennon A, Egan R, Wilkie O, Yao Y. Design and characterization of an adhesion strength tester for evaluating metal contacts on solar cells. In: 40th IEEE Photovoltaics Specialist Conference. Denver, USA, 2014

Wendt J, Trager M, Klengel R, Petzold M, Schade D, Sykes R. Improved quality test method for solder ribbon interconnects on silicon solar cells. In: 2010 12th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm). 2010, 1–4

Mondon A, Jawaid M N, Bartsch J, Glatthaar M, Glunz S W. Microstructure analysis of the interface situation and adhesion of thermally formed nickel silicide for plated nickel-copper contacts on silicon solar cells. Solar Energy Materials and Solar Cells, 2013, 117: 209–213

Horzel J, Bay N, Passig M, Sieber M, Burschik J, Kühnlein H. Low cost metallisation based on Ni/Cu plating enabling high efficiency industrial solar cells. In: 29th European Photovoltaic Solar Energy Conference. Amsterdam, NL, 2014

Mai L, Wenham A M, Wenham S R. Photo plating of metal electrodes for solar cells. U.S. Patent 9040128, 2015

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, R., Wang, S., Wenham, A. et al. Plated contacts for solar cells with superior adhesion strength to screen printed solar cells. Front. Energy 11, 72–77 (2017). https://doi.org/10.1007/s11708-016-0428-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-016-0428-4